Mounting mechanism for swash plate of oblique plunger pump and driving lever

A technology for mounting mechanisms and plunger pumps, which is applied to parts, pumps, and multi-cylinder pumps of elastic fluid pumping devices, and can solve the problems of inconvenient adjustment of the angle of the swash plate and achieve the effect of convenient adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described in conjunction with specific embodiment now. These drawings are simplified schematic diagrams only to illustrate the basic structure of the present invention in a schematic way, so they only show the components relevant to the present invention.

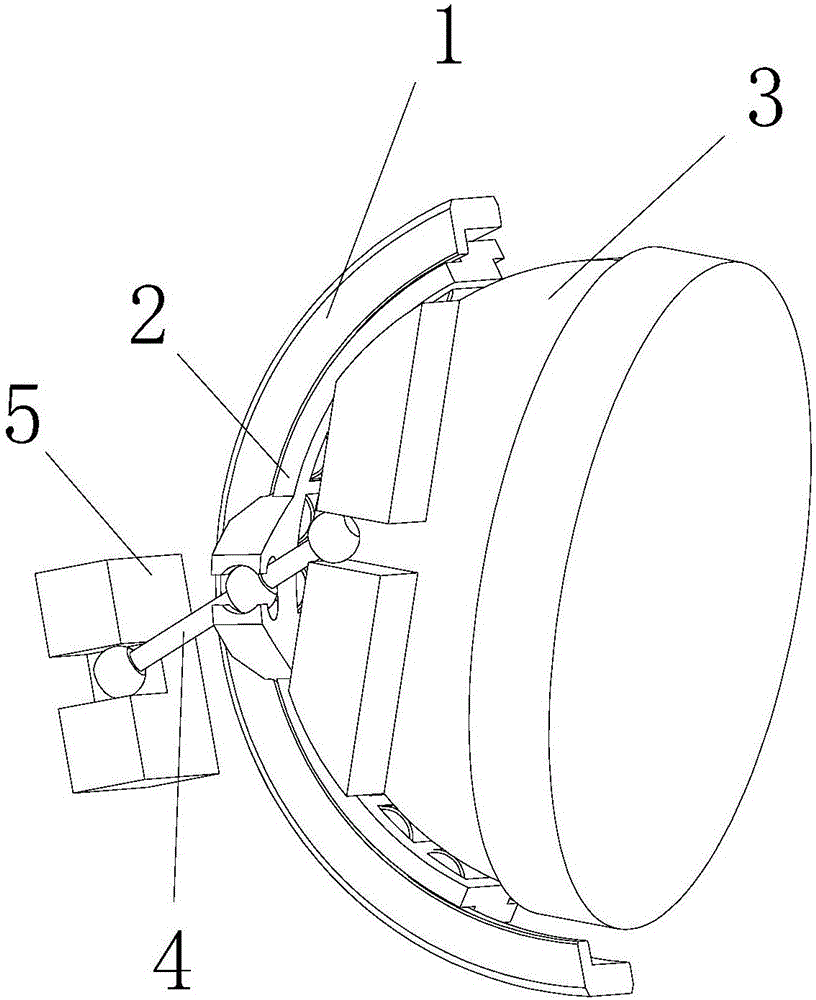

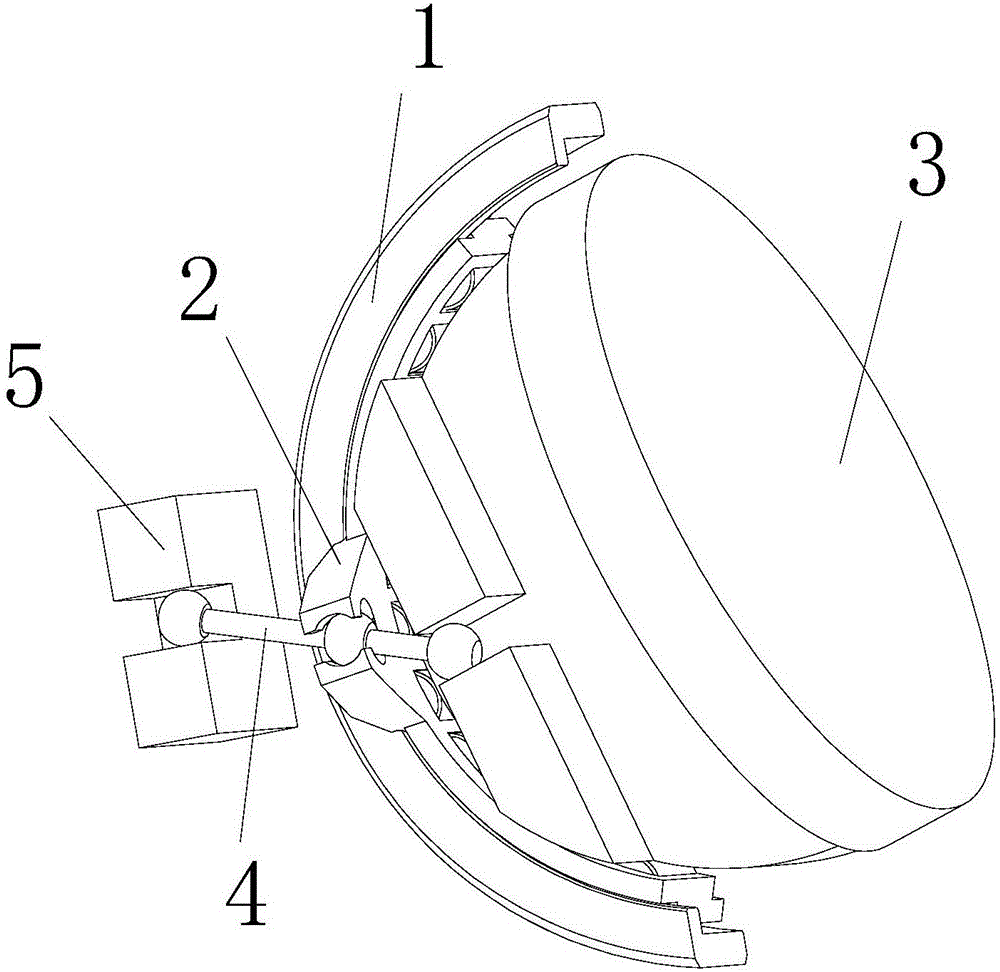

[0019] Such as figure 1 figure 2 As shown, a slant plate installation mechanism of a slanted plunger pump includes a plunger pump body, a crescent outer ring 1 is fixedly installed on the plunger pump body, and a crescent outer ring 1 is provided with a The crescent bearing 2 that moves up and down is provided with the swash plate 3 of the plunger pump on the crescent bearing 2. The crescent bearing 2 includes a cage and rollers distributed on the cage.

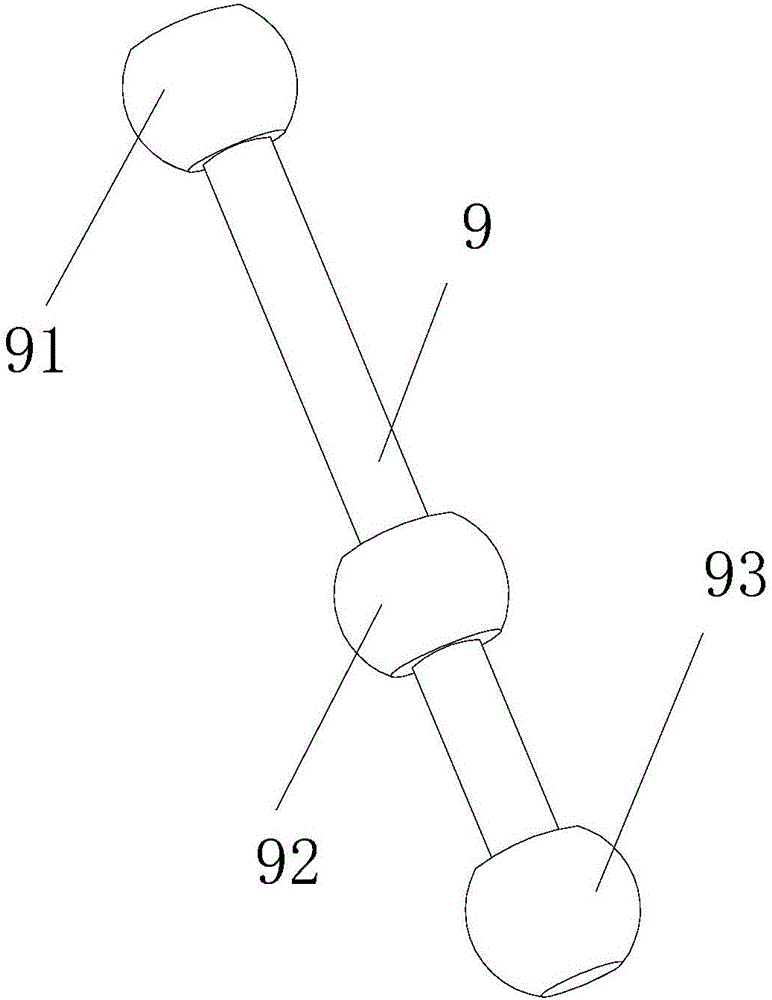

[0020] One side of the crescent bearing 2 cage forms a ball cavity, one side of the swash plate 3 forms an upper cavity, and the plunger pump body forms a lower cavity, and a driving rod 4 is connected to the cage ball cavit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com