High-precision rapid positioning device for automatic production line

An automated production line and positioning device technology, applied to large fixed members, measuring/indicating equipment, manufacturing tools, etc., can solve problems such as poor reliability, easy shaking, and low positioning accuracy, and achieve good guiding effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] This embodiment is a high-precision fast positioning device used in an automated production line.

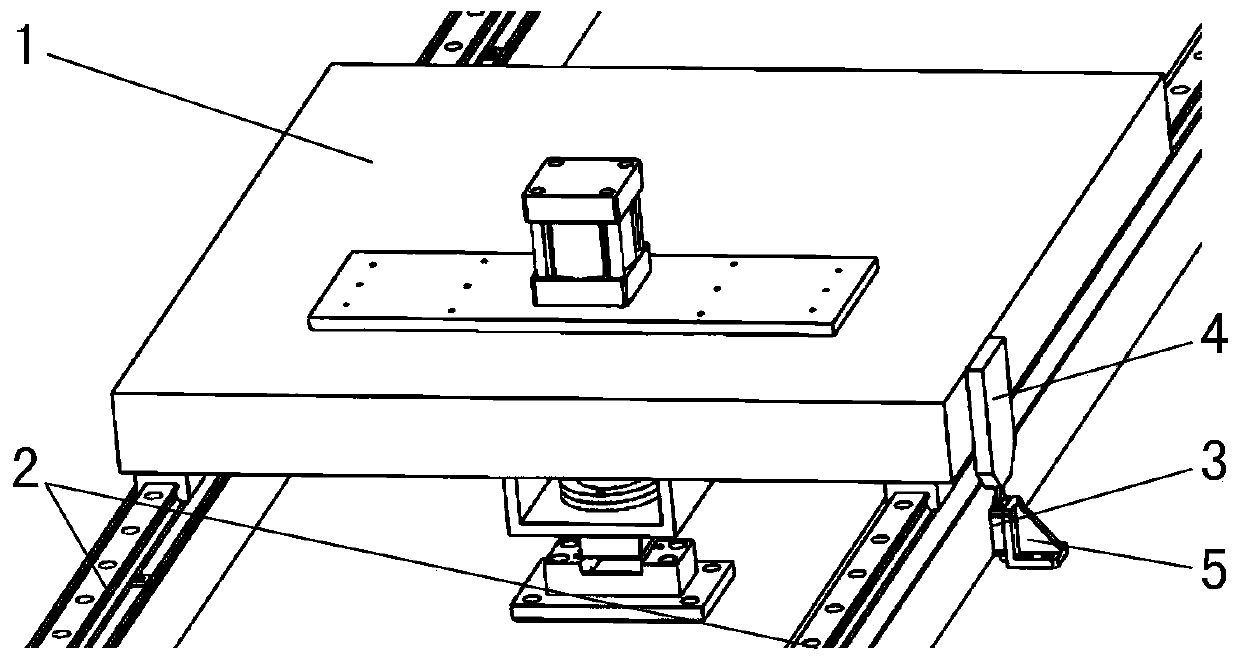

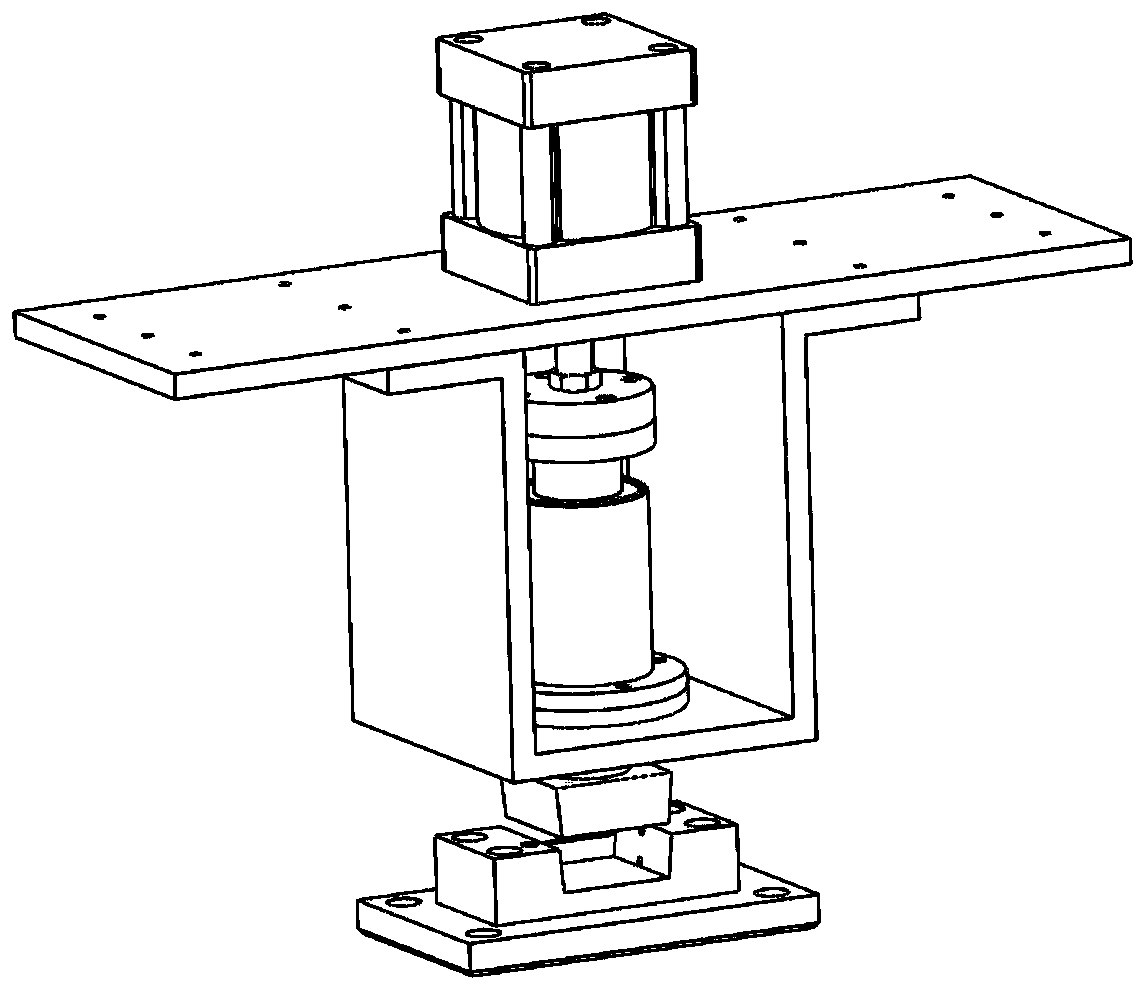

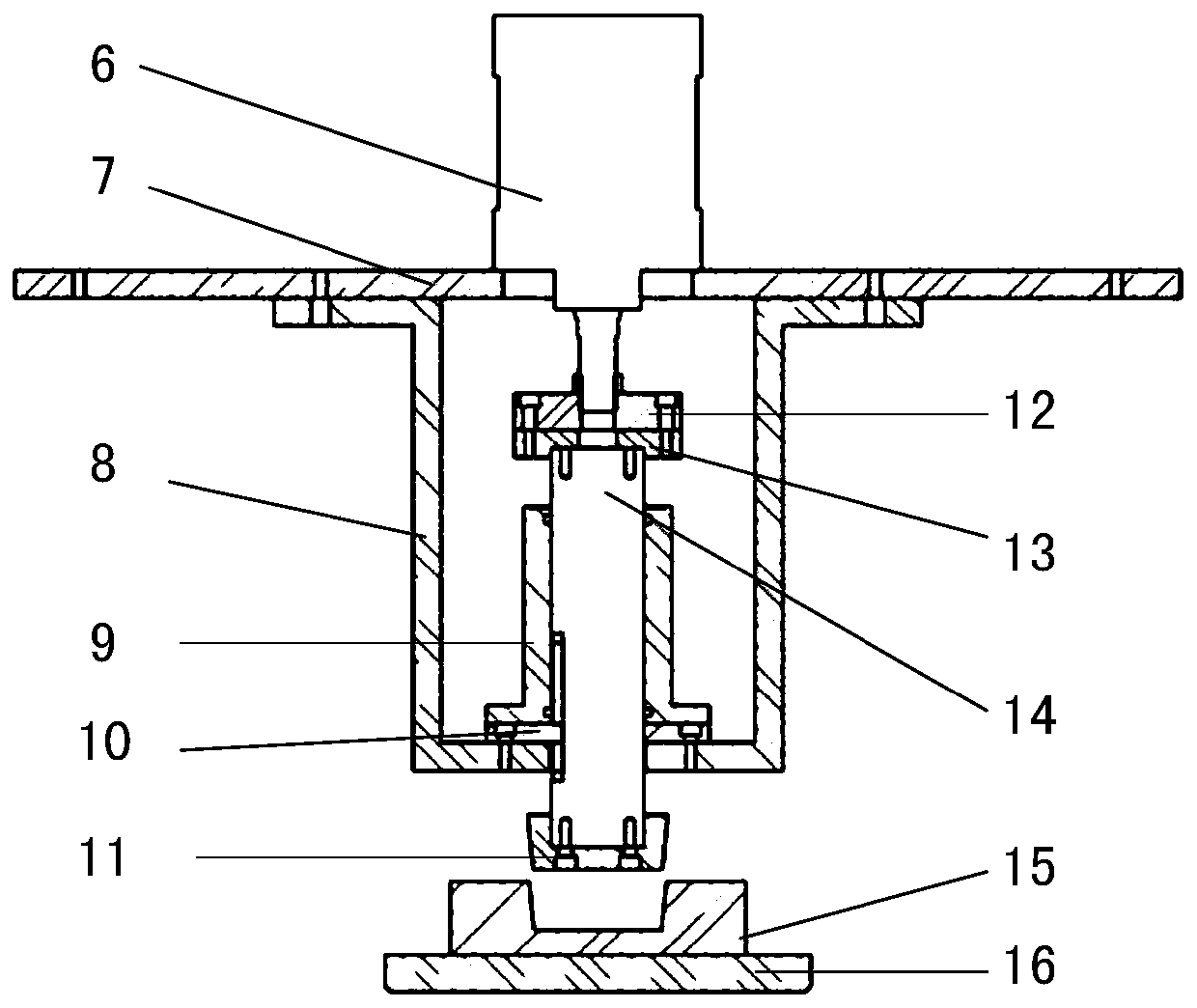

[0020] refer to Figure 1 ~ Figure 4 , the high-precision fast positioning device used in the automatic production line in this embodiment consists of a mobile device 1, a guide mechanism 2, a position detection sensor 3, a sensor trigger block 4, a sensor support plate 5, a fixed support plate 7, a U-shaped support frame 8, a concave The positioning groove 15, the ground fixing base 16 and the transmission assembly are composed; wherein, the mobile device 1 is fixed on the upper part of the guide mechanism 2, and the mobile device 1 and the guide mechanism 2 are installed through guide rail sliders. The sensor trigger block 4 is fixed on the side end of the mobile device 1, the position detection sensor 3 is fixed on the side of the upper guide rail of the guide mechanism 2 through the sensor support plate 5, and cooperates with the sensor trigger block 4, and the sensor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com