Scraping device for a cutting roller mounted in a construction machine

A technology for scraping devices and construction machinery, applied in construction, roads, road repair and other directions, can solve problems such as injuries, and achieve the effect of maintaining mobility and preventing jams

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

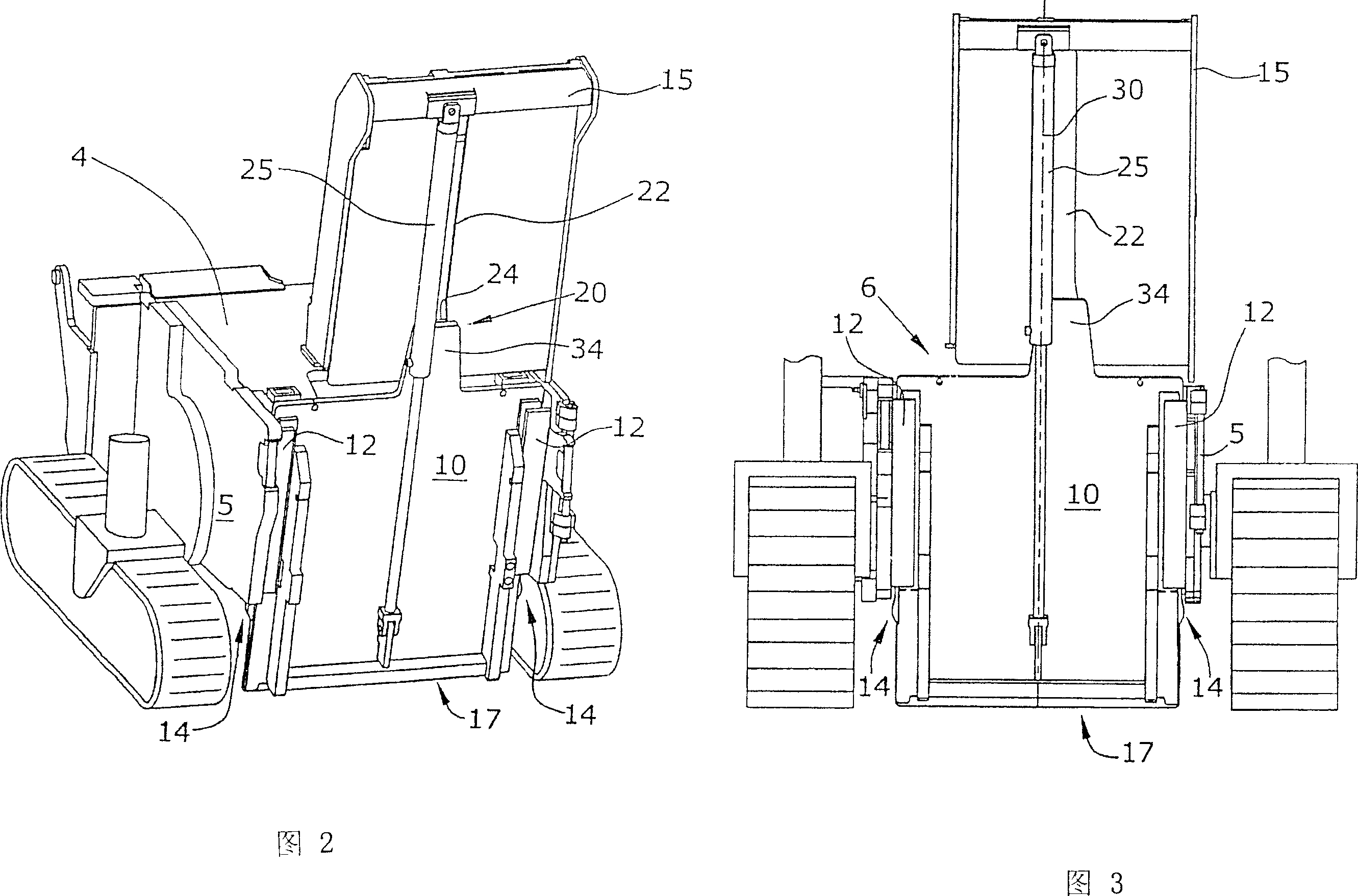

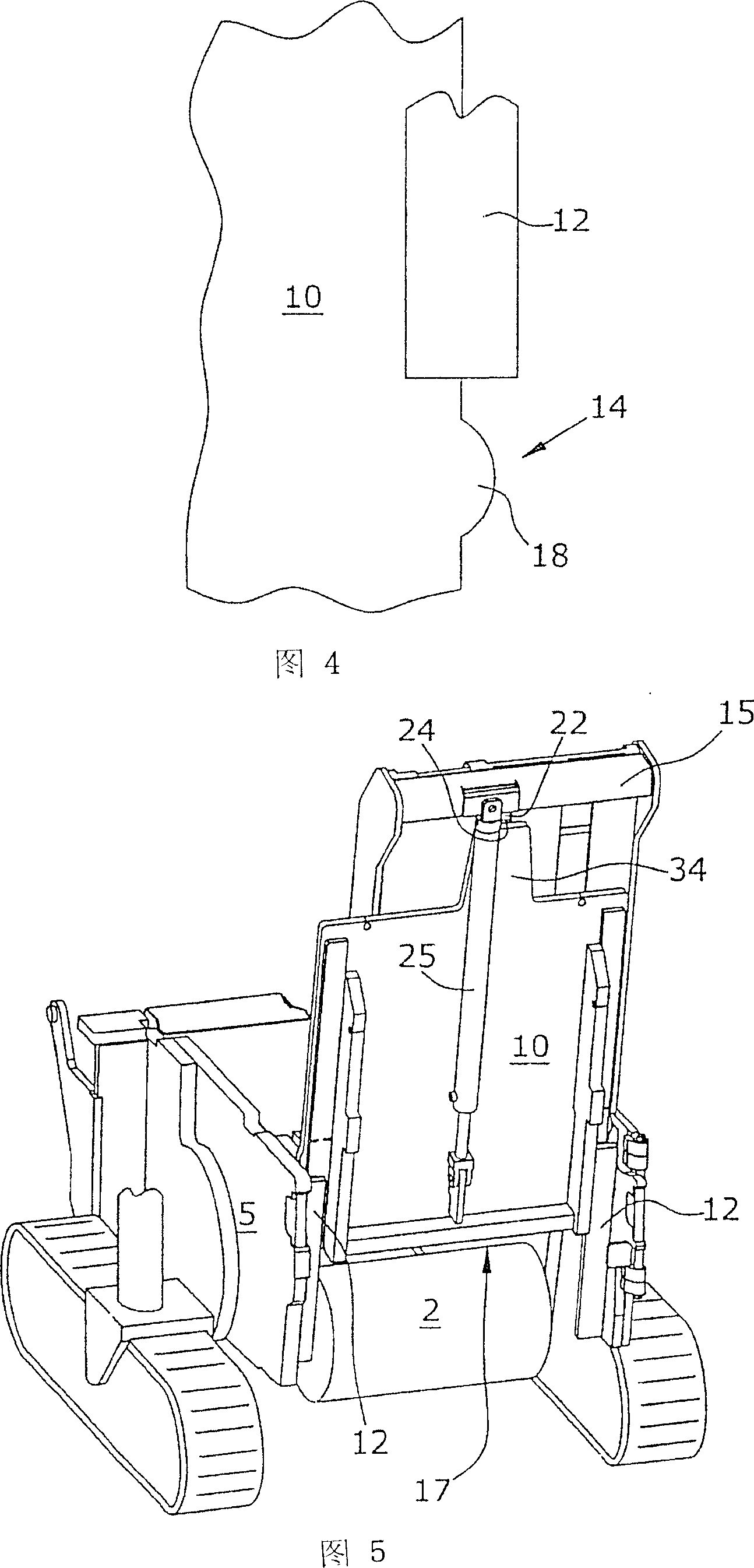

[0039] Figure 1 shows the invention applied to a front loading road milling machine. The automatic road milling machine 1 shown in FIG. 1 is provided with wheels, but it can of course also be supported by crawler units, as shown in FIG. 2 . In the embodiment of the road milling machine 1 according to FIG. 1 , the milling drum 2 is arranged at the machine rear end and is closed by a drum housing 4 .

[0040] When viewed in the direction of travel, a scraping device 6 with a mast 15 and a piston-cylinder unit 25 is arranged at the rear end of the drum shell 4, the scraping device 6 has a height-adjustable scraper 10, the scraper seal The milling width of the milling drum 2 is covered and guided in a height-adjustable manner on a mast 15 which is connected to the machine frame 5 , for example via a piston-cylinder unit 25 .

[0041] The doctor blade 10 is guided on the lateral guides 12 of the machine frame 5, whereby it must be clear that the machine element indicated by refere...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com