An electromechanical braking device

An electro-mechanical brake and brake caliper technology, applied in mechanical equipment, brake actuators, gear shifting mechanisms, etc. The effect of fast response to requirements, large transmission ratio, and improved response speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] A specific embodiment of the present invention will be described in detail below in conjunction with the accompanying drawings, but it should be understood that the protection scope of the present invention is not limited by the specific embodiment.

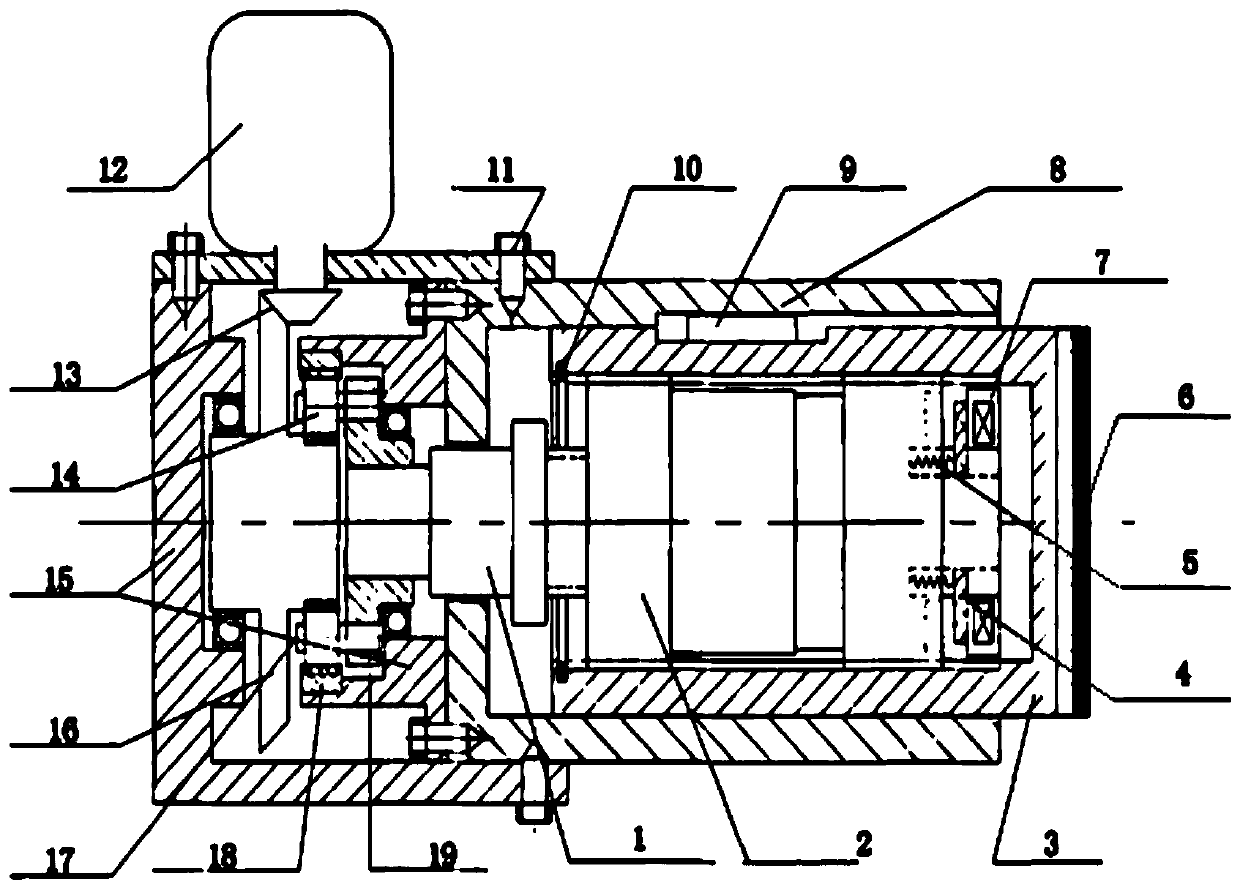

[0016] Such as figure 1 As shown, the embodiment of the present invention provides an electromechanical braking device, including a brake caliper body 8, a ball screw 1 is arranged inside the brake caliper body 8, and balls are sleeved on the ball screw 1. A screw nut 2, the ball screw nut 2 is sleeved with a sliding screw nut 3; the right end of the ball screw nut 2 is symmetrically arranged with a pair of springs 5 along its axial direction, and the other end of the spring 5 is connected with Armature 4; the armature 4 is matched with the electromagnetic clutch 7 arranged on the right side of the ball screw nut 2; the left side of the brake caliper body 8 is connected with a box body 15 through a screw 11, and the top ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com