A speed control device for an engine

A technology of speed control device and engine, which is applied in the direction of engine control, machine/engine, mechanical equipment, etc., can solve the problems of a large number of parts of the speed governor, a large number of precision machining parts, and a large movement gap, and achieves a small number of parts and eliminates the Effects of delayed response and less movement gap

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

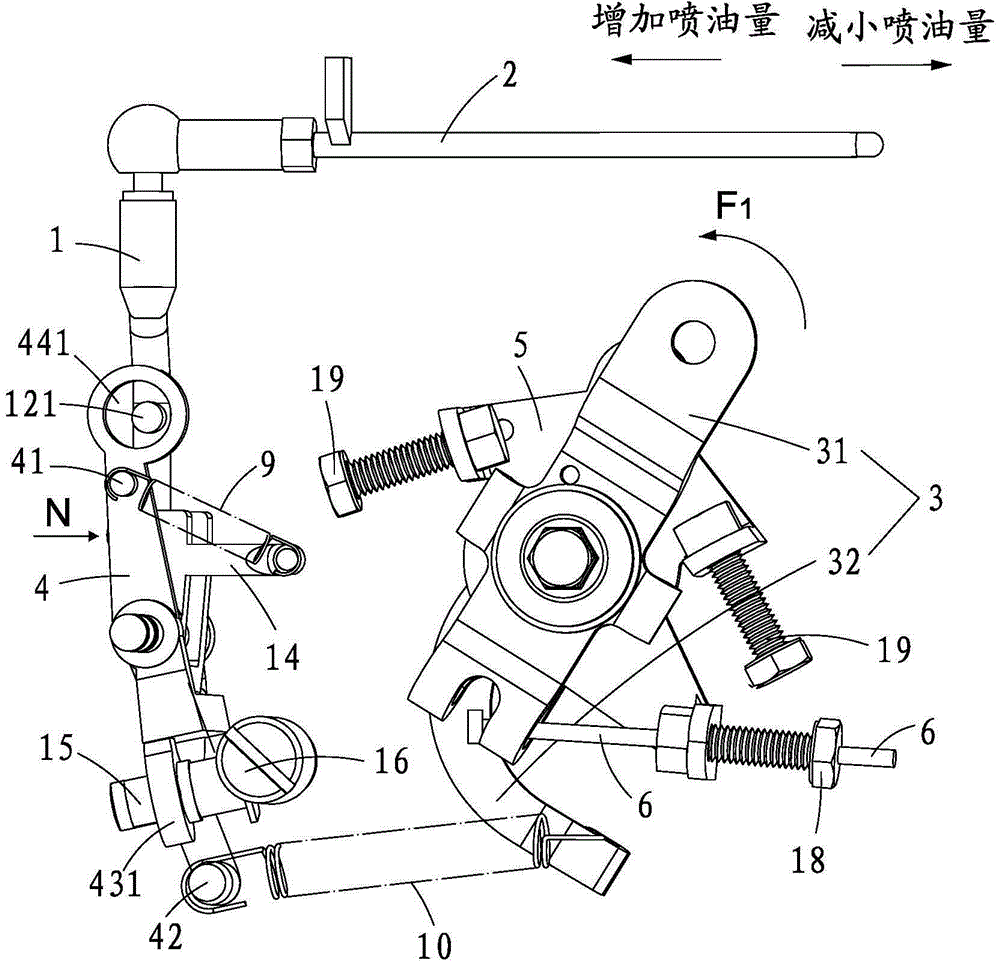

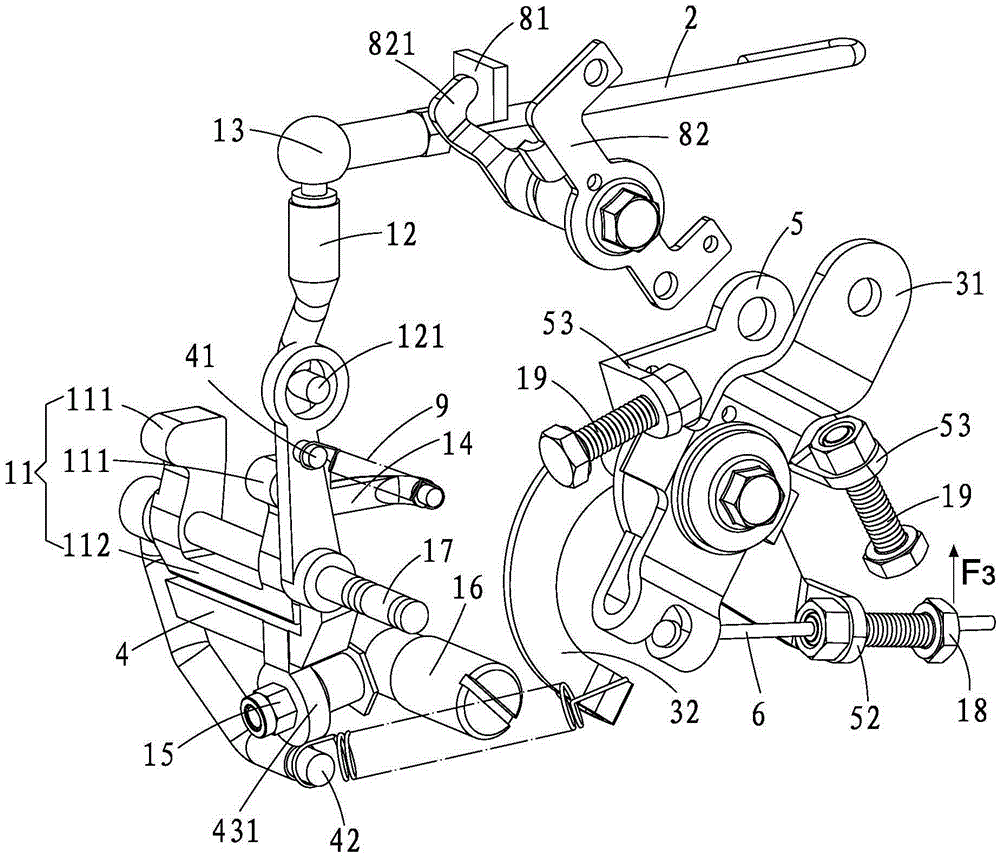

[0029] see Figure 1-2 , a speed control device for an engine, including a shift fork 1, a pull rod 2, a speed setting part 3, a speed control lever 4, a fixed frame 5, a flexible shaft 6, a return unit 7 and a stop Unit 8; the shift fork 1 is movably connected to the speed regulating lever 4, the speed setting part 3 is movably connected to the fixed frame 5, and the speed setting part 3 has a rocker arm 31 and a crank arm 32; The fixed frame 5 is fixedly connected with the engine (not shown).

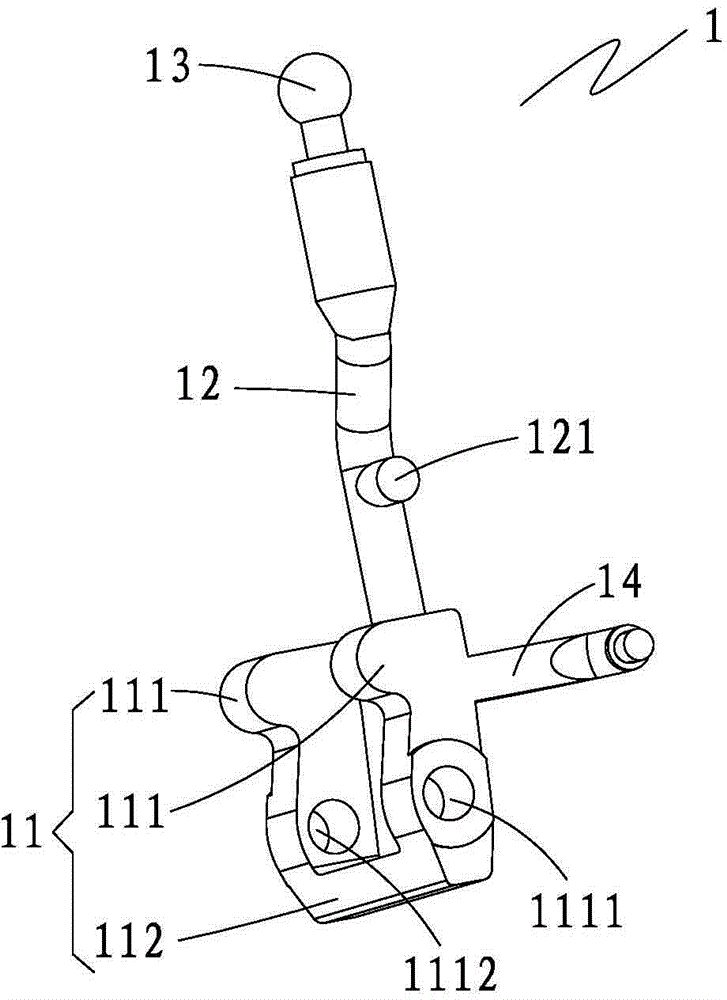

[0030] see again Figure 2-3 , the shift fork 1 includes a support frame 11 , a bending rod 12 , a ball head 13 and an adjustment component 14 . The support frame 11 includes a pair of tongues 111 and a horizontal member 112 connected to the bottoms of the two tongues 111; column 121 , and the ball head 13 is located at the top of the bending rod 12 . The ball head 13 is hinged to the pull rod 2 ; the adjustment component 14 is arranged at the rear upper part of the tongue 111 on ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com