Wide fiber widening arrangement equipment

A fiber and wide-width technology, which is applied in the field of wide-width fiber spreading and arrangement equipment, can solve the problems affecting the mechanical properties and quality stability of composite products, and reduce the strength and modulus, so as to simplify the overall equipment structure and reduce the damage rate. , the effect of improving quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

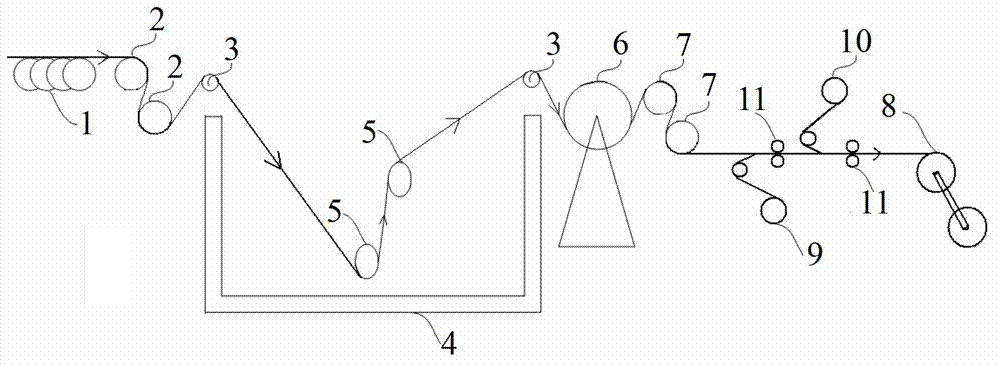

[0022] figure 1 It shows a schematic structural view of the device for widening and arranging wide-width fibers in this embodiment. Referring to the diagram, the device includes: a creel 1, on which a multi-spindle fiber is arranged, and the fiber is a fiber before widening; an ultrasonic groove 4, a multi-spindle The fiber passes through it, and an ultrasonic transducer is arranged inside it for oscillating the liquid dissolved in it so as to widen the fiber in the liquid; the prepreg arrangement unit is arranged behind the outlet of the widened fiber , the stretched fibers are arranged and wound into rolls in the prepreg arranging unit.

[0023] Preferably, the creel 1...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap