Device for cleaning sand ejecting holes of mould for casting production line automatically

A casting production line and automatic cleaning technology, applied in the direction of manufacturing tools, casting molding equipment, molding machines, etc., can solve the problems of high labor intensity and easy damage to molds

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

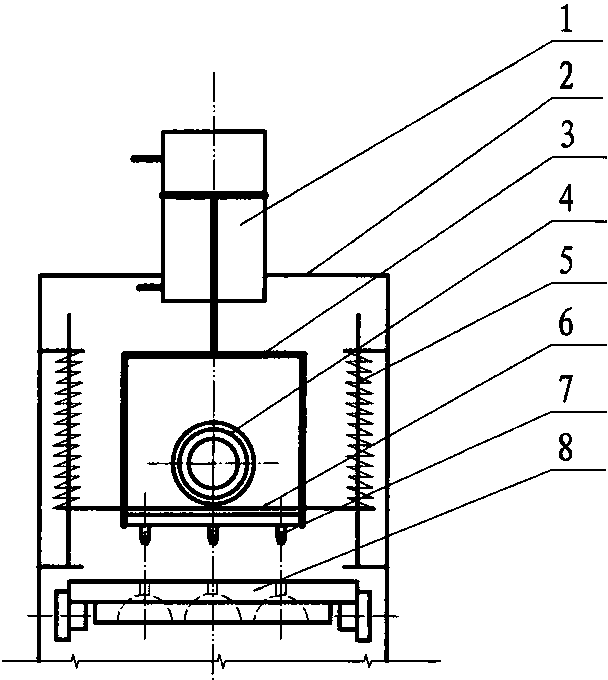

[0010] see figure 1 , the automatic cleaning device for the mold shot hole of the casting production line includes a gantry-type bracket 2, a cylinder 1 is fixedly installed in the middle of the top of the bracket 2, and the piston rod of the cylinder 1 is vertically downward, and the lower end of the piston rod is connected to the movable frame 3, which is movable The frame 3 can move up and down in the support 2 . The movable frame 3 is a box-type frame, and punches 7 corresponding to the sand holes on the mold are evenly distributed on the lower side of the bottom surface, and a flat plate 6 is installed on the inner side of the bottom surface, and both sides of the flat plate 6 extend to the outside of the movable frame 3 respectively. Upright guide rods 5 are respectively fixedly installed on the corresponding two sides in the bracket 2, and springs are set on each guide rod 5, and the upper end of each spring is connected to the upper part of the guide rod 5, and the low...

Embodiment 2

[0013] Two upright guide rods 5 are respectively fixedly installed on the corresponding two sides in the bracket 2, and springs are set on each guide rod 5, and the upper end of each spring is connected with the upper part of the guide rod 5, and the lower end is connected with the bottom of the flat plate 6. corner.

[0014] Other structures are with embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com