Patents

Literature

38results about How to "Small movement gap" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

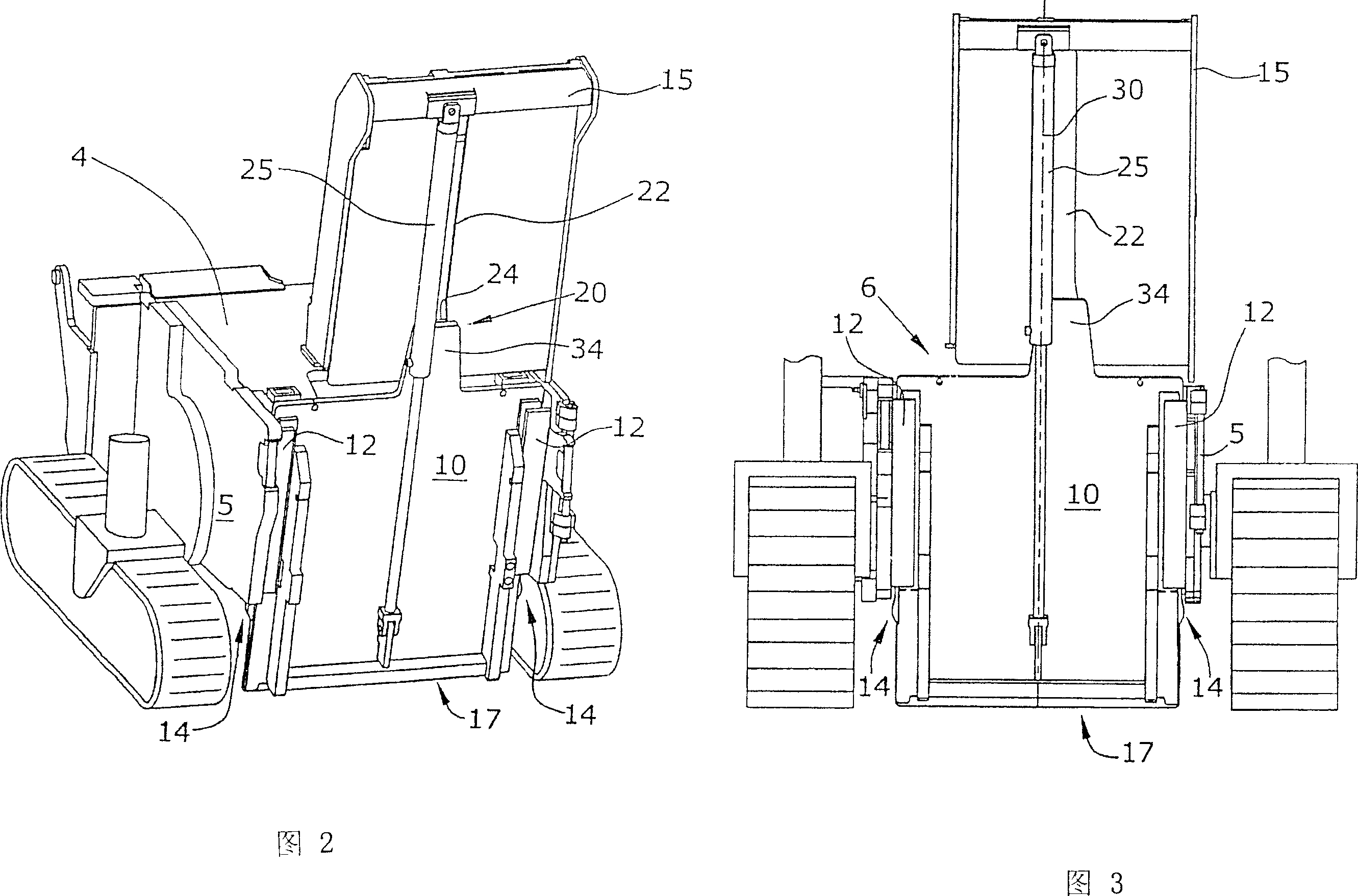

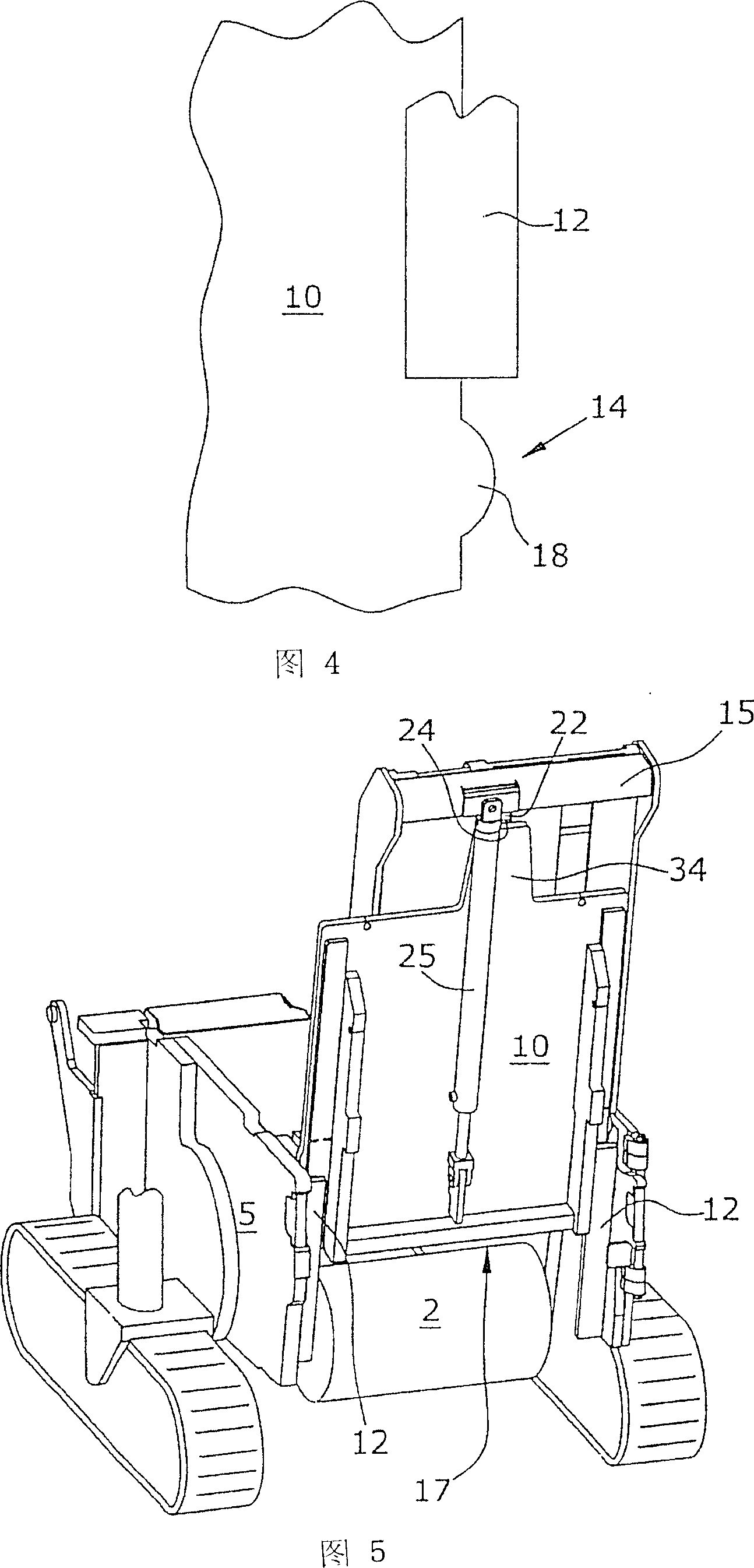

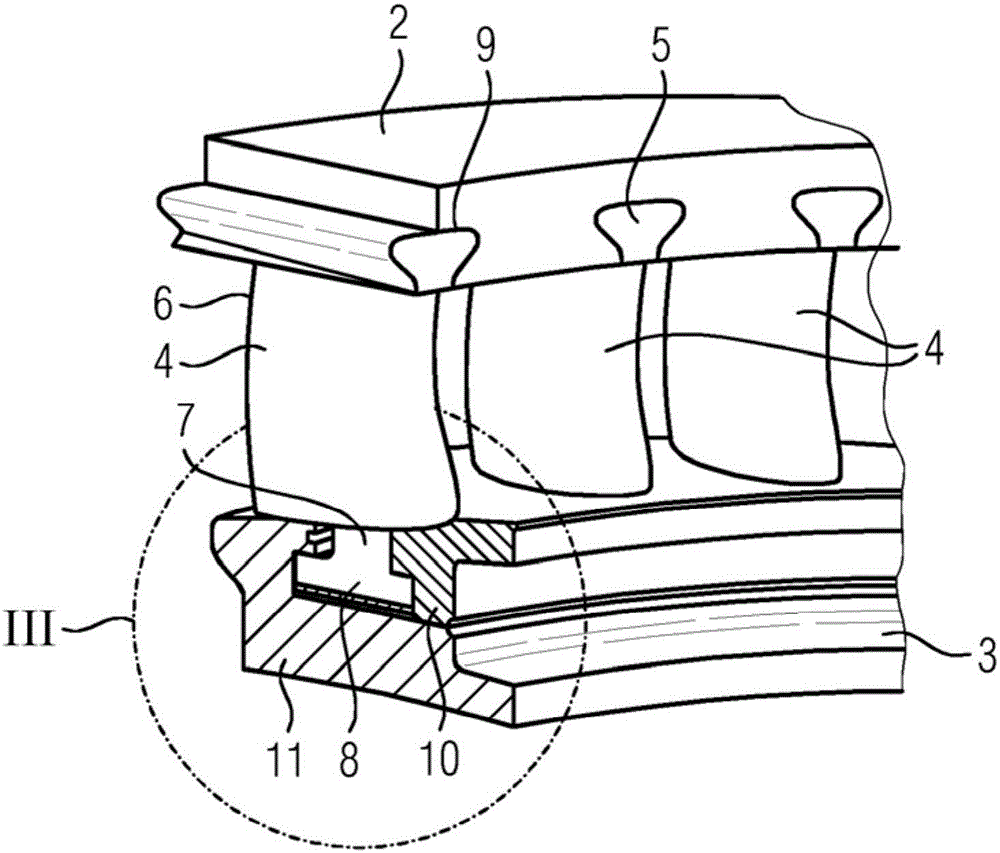

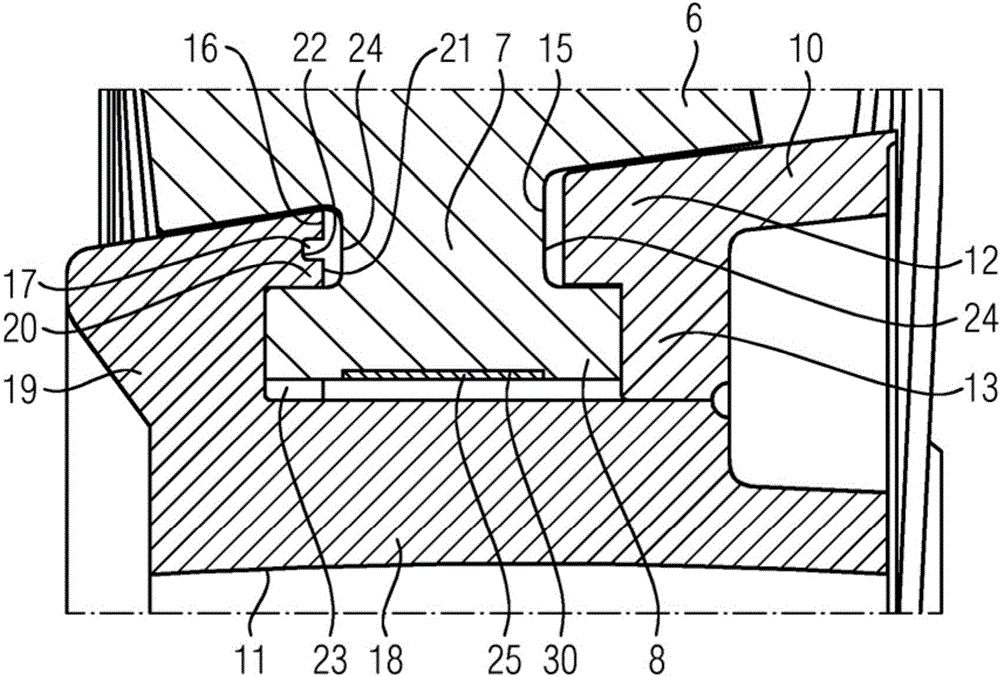

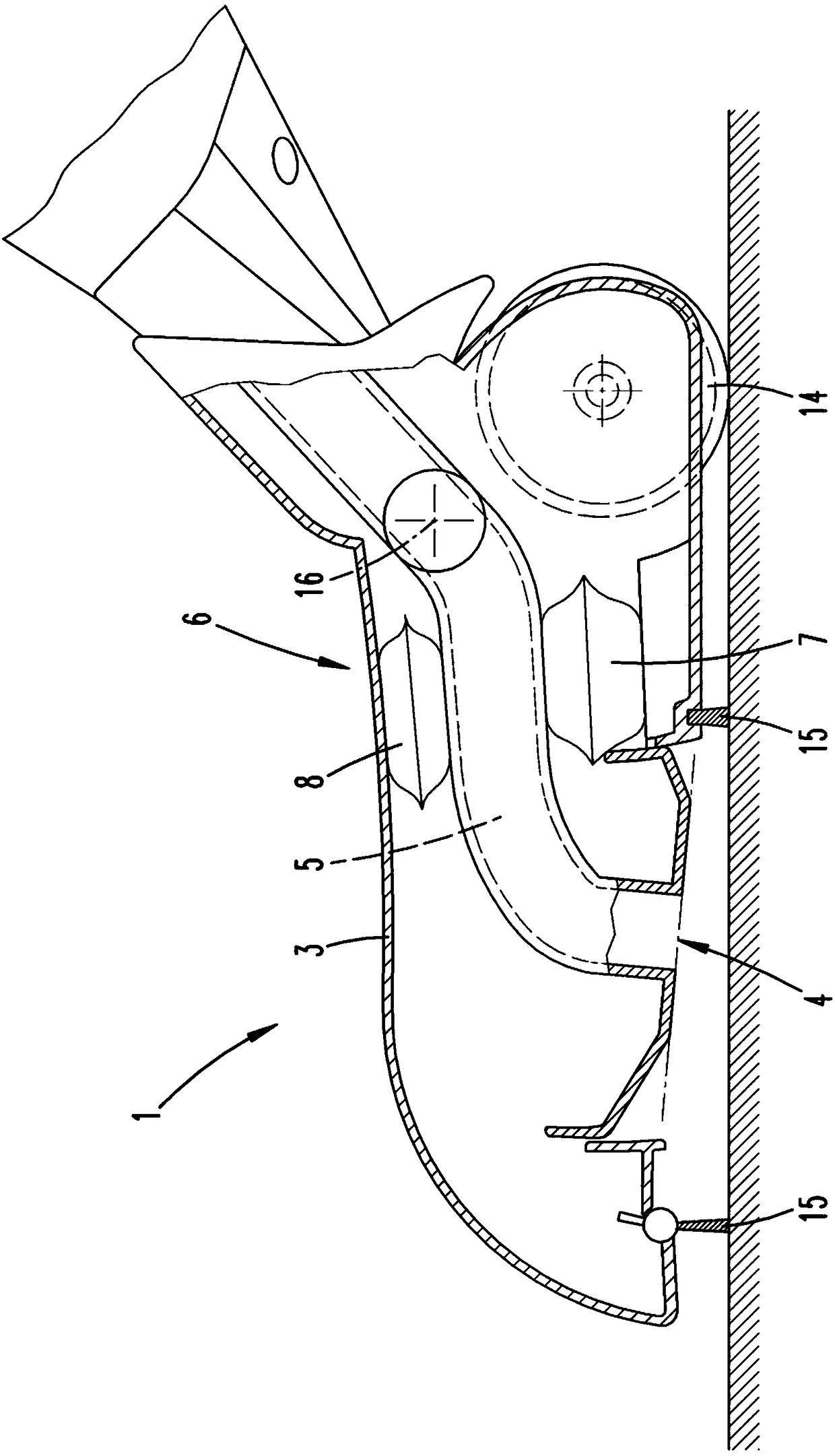

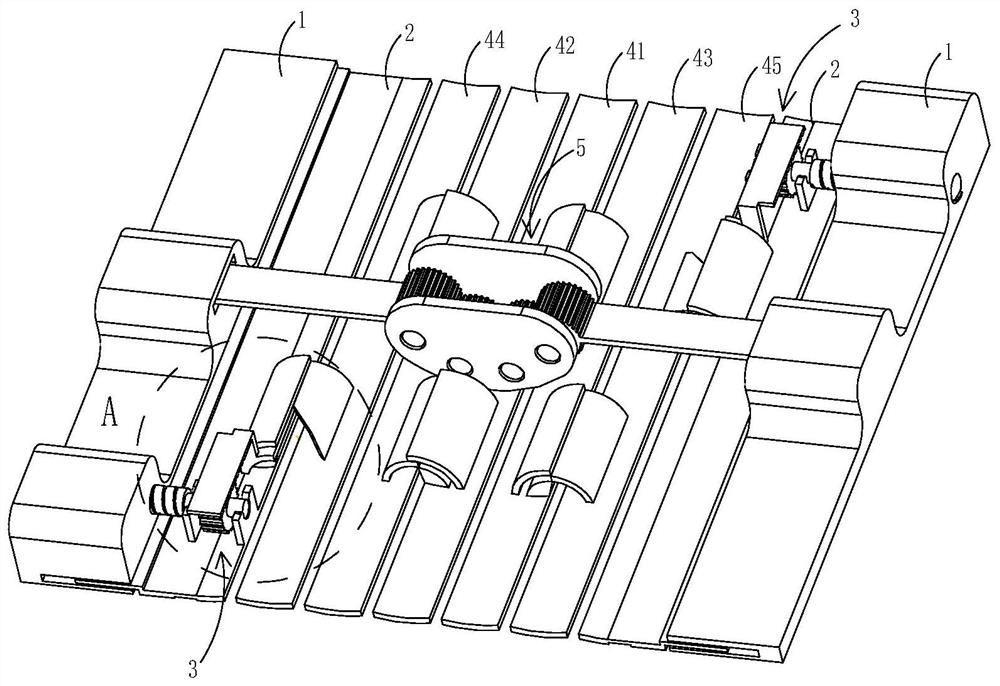

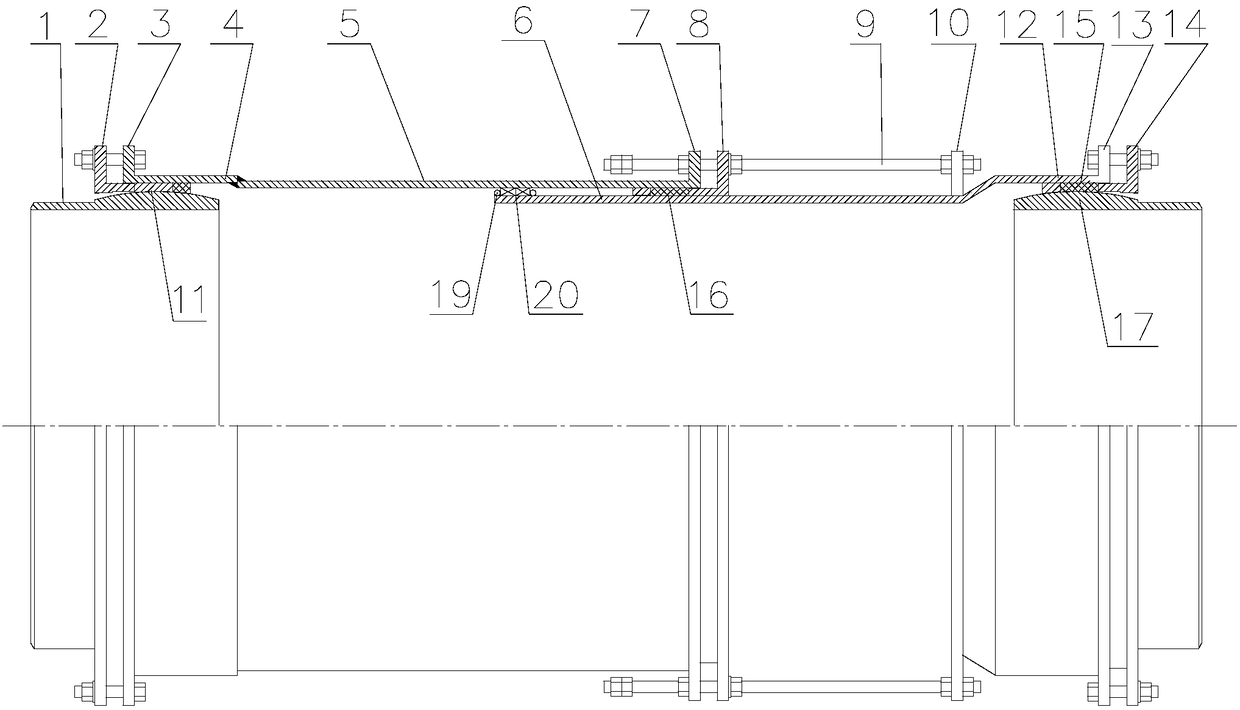

Scraping device for a cutting roller mounted in a construction machine

In a scraper device for a milling drum ( 2 ) mounted in a construction machine, with a scraper blade ( 10 ) arranged in a height-adjustable manner behind the milling drum ( 2 ) when seen in the direction of travel, which can glide on the surface ( 3 ) milled or to be milled by the milling drum ( 2 ), where the scraper blade ( 10 ) is guided in lateral guides ( 12 ) in a height-adjustable manner relative to the milling drum ( 2 ), and where first centering devices ( 14 ) are provided which center the scraper blade ( 10 ) between the guides ( 12 ) with small lateral play of movement when in a raised position, and which allow a greater lateral play of movement of the scraper blade ( 10 ) when the scraper blade ( 10 ) is in a lowered working position, it is provided that the second centering devices ( 20 ) act upon the upper end ( 16 ) of the scraper blade ( 10 ), restricting the lateral displacement of the scraper blade ( 10 ) at the upper end ( 16 ) in case of a lateral movement of the scraper blade ( 10 ) in the guides ( 12 ).

Owner:WIRTGEN GMBH

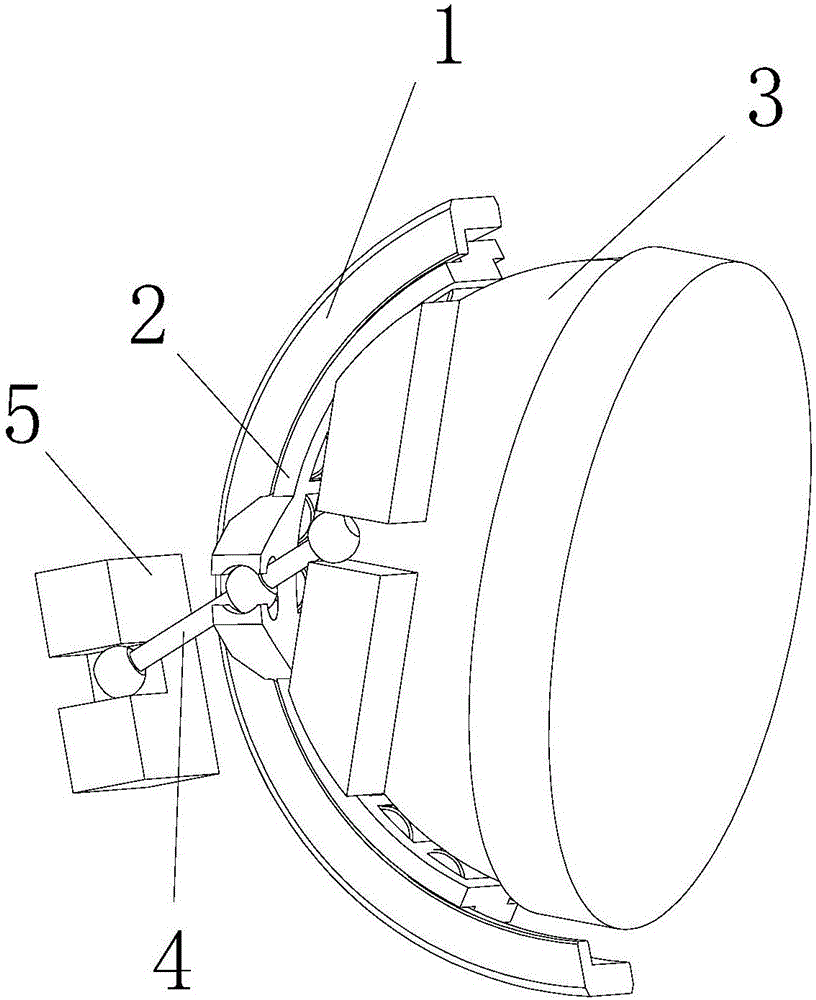

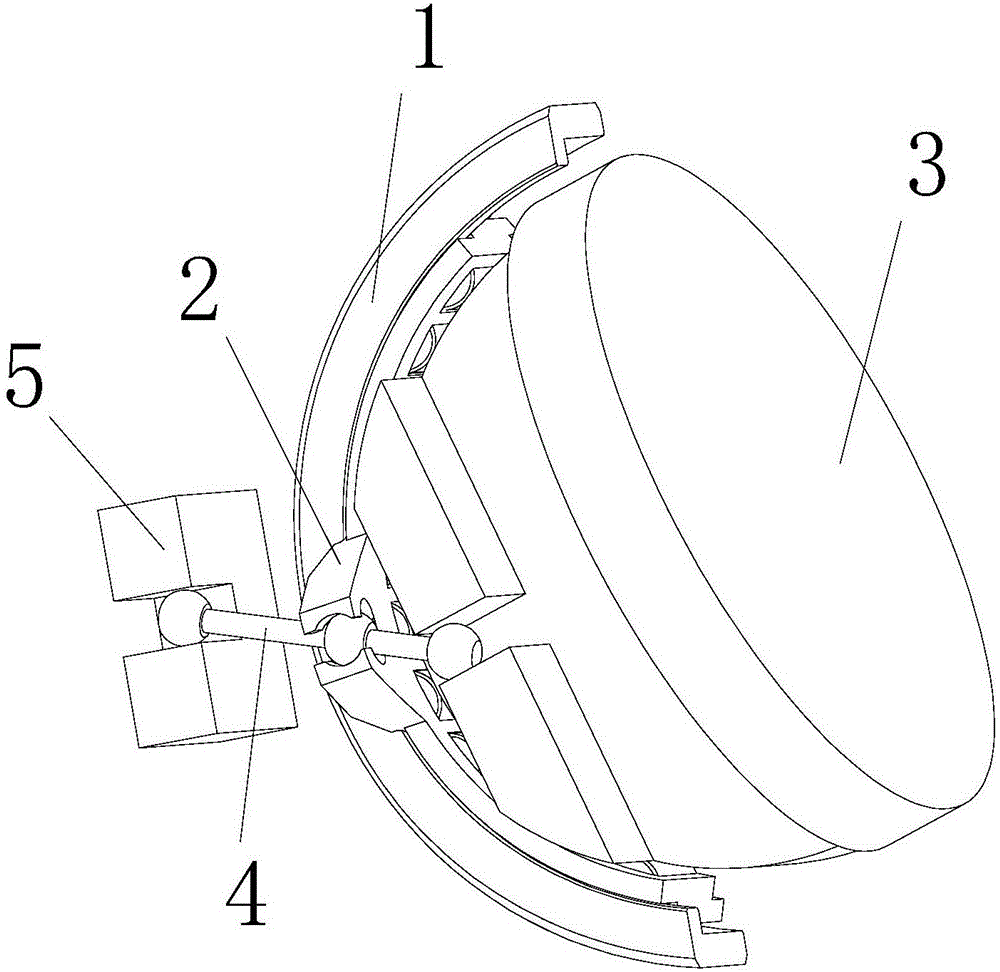

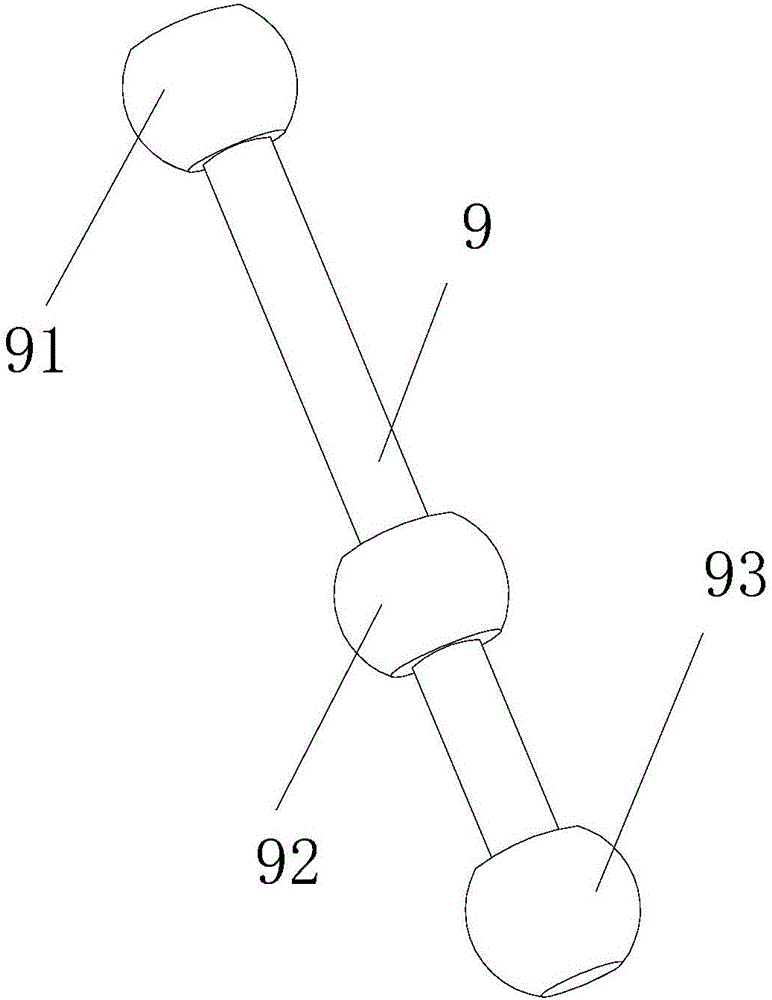

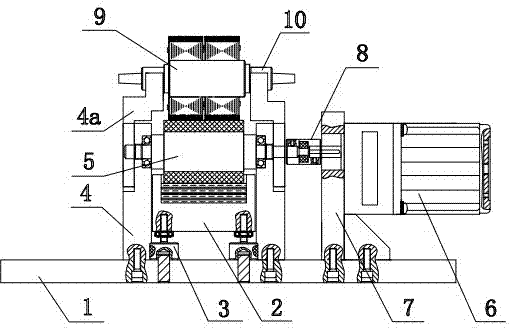

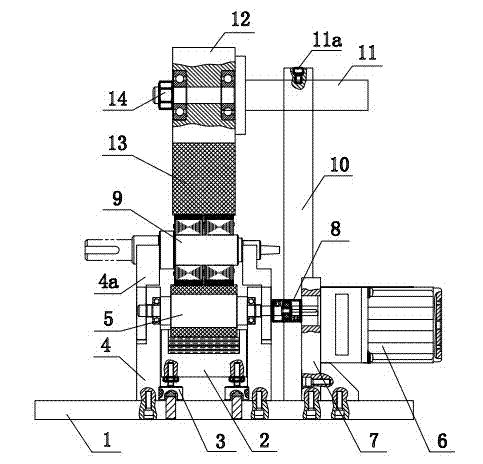

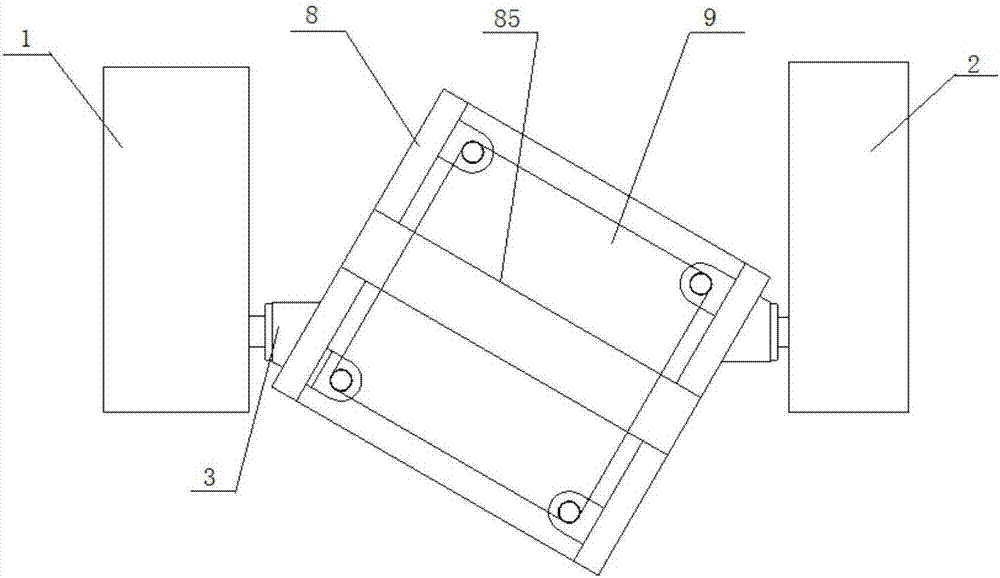

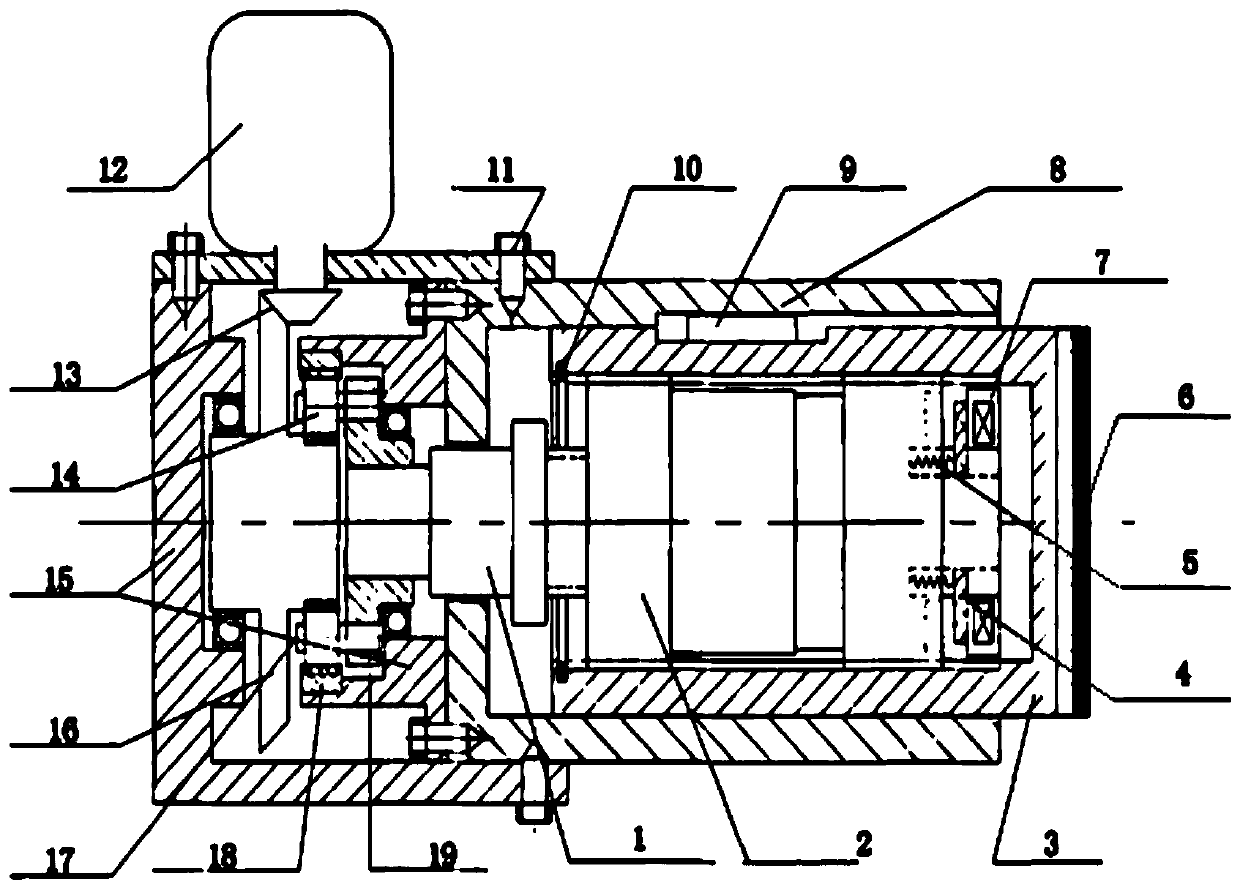

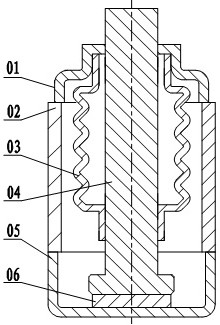

Mounting mechanism for swash plate of oblique plunger pump and driving lever

PendingCN107435618AAdjust the tilt angleEasy to operatePositive displacement pump componentsPositive-displacement liquid enginesEngineeringStructural engineering

The invention relates to a mounting mechanism for the swash plate of an oblique plunger pump. The mounting mechanism comprises a plunger pump body and is characterized in that a crescent outer ring is fixedly mounted on the plunger pump body, a crescent bearing which can move up and down along the inner curve surface of the crescent outer ring is arranged in the crescent outer ring, and the swash plate of the plunger pump is arranged on the crescent bearing. By the mounting mechanism, the inclination angles of the swash plate on the plunger pump can be adjusted conveniently. The driving lever comprises a driving lever body and is characterized in that the upper end of the driving lever body is provided with an upper bulb in rotation fit with the swash plate, the lower end of the driving lever body is provided with a lower bulb in rotation fit with the plunger pump body, and the middle of the driving lever body is provided with a middle bulb in rotation fit with a crescent bearing retainer. By the three bulbs on the driving lever, the upper part, the middle part and the lower part of the driving lever can be in good rotation fit with the swash plate, the retainer and an adjusting block, motion gaps can be reduced, and the mechanism can operate stable.

Owner:CHANGZHOU CRONOS SPECIAL BEARING MFG

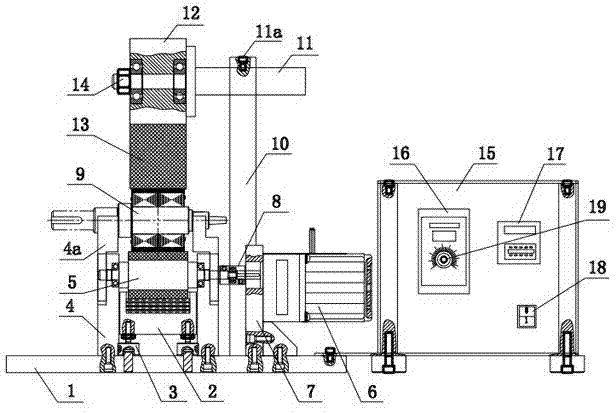

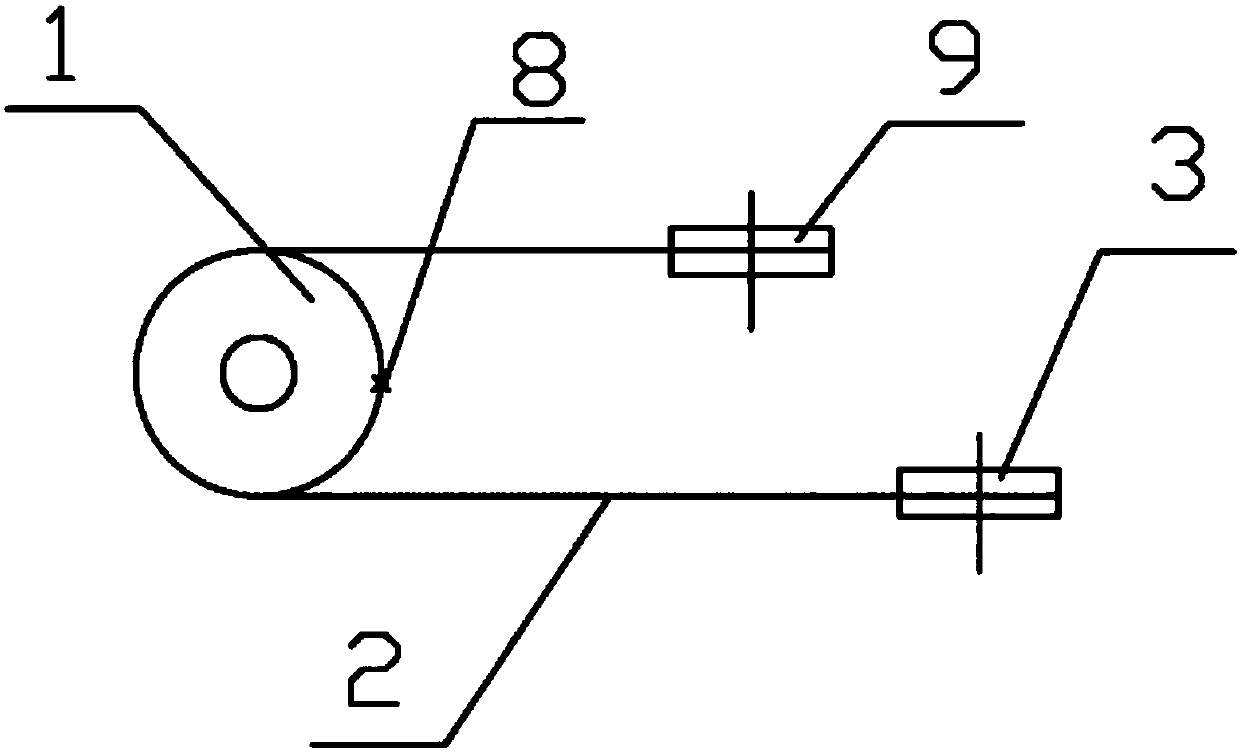

Intelligent glue rolling device for motor rotor

ActiveCN103657944AGuaranteed uniformityEnsure consistencyLiquid surface applicatorsManufacturing stator/rotor bodiesMotor speedGlass fiber

The invention relates to glue coating equipment, in particular to an intelligent glue rolling device for a motor rotor. The intelligent glue rolling device is characterized by comprising a bracket bottom plate, a glue tank, an adsorption type rolling roller, an AC speed reducer motor and an electric control box, wherein the glue tank is arranged on the bracket base board; the adsorption rolling roller is arranged just above the glue tank, and the cylindrical surface of the adsorption rolling roller is in matched contact with the liquid level of the glue tank; the rotor is arranged just above the adsorption rolling roller, and the cylindrical surface of the adsorption rolling roller is matched with the cylindrical surface of the rotor in a rolling manner; an adjustable motor speed reducer, an adjustable time delay and a control switch are arranged on the electric control box, and the AC speed reducer motor, the adjustable motor speed regulator, the adjustable time relay and the control switch form a control loop. The intelligent glue rolling device uses the adsorption rolling roller to coat the rotor with glue, and can ensure the uniformity of a glass fiber cloth surface; the rotation speed of the AC speed reducer motor can be set via the adjustable motor speed reducer, the operation is very flexible, and requirement on different rotation speeds can be satisfied.

Owner:ZHEJIANG LINIX MOTOR

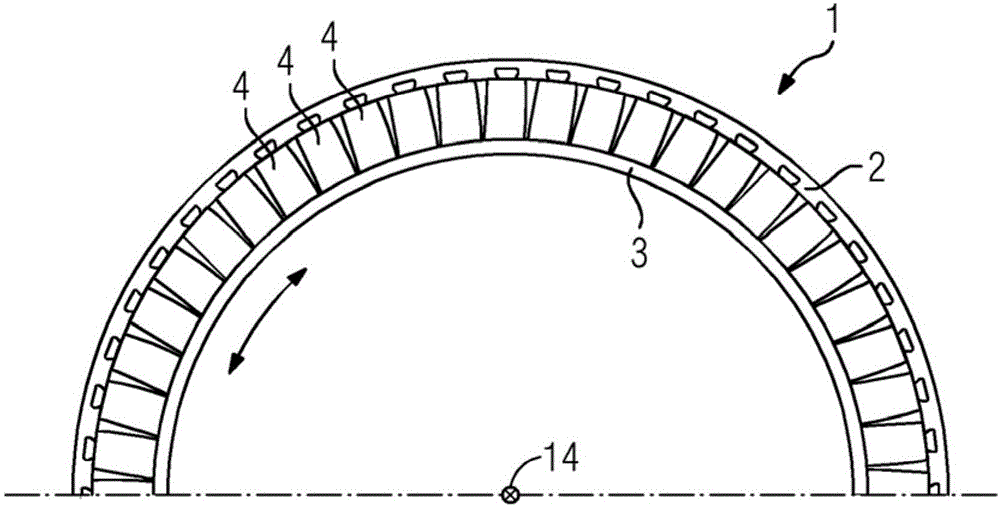

Guide vane assembly

InactiveCN107438702ASimple cost manufacturingSimple structurePump componentsStatorsEngineeringMechanical engineering

The invention relates to a guide vane assembly (1) comprising at least partially resilient brackets (25; 31; 34), each of which has some tolerance between a web (7) of a guide vane (4) and an inner ring (3) of the guide vane assembly (1), the web (7) being located between a boot (8) and an airfoil (6) of the guide vane (4).

Owner:SIEMENS AG

Automatic gluing device

ActiveCN103657948AGuaranteed uniformityHigh repeat positioning accuracyLiquid surface applicatorsCoatingsGlass fiberCoupling

The invention relates to a machine tooling, particularly to an automatic gluing device. The device is characterized by comprising a base plate, a rubber pool, an adsorption type rolling wheel and an AC gear motor, wherein the rubber pool is arranged on the base plate; the adsorption type rolling wheel is arranged right above the rubber pool, and the cylindrical surface of the adsorption type rolling wheel is in contact fit with the liquid level of the rubber pool; a cylindrical workpiece to be coated is arranged right above the adsorption type rolling wheel, and the cylindrical surface of the adsorption type rolling wheel is matched with that of the cylindrical workpiece to be coated in a rolling manner. According to the invention, the adsorption type rolling wheel is adopted for gluing the cylindrical workpiece to be coated with rubber, the uniformity of the glass fiber cloth surface is ensured; the AC gear motor and the adsorption type rolling wheel are connected through a high-precision coupler, so that repositioning accuracy is high, and moving gap is small; a liftable regulator is used, and when the liquid level of the rubber pool drops, the rubber pool is lifted by only adjusting the liftable regulator, so that the liquid level of the rubber pool rises, thereby realizing automatic feeding and avoiding frequent addition of rubber.

Owner:ZHEJIANG LINIX MOTOR

Robot joint movement device

InactiveCN108032326AHigh precision of joint movementSimple structureProgramme-controlled manipulatorJointsSacroiliac jointEngineering

The invention provides a robot joint movement device. The robot joint movement device comprises an oscillating wheel connected to a joint body, wherein a flexible rope sleeve is wound on the oscillating wheel, and meanwhile is further mounted on a plurality of transition wheels in a sleeving manner to form a ring-shaped transmitting path; a nut is fixedly mounted on the flexible rope sleeve, and is cooperatively mounted on a lead screw in a threaded fit manner; one end of the lead screw is in transmission connection with a motor; the flexible rope sleeve is wound on the oscillating wheel at acircle at least; and a fixing clamp which is in clamped connection to the flexible rope sleeve is fixedly arranged on the outer periphery of the oscillating wheel. The robot joint movement device is simple in structure, convenient to machine and manufacture and small in movement gap, is used for driving a robot joint to move, and is high in accuracy and large in oscillating amplitude.

Owner:CHANGSHA ZHIWEI ELECTRONICS TECH CO LTD

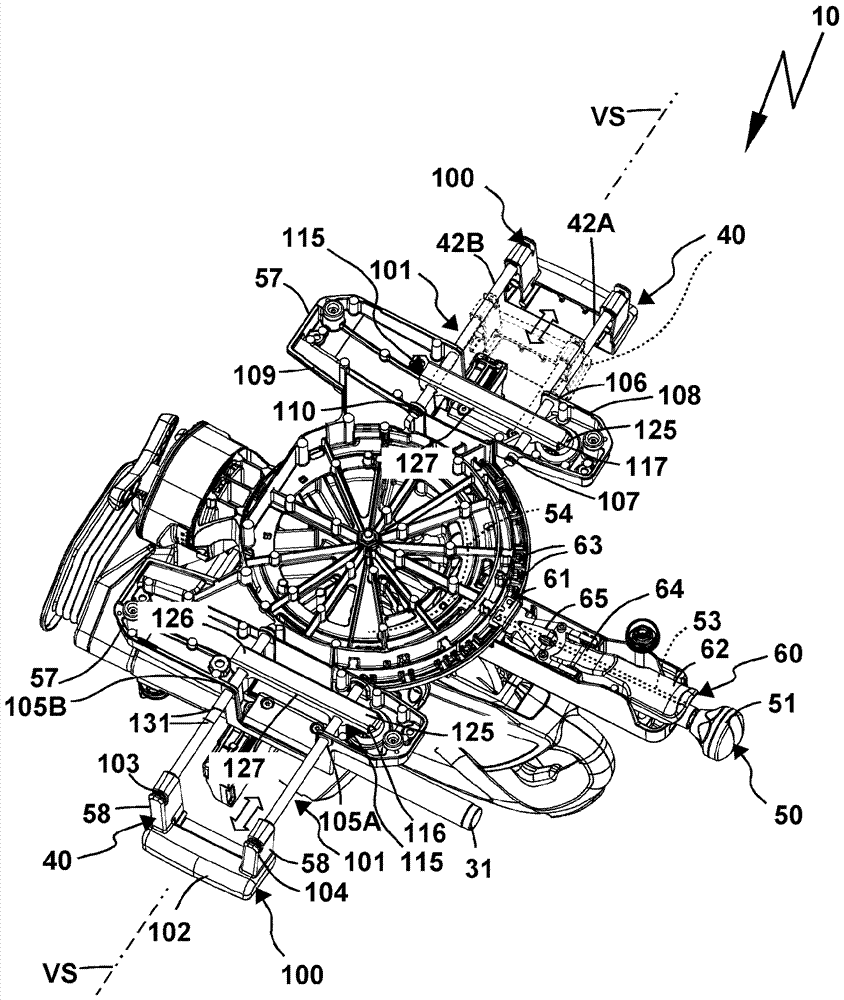

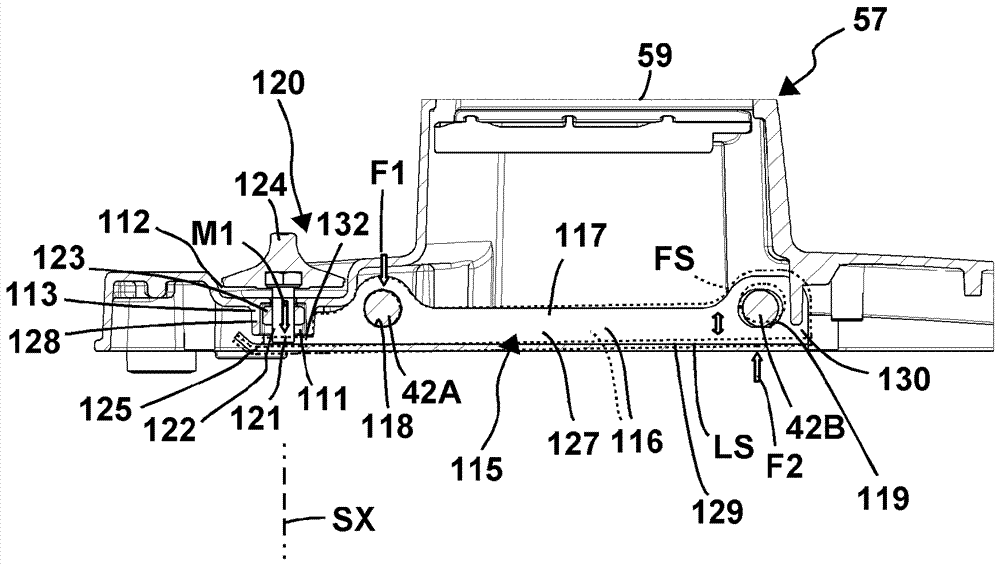

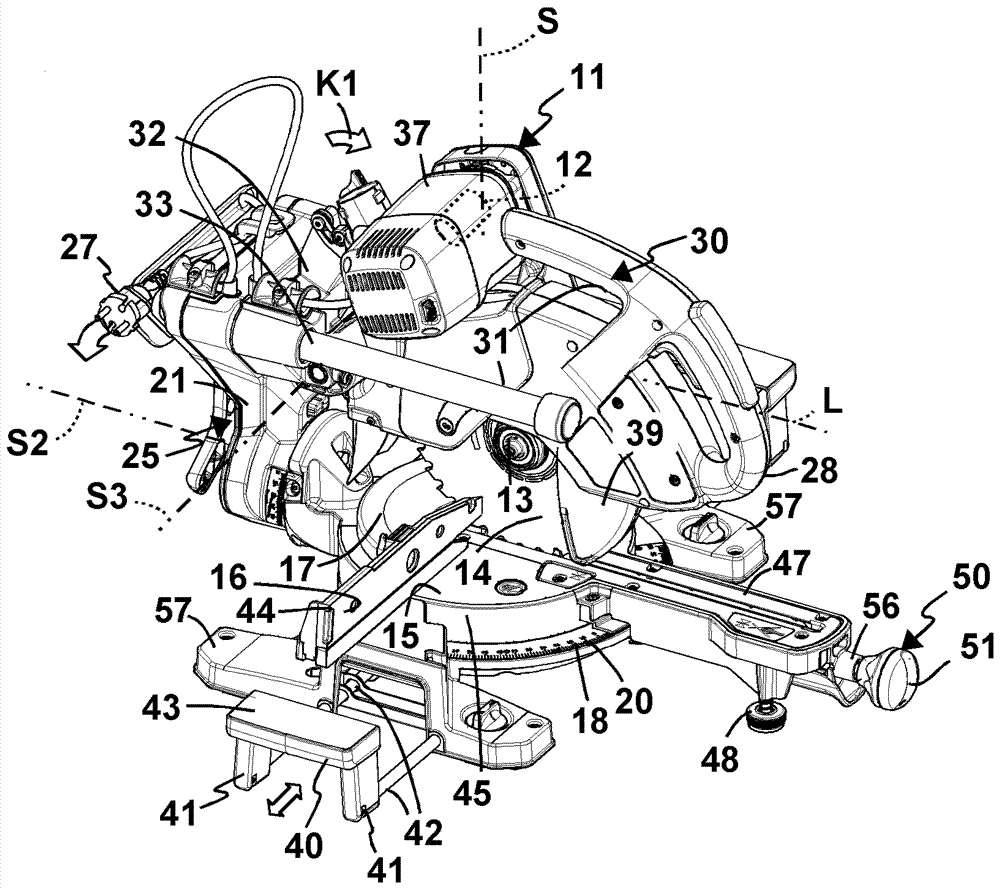

Machine tool with a support piece

ActiveCN107398592ASmall movement gapMetal sawing devicesPortable power-driven toolsDrive motorEngineering

The invention relates to a machine tool (10) for machining workpieces with the aid of a tool. The machine tool (10) has a drive assembly arranged on a machine base (20). The drive assembly has a drive motor and a tool holder (13) for the tool. A support part (100) for supporting workpiece (W) or supporting the machine tool in the workpiece is vertically adjustably arranged on the machine base (20) through a vertical adjusting mechanism (101) relative to the vertical axis (VS). The vertical adjusting mechanism (101) comprises two rod like members namely a first guiding element and a second guiding element (42), which can move along the vertical axis (VS) and are supported by a first bearing component and a second bearing component (105 A, 105B) respectively.

Owner:FESTOOL GMBH

Automobile hopper elevator for automobile making

The invention discloses an automobile hopper elevator for automobile making. The automobile hopper elevator comprises a machine frame; multiple clamping heads are arranged on a chassis of the machine frame; a double-shaft extension motor is adopted for elevating power of the elevator; transmission devices on the two sides of the double-shaft extension motor are completely symmetrical and are connected with worm reduction gears through two couplings; the worm reduction gears are installed on the machine frame; elevating lead screws are sleeved with center holes of the worm reduction gears; the elevating lead screws are fixed in vertical pipes of the machine frame through a pair of bearings; guide sleeves of elevating pipes are made of polytef. The automobile hopper elevator for automobile making is simple in structure, convenient to use, stable in work and firm in clamping.

Owner:CHONGQING DONGKE MOLD MFG

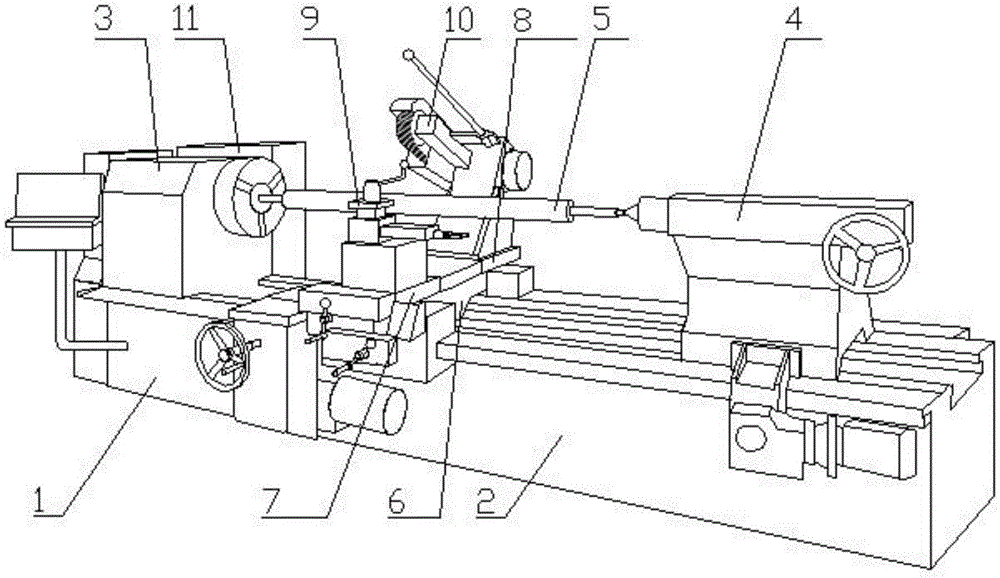

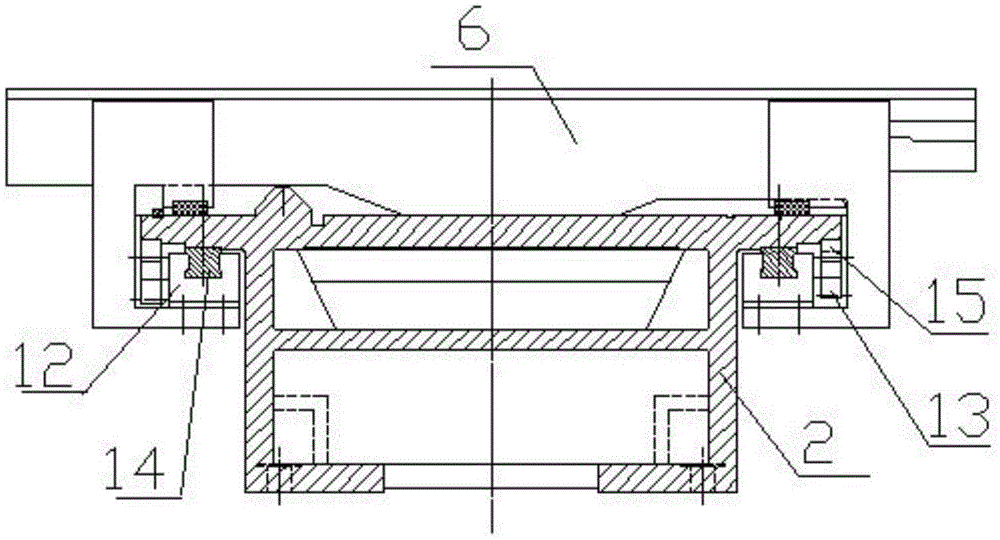

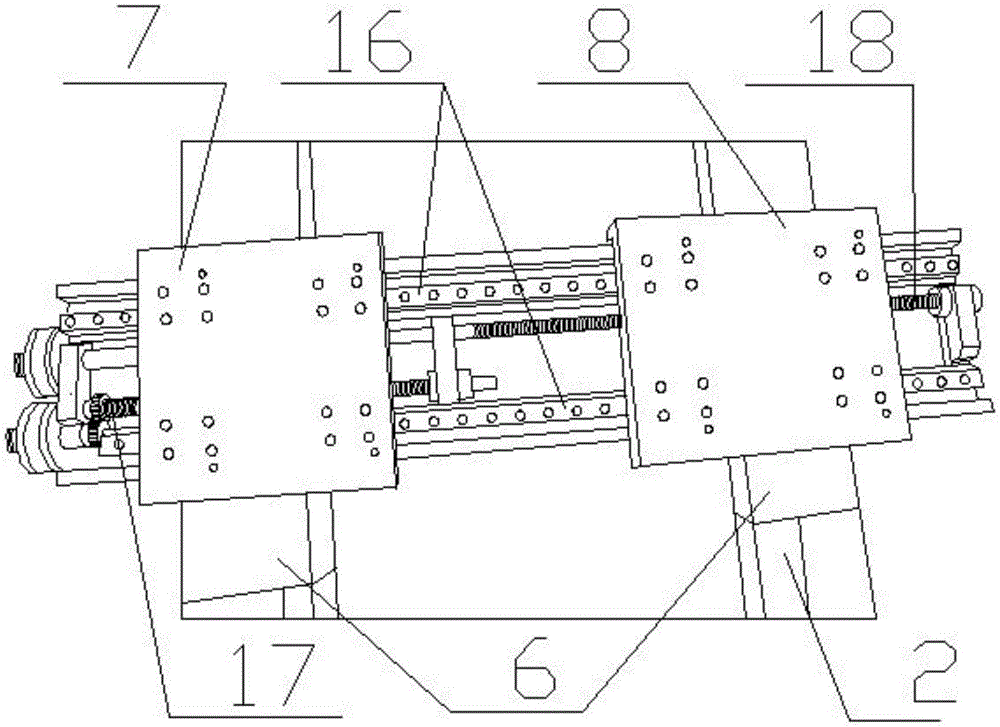

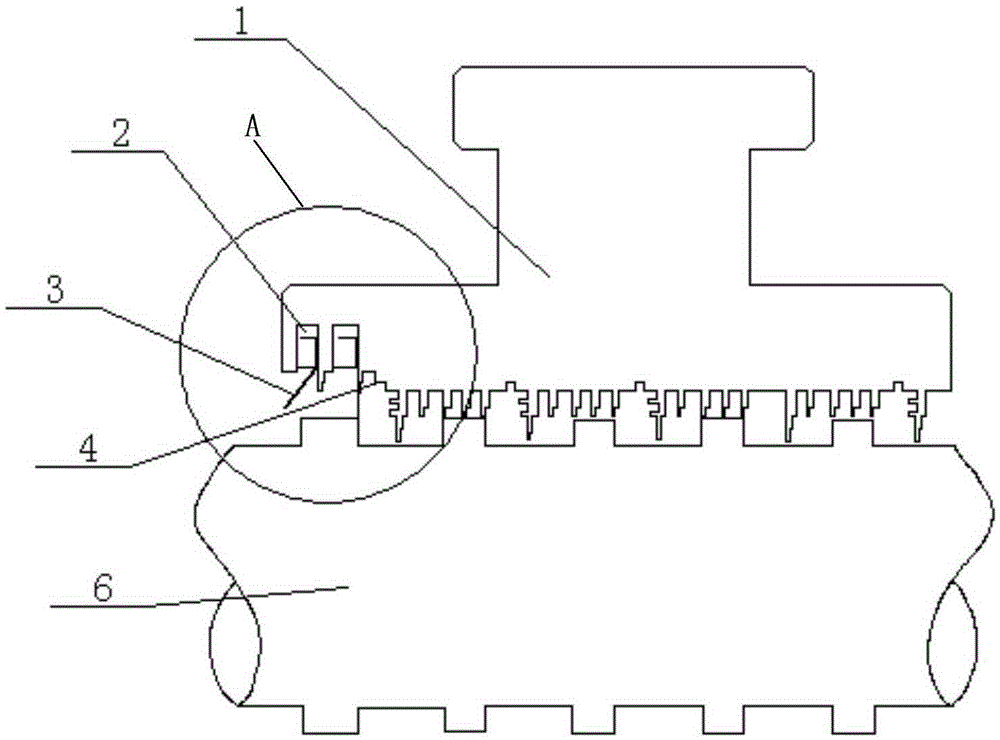

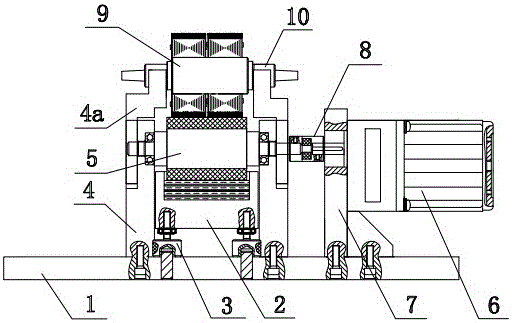

A rubber grinding machine for rubber rollers

ActiveCN103331614BExtended use timeExtend the life cycleTurning toolsOther manufacturing equipments/toolsSand blastingEngineering

The invention discloses a special automobile rubber grinding machine for a rubber covered roller. The special automobile rubber grinding machine comprises a lathe head and a lathe bed which are sequentially connected, wherein the lathe head is provided with a headstock, the lathe bed is provided with a tailstock, and a workpiece is fixed between the headstock and the tailstock; the lathe bed below the workpiece is provided with a large planker, a sliding block and a gear are arranged on the large planker, the lathe bed is provided with a linear guide rail and a rack, the sliding block is matched with the linear guide rail, and the gear is matched with the rack; the large planker is provided with a premedial planker and a postmedial planker which can move on the large planker, the premedial planker is provided with a knife rest, and the postmedial planker is provided with a belt sanding machine. According to the special automobile rubber grinding machine, the firmness between a bonding agent and a central spindle can be guaranteed, a traditional sand blasting technology can be replaced, and the surface is not needed to be washed by any solvent, so that the balance of the central spindle can not be damaged, the production efficiency can be improved, the cost is reduced and the labor force is saved, and the key is that the bonding between the rubber and the central spindle can be reliably guaranteed. According to the special automobile rubber grinding machine, the consumable materials can be saved and the environment pollution can be reduced.

Owner:JINAN POWER RUBBER ROLLER EQUIP

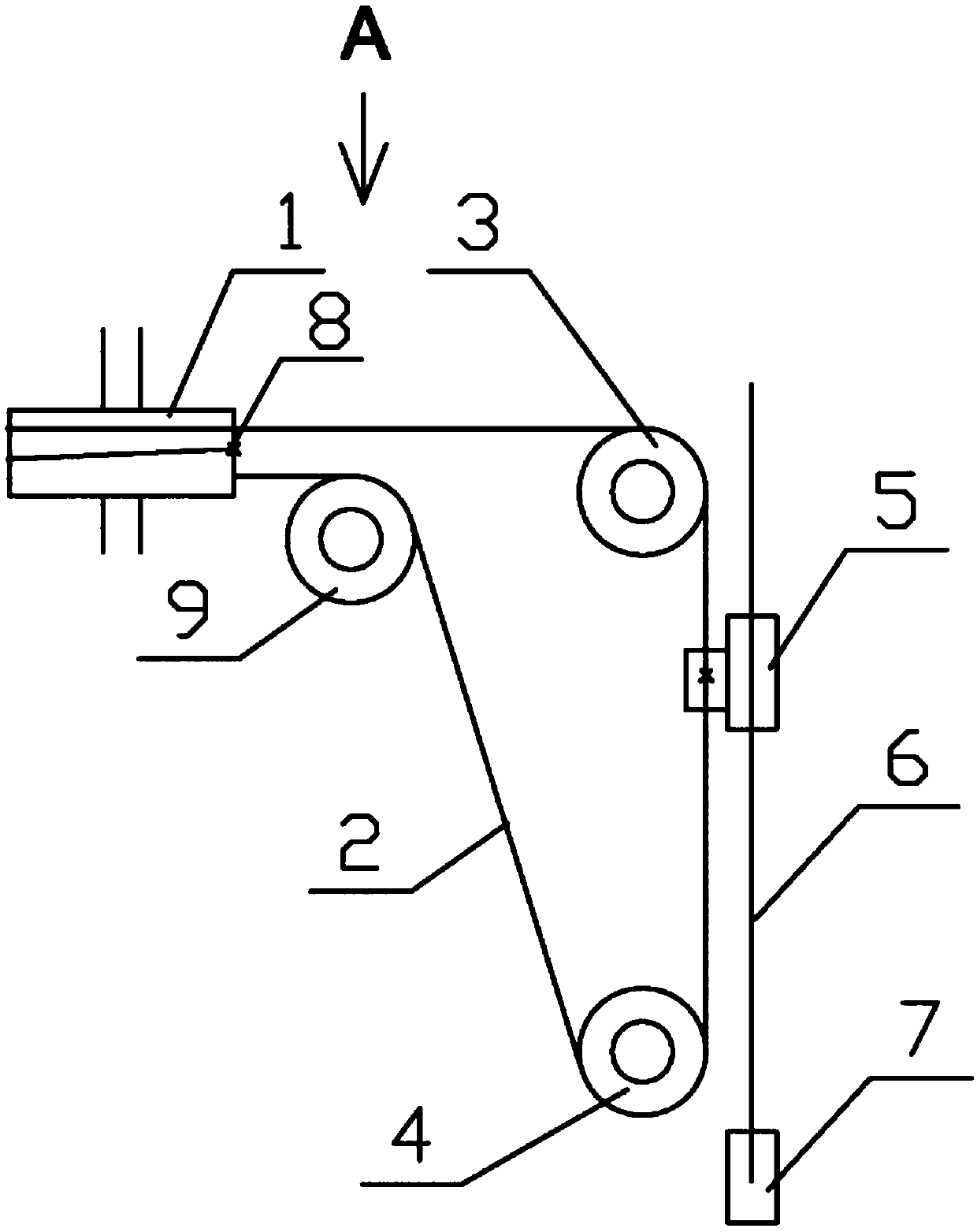

Automatic glue rolling device for motor rotor

ActiveCN103657943AGuaranteed uniformityGuaranteed accuracyLiquid surface applicatorsManufacturing stator/rotor bodiesFiberGlass fiber

The invention relates to glue coating equipment, in particular to an automatic glue rolling device for a motor rotor. The automatic glue rolling device is characterized by comprising a bracket bottom board, a glue tank, an adsorption rolling roller and an AC speed reducer motor, wherein the glue tank is arranged on the bracket bottom board; the adsorption rolling roller is arranged just above the glue tank, and the cylindrical surface of the adsorption rolling roller is in contact and matched with the liquid level of the glue tank; the rotor is arranged just above the adsorption rolling roller; the cylindrical surface of the adsorption rolling roller is in rolling match with the cylindrical surface of the rotor; a glass fiber cloth ring is arranged above the rotor, and glass fiber cloth is wound on the glass fiber cloth ring, and the glass fiber cloth ring is fixed on a glass fiber cloth fixing rack via a glass fiber cloth core shaft. The automatic glue rolling device uses the adsorption rolling roller to coat the rotor with glue, can automatically reduce the amount of the glue on the rotor and ensure the uniformity of the surface of the glass fiber cloth; the glass fiber cloth ring is directly arranged above the rotor and matched with the overall device, and the glass fiber cloth is wound after spreading the glue.

Owner:ZHEJIANG LINIX MOTOR

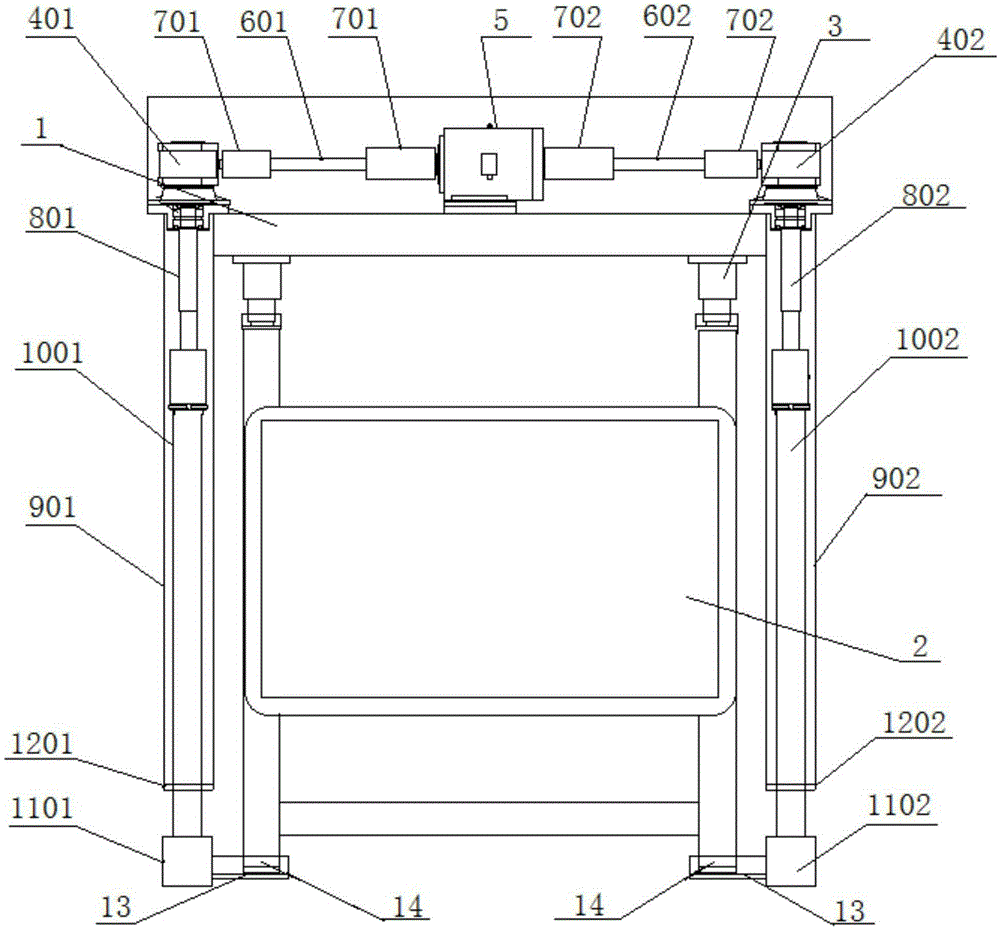

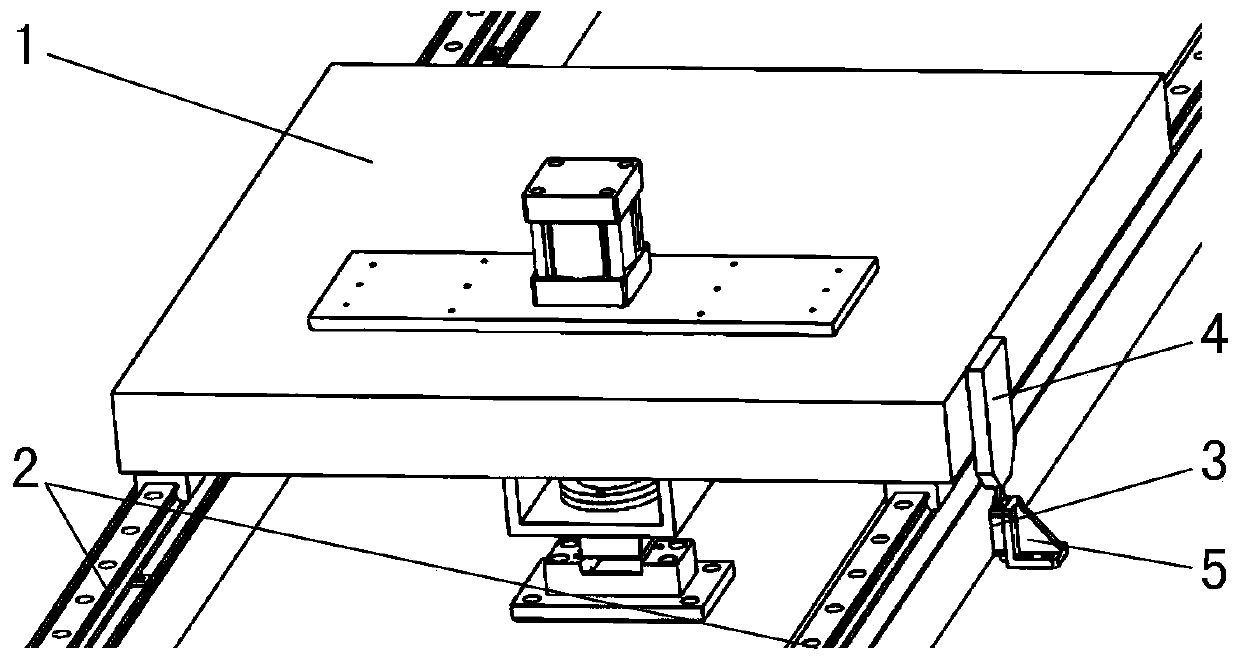

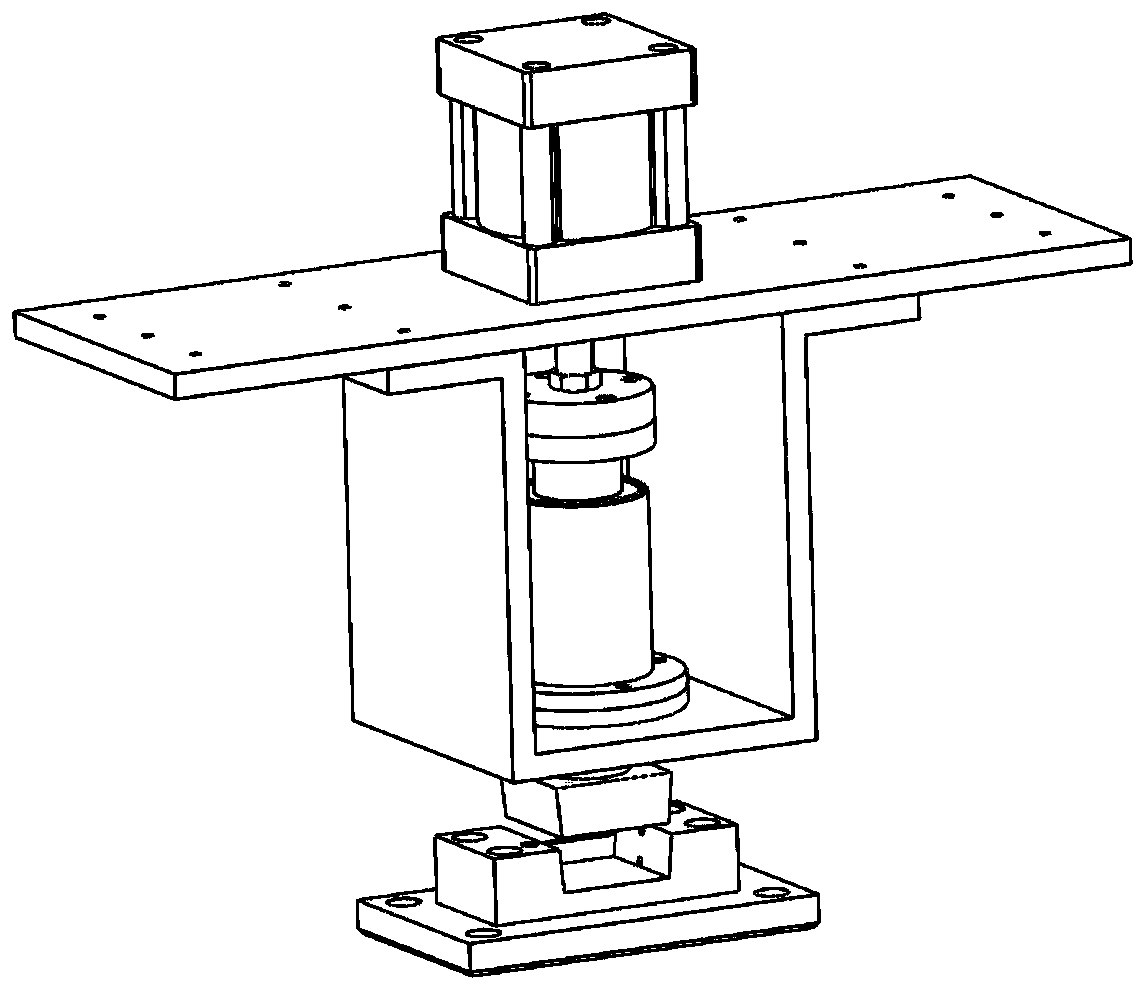

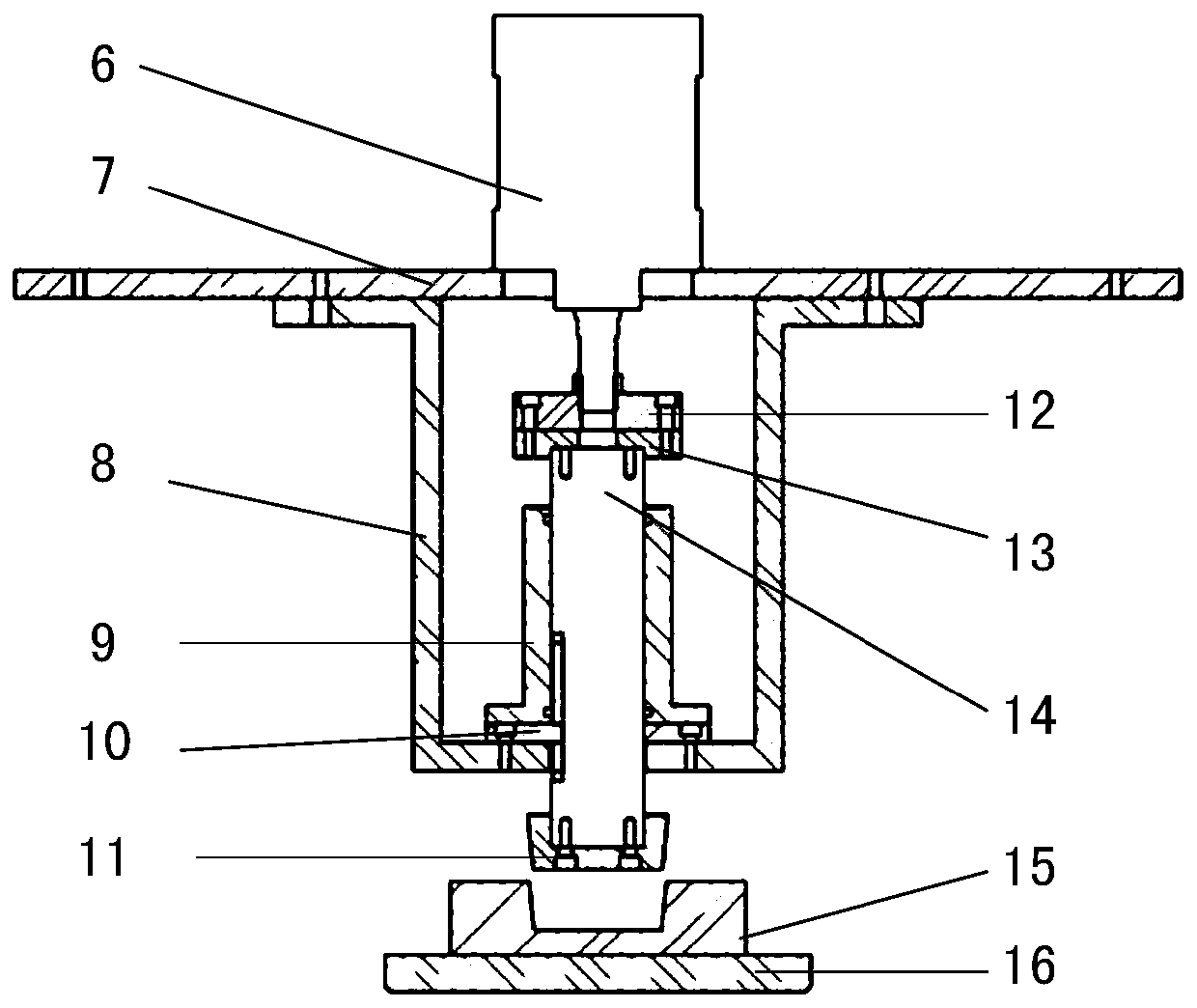

High-precision rapid positioning device for automatic production line

InactiveCN110000593ASmall movement gapHigh precisionMeasurement/indication equipmentsLarge fixed membersProduction lineInterference fit

The invention discloses a high-precision rapid positioning device for an automatic production line. The high-precision rapid positioning device is composed of a moving device, a guide mechanism, a position detection sensor, a sensor trigger block, a fixed supporting plate, a concave positioning block, a concave positioning groove, a transmission assembly and a ground fixing base, the position detection sensor is arranged on the moving device, moreover, whether the moving device reaches the target position or not is detected and judged through the sensor, after the moving device reaches the pre-stop position, the position detection sensor sends a feedback signal to automatically control the moving device to stop moving so as to realize one-time automatic positioning, the transmission assembly adopts an air cylinder as a driving element, a linear bearing is used for reducing the movement gap of a guide shaft, the guide shaft rolls in the linear bearing in an interference fit mode, no radial gap exists, the air cylinder pushes the concave positioning block to be in coaxial fit with the concave positioning groove to be rapidly positioned in the moving direction of the moving device ina high-precision mode. The high-precision rapid positioning device has the characteristics of being high in automation degree, reliable in positioning and good in guiding performance.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

Sealing paste

The invention discloses a sealing paste, and belongs to the technical field of chemical engineering in order to solve the problem of influence of unable formation of a thick and stable oil film due to poor adhesiveness of present sealing pastes on the sealing performance of devices. The sealing paste comprises a common grease and a copper-based composite powder material uniformly dispersed in the common grease, a mass ratio of the copper-based composite powder material to the common grease is 0.5-20:100, and the particle size of the copper-based composite powder material does not exceed 30[mu]m. The sealing paste can greatly improve the adhesion performance of the sealing paste on the working surface of a machine to form a thick and stable oil film in order to improve the sealing performance.

Owner:CHONGQING TAILU TECH DEV

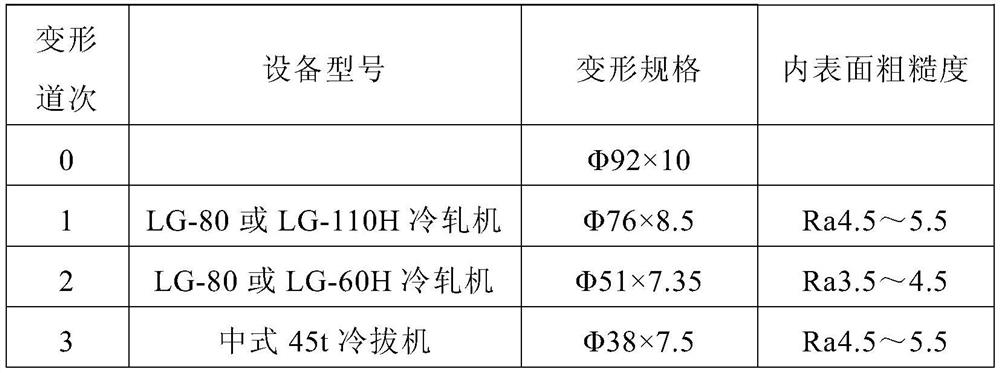

Cold rolling pipe manufacturing method for improving roughness quality of inner wall of stainless steel seamless pipe for power station boiler

ActiveCN111940518AQuality improvementImprove performanceRoll mill control devicesMetal rolling arrangementsPower stationPunching

A cold rolling pipe manufacturing method for improving the roughness quality of the inner wall of a stainless steel seamless pipe for a power station boiler adopts a two-pass cold rolling deformationprocess to roll to obtain finished pipes for delivery, that is, an LG-80 or LG-110H cold rolling mill is adopted for cogging rolling and an SKW-75 high-speed cold rolling mill is adopted for rolling to obtain the finished products. Meanwhile, by optimizing parameters such as a roller device, a hole pattern and a core rod related to cold rolling deformation and taking measures such as increasing the diameter of the core rod, widening a hole pattern opening and reducing a movement gap, the cold rolling pipe making quality and efficiency of the stainless steel seamless pipe for the power stationboiler are improved. On the basis of meeting the technical requirements for cold rolling of the boiler pipe of the power station, the quality loss of the roughness of the inner wall caused by abnormalworking conditions such as "top punching" and "insufficient rotation" of a pipe blank is reduced, the yield is increased, and the production cost is reduced.

Owner:宝武特种冶金有限公司

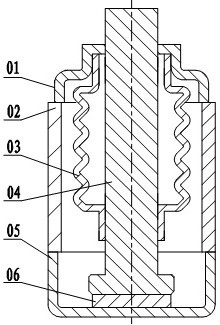

Novel self-adjustment spring type steam seal

InactiveCN106703900AReasonable structural designImprove sealing performanceLeakage preventionMachines/enginesSelf adjustmentSteam turbine

The invention discloses a novel self-adjustment spring type steam seal and belongs to the technical field of steam turbines. A steam seal body is provided with spring pieces and spring piece pressing blocks which are combined in a mutually staggered and overlapped manner. One side of each spring pressing block is provided with a spring piece embedding groove, the spring thin pieces are matched with the spring piece embedding grooves, and one ends of the spring thin pieces are overlapped and riveted into the spring piece embedding grooves; spring piece supporting back teeth at the bottom of the steam seal body are matched with a rotor, and the inner periphery of each spring thin piece is matched with the outer diameter of the rotor. The novel self-adjustment spring type steam seal is reasonable in structural design, and the double-barreled question of greatly improving sealing performance and meeting the requirement for safe operation of a unit can be solved.

Owner:广州市智伟电力科技开发有限公司

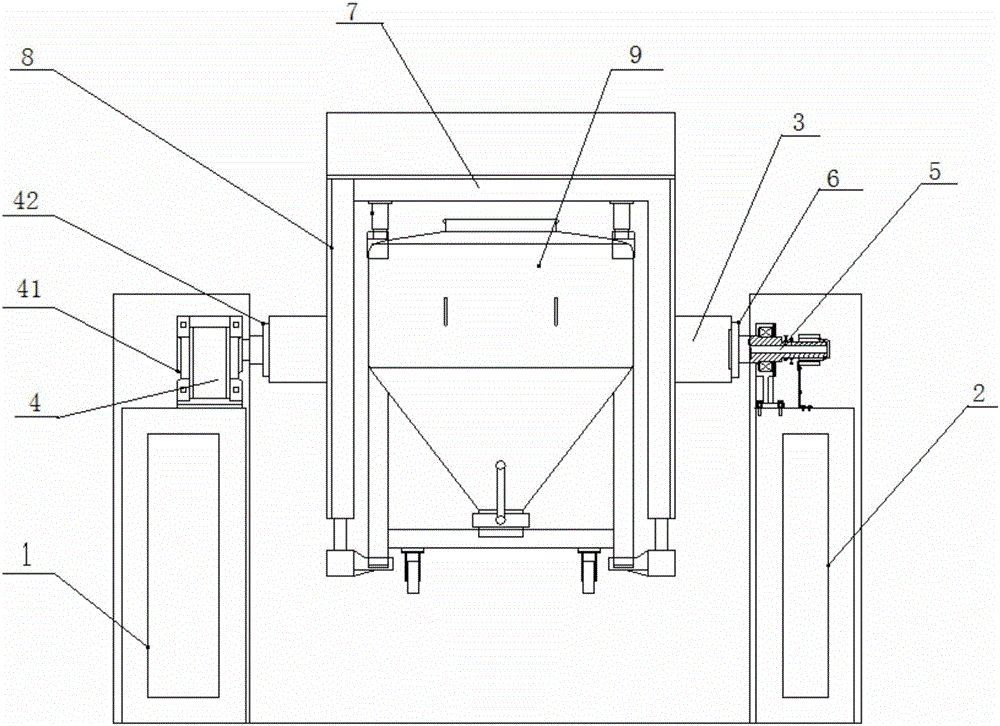

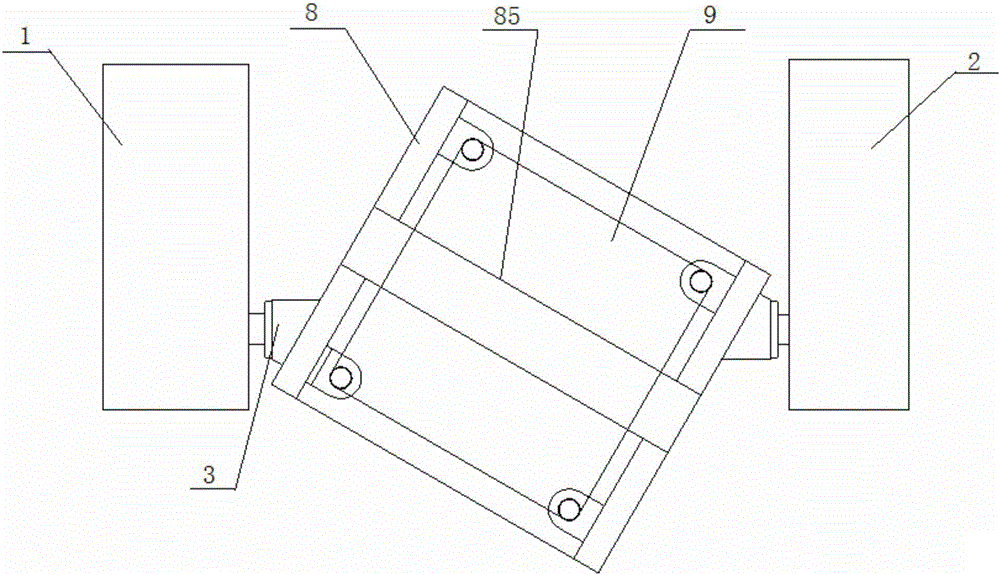

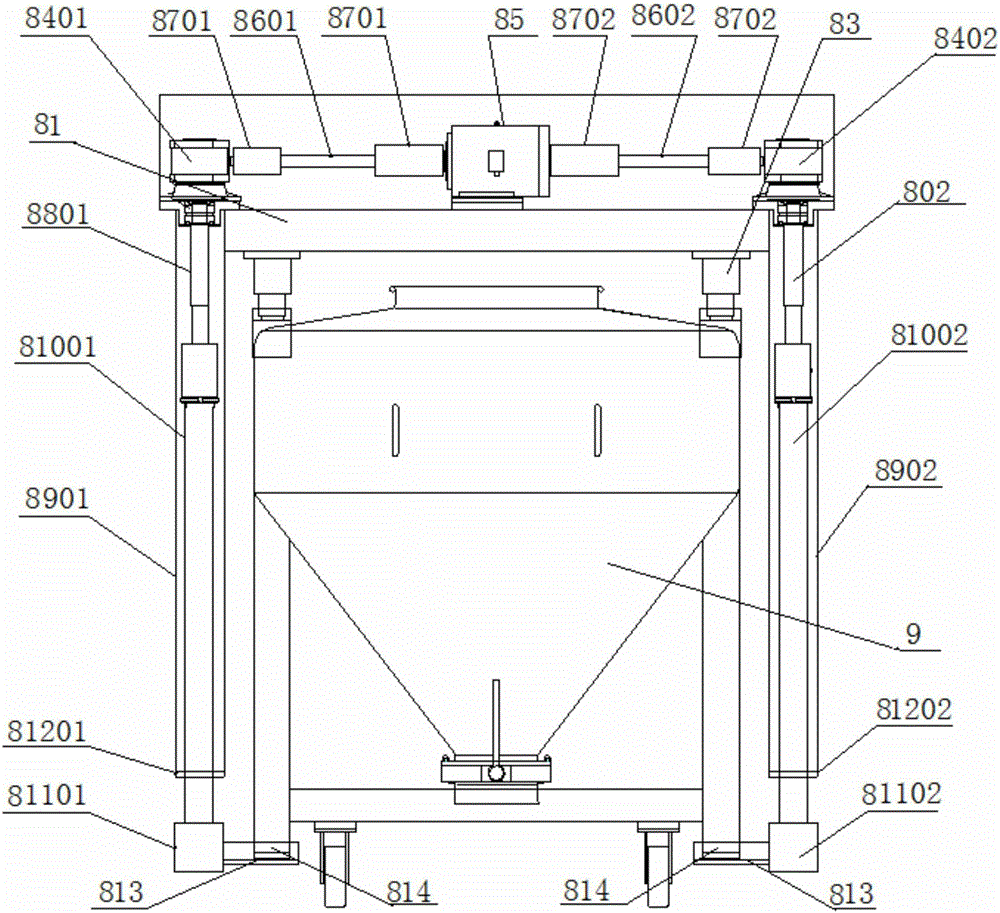

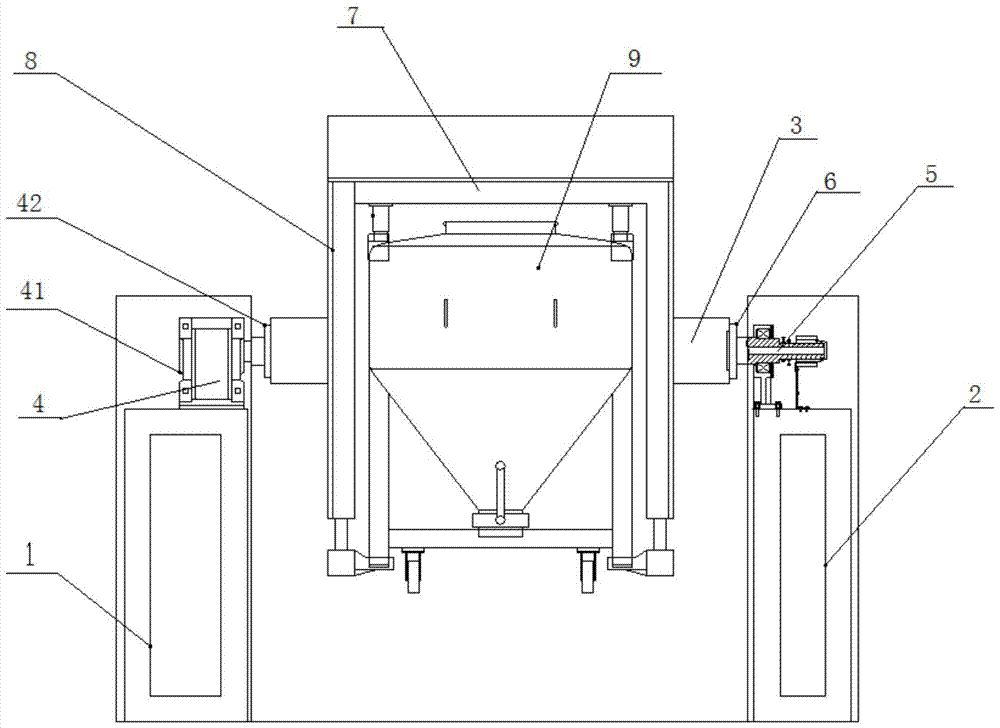

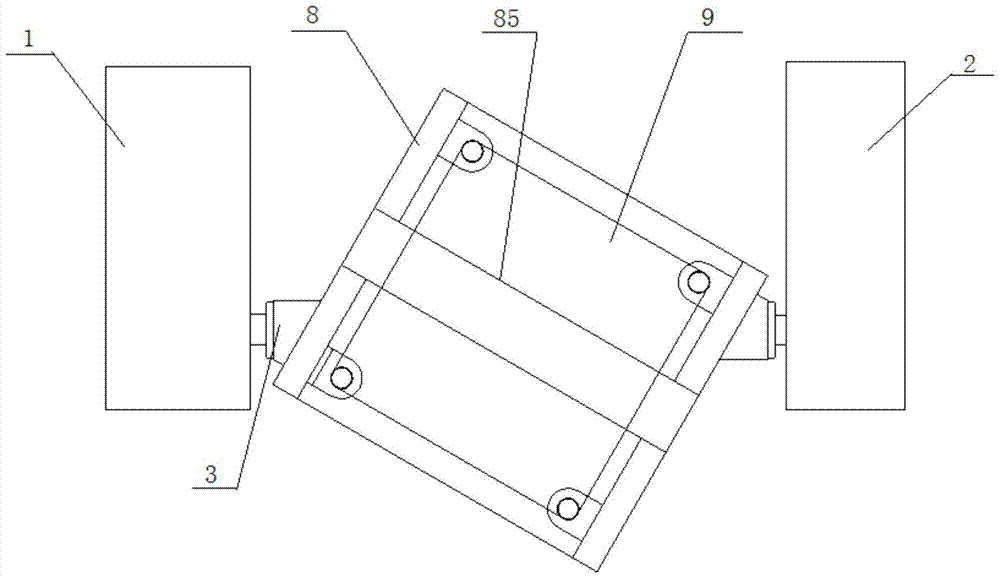

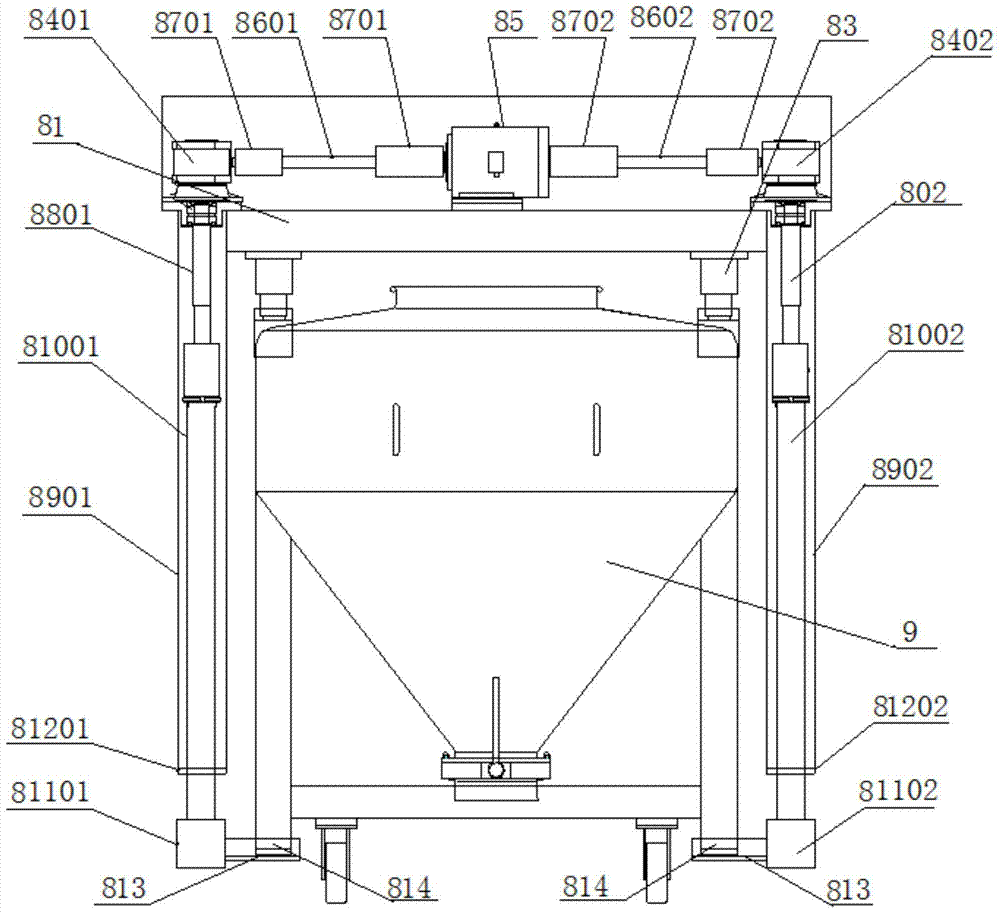

Double-spiral conical mixer

InactiveCN107051287AWith linear speed changeSmooth runningRotating receptacle mixersTransportation and packagingAgricultural engineeringReducer

The invention discloses a double-spiral conical mixer. The double-spiral conical mixer comprises a left rack, a right rack and a rotating shaft, wherein the rotating shaft is arranged on the left rack and the right rack, a driving device is arranged on the left rack, a rotary electric transmission device is arranged on the right rack, the left end of the rotating shaft is connected with the driving device, and the right end of the rotating shaft is connected with the rotary electric transmission device through a right connecting flange; a mixing device is arranged on the rotating shaft, and an included angle between the mixing device and the rotating shaft is 25-35 degrees. The driving device comprises a speed reducer and a left connecting flange, and the rotating shaft is connected with a shaft extension unit of the speed reducer through the left connecting flange. The mixing device comprises a lifting and clamping mechanism and a mixing hopper which is arranged in the lifting and clamping mechanism.

Owner:HUZHOU ZHONGCHEN CONSTR

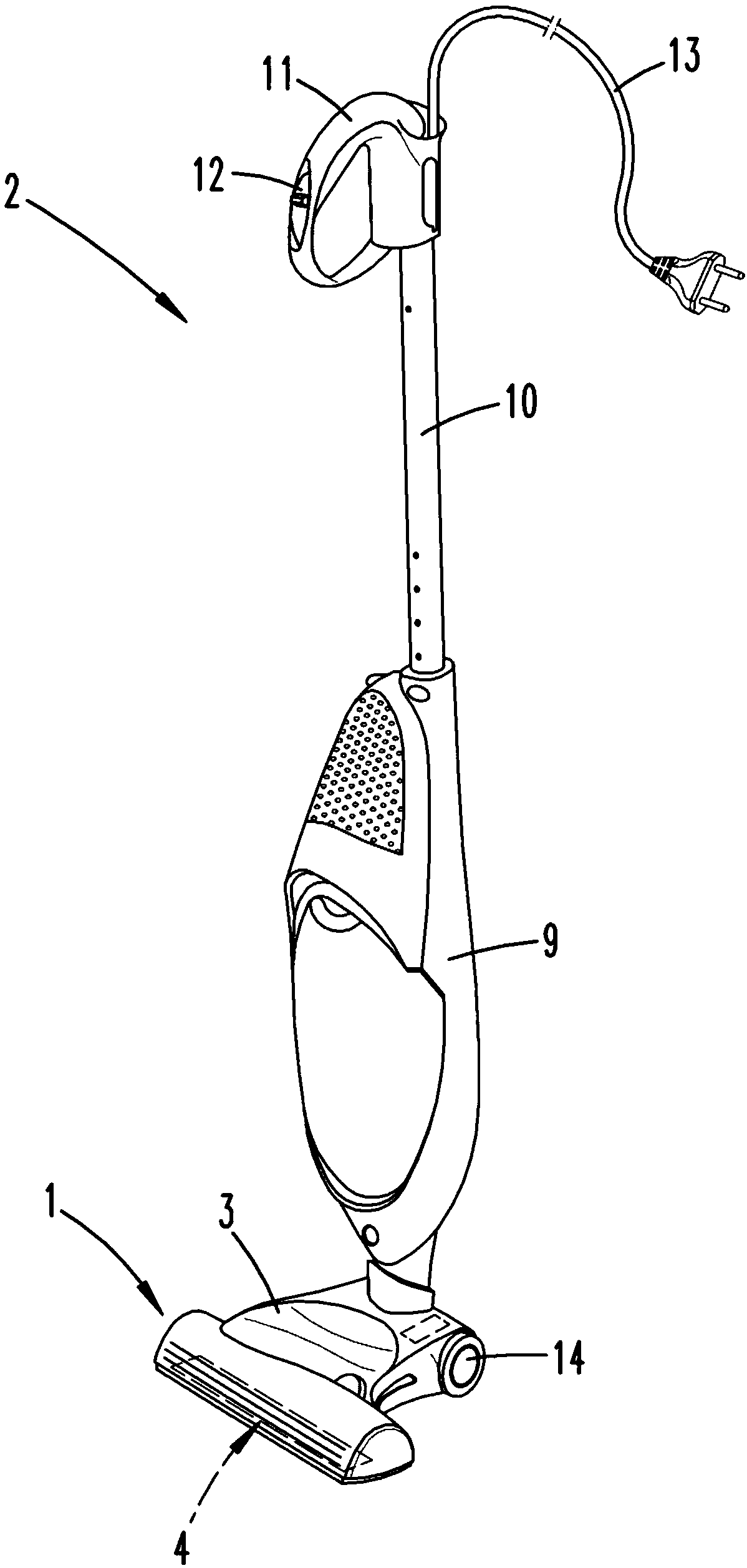

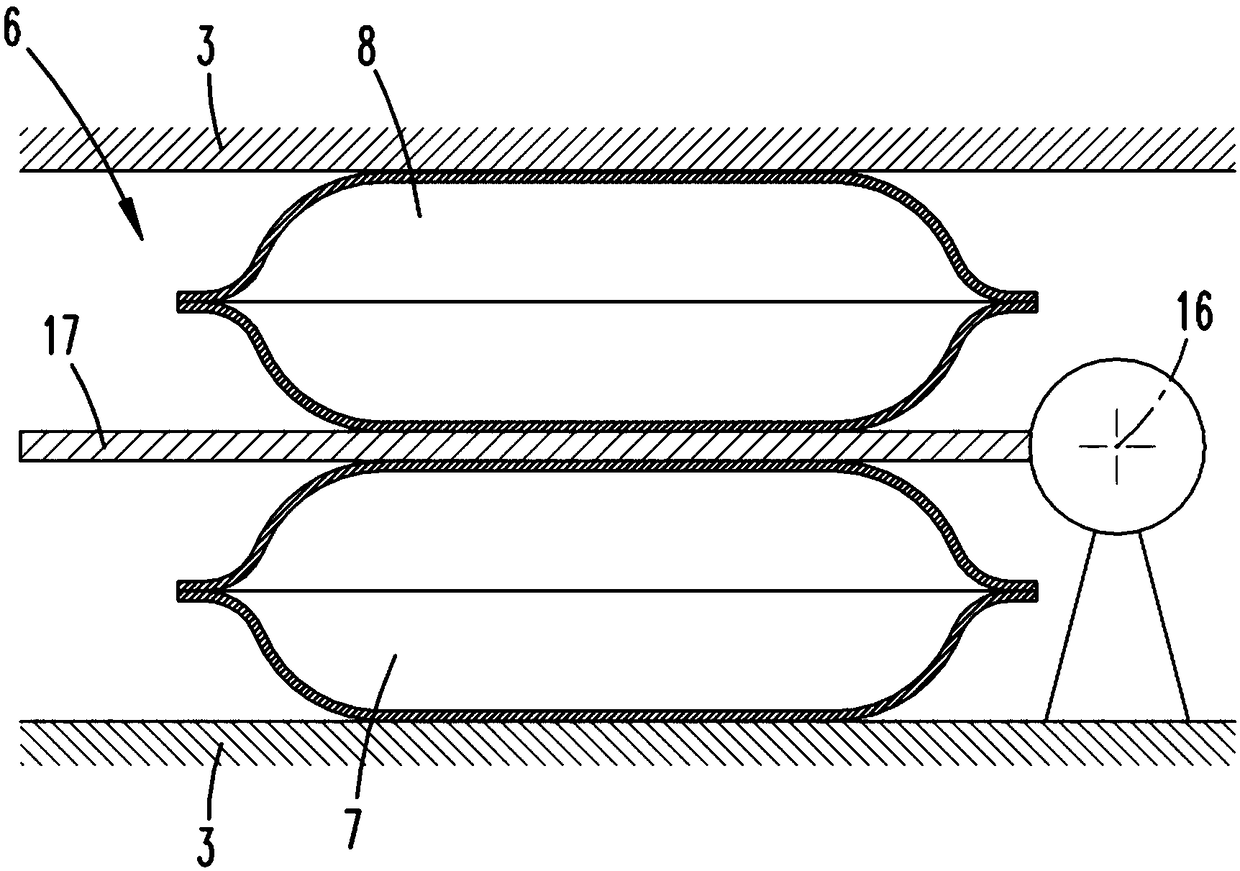

Suction nozzle for a vacuum cleaning device

The invention relates to a functional part of a cultivator, in particular a suction nozzle (1), with an actuator (6) from a first to a second position, and vice versa, displaceable component. In orderto shift the functional part from a hard floor position into a carpet position, or vice versa, the actuator (6) has two mechanically coupled expansion elements (7, 8) which can be acted upon by air pressure whose expansion directions are opposite to one another.

Owner:VORWERK & CO INTERHOLDING GMBH

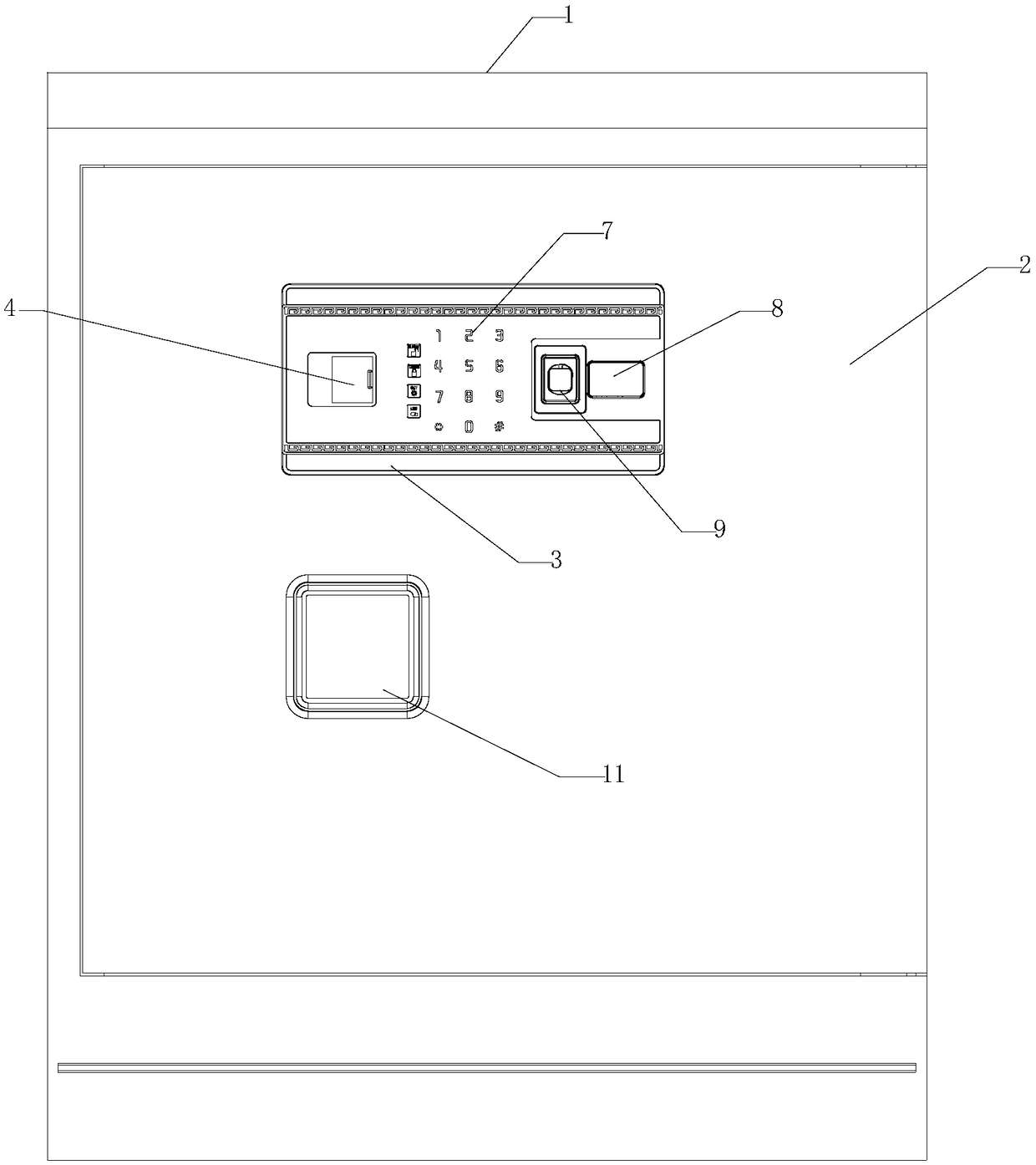

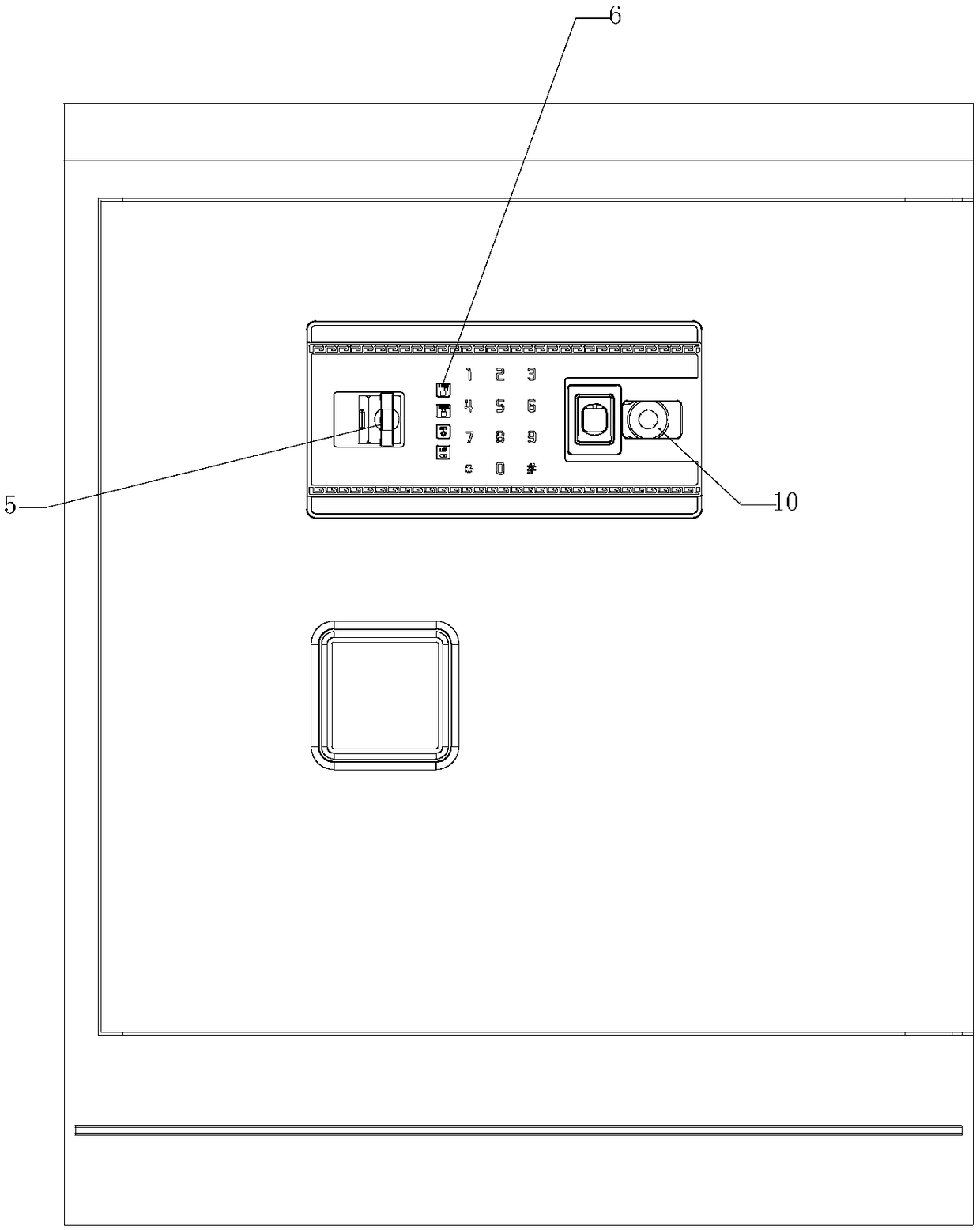

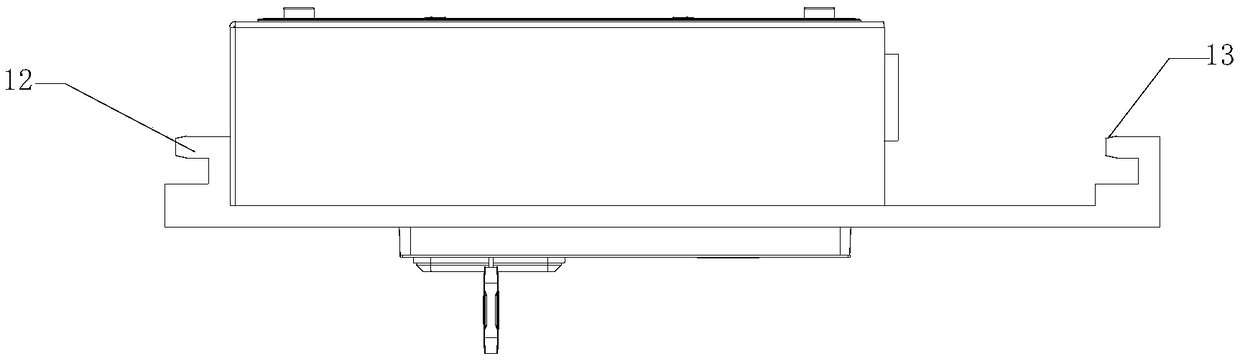

Safety box with sliding door

InactiveCN109025655ASimple structureEasy to operateConstruction fastening devicesElectric permutation locksKey pressingPassword

The invention discloses a safety box with a sliding door. The safety box with the sliding door is characterized in that the safety box with the sliding door comprises a box body, a door plate is arranged on the front side of the box body, a control panel is arranged on the upper portion of the front side of the door plate, a sliding cover is arranged on the left side of the control panel and can move leftwards, a main lock is arranged under the sliding cover, a state display zone is arranged on the left side of the middle of the control panel and displays the states such as the opening state,the wrong password state, the undervoltage state and the setting state, a touch digital button zone is arranged in the middle of the control panel and used for inputting and setting passwords, an emergency lock cover is arranged on the rightmost side, a fingerprint head is arranged on the left side of the emergency lock cover and can collect fingerprints, an emergency lock is arranged under the emergency lock cover, and a handle is arranged in the middle of the front side of the door plate.

Owner:宁波胜势峰科技有限公司

Double-spiral conical mixing machine

InactiveCN106732072AWith linear speed changeSmooth runningRotating receptacle mixersTransportation and packagingEngineeringReducer

The invention discloses a double-spiral conical mixing machine. The double-spiral conical mixing machine comprises a left machine frame, a right machine frame and a rotary shaft, wherein the rotary shaft is arranged on the left machine frame and the right machine frame; a driving device is arranged on the left machine frame; a rotary electric transmission device is arranged on the right machine frame; the left end of the rotary shaft is connected with the driving device, and the right end of the rotary shaft is connected with the rotary electric transmission device through a right connecting flange; a mixing device is arranged on the rotary shaft, and an included angle between the mixing device and the rotary shaft is 25 to 35 degrees; the driving device comprises a speed reducer and a left connecting flange, and the rotary shaft is connected with an output shaft of the speed reducer through the left connecting flange; the mixing device comprises a lifting and tightening mechanism and a mixing material hopper, and the mixing material hopper is arranged in the lifting and tightening mechanism. The double-spiral conical mixing machine has the advantages that the installation and maintenance are simple, the working is stable, the noise is little, the mixing material hopper is fixedly clamped with a lifting chassis, and the convenience in use is realized.

Owner:陈毅桦

An electromechanical braking device

InactiveCN107489713BLarge transmission ratioQuick responseBrake actuating mechanismsActuatorsElectromagnetic clutchBall screw

The invention discloses an electronic mechanical brake device. The device comprises a brake clamp body, a ball screw is arranged in the brake clamp body, and is sleeved with a ball screw nut, the ball screw nut is sleeved with a sliding screw nut, a pair of springs are symmetrically arranged at the right end of the ball screw nut in the axial direction, the other ends of the springs are connected with an armature, the armature is matched with an electromagnetic clutch on the right side of the ball screw nut, the left side of the brake clamp body is connected with a box body through a screw, a motor is arranged above the box body, a spiral bevel gear is connected to an output shaft of the motor, a planet gear is connected to the lower portion of the spiral bevel gear, and a sun gear in the planet gear is rotatably connected with the left end of the ball screw. According to the device, through a ball screw nut pair and a sliding nut screw pair, traveling and parking can be comprehensively achieved, the traveling brake time can be shortened, meanwhile, the parking self-locking problem can be ingeniously solved, and the whole structure is compact and concentrated.

Owner:PUYANG VOCATIONAL & TECHN COLLEGE

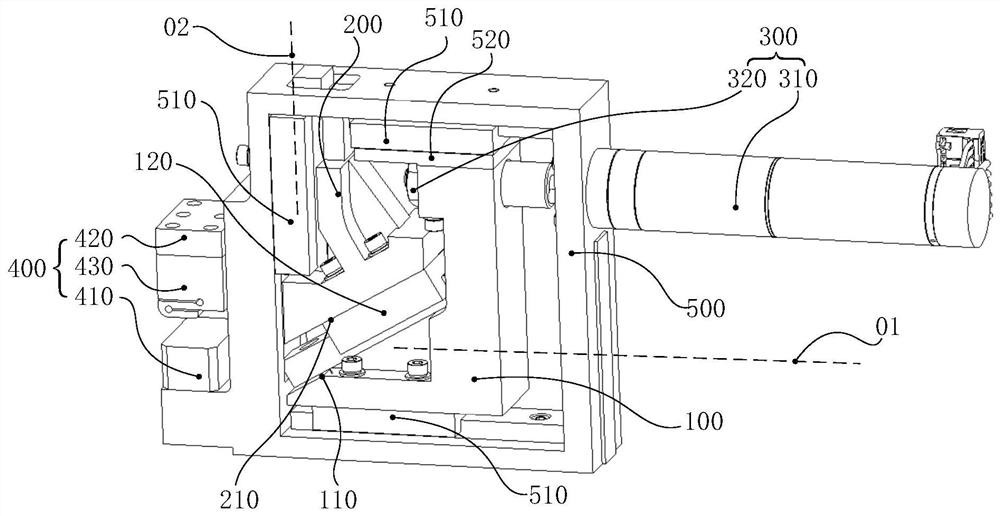

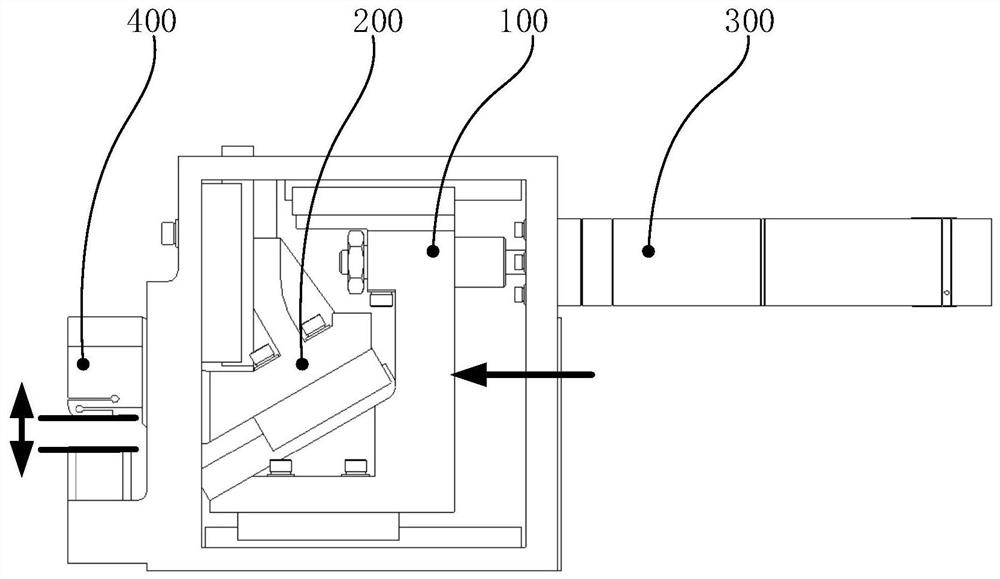

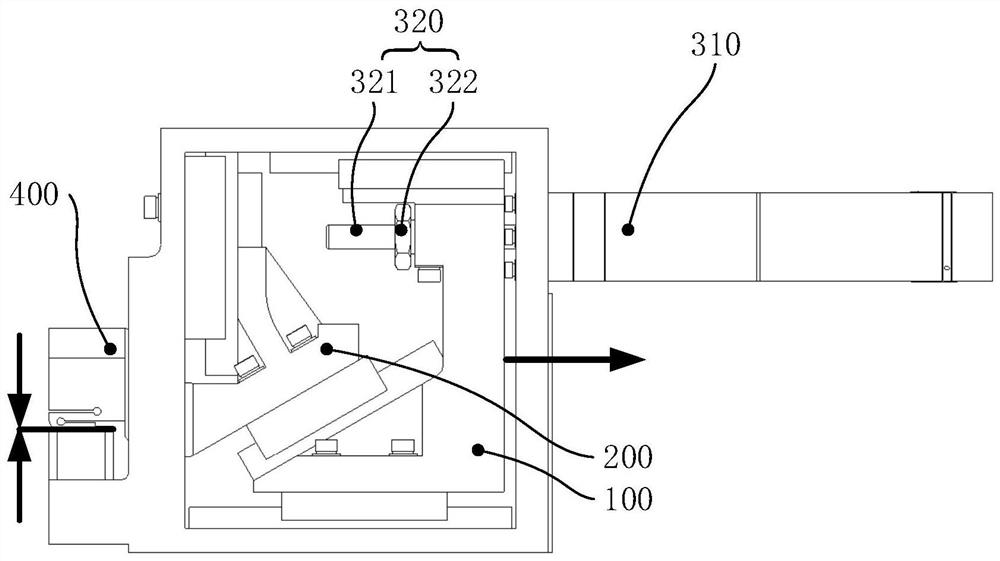

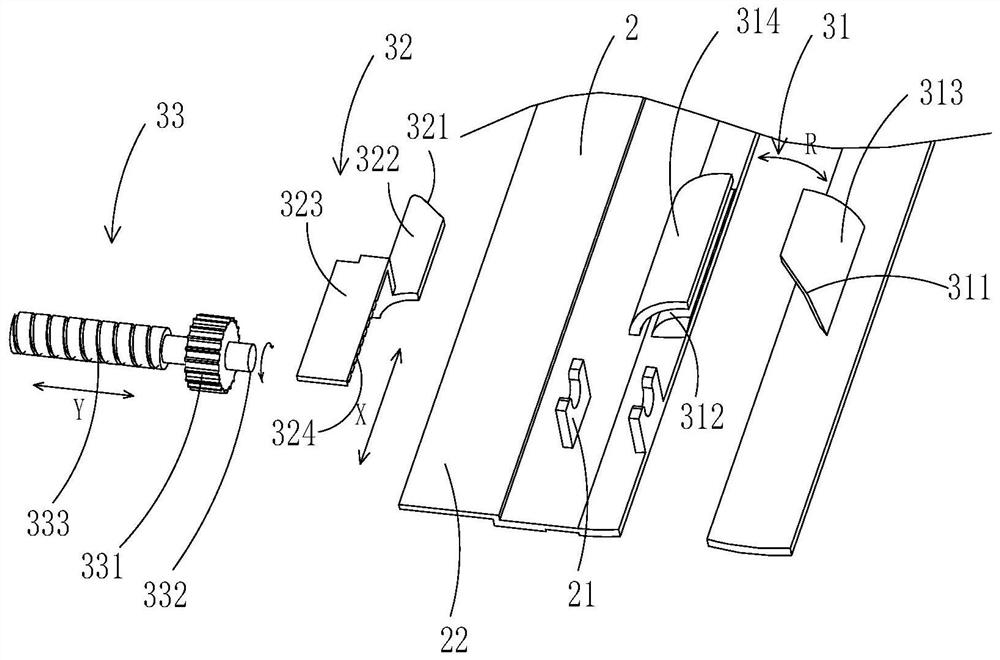

Mask clamping module, mask stretching device and net stretching machine

ActiveCN113584428AImprove clamping qualityHigh precisionSolid-state devicesVacuum evaporation coatingPhysicsEngineering

The invention provides a mask clamping module, a mask stretching device and a net stretching machine. The mask clamping module comprises a driving assembly, a first movable block, a second movable block and a clamping assembly, wherein the first moving block is driven by the driving assembly to move horizontally in the first direction; the first movable block comprises a first contact surface, the second movable block comprises a second contact surface arranged opposite to the first contact surface, the first movable block and the second movable block are connected through the first contact surface and the second contact surface, and the first contact surface and the second contact surface are limited at the moving freedom degree in the direction perpendicular to the first contact surface and the second contact surface; the second moving block is driven by the translational motion of the first moving block to do a translational motion along a second direction; and the clamping assembly is connected with the second movable block, moves along with the second movable block and is used for clamping the mask. According to the configuration, the transmission mechanism is simple in structure, stable and reliable in transmission and high in movement precision, clamping force transmission errors are reduced, and the clamping quality of the mask is improved.

Owner:SHANGHAI MICRO ELECTRONICS EQUIP (GRP) CO LTD

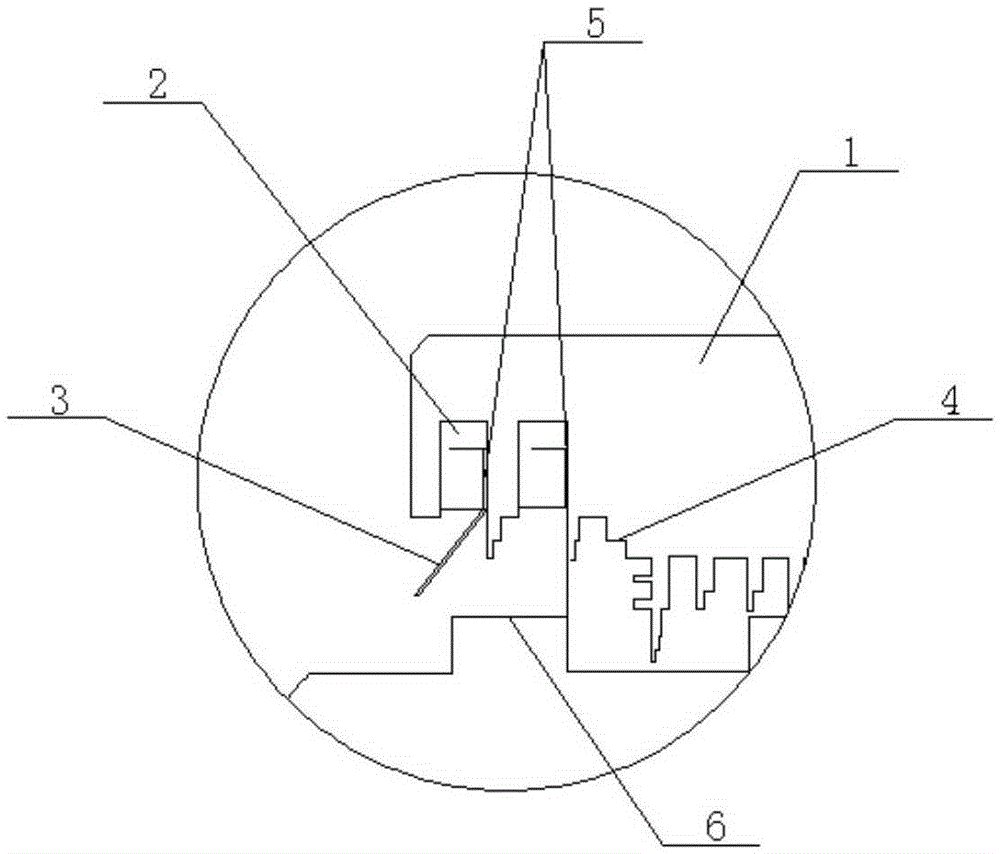

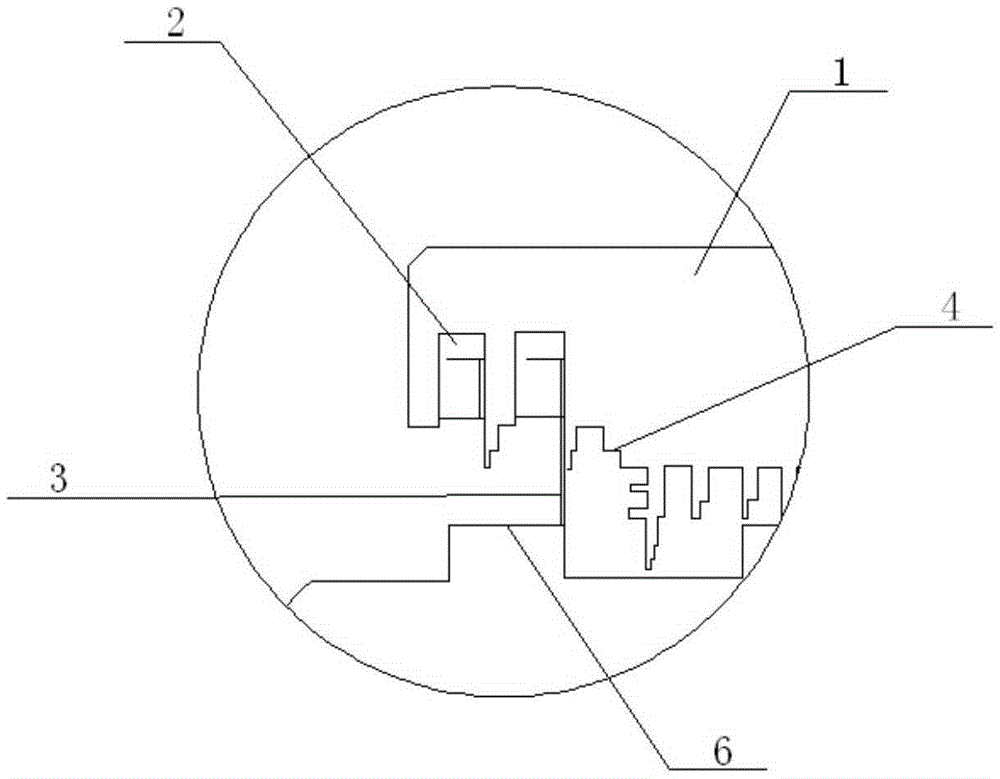

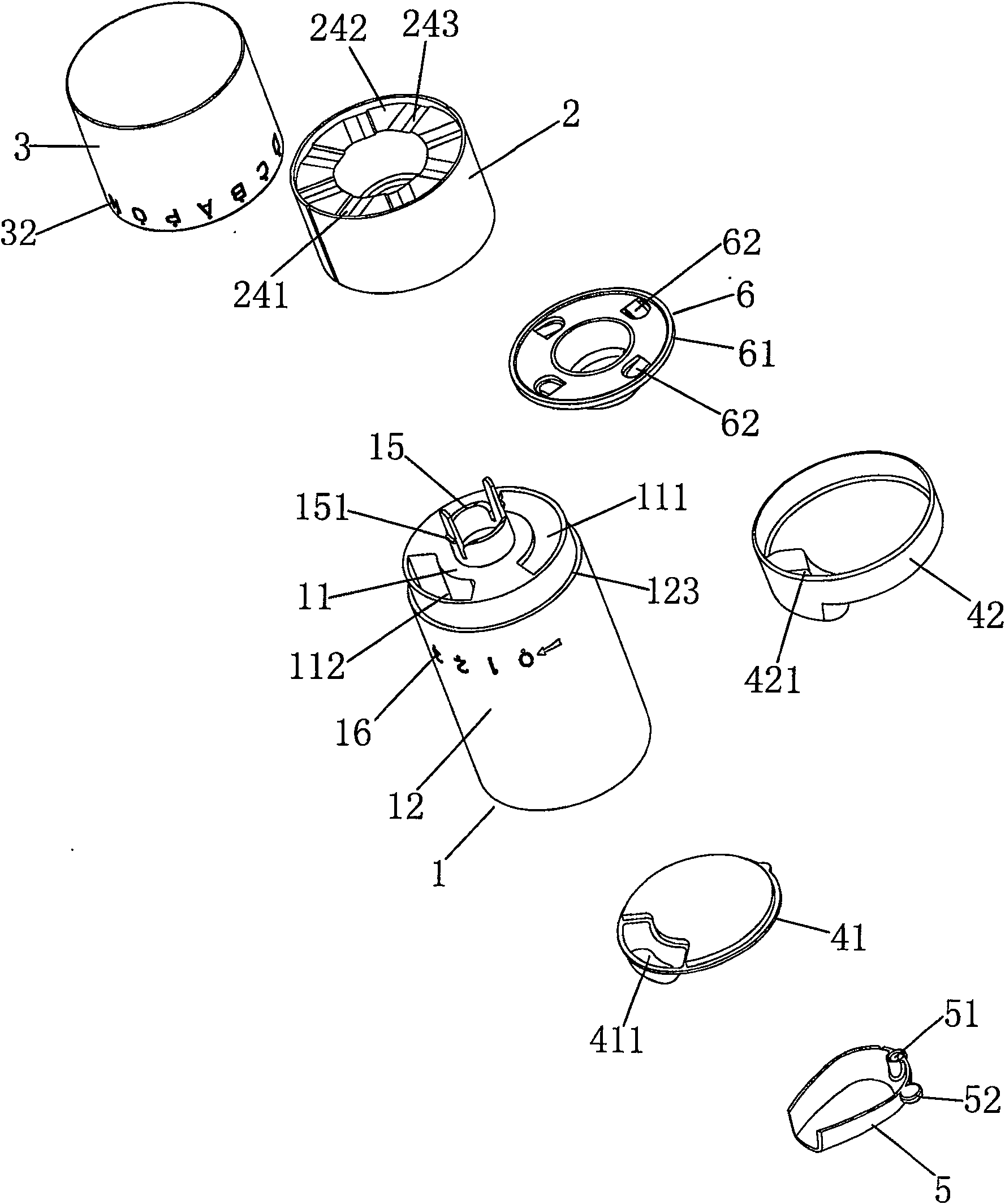

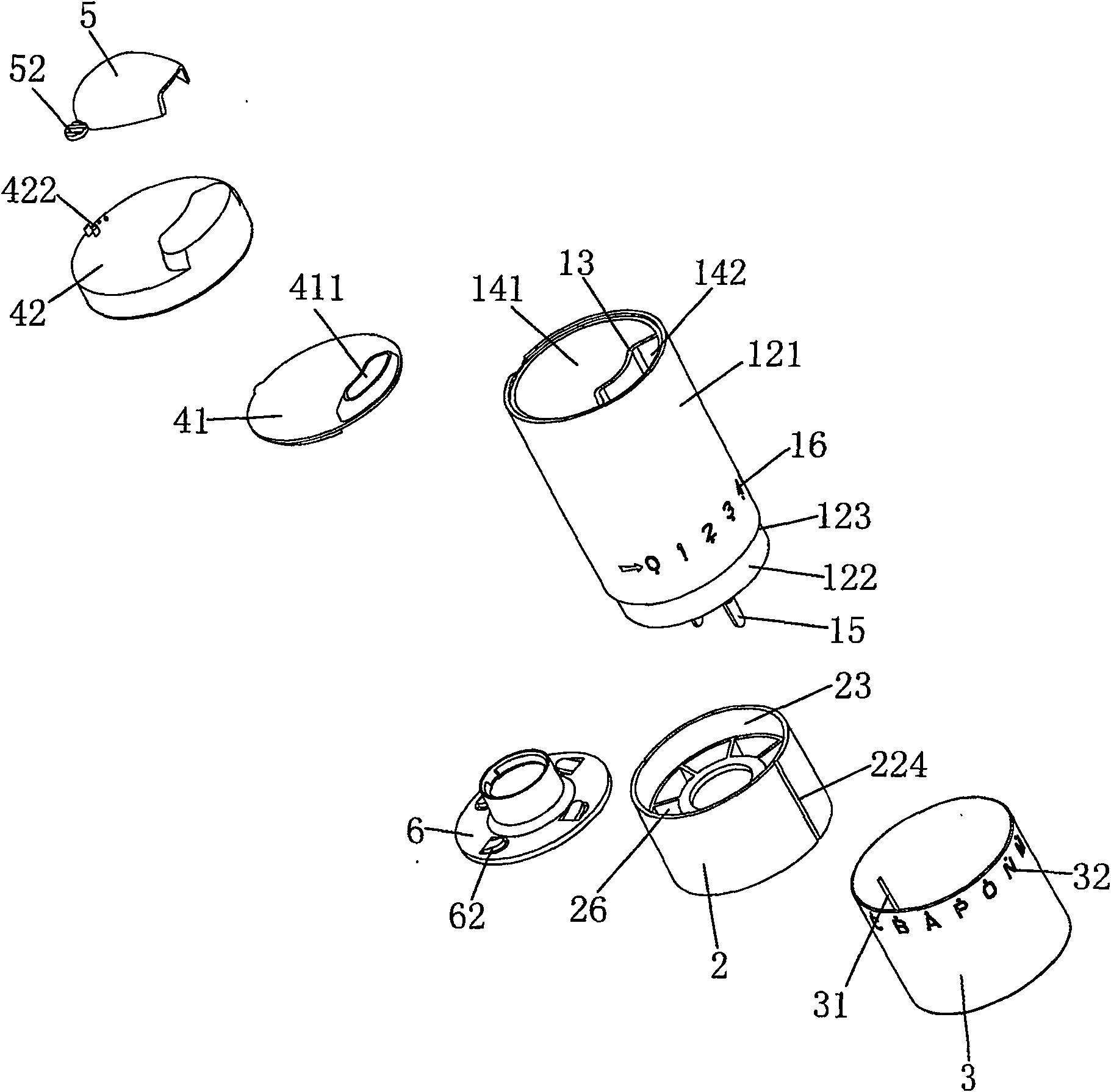

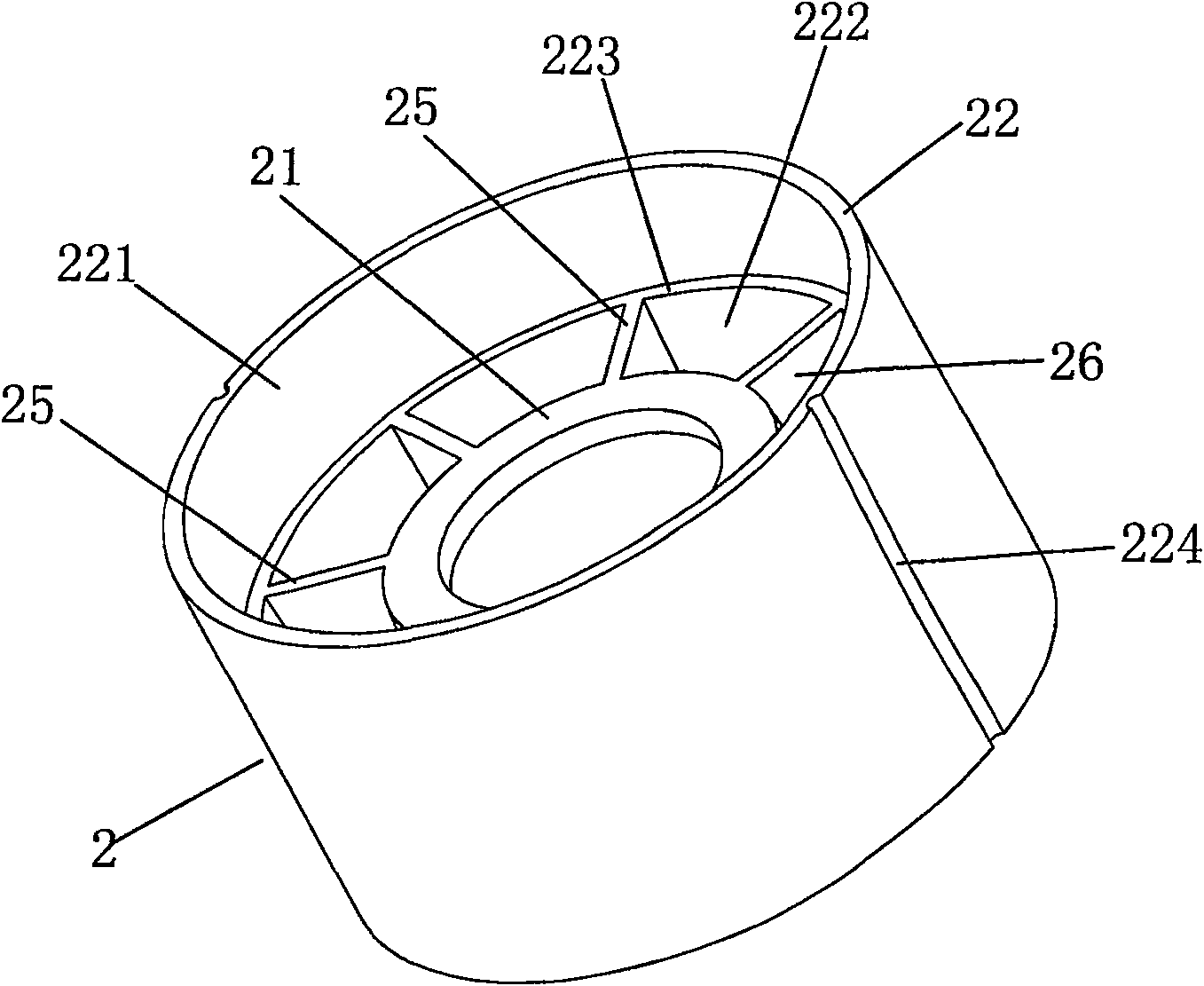

Rotary quantitative taking out device

ActiveCN100560442CSmall movement gapSmooth movementPowdered material dispensingStationary measuring chambersRotational axisEngineering

The invention discloses a rotary quantitative taking device, which comprises a storage tank, a measuring bucket and an elastic mounting part. The storage tank has a tank cavity and a mating surface at the bottom thereof, and the tank cavity is divided into phases and partitioned by a partition plate. The powder inlet chamber and the powder outlet chamber, the measuring bucket is pressed against the fitting surface by the elastic force of the mounting part and can rotate around the axis of rotation against the fitting surface, the measuring bucket has at least one Circle quantitative groove, each circle quantitative groove includes at least two mutually isolated quantitative grooves, the measuring bucket has at least two working positions on its rotation track, and at least one quantitative groove communicates with the powder inlet chamber in each working position. At least another quantitative groove communicates with the powder outlet chamber. Through the elastic mounting parts, the measuring bucket is always pressed against the mating surface of the storage tank with proper elastic force, which can effectively reduce the movement gap between the measuring bucket and the storage tank and make the measuring bucket move smooth.

Owner:彭实

Folding screen terminal hinge length adjusting device and folding screen terminal

PendingCN111866239ASmall movement gapFew partsTelephone set constructionsEngineeringStructural engineering

Owner:GREE ELECTRIC APPLIANCES INC

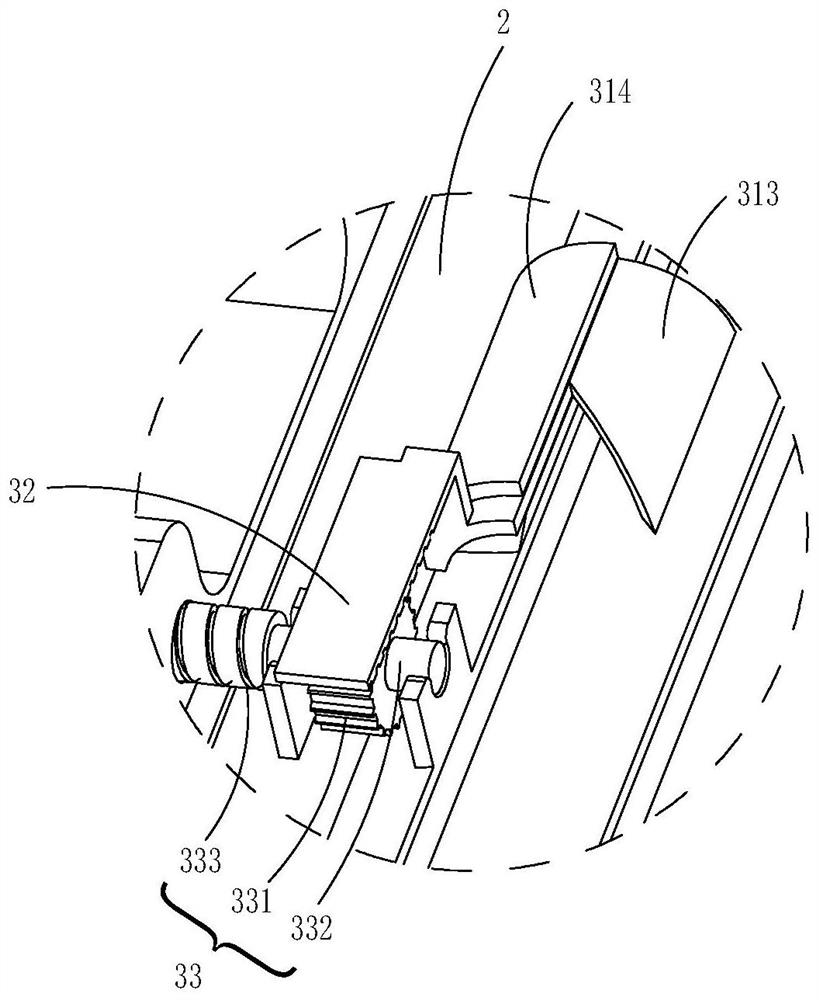

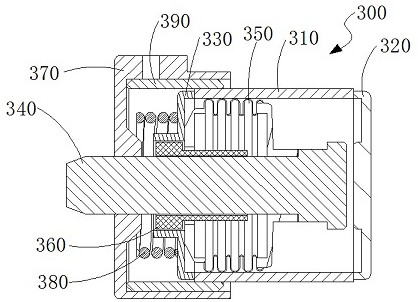

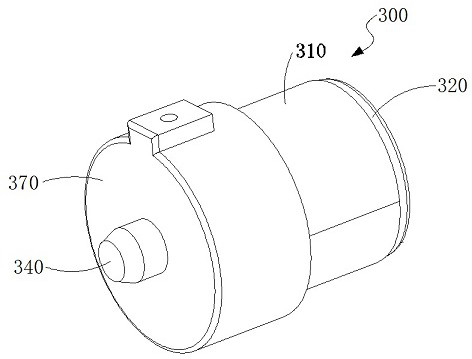

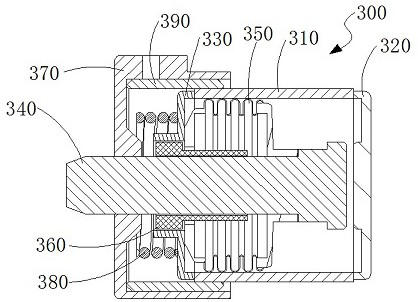

A closed switch tube

ActiveCN112992598BImmune to side impactReduce side impactHigh-tension/heavy-dress switchesAir-break switchesElectrical conductorMechanical engineering

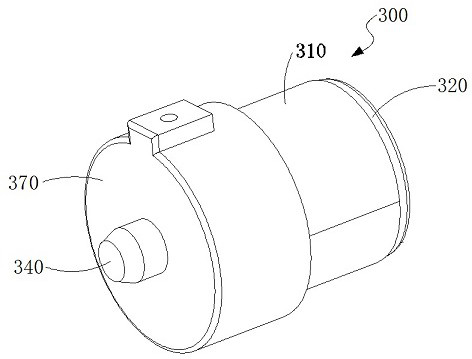

The invention discloses a closed switch tube, comprising an insulator (310), a first conductor (320), a first support (330), a second conductor (340) and a third conductor (370). One end of the second electrical conductor (340) is disposed in the cavity formed by the insulator (310), the first electrical conductor (320) and the first support (330) and can be connected with the The first conductor (320) is contacted or separated, characterized in that the third conductor (370) is sleeved on the outside of the insulator (310) and is fixedly connected with the second conductor (340). A second elastic member (380) is arranged between the third electrical conductor (370) and the first support member (330), and the closed switch tube of the present invention is not affected by external force, and the internal conductive members are always in a constant state. Open state, can meet different applications.

Owner:BEIJING JINGREN ELECTRICAL CO LTD +1

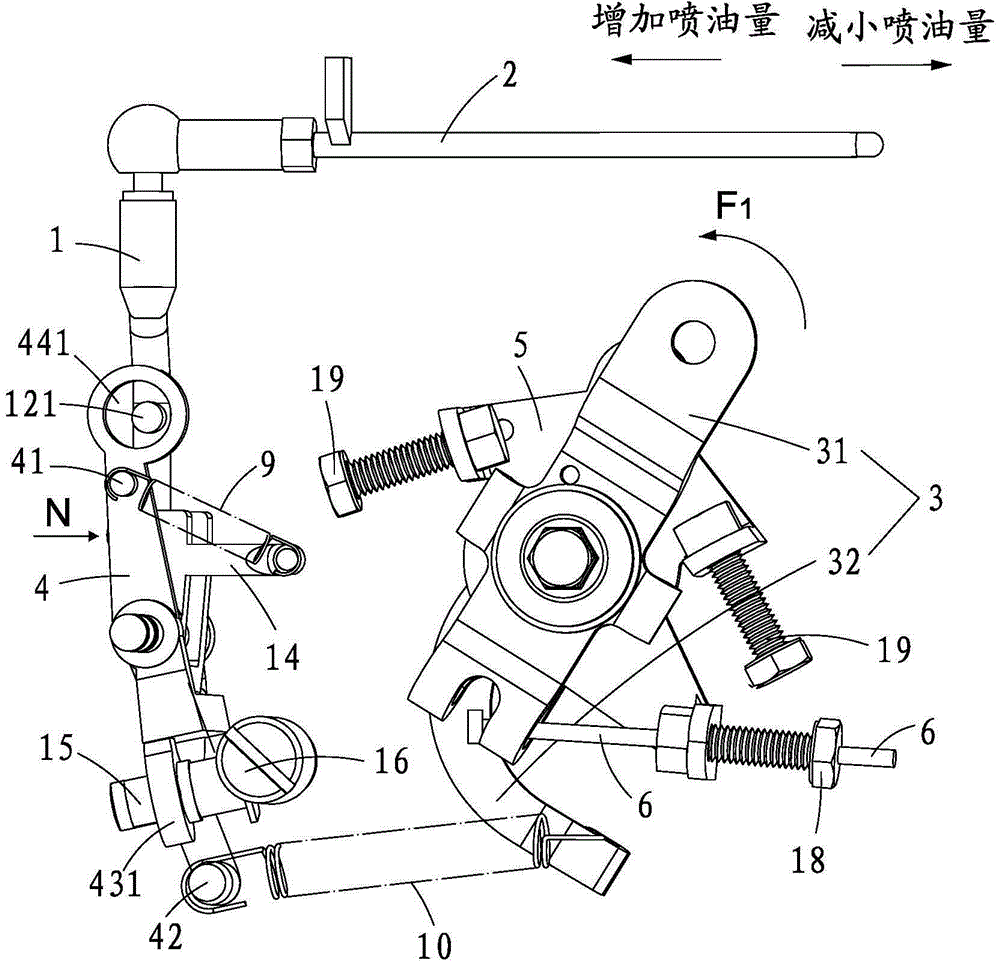

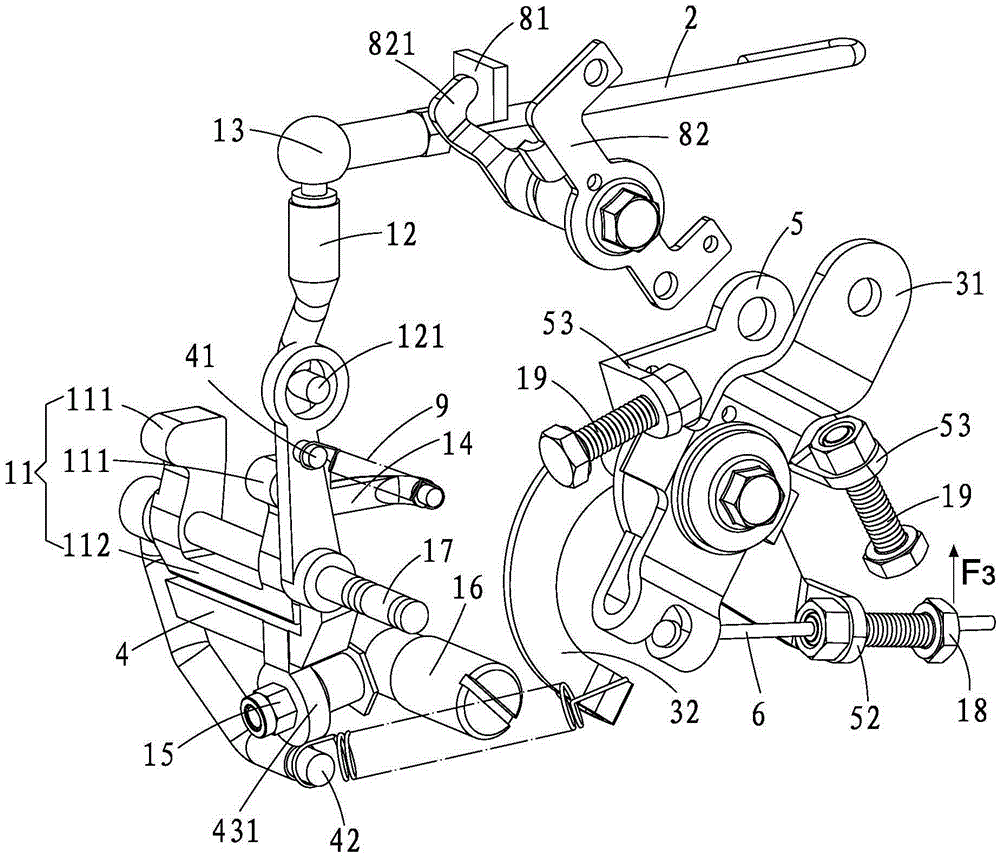

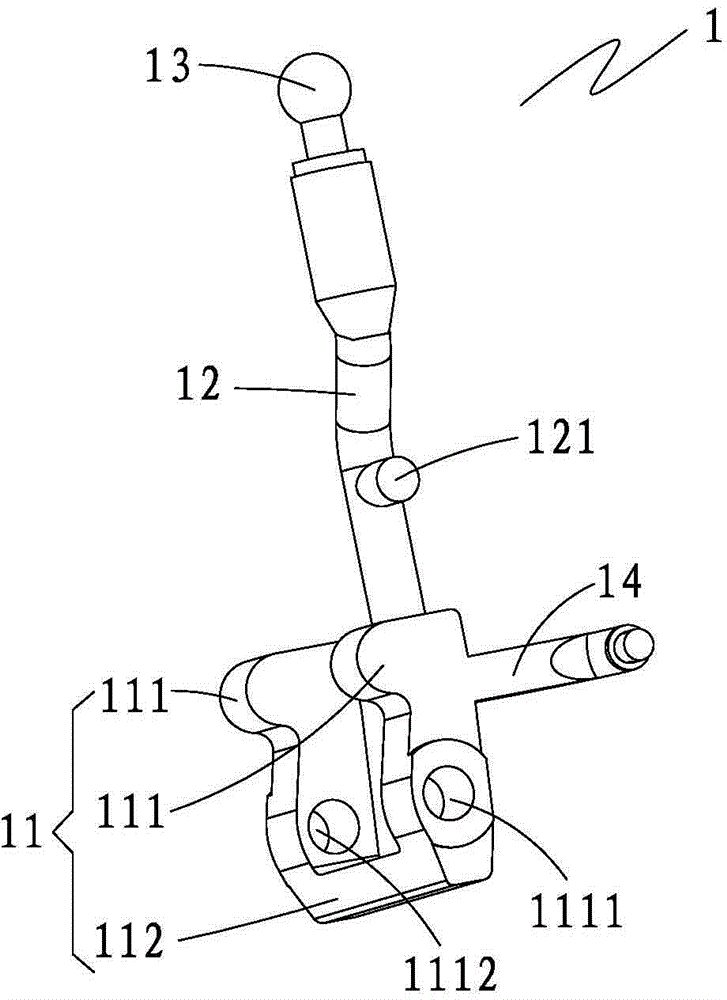

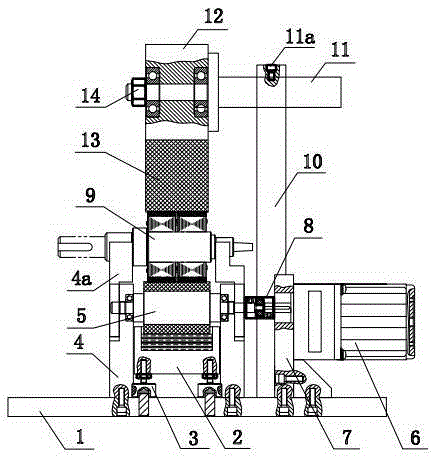

A speed control device for an engine

ActiveCN102777265BEliminate Response HysteresisFunctionalFuel-injection pumpsMachines/enginesHigh volume manufacturingDie casting

Owner:FUJIAN EVERSTRONG LEGA POWER EQUIP CO LTD

Three-dimensional spherical compensator with sealing device

PendingCN108131523ASmall movement gapSmooth movementEngine sealsPipeline expansion-compensationAxial displacementSpherical shaped

The invention discloses a three-dimensional spherical compensator with a sealing device. The three-dimensional spherical compensator with the sealing device comprises a ball head connecting tube and aliner tube. The ball head connecting tube comprises a first ball head connecting tube body and a second ball head connecting tube body. A middle connecting tube comprises a first connecting tube bodyand a second connecting tube body. The first ball head connecting tube body is arranged in the first connecting tube. A first flange is arranged at the left end of the first connecting tube body. A first filler chamber is arranged between the first ball head connecting tube body and the first connecting tube body. A first pressing cover is arranged on the left side of the first filler chamber. The first pressing cover is connected with the first flange through bolts. Skeleton sealing filler is arranged between the outer surface of the liner tube and the second connecting tube body. Accordingto the three-dimensional spherical compensator with sealing device, the movement gap of the compensator is narrowed because of the sealing filler, dust is stopped from entering the compensator at thesame time, and therefore, the axial displacement movement is smoother. The three-dimensional spherical compensator with the sealing device is applied to pulverized coal conveying pipelines, and because both the deflection angle and the axial displacement of the compensator are large, the displacement generated by pipeline equipment during running can be effectively compensated and absorbed. The three-dimensional spherical compensator with the sealing device is simple in structure, convenient to use, practical, long in service life, and very convenient to make, install and maintain.

Owner:JIANGSU HENGFENG BELLOWS

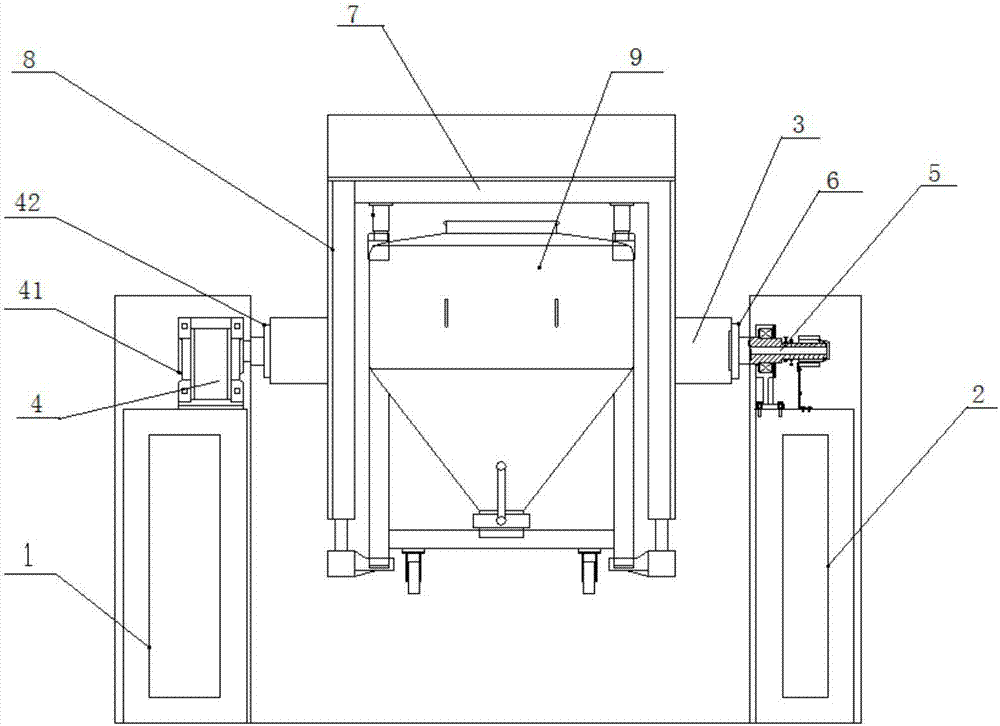

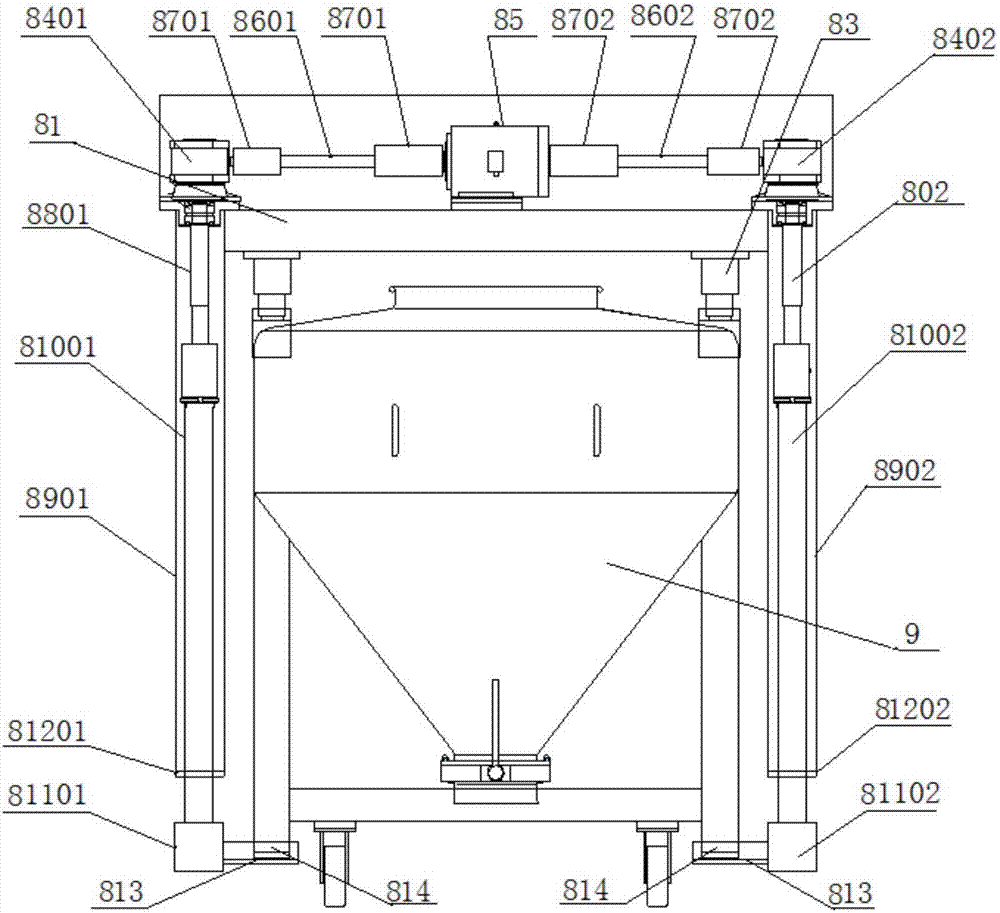

A turnover hopper mixer

ActiveCN104801222BEasy alignmentEasy to installRotating receptacle mixersTransportation and packagingAgricultural engineeringReducer

The invention discloses a rotary hopper mixer, which comprises a left frame, a right frame and a rotating shaft, the rotating shaft is arranged on the left frame and the right frame, and a driving device is arranged on the left frame , the right frame is provided with a rotating power transmission device, the left end of the rotating shaft is connected to the driving device, and the right end of the rotating shaft is connected to the rotating power transmitting device through a right connecting flange; the rotating shaft is provided with a mixing device, the angle between the mixing device and the rotating shaft is 25°-35°. The drive device includes a reducer and a left connecting flange, and the rotating shaft is connected to the shaft extension of the reducer through the left connecting flange. The mixing device includes a lifting and tightening mechanism and a mixing hopper, and the mixing hopper is arranged in the lifting and tightening mechanism. The turnover hopper mixer provided by the invention has the advantages of simple installation and maintenance, stable operation, low noise, firm clamping between the mixing hopper and the lifting chassis, and very convenient use.

Owner:钱勇 +1

An automatic rubber rolling device

ActiveCN103657948BGuaranteed uniformityHigh repeat positioning accuracyLiquid surface applicatorsCoatingsGlass fiberCoupling

The invention relates to a machine tooling, particularly to an automatic gluing device. The device is characterized by comprising a base plate, a rubber pool, an adsorption type rolling wheel and an AC gear motor, wherein the rubber pool is arranged on the base plate; the adsorption type rolling wheel is arranged right above the rubber pool, and the cylindrical surface of the adsorption type rolling wheel is in contact fit with the liquid level of the rubber pool; a cylindrical workpiece to be coated is arranged right above the adsorption type rolling wheel, and the cylindrical surface of the adsorption type rolling wheel is matched with that of the cylindrical workpiece to be coated in a rolling manner. According to the invention, the adsorption type rolling wheel is adopted for gluing the cylindrical workpiece to be coated with rubber, the uniformity of the glass fiber cloth surface is ensured; the AC gear motor and the adsorption type rolling wheel are connected through a high-precision coupler, so that repositioning accuracy is high, and moving gap is small; a liftable regulator is used, and when the liquid level of the rubber pool drops, the rubber pool is lifted by only adjusting the liftable regulator, so that the liquid level of the rubber pool rises, thereby realizing automatic feeding and avoiding frequent addition of rubber.

Owner:ZHEJIANG LINIX MOTOR

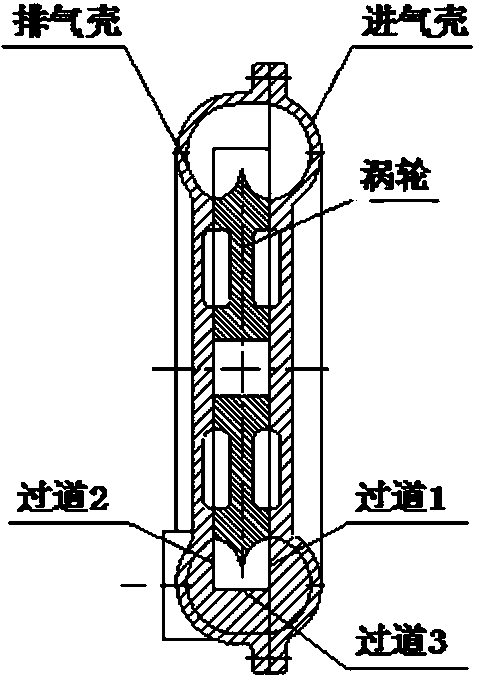

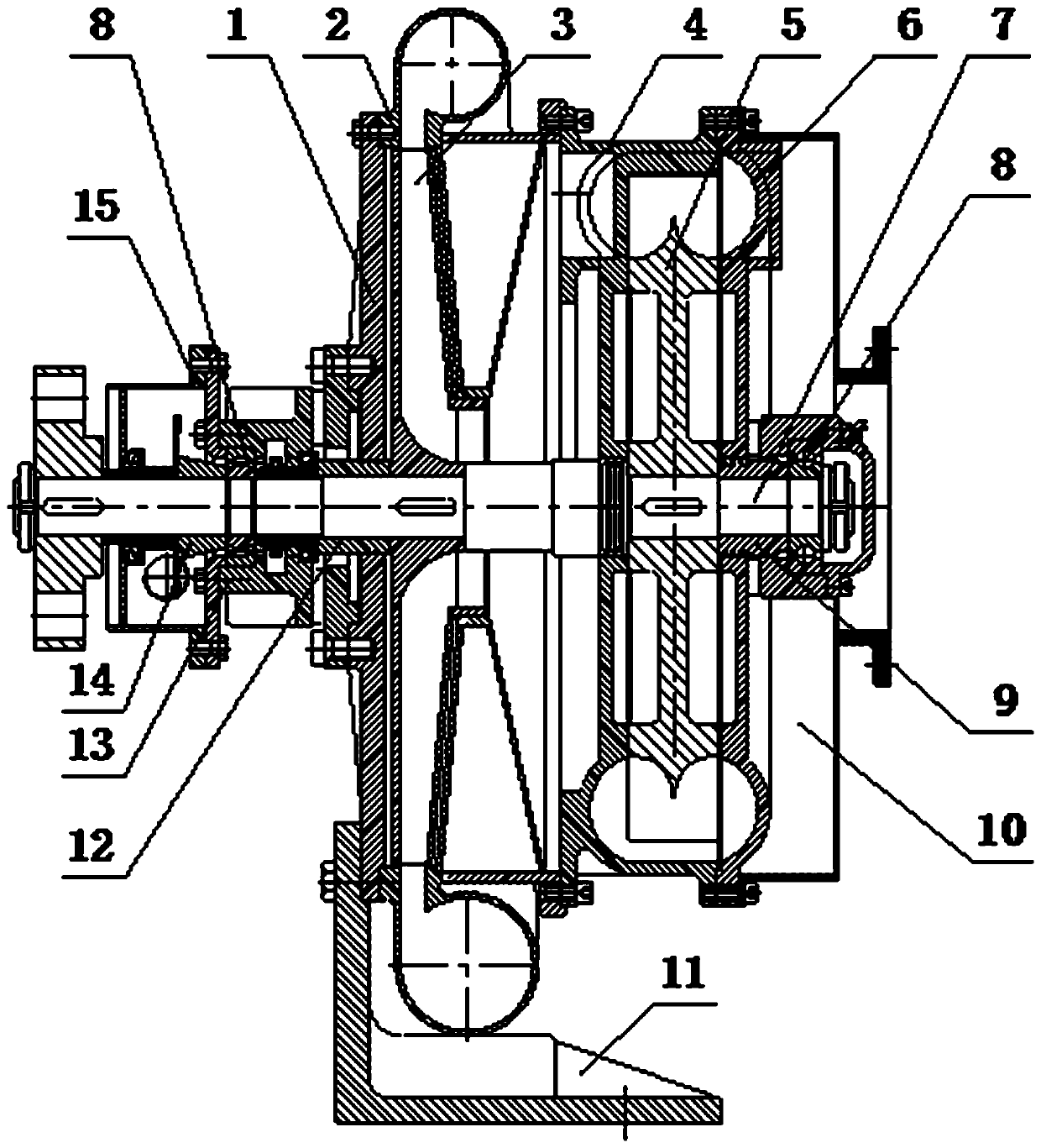

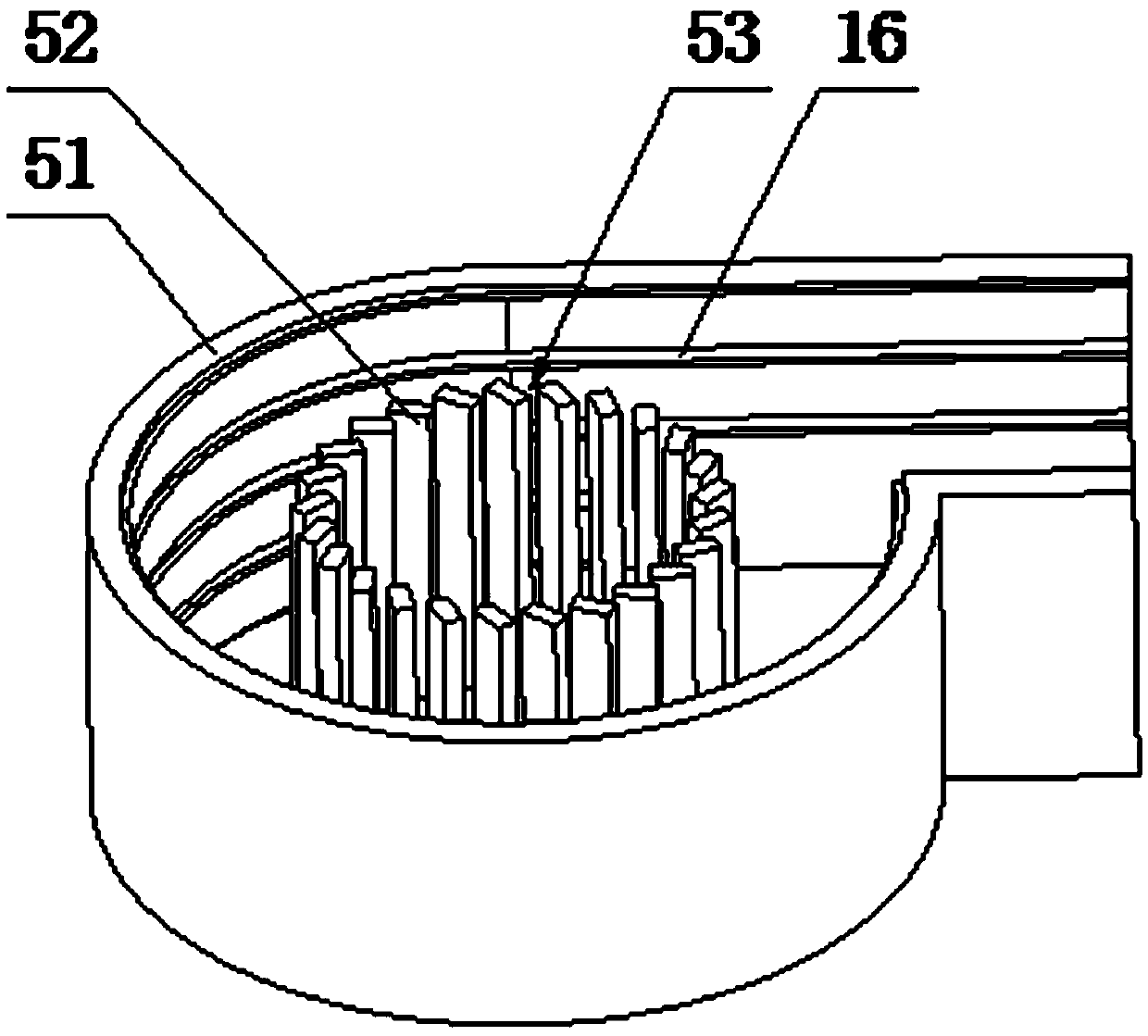

A small high pressure centrifugal blower

InactiveCN107044434BSmall movement gapGuaranteed uptimePump componentsPump installationsImpellerAgricultural engineering

The invention discloses a small-scale high-pressure centrifugal blower. The small-scale high-pressure centrifugal blower comprises a main shaft, a gas inlet housing, a turbine, an exhaust housing, a spiral housing, a vane wheel and a side cover, wherein the gas inlet housing, the turbine, the exhaust housing, the spiral housing, the vane wheel and the side cover are sequentially arranged on the main shaft; the turbine is located in a shell formed by the gas inlet housing and the exhaust housing, and the moving gap between the turbine and the side wall of the shell is smaller than 0.5mm; and the spiral housing is a high-flow velocity type spiral housing, and is used for converting high-temperature gas from the exhaust housing into a volute flow type high-pressure gas to be supplied to the vane wheel. According to the small-scale high-pressure centrifugal blower disclosed by the invention, part of the advantages of an annular blower are applied to the vane wheel and the spiral housing, so that the comprehensive performance of the small-scale high-pressure centrifugal blower is far better than that of a secondary annular blower having many defects, and the outlet pressure can achieve 60kPa; the design of the structure of the small-scale high-pressure centrifugal blower is adopted, so that the blower can be safely operated for a long time.

Owner:FUJIAN EAST ASIA BLOWER

A motor rotor automatic rubber rolling device

ActiveCN103657943BGuaranteed uniformityGuaranteed accuracyLiquid surface applicatorsManufacturing stator/rotor bodiesFiberGlass fiber

The invention relates to glue coating equipment, in particular to an automatic glue rolling device for a motor rotor. The automatic glue rolling device is characterized by comprising a bracket bottom board, a glue tank, an adsorption rolling roller and an AC speed reducer motor, wherein the glue tank is arranged on the bracket bottom board; the adsorption rolling roller is arranged just above the glue tank, and the cylindrical surface of the adsorption rolling roller is in contact and matched with the liquid level of the glue tank; the rotor is arranged just above the adsorption rolling roller; the cylindrical surface of the adsorption rolling roller is in rolling match with the cylindrical surface of the rotor; a glass fiber cloth ring is arranged above the rotor, and glass fiber cloth is wound on the glass fiber cloth ring, and the glass fiber cloth ring is fixed on a glass fiber cloth fixing rack via a glass fiber cloth core shaft. The automatic glue rolling device uses the adsorption rolling roller to coat the rotor with glue, can automatically reduce the amount of the glue on the rotor and ensure the uniformity of the surface of the glass fiber cloth; the glass fiber cloth ring is directly arranged above the rotor and matched with the overall device, and the glass fiber cloth is wound after spreading the glue.

Owner:ZHEJIANG LINIX MOTOR

Closed switch tube

ActiveCN112992598AImmune to side impactReduce side impactHigh-tension/heavy-dress switchesAir-break switchesEngineeringMechanical engineering

Owner:BEIJING JINGREN ELECTRICAL CO LTD +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com