Bottle stacking machine in high position

A high-level bottle stacking machine and bottle stacking technology, which is applied in the stacking, transportation and packaging of objects, can solve the problems of unsatisfactory quality and appearance of bottle stacking, difficult to place partitions accurately, and easy to release dangers, etc., to achieve The layout of internal facilities is reasonable, the effect of reducing labor intensity and improving production safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

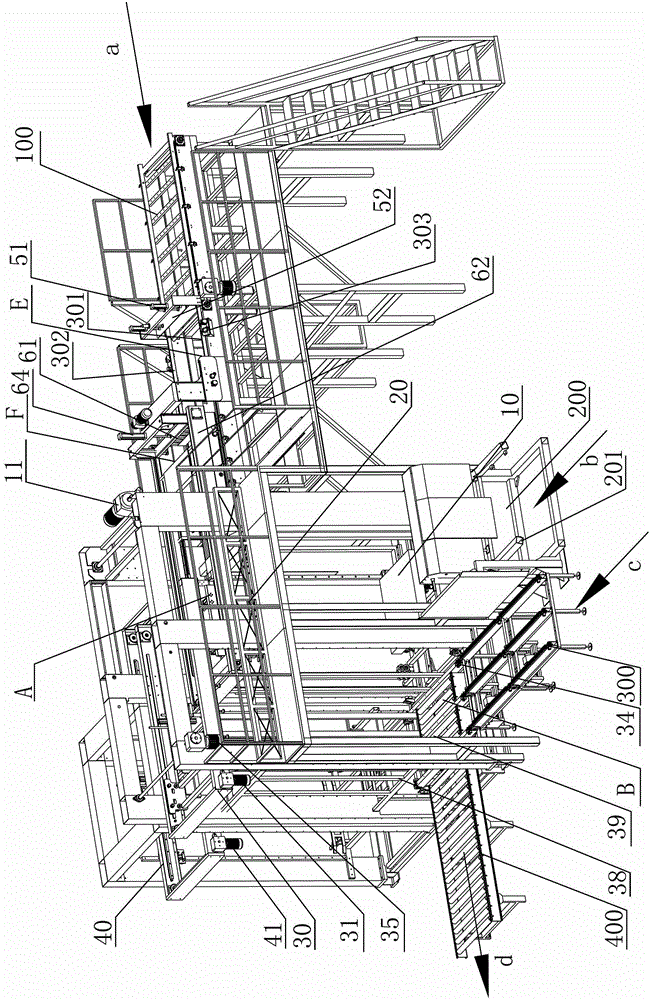

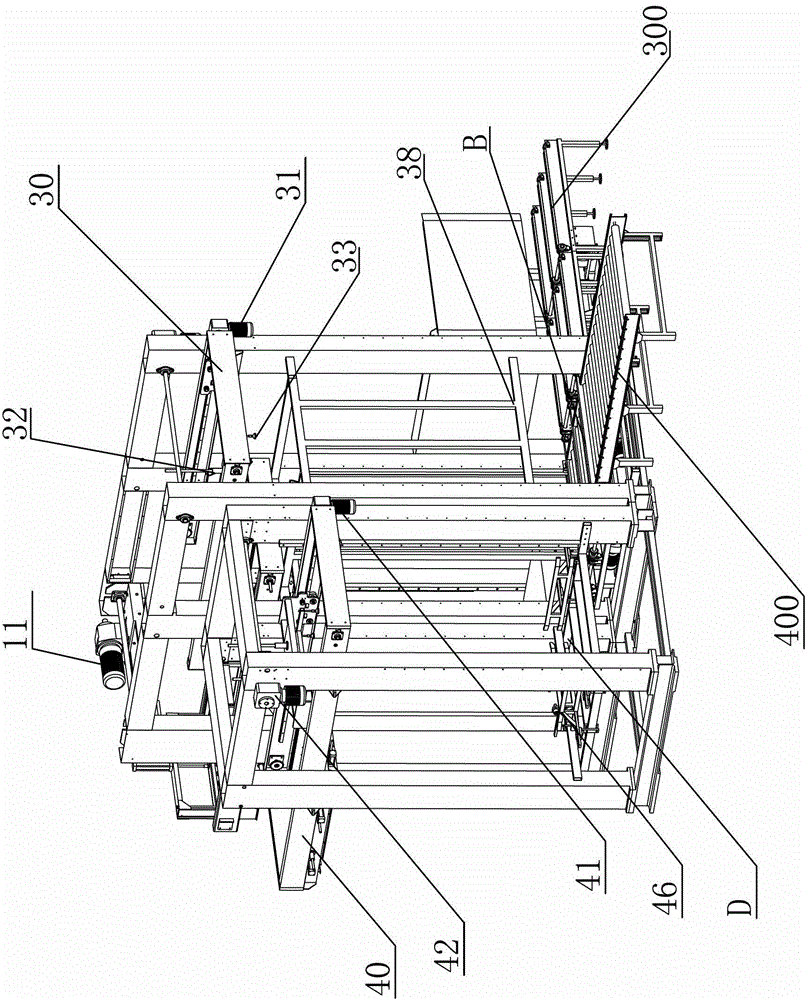

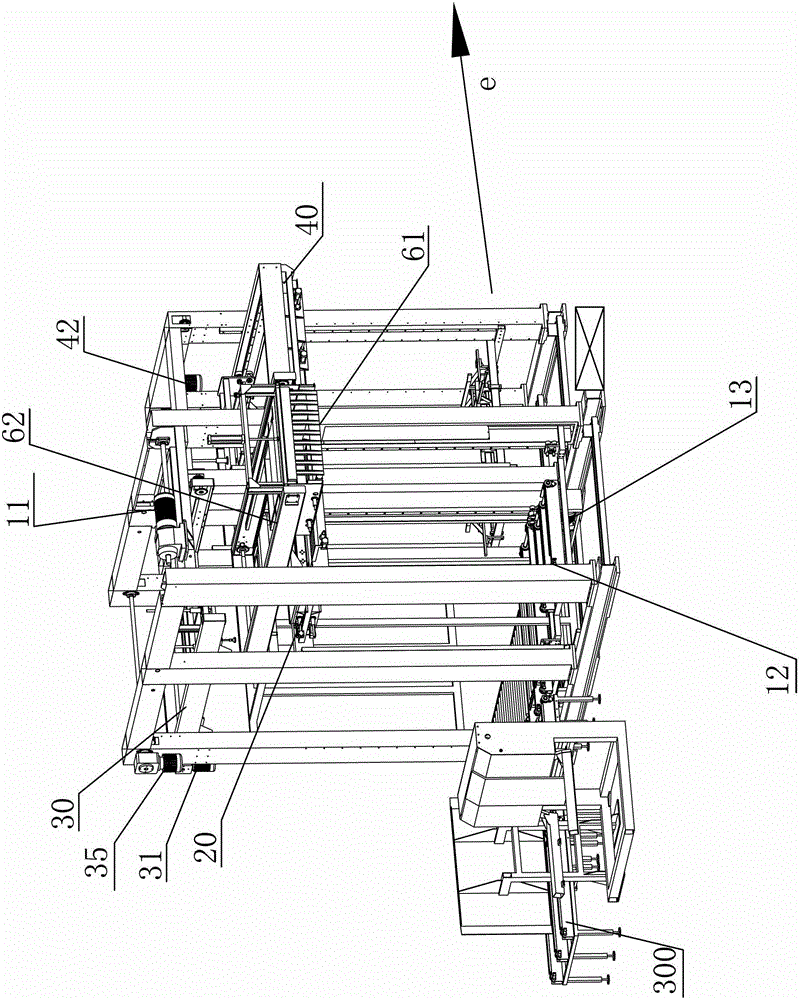

[0030] Refer to attached picture. The present invention includes a bottle conveying line 100 at a high position, a pallet conveying line 200 at a low position, and a bottle stack output line 500 at a low position; Between the two pallets, through its swing, the pallet stack above the penultimate pallet is slightly lifted, and the pallet conveying line 200 transports the lowermost pallet to the following bottle stack support structure 12 , the reference numeral 10 is the pallet placed on the second conveying device of the bottle stacking station A. The high position means that its height is generally higher than that of the bottle stack; the low position is relative to the high position, and is generally as low as possible without hindering the installation of equipment.

[0031] The bottle conveying line 100 can adopt a plate chain conveying mechanism or a belt conveying mechanism, the pallet conveying line 200 can adopt a roller table or a chain conveying mechanism, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com