Novel self-adjustment spring type steam seal

A self-adjusting, spring-type technology, applied in the field of steam turbines, can solve the problems of damage to the large shaft of the steam turbine, permanent bending of the large shaft, major accidents of major bending shafts, etc., and achieve the effect of reasonable structural design and improved sealing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

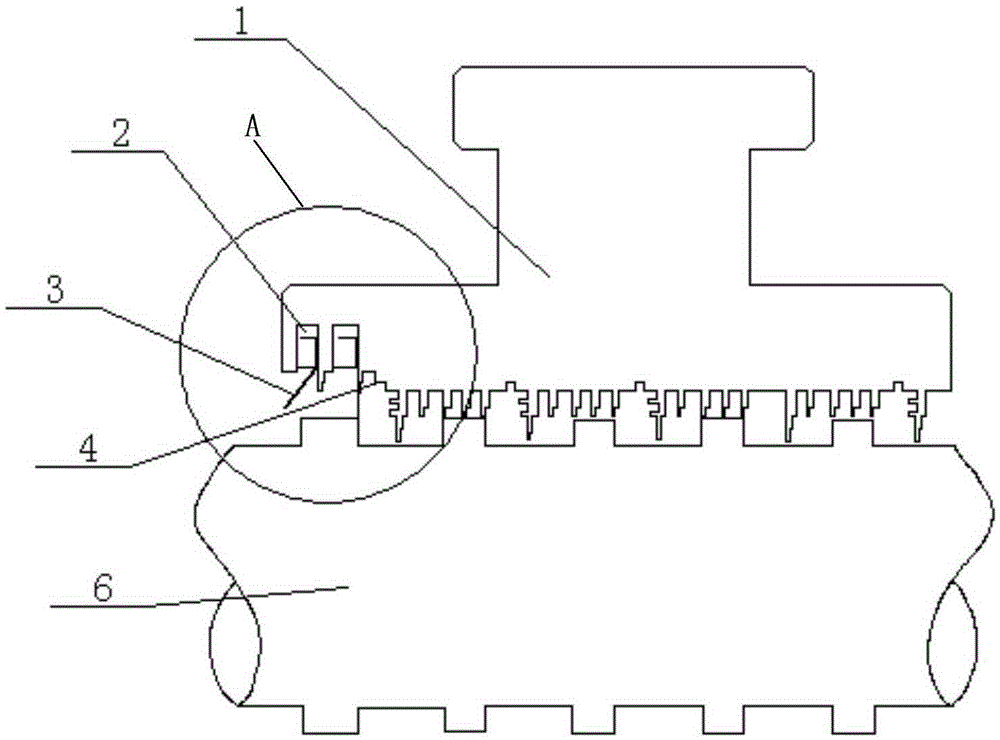

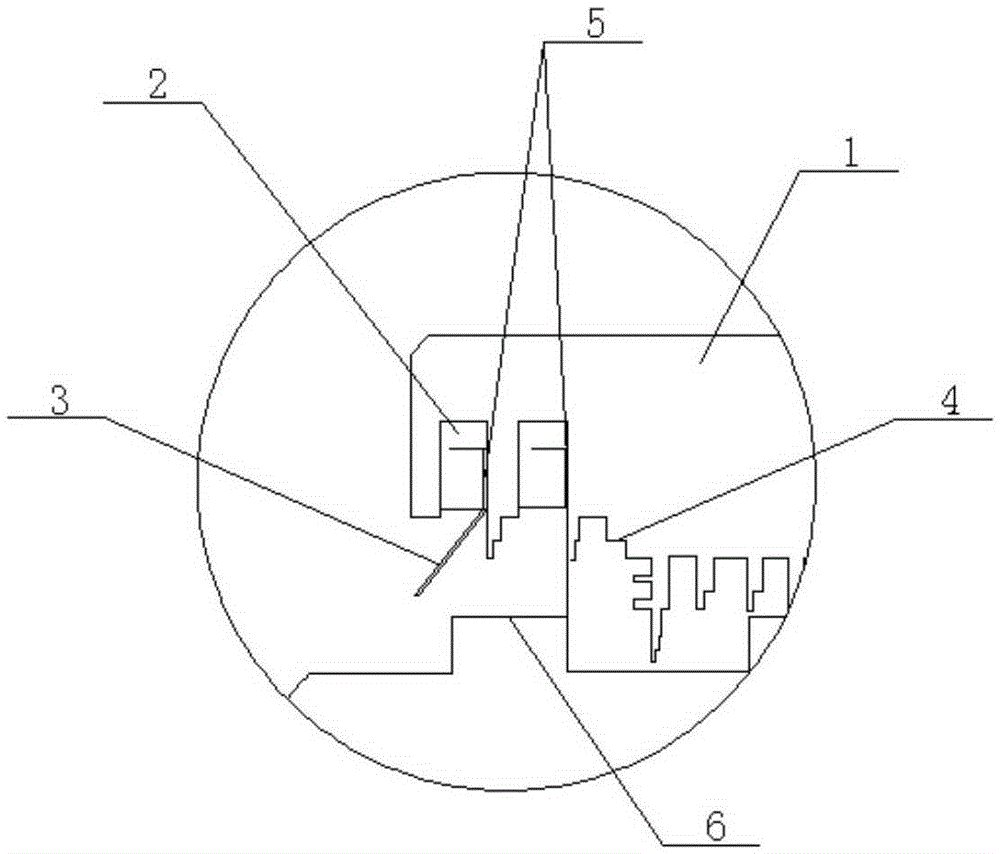

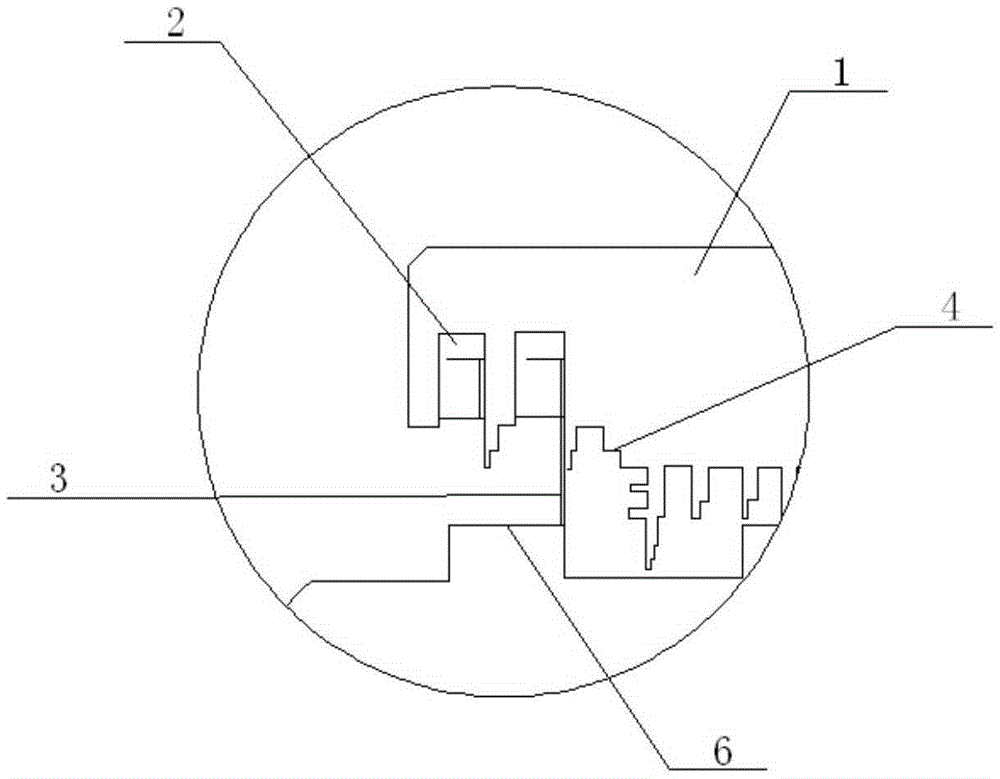

[0021] like Figure 1 to Figure 3 As shown, this specific embodiment adopts the following technical scheme: it includes a steam seal body 1, a spring leaf pressing block 2, a spring sheet 3, a reed supporting back tooth 4, a reed inlay groove 5, and a rotor 6; The cover body 1 is provided with a spring leaf and a spring leaf pressing block 2 which are combined by two coils in a mutual dislocation and overlapping manner. One side of the spring leaf pressing block 2 is provided with a reed inlay groove 5, and the spring sheet 3 and the spring leaf The mosaic grooves 5 cooperate with each other, and one end of the spring sheet 3 is overlapped and riveted in the reed mosaic groove 5, the reed support back tooth 4 at the bottom of the steam seal body 1 cooperates with the rotor 6, and the inner circumference of the spring sheet 3 is aligned with the rotor 6. The outer diameters of the rotors 6 fit each other.

[0022] When this specific embodiment is in operation, each reed is inl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com