Novel fabric wrinkling device and wrinkle resistance test method

A wrinkle resistance and fabric technology, applied in the direction of textile testing, material inspection, etc., can solve the problem of single shape and direction, unable to simulate and reproduce creases and creases of elbows and knees, and achieve good simulation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with accompanying drawing.

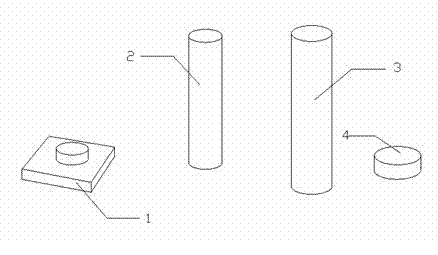

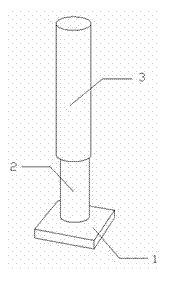

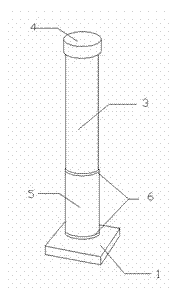

[0026] The fabric wrinkling device in the present invention comprises a wooden base 1 with a cylindrical protrusion in the middle, a hard hollow inner shaft 2 and a hard sleeve 3, and a weight 4, such as figure 1 shown. The relationship of each part is: the inner diameter of hard sleeve 3 is greater than the outer diameter of hard hollow inner shaft 2, the inner diameter of hard hollow inner shaft 2 matches the cylindrical protrusion in the middle of the wooden base 1, and the hard sleeve The height of the barrel 3 is greater than that of the hard hollow inner shaft 2 .

[0027] Fabric crease resistance testing method of the present invention comprises the following steps:

[0028] 1. Use the above-mentioned creping device to crepe the fabric. The specific operation is:

[0029] (1) Put the hard hollow inner shaft 2 on the cylindrical convex part of the wooden base 1, p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com