A small high pressure centrifugal blower

A centrifugal blower, high-pressure technology, used in mechanical equipment, machines/engines, liquid fuel engines, etc., can solve problems such as reducing the failure rate of fans, low outlet efficiency, and broken blades

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The above and other technical features and advantages of the present invention will be clearly and completely described below in conjunction with the accompanying drawings. Apparently, the described embodiments are only some of the embodiments of the present invention, not all of them.

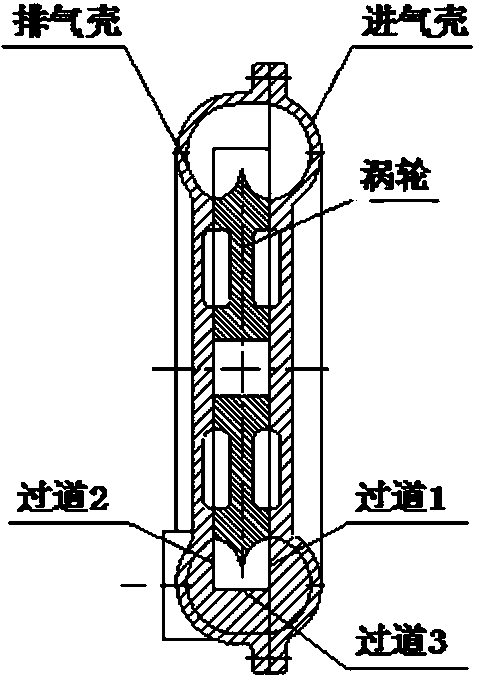

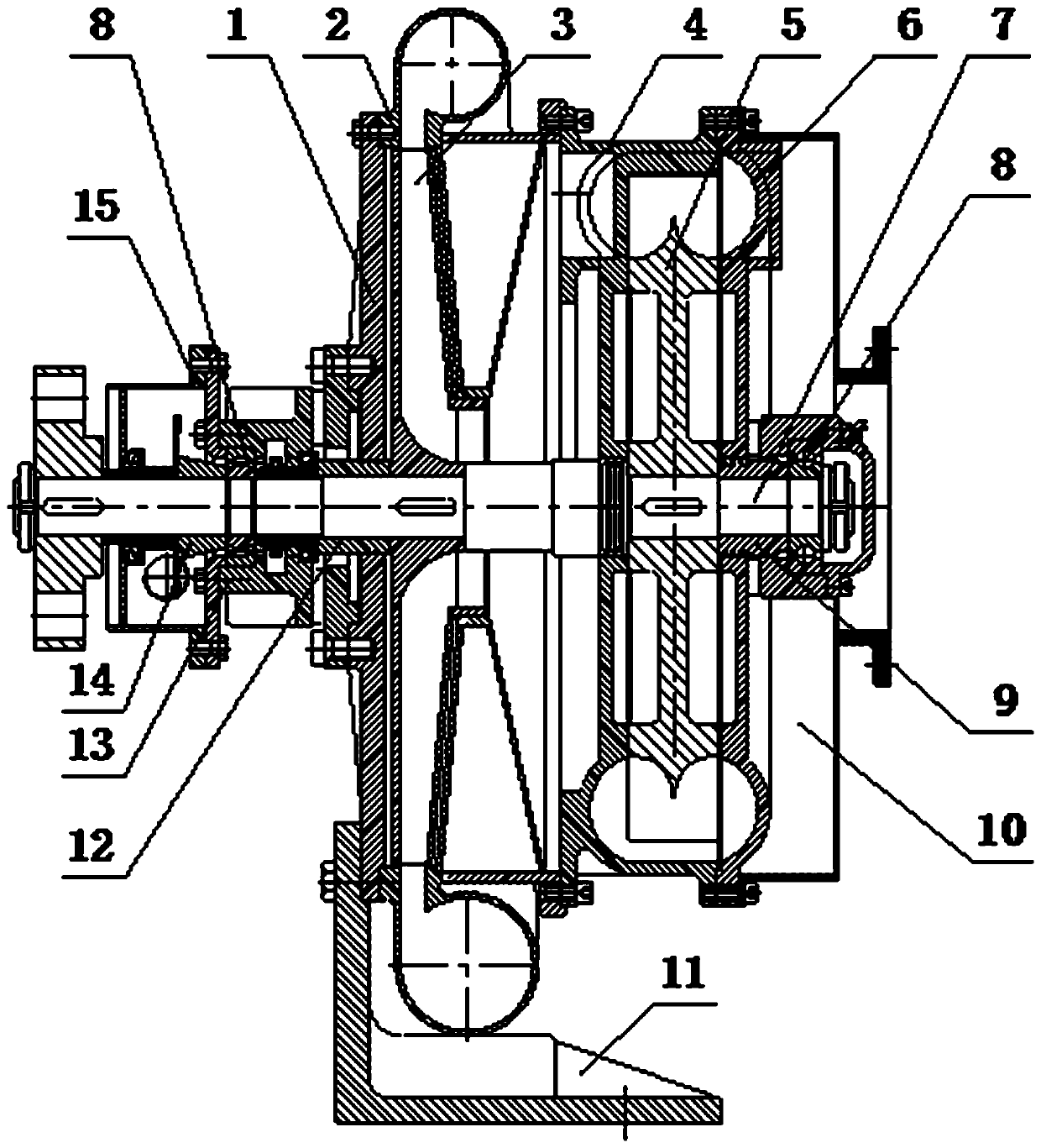

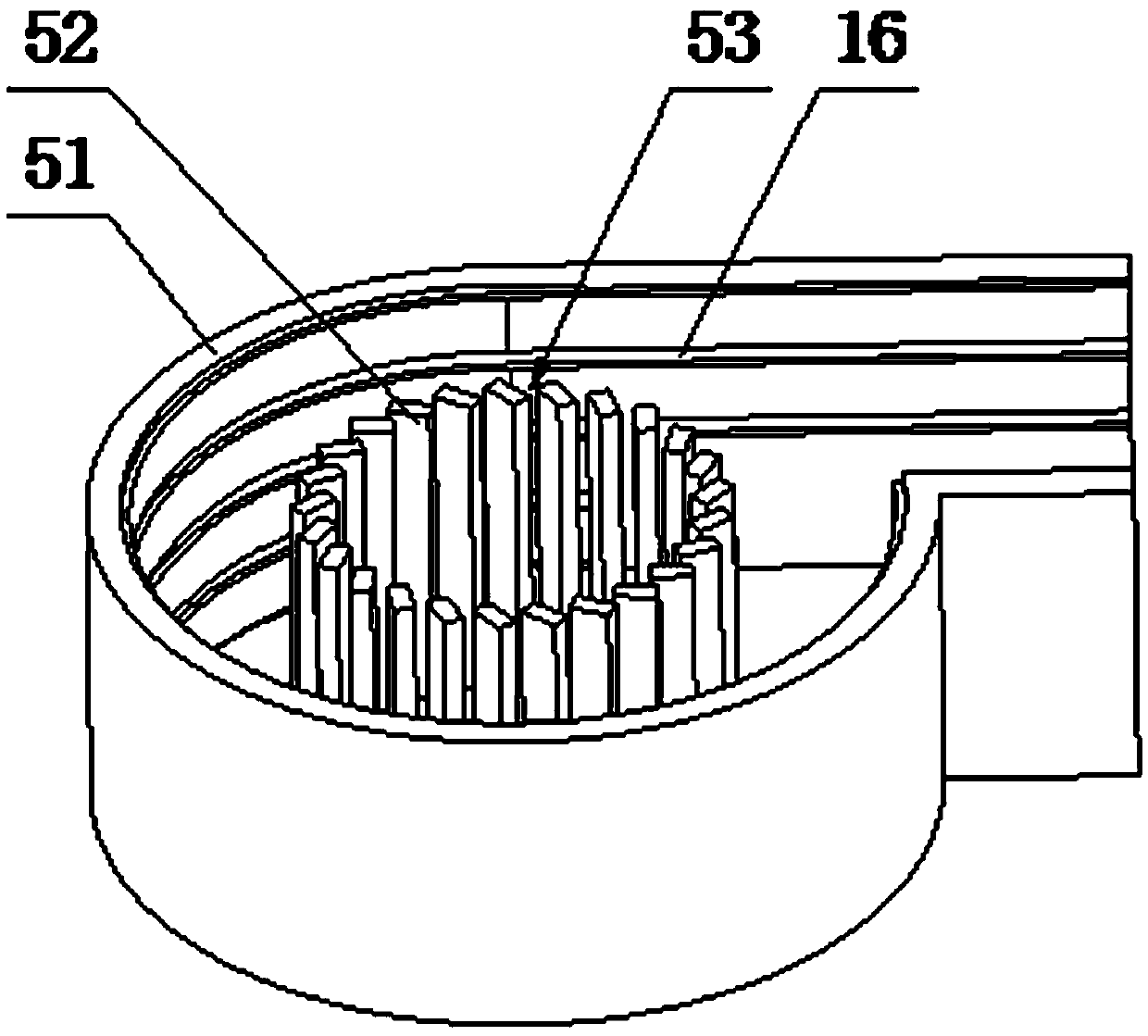

[0026] refer to figure 2 , the present embodiment provides a small high-pressure centrifugal blower, including a main shaft 7, an air intake shell 6, a turbine 5, an exhaust shell 4, a volute 2, an impeller 3, and a side cover 1; an air intake shell 6, a turbine 5, The exhaust casing 4, the volute 2, the impeller 3, and the side cover 1 are sequentially arranged on the main shaft 7, wherein the turbine 5 is located in a casing composed of the intake casing 6 and the exhaust casing 4, and the side walls of the turbine 5 and the casing are The movement gap is less than 0.5mm; the volute 2 is a high-velocity volute 2, which is used to convert the high-temperature gas from the exhaust case...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com