Hedging type exhaust silencer

An exhaust muffler and hedging technology, applied in mufflers, machines/engines, engine components, etc., can solve problems such as unsatisfactory muffler effect, achieve smooth and gentle airflow, maintain airflow, and suppress pulse air pressure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

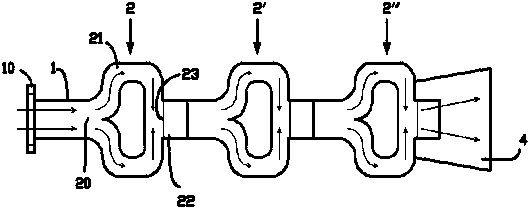

[0018] figure 1 Shown is embodiment one of the present invention, and in this embodiment, this opposite type exhaust muffler comprises a main intake pipe 1 that joins with engine exhaust pipe, and its end is provided with matching flange 10; Three hedges 2, 2', 2" are connected in series behind the main air intake pipe 1; each of the hedges has an air inlet 20 and an exhaust port 22, and two sections of elbows 21, the two sections of elbows 21 are respectively drawn from the air inlet 20, and meet at the air outlet 22; the two sections of elbows 21 are symmetrical about the center line of the air inlet 20 and the air outlet 22; The direction of the airflow path in the two sections of the elbow is 180° in front of the exhaust port 22; the air inlet 20 of the first said hedge 2 is connected to the main air intake pipe 1, and the last said hedge 2" The exhaust port of the exhaust port communicates with a trumpet-shaped diffuser pipe 4.

[0019] Above-mentioned hedging type exha...

Embodiment 2

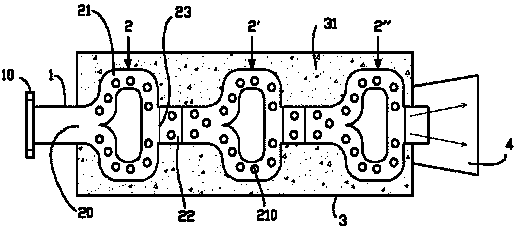

[0022] figure 2 Shown is Embodiment 2 of the present invention. In Embodiment 2, the difference from Embodiment 1 is that: the outside of the hedge group formed by each of the hedges 2, 2', 2" also surrounds a sealed Silencer chamber 3; Silencer material 31 is provided between the silencer chamber 3 and the hedge group; completely consistent silencer holes 210 are provided on the pipe walls of the two sections of elbows of each of the hedges, and the air intake of each hedge The pipe wall of the port 20 and the pipe wall of the exhaust port 22 are also provided with sound-absorbing holes, and the sound-absorbing holes allow a part of the noise airflow flowing through the flusher group to flow into the sound-absorbing chamber 3 and be absorbed by the sound-absorbing chamber. Absorbed by the sound-absorbing material 31 in the sound-absorbing chamber 3.

Embodiment 3

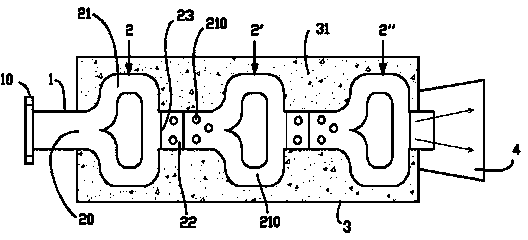

[0024] image 3 Shown is Embodiment 3 of the present invention, and its difference with Embodiment 2 is: the sound-absorbing holes 210 are only distributed on the pipe wall of the air inlet 20 and the pipe wall of the exhaust port 22 of each flusher; Thereby, the noise air flow can only flow into the muffler chamber 3 through the pipe wall of the air inlet 20 or the air outlet 22, and ensure that the air flow state in the two sections of the elbow 21 of each hedge is completely symmetrical, so as to ensure the hedging effect .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com