Toroidal continuously variable transmission

A continuously variable transmission, ring-type technology, applied in friction transmissions, elements with teeth, belts/chains/gears, etc., can solve the problems of difficulty in ensuring, difficult to achieve cost reduction and sufficient reliability assurance, etc. To achieve the effect of improving durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0115] [The first example of the first embodiment]

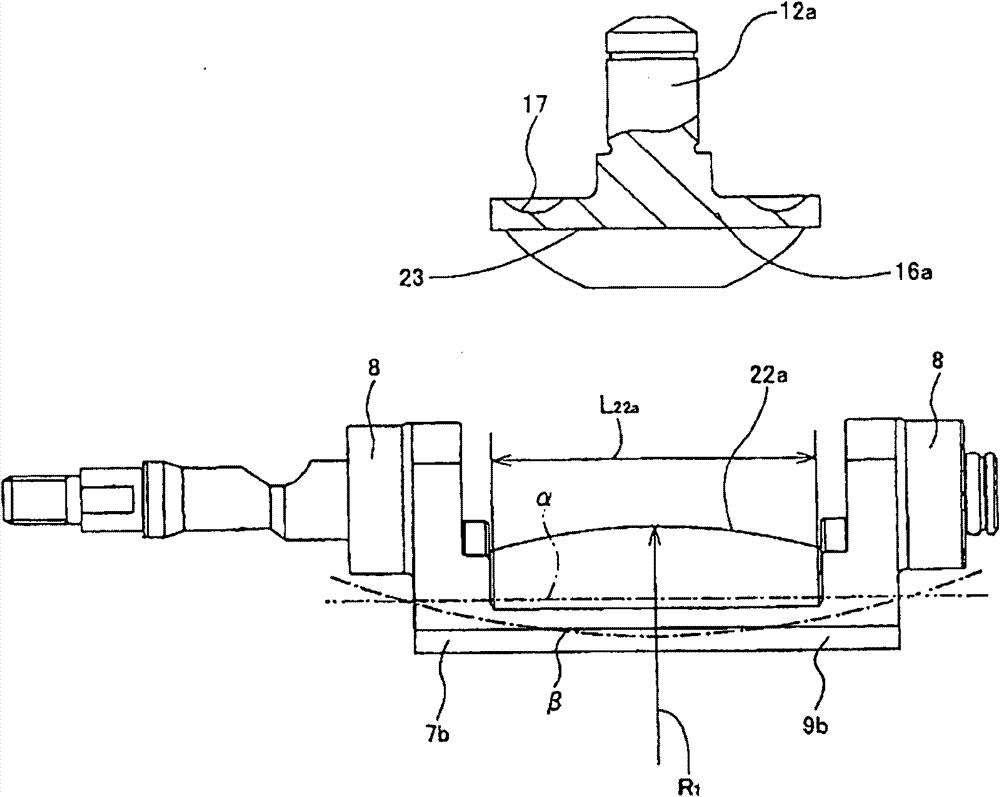

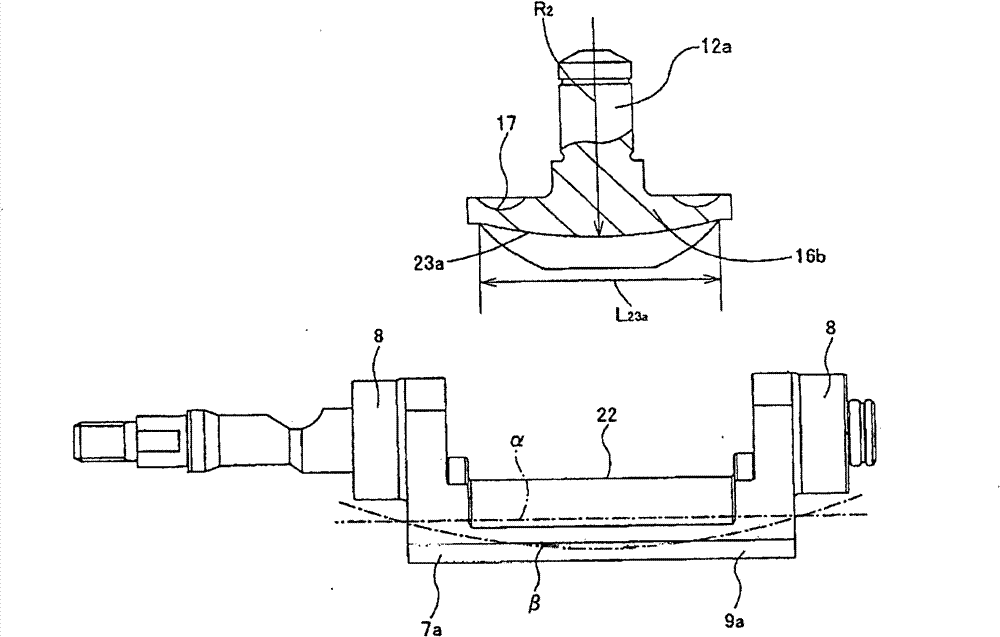

[0116] figure 1 The first example of the first embodiment of the present invention is shown. In addition, this example is characterized in that it is provided on the inner surface of the support beam portion 9b constituting the trunnion 7b ( figure 1 The shape of the cylindrical convex surface 22a in the upper side). The structure and function of the other parts are the same as those of the second example of the conventional structure, so the same symbols are assigned to the same parts, and repeated illustrations and descriptions are omitted or simplified. The following description will focus on the characteristic parts of this example.

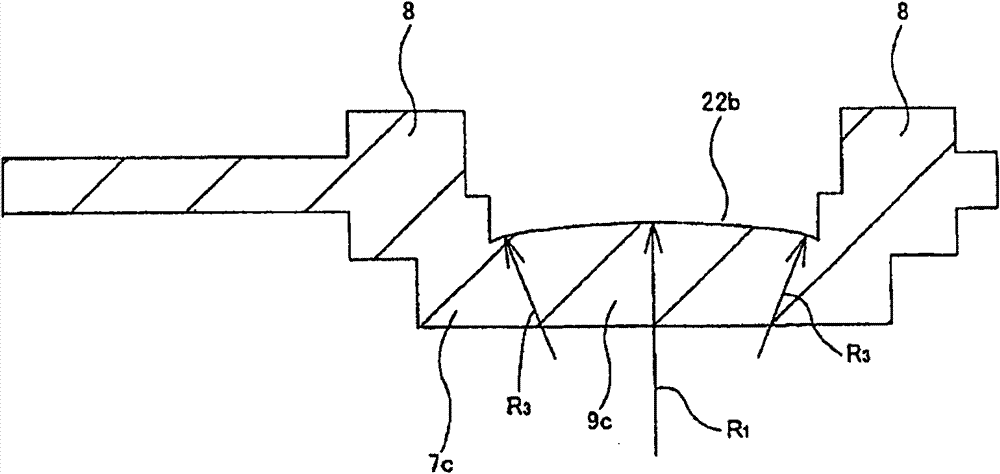

[0117] In the case of this example, the cylindrical convex surface 22a is not a simple cylindrical convex surface, and the entire cylindrical convex surface 22a is implemented in a figure 1 Crowning as exaggeratedly shown in . Specifically, the entire generatrix shape of the cylindri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com