Machine tool with a support piece

A technology for supporting components and machine tools, which is applied in the direction of manufacturing tools, workbenches, portable motorized devices, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

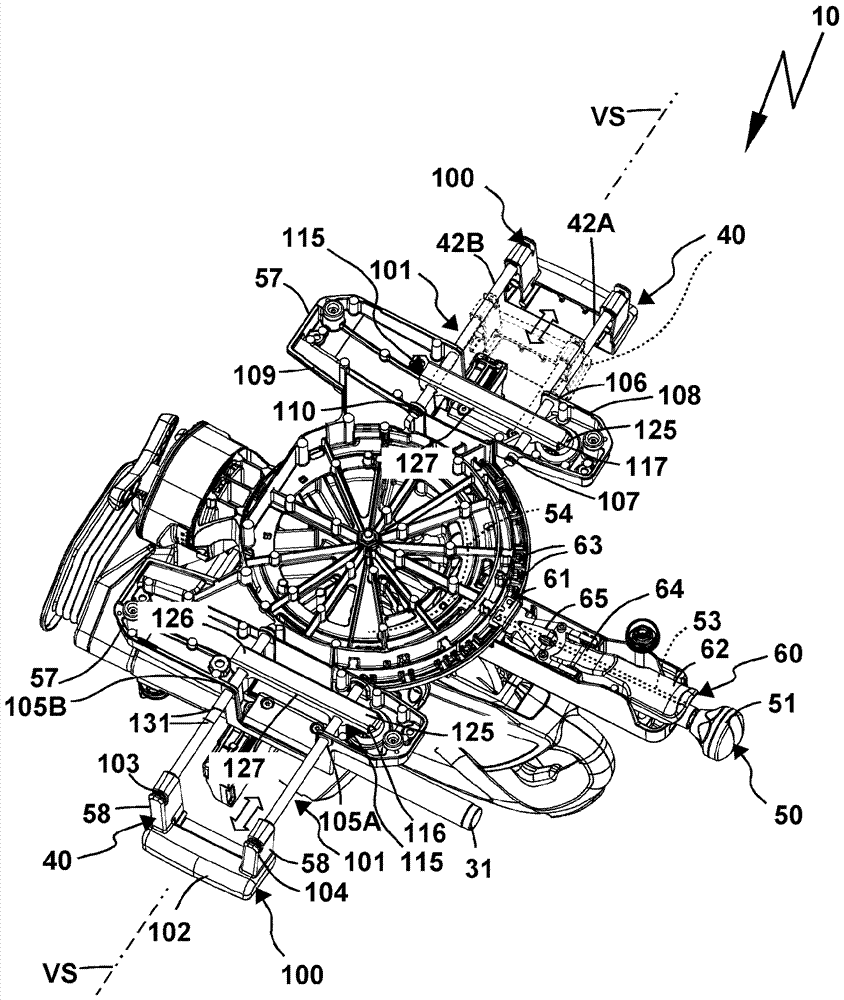

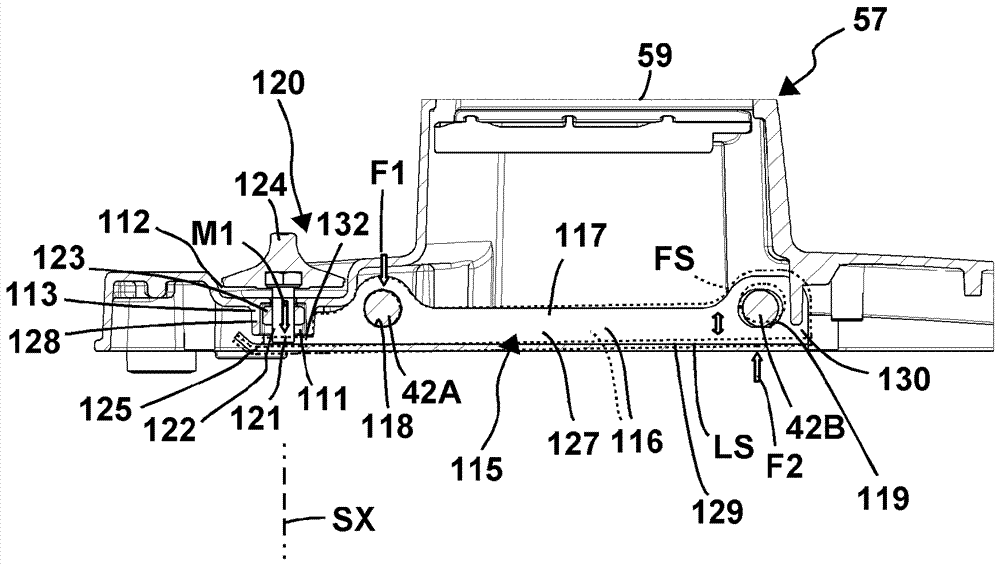

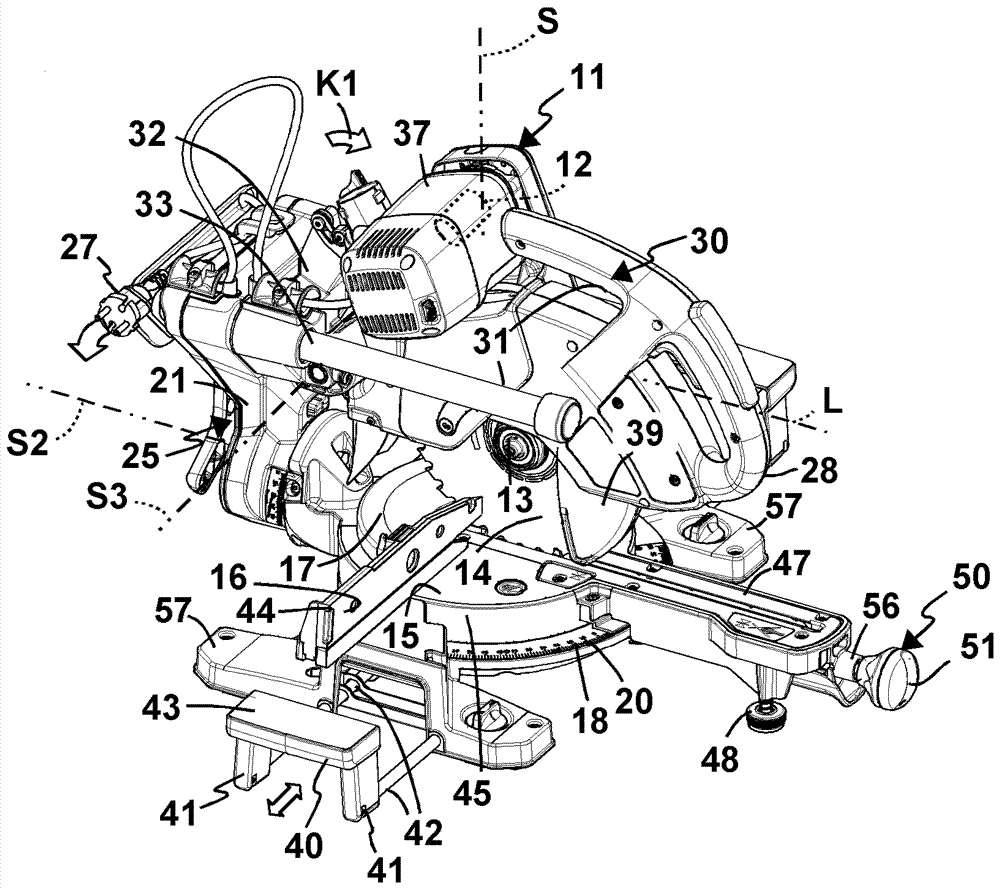

[0057] Machine tool 10 is designed, for example, as an oscillating saw. The drive assembly 11 of the power tool 10 comprises a drive motor 12 , which drives a tool receptacle 13 directly or via a transmission not shown, on which a detachable coupling can be arranged. Tool 14, such as a saw blade. The drive motor 12 is an electric drive motor, in particular a brushless drive motor.

[0058] The drive assembly 11 is arranged above a support surface 15 for supporting the workpiece W. As shown in FIG. The workpiece W can be placed on the support surface 15 and can be brought into contact with the contact surface 16 in order to carry out a separate cut by means of the separating tool 14 .

[0059] The bearing surface 15 is arranged on a pivot element 17 which is pivotable about a pivot axis S relative to a pivot base 18 . The pivot base 18 forms a machine base 20 .

[0060] The angular position of the tool receptacle 13 and thus the separating tool 14 relative to the abutment s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com