Yarn pressing wheel of loom

A wire pressing wheel and loom technology, which is applied in looms, textiles, textiles and papermaking, etc., can solve the problems of uneven pressing force, fluffing of silk threads, and low production efficiency, so as to prevent radial runout, press Uniform wire strength and increase product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention is described below in conjunction with accompanying drawing.

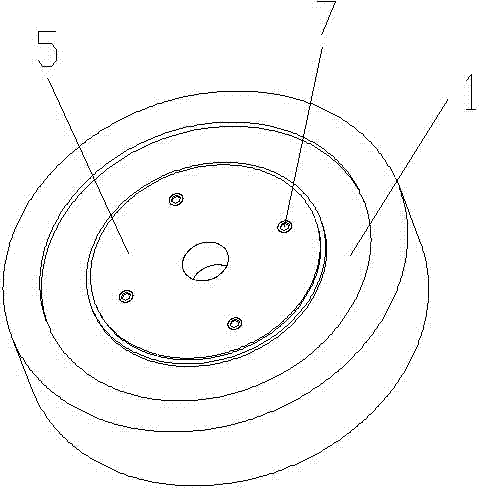

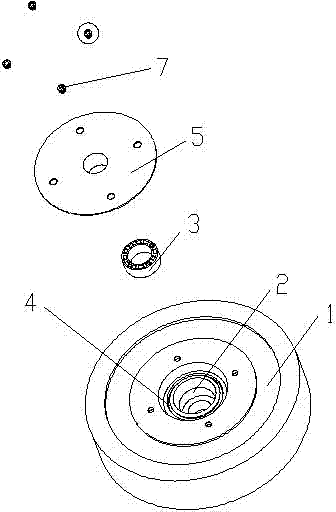

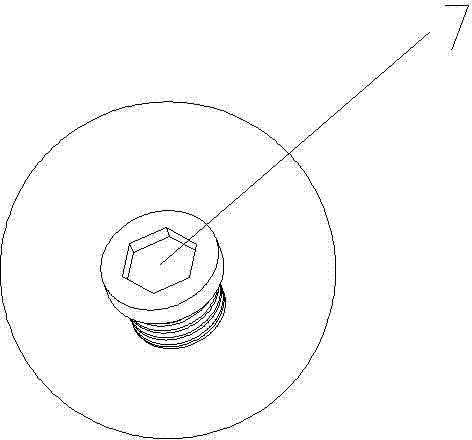

[0015] as attached Figure 1-4 The shown thread pressing wheel of the present invention includes a thread pressing wheel 1, an accommodating space 2 and a ball bearing 3; the center hole of the thread pressing wheel 1 has an accommodation space 2; The ball bearing 3 is installed in the accommodating space 2; the accommodating space 2 has a stepped conical shape; a circle of concave ribs 4 is provided on the round platform of the accommodating space 2; the top of the crimping wheel 1 is fastened to a The positioning end cap 5; the lower end of the positioning end cap 5 is provided with a circle of convex ribs 6; the convex ribs 6 cooperate with the concave ribs 4 to radially fix the crimping wheel 1; the positioning end cap 5 It is connected to the top of the pressing wheel 1 by bolts 7.

[0016] Due to the application of the above-mentioned technical solution, the present invention ha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com