Rotary quantitative taking out device

A rotary, rotating axis technology, applied in fixed measuring chambers, powder material distribution, etc., can solve problems such as failure to achieve functions, powder leakage from the slide, and obstruction of the slide bucket, so as to achieve smooth movement and reduce production and assembly. Accuracy requirements, the effect of reducing the movement gap

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 4 Embodiment approach

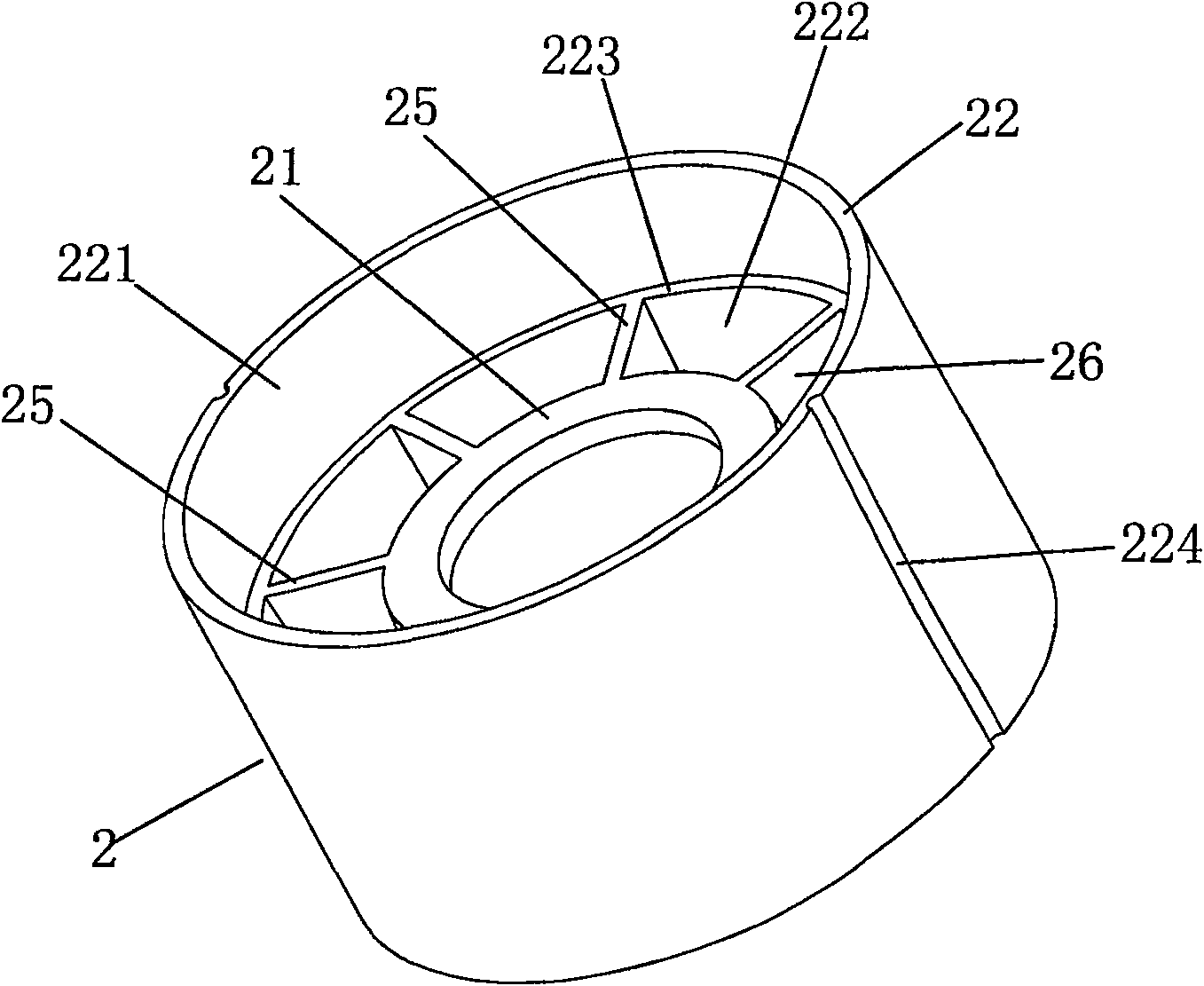

[0062] see Figure 19 and Figure 20 , which is the fourth specific embodiment of the present invention. The main difference between this embodiment and the third embodiment is that: the measuring bucket 2 is provided with a matching cavity 21, and the bottom of the storage tank 1 is put into the matching cavity 21 and connected with the matching cavity. 21 friction fit, and the connection between the measuring bucket 2 and the storage tank 1 is also tightly covered with an elastic sealing ring 3, so as to better play the role of sealing and moisture-proof.

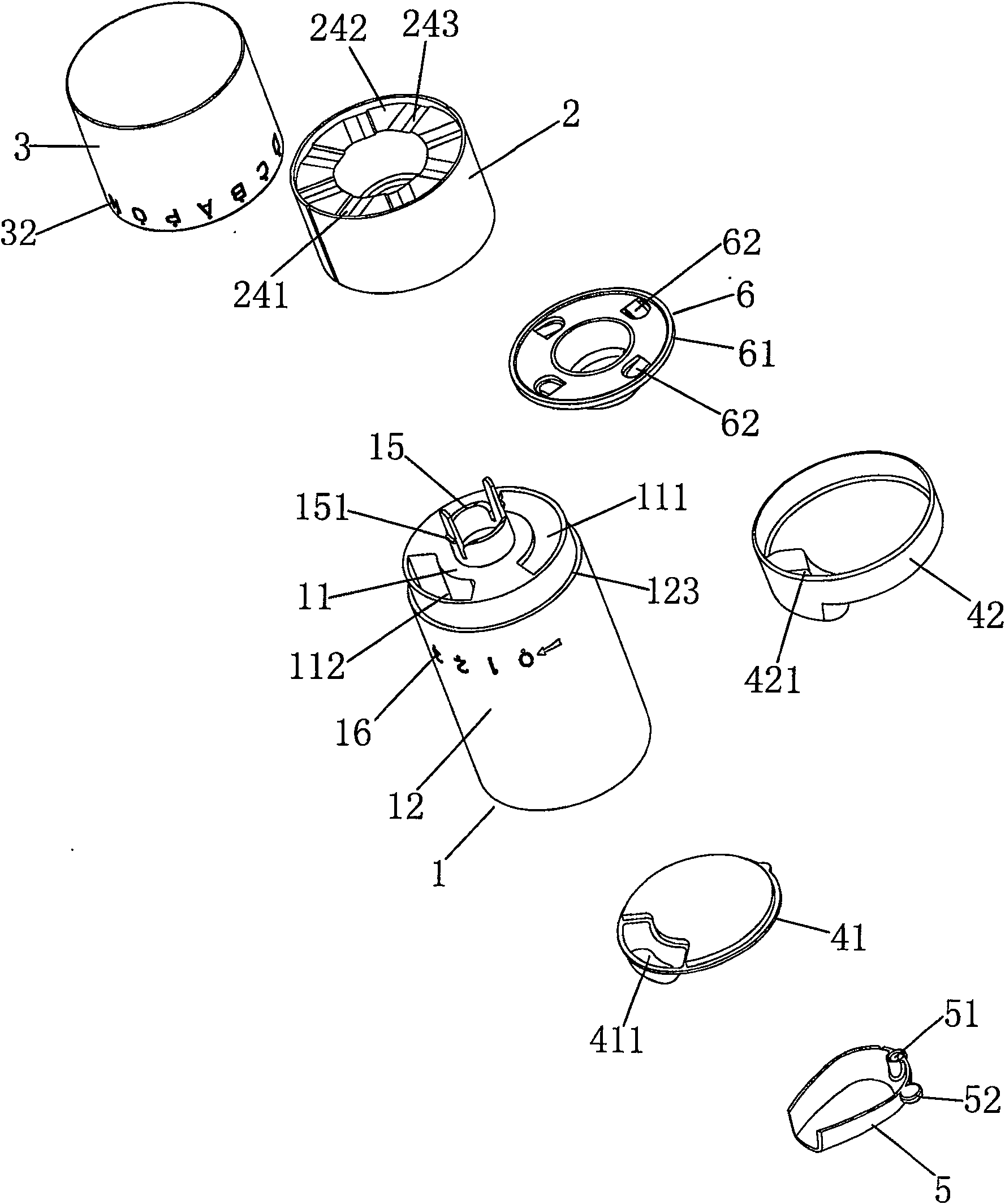

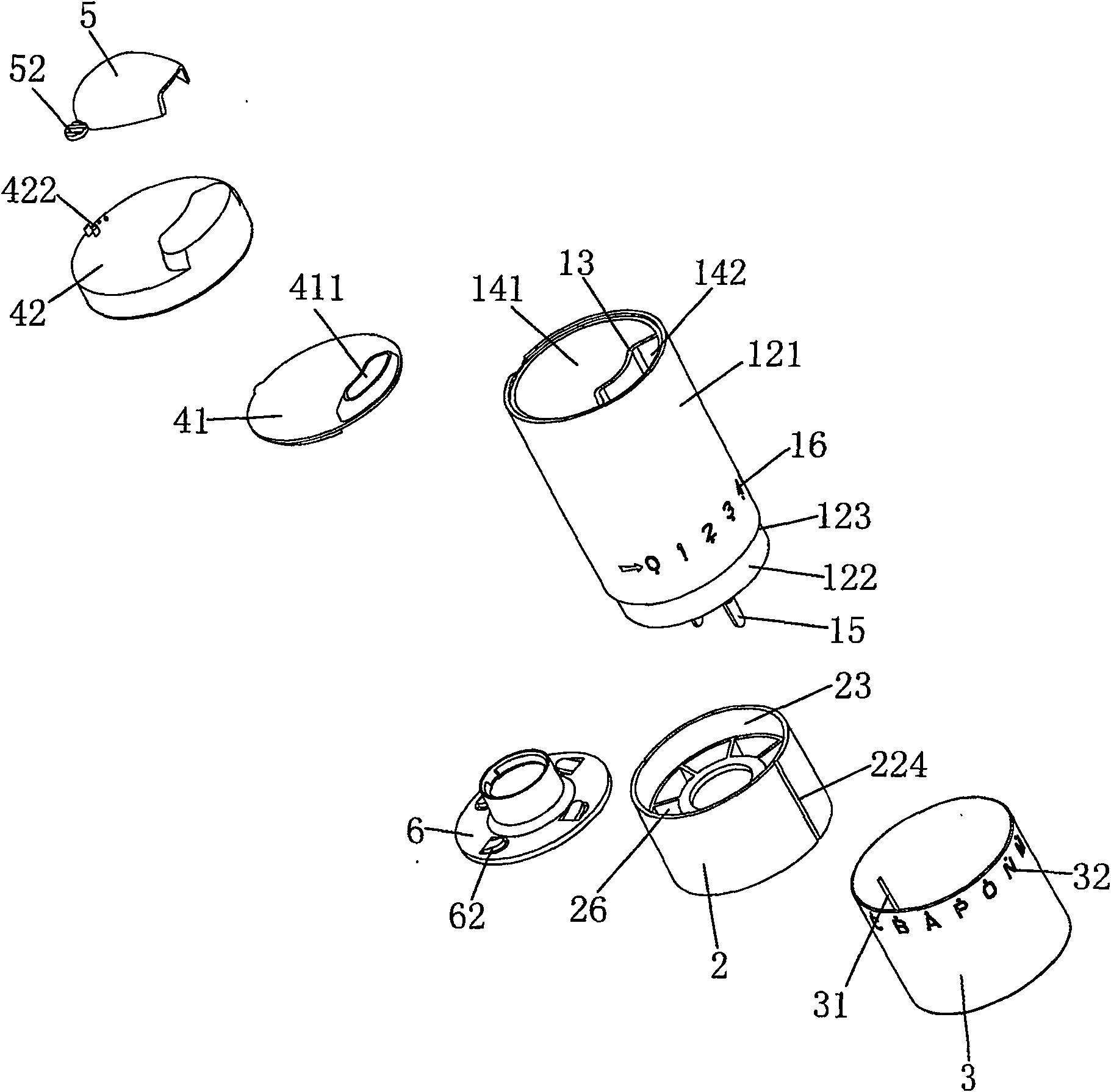

[0063] see Figure 21 to Figure 24 , which is the fifth embodiment of the present invention. The rotary quantitative taking device includes a storage tank 1 , a measuring bucket 2 , a top cover 3 , a bottom cover 4 and an elastic mounting part 5 .

[0064]The storage tank 1 includes a circular bottom plate 11, an annular side plate 12 and a partition 13, the side plate 12 extends vertically upward from the edge of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com