Wing surface root rib and capsule section longitudinal beam integrated structure of guided missile

A technology of missile cabin section and missile cabin, applied in the aviation field, can solve problems such as heavy structure weight, achieve the effect of good aerodynamic shape and reduce structure weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

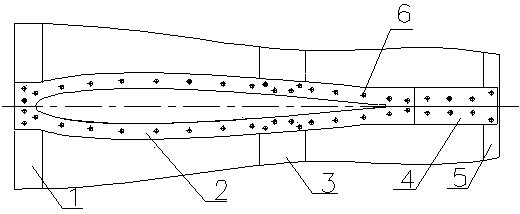

[0008] Embodiment: A missile wing surface root rib and cabin longitudinal beam integrated structure, including missile cabin section I frame 1, missile cabin section II frame 3 and missile cabin section III frame 5, said wing surface root rib 2 is a wing The connecting piece between the surface frame and the longitudinal beam of the missile cabin, the overlapping edge of the root rib 2 of the wing surface is integrated with the longitudinal beam of the missile cabin section, the outer edge of the overlapping edge is 1.5mm away from the shape of the missile cabin section, and the thickness of the overlapping edge is 4mm. The outer surface of the overlapping edge is consistent with the outer surface of the missile cabin, and the equal width of the overlapping edge is 17mm, which ensures the riveting edge distance with the longitudinal beam of the missile cabin and the missile skin. Considering the operability of the processing technology of the root rib parts of the wing surface,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com