Three-dimensional spherical compensator with sealing device

A spherical compensator and sealing device technology, which is applied in the field of compensators, can solve problems such as heavy maintenance and replacement workload, short service life of compensators, and affecting normal operation of enterprises, and achieves convenient installation and maintenance, smooth movement, and simple structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Below in conjunction with accompanying drawing and specific embodiment the present invention will be further described:

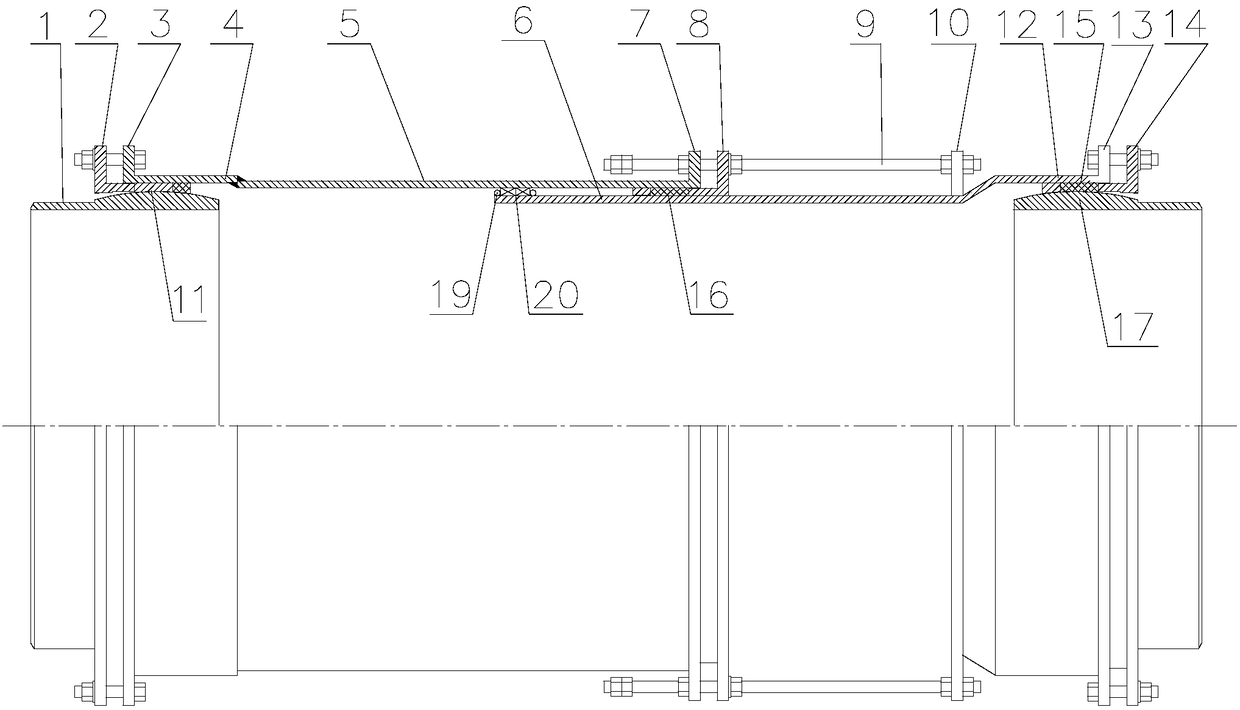

[0019] Such as figure 1 As shown, the three-dimensional spherical compensator with a sealing device includes a ball joint, an intermediate joint and a liner 6. The ball joint includes ball joint I1 and ball joint II17 located at the left and right ends of the compensator, and the intermediate joint Including connecting pipe I4 and pipe II5, the spherical surface of ball joint I1 is set in joint I4, the left end of joint I4 is provided with flange I3, and the inner wall of ball joint I1 and joint I4 is provided with packing chamber I11. The cavity I11 is provided with packing, and the left side of the packing cavity I11 is provided with a gland I2, and the gland I2 is connected with the flange I3 through bolts.

[0020] The left end of the liner 6 is sleeved in the adapter II5, the right end of the liner 6 is provided with an adapter III12, the spher...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com