Intelligent glue rolling device for motor rotor

A motor rotor and glue rolling technology, which is used in the manufacture of stator/rotor body, devices for coating liquid on the surface, coating, etc. The effect of stability, accurate operation, convenient and quick operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

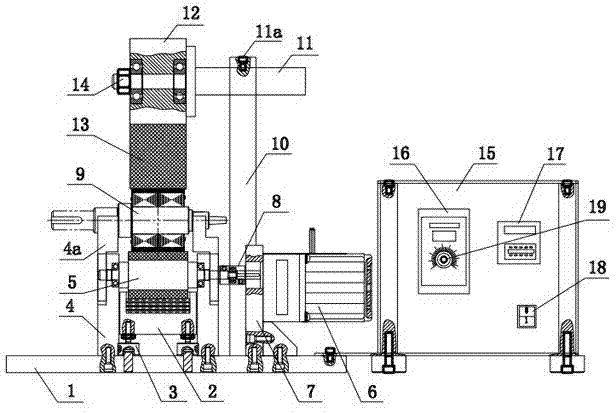

[0016] Below in conjunction with accompanying drawing, the present invention will be further described:

[0017] An automatic rubber rolling device for a motor rotor, comprising a base plate 1, a glue pool 2, an adsorption type rolling roller 5, an AC deceleration motor 6 and an electric control box 15, the glue pool 2 is arranged on the base bottom plate 1, and the adsorption type rolling wheel 5 is set directly above the glue pool 2 and the cylindrical surface of the adsorption type rolling roller 5 is in contact with the liquid surface of the glue pool 2. As long as the adsorption type rolling roller 5 turns over the glue pool 2, glue is adhered to the adsorption type rolling roller 5 , when the suction-type rolling roller 5 and the rotor 9 roll and cooperate, the glue on the suction-type rolling roller 5 will be coated on the rotor 9, and the coating is very uniform; Supported by the roller bracket 4, one end of the adsorption-type rolling roller 5 is connected with the AC...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com