Suction nozzle for a vacuum cleaning device

A technology for cleaning equipment and processing equipment, which is applied in the field of functional parts to achieve the effect of reducing power consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

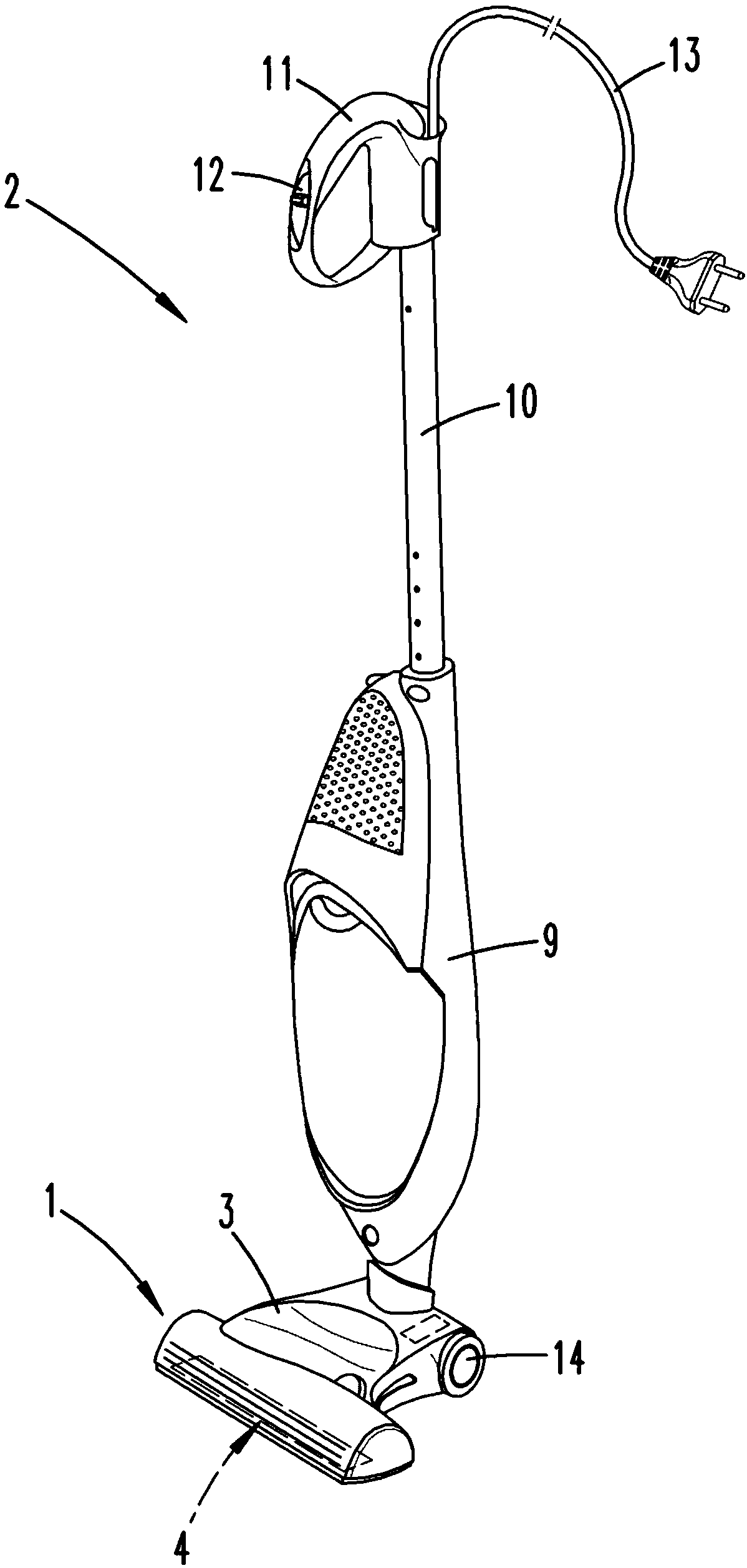

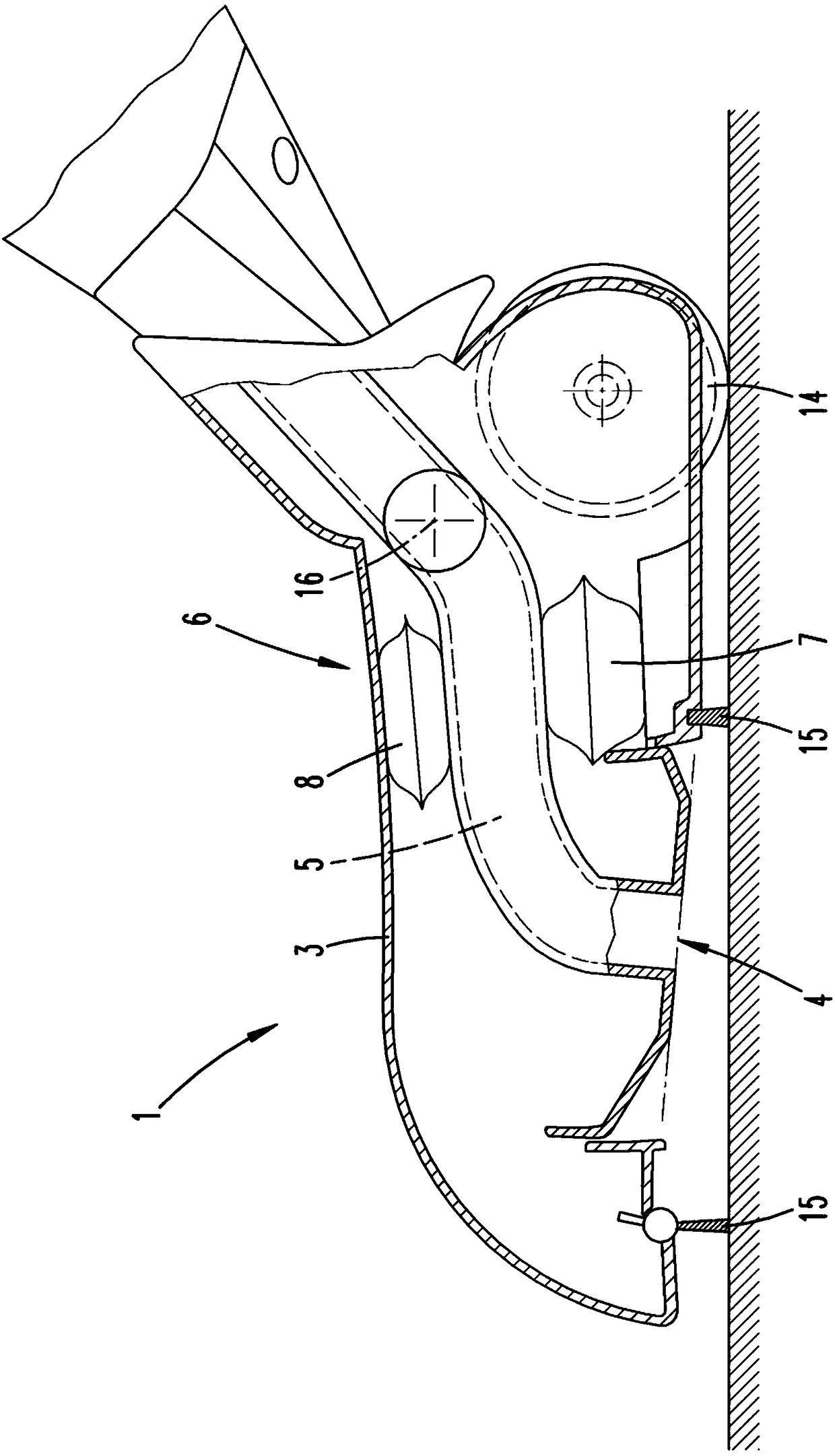

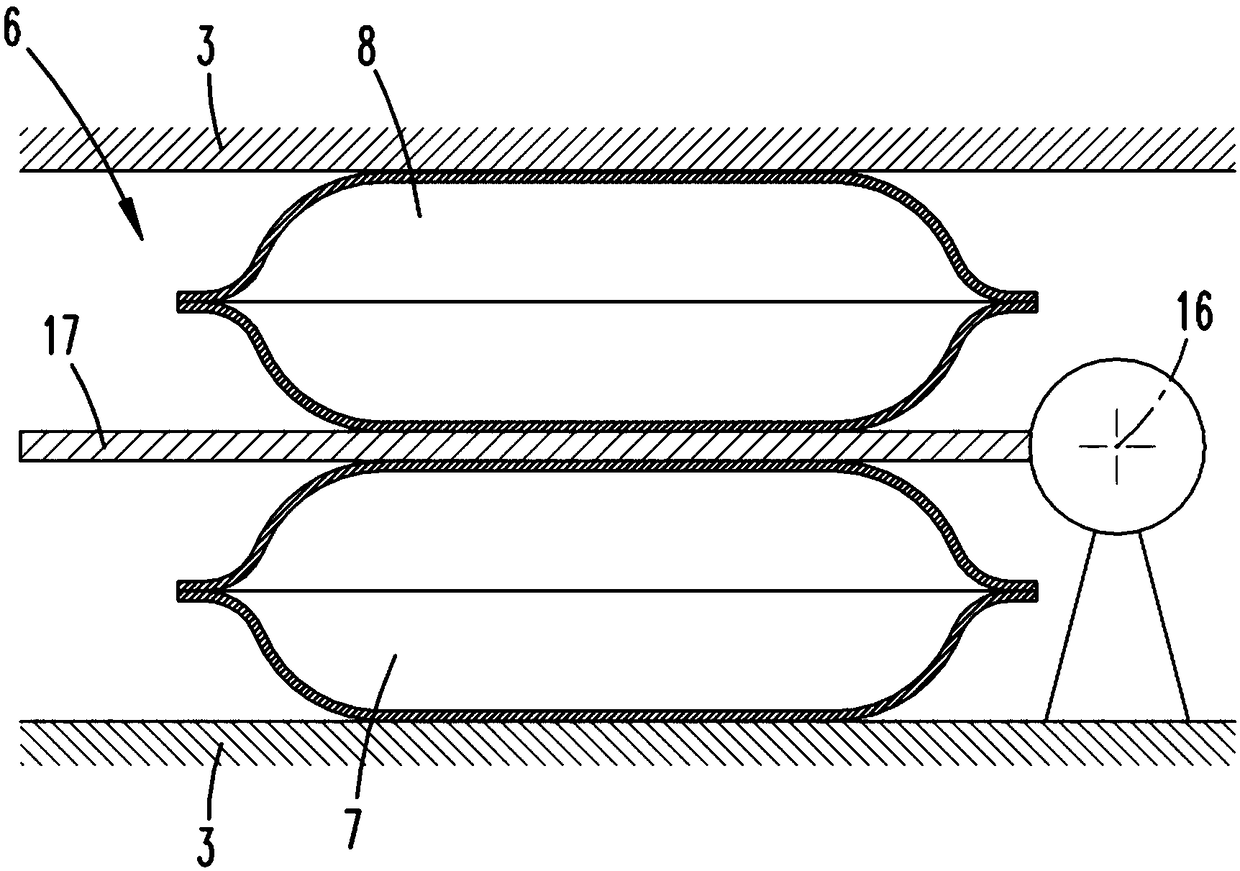

[0030] figure 1 A dust extraction device 2 with a suction nozzle 1 is shown by way of example. The vacuum cleaner 2 is designed here as a hand-held vacuum cleaner. The suction nozzle 1 is here a separate accessory device which can be detached from the base device 9 of the dust suction device 2 . In a general manner, the dust extraction device 2 has a motor-driven fan (not shown), by means of which suction material can be collected from the surface to be cleaned. For this purpose, the fan creates a suction air flow which flows through the suction channel 5 of the suction nozzle 1 . The suction channel 5 opens into the suction opening 4 on the underside. Furthermore, the suction nozzle 1 has a housing 3 on which two rollers 14 are mounted, which roll on the surface to be cleaned when the suction nozzle 1 is moved.

[0031] The base device 9 is connected to a pole 10 which can be configured telescopically in order to adjust the length of the pole 10 to the height of the user....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com