Electric transporting mechanism and transporting method

An electric and carrying device technology, applied in the fields of botany equipment and methods, greenhouse cultivation, climate change adaptation, etc., can solve the problems of labor cost, uneven spreading, low work efficiency, etc., and achieve the effect of reducing labor costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

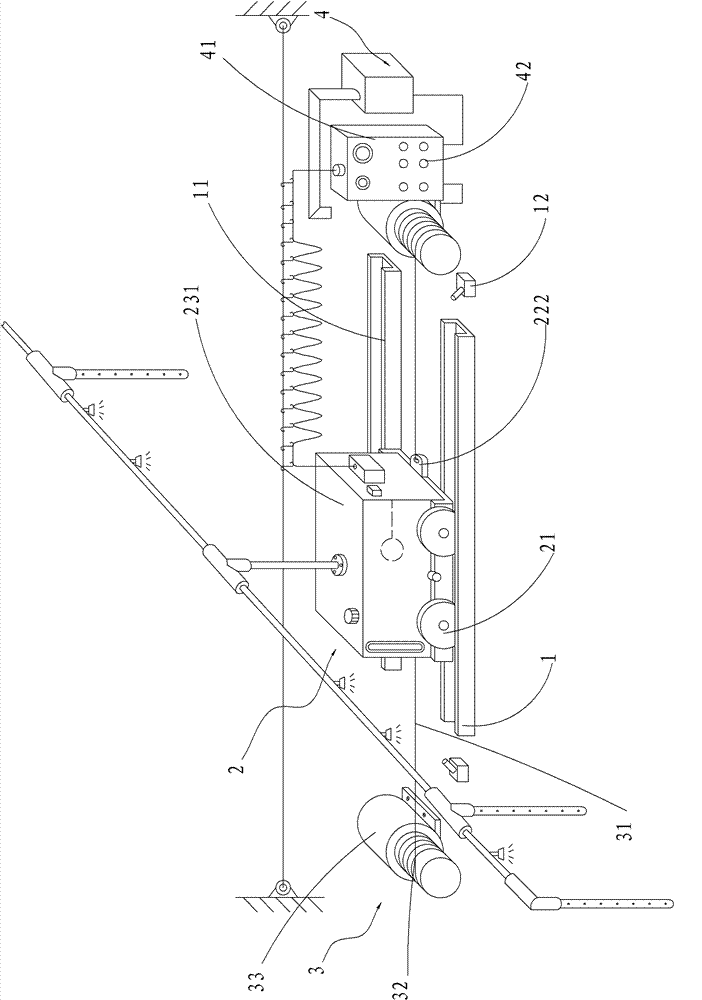

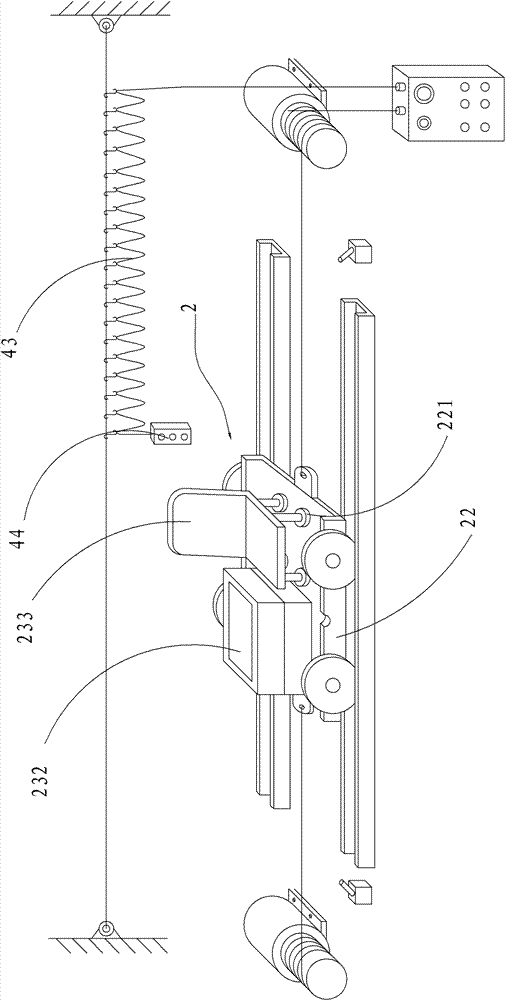

[0054] Please refer to the figure together, an electric carrying mechanism of the present invention includes a guide rail 1, a carrying device 2, a traction device 3 and an electric control device 4;

[0055] The guide rails 1 are double tracks arranged in parallel, and the rails are separate guide rails 1 or guide rails 1 connected together. The guide rails 1 can be directly used as guide channel steel or guide angle steel without designing molds for recasting. The guide rail 1 is provided with a The guide groove 11 for the movement of the carrying device 2 is provided with a stroke detection switch at both ends of the guide rail 1 to prevent the carrying device 2 from exceeding the guide rail 1;

[0056] The carrying device 2 includes front and rear wheels 21, a chassis 22 driven by the wheels 21 and functional components installed on the chassis 22, the wheels 21 are adapted to the guide groove 11, so that the wheels 21 will not deviate from the track when moving on the guid...

Embodiment 2

[0064] Please also refer to the figure, an automatic spraying method of the present invention is to use the electric carrying mechanism equipment in Embodiment 1 to complete the automatic spraying.

[0065] Include the following steps:

[0066] 1) The carrying device 2 is at the initial position, and a liquid storage tank 231 is installed on the carrying device 2, and the liquid storage tank 231 is filled with liquid;

[0067] 2) Select the continuous movement mode, and adjust the reciprocating movement speed of the carrier device 2;

[0068] 3) The forward traction motor 33 rotates, the carrying device 2 moves forward from the starting point, the carrying device 2 reaches the spray starting point, touches the spray stroke switch 12, and the spray electric pump on the liquid storage tank 231 starts, start spraying;

[0069] 4) When the carrying device 2 reaches the forward end position, touch the travel switch 12, the forward traction motor 33 stops, and the carrying device ...

Embodiment 3

[0082] Please refer to the figure together, an automatic heating method of the present invention is to use the electric carrying mechanism equipment in Embodiment 1 to complete automatic heating.

[0083] Include the following steps:

[0084] 1) The carrying device 2 is at the initial position, and a heater is installed on the carrying device 2;

[0085] 2) Select the continuous movement mode, the forward traction motor 33 rotates, and the carrying device 2 moves forward;

[0086] 3) Press the heater to start working switch, the heater is energized, and the fan in the heater starts to spread the heat of the heater to the surrounding;

[0087] 4) When the carrying device 2 reaches the forward end position, touch the travel switch 12, the forward traction motor 33 stops, and the carrying device 2 stops moving forward;

[0088] 5) Return traction motor 33 to turn on and rotate automatically, and carrying device 2 returns to move;

[0089] 6) When the carrier 2 reaches the star...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com