Stirring bracket

A technology for supporting bases and supporting units, which is applied in biochemical instruments, biochemical equipment and methods, enzymology/microbiology devices, etc., and can solve the problems of stirring support wear, material waste, and increased production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

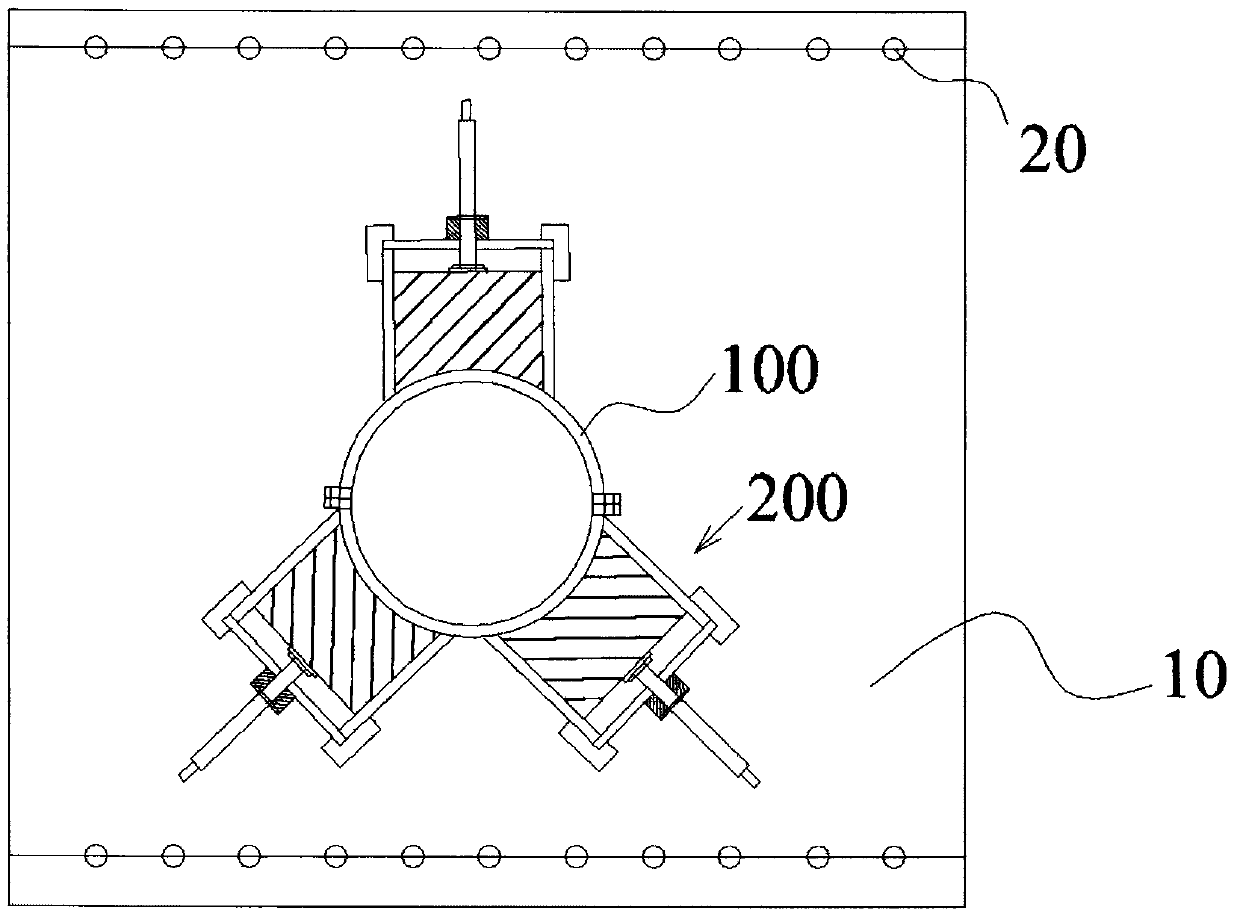

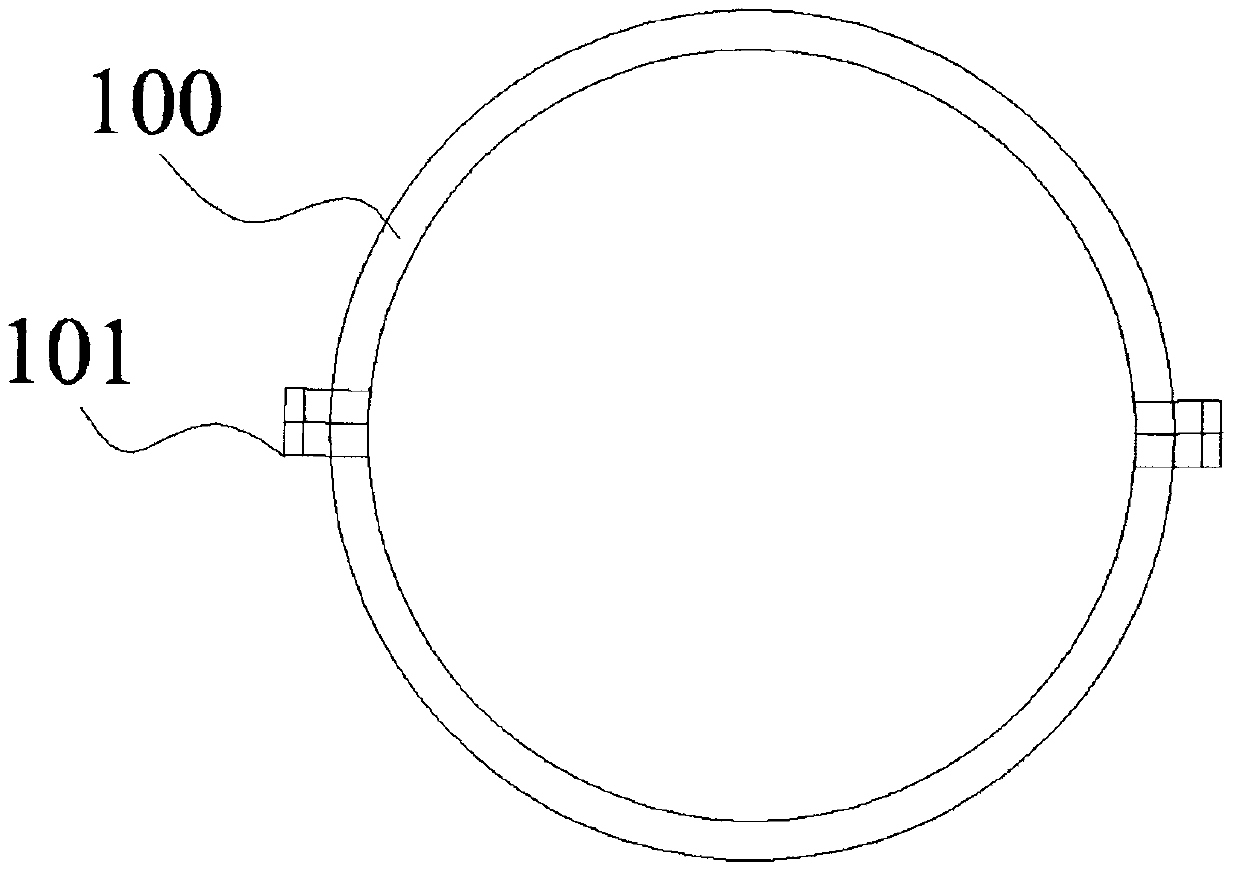

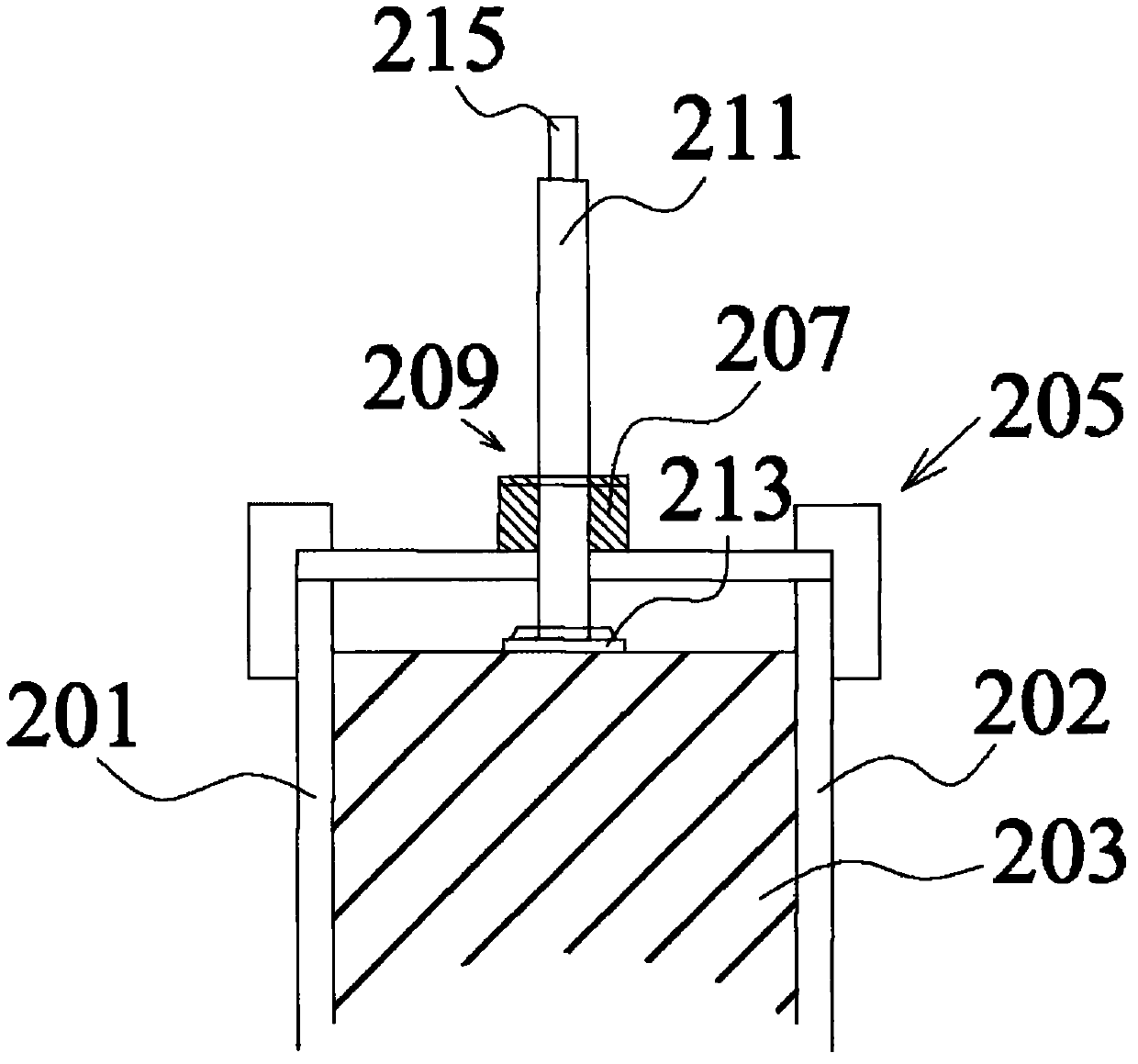

[0017] In one embodiment of the present invention, three sets of supporting units (200) are connected to the clamping shell (100). The included angle between the central axes of each supporting unit (200) is 120°. The support unit (200) is provided with two symmetrical baffles (201, 202), the two baffles (201, 202) are perpendicular to the support base (10) and connected with the semicircular surface of the folder (100), and the two baffles The distances from the plane where the plates (201, 202) are located to the center of the semicircular cladding (100) are equal. The two baffles (201, 202) are sandwiched with hardwood blocks as wear-resistant blocks (203). In another embodiment of the present invention, the wear-resistant block (203) can also be an organic wear-resistant material.

[0018] The two baffle plates (201, 202) are provided with an "I"-shaped positioning plate (205) away from the end of the clamp housing (100), and the "I"-shaped positioning plate (205) includ...

Embodiment 2

[0021] Such as Figure 5 As shown, in another embodiment of the present invention, four sets of support units (200) are connected to the cladding shell (100). The included angle between the central axes of each supporting unit (200) is 90°.

[0022] Two symmetrical baffles (201, 202) are arranged in a set of support units (200), and the two baffles (201, 202) are perpendicular to the support base (10) and connected to the semicircular surface of the shell (100), The central axes of the two baffles (201, 202) in the horizontal direction intersect with the center of the semicircular shell (100) at an angle of 45°, and the two baffles (201, 202) are vertically aligned with another set of support units The two baffles (201, 202) of (200) are vertical respectively, and the two baffles (201, 202) are clamped with hardwood blocks as wear-resistant blocks (203), and the wear-resistant blocks (203) can be hardwood blocks or wear-resistant Material.

[0023] The two baffle plates (20...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com