Guide vane assembly

A technology of guide vanes and components, applied to pump components, engine components, components of pumping devices for elastic fluids, etc., can solve problems such as tedious manufacturing of holes, low elastic travel of clamping sleeves, etc., and achieve simple cost The effect of manufacturing and simplifying the structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

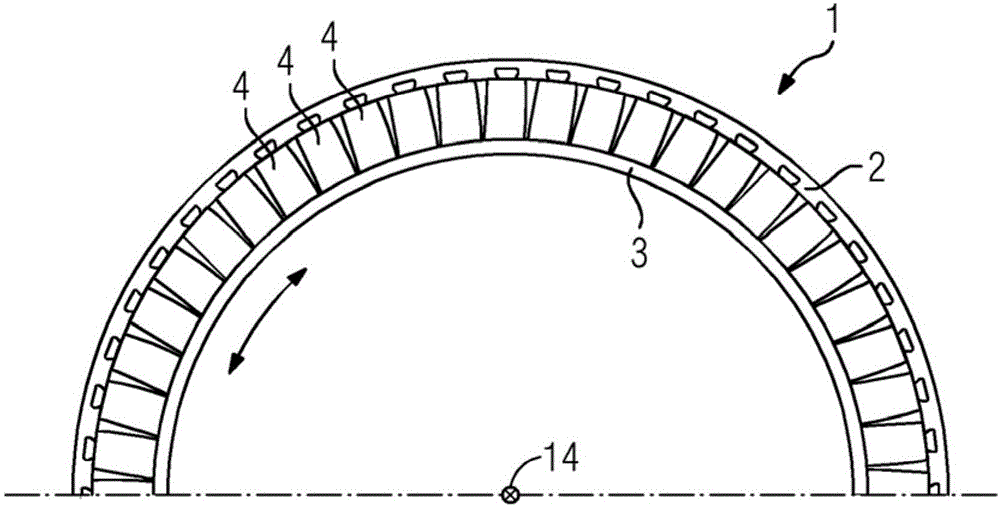

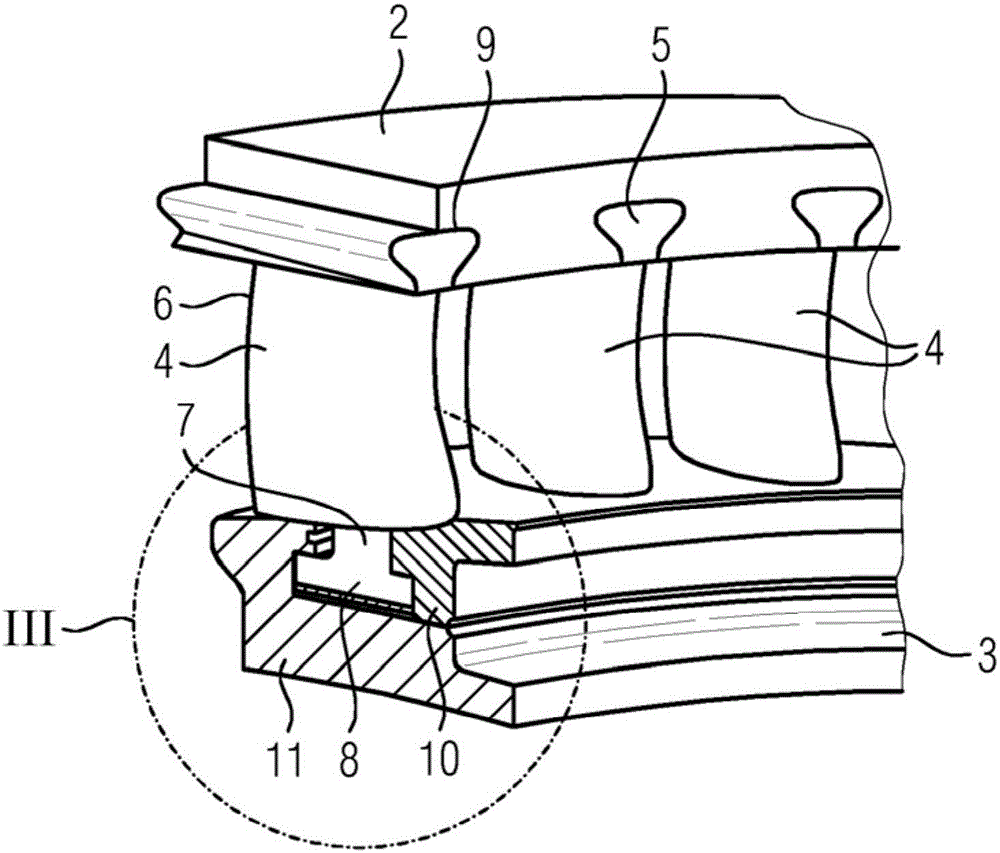

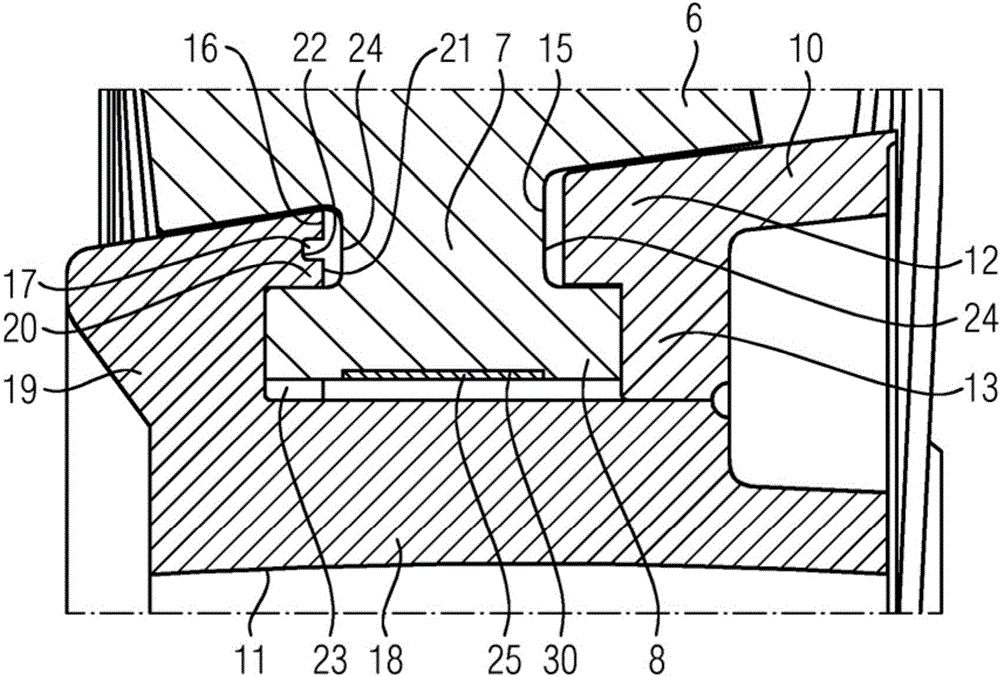

[0030] Figure 1 to Figure 15 Shown is a guide vane assembly 1 or parts thereof according to one embodiment of the invention. The guide vane assembly 1 includes an outer ring 2 as main components, an inner ring 3 and a plurality of guide vanes 4, these guide vanes extend between the outer ring 2 and the inner ring 3, and these guide vanes respectively have stationary vane roots 5, static vanes The vane 6 and the vane head 8, the vane root 5 is fastened at the outer ring 2, the vane 6 extends between the outer ring 2 and the inner ring 3, and the vane head 8 passes through the vane joint 7 is connected with the stator blade 6 and has a hook structure, and the stator blade head 8 is fastened at the inner ring 3 .

[0031] The outer ring 2 and the inner ring 3 are arranged concentrically in a known manner on a virtual machine axis 14 , which is used as the reference axis for the terms “radial” and “axial”.

[0032] A plurality of vane root receiving grooves 9 are provided along...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com