Self-locking device of gears of speed changer

A technology of self-locking device and transmission, applied in transmission control, components with teeth, belts/chains/gears, etc., can solve the problems of complex manufacturing process and unreliable positioning, and achieve simple manufacturing process, reliable positioning, Simple fixed structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

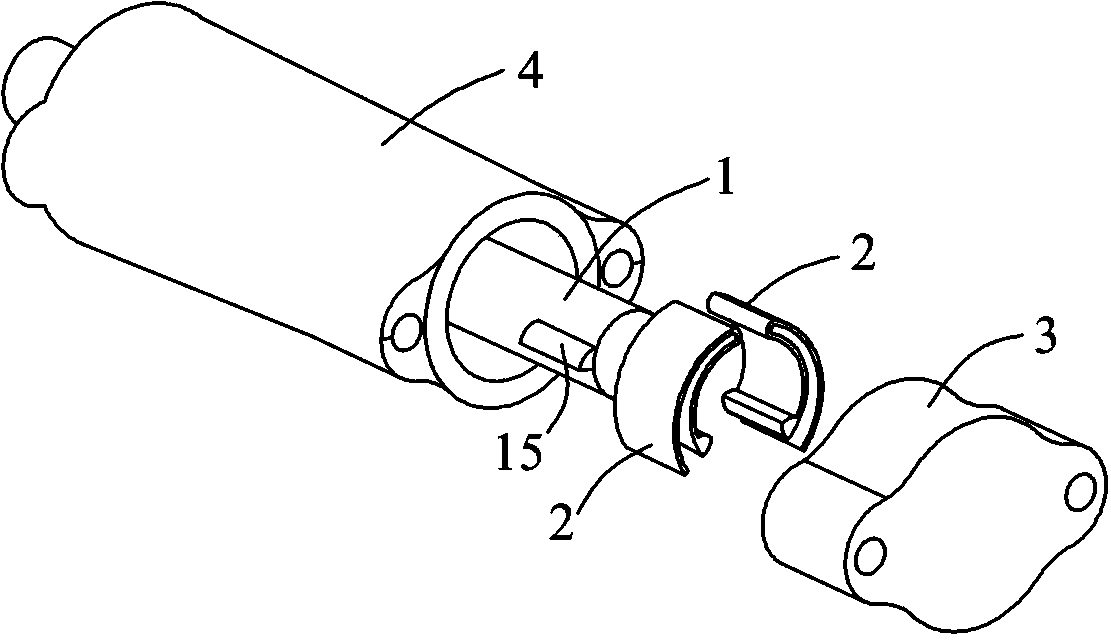

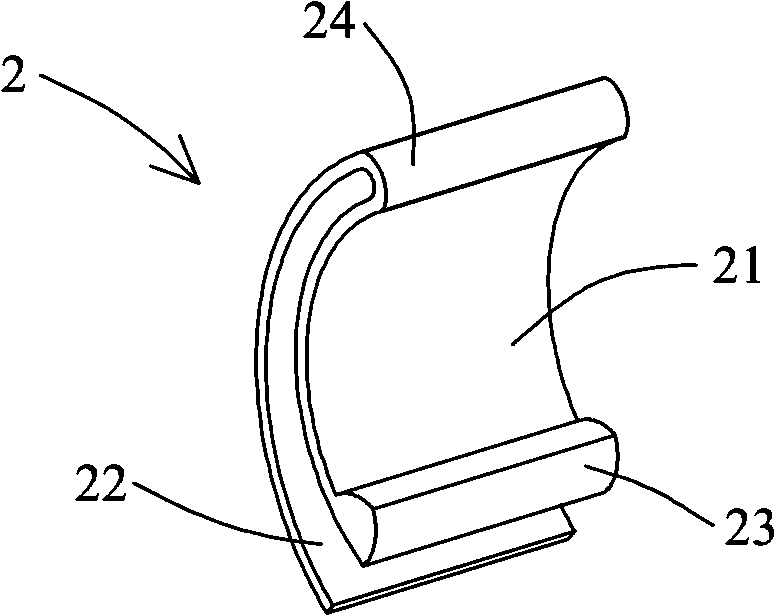

[0022] The present invention is a transmission gear self-locking device, the structure is as follows: Figure 1 to Figure 3 As shown, it includes a shift shaft 1 arranged on the transmission housing. The shift shaft 1 can slide axially between different shift positions. When it slides to the corresponding gear position, it can rotate around itself The axis of the shaft rotates, and the corresponding shift fork shaft is moved during the rotation to complete the shifting action. Two protruding self-locking blocks 15 are symmetrically arranged on both sides of the outer cylindrical surface of the shift shaft 1 , and two reeds 2 cooperating with the self-locking blocks 15 are correspondingly arranged on the transmission case.

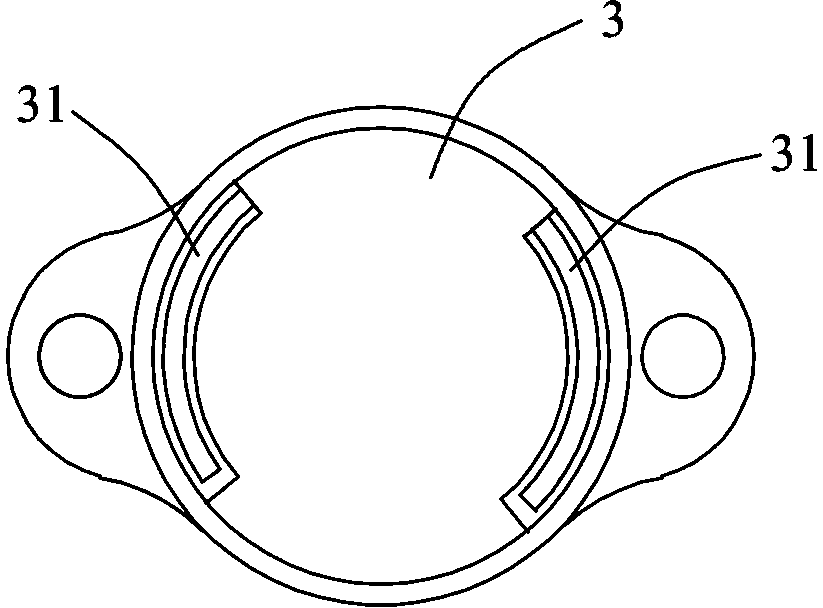

[0023] A connecting seat 3 is fixedly connected to the transmission housing, and the connecting seat 3 is used to fix the reed 2 on the housing. It has two symmetrical half-ring-shaped slots 31 inside. The stop shaft 1 is arranged coaxially, and is used fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com