Limitable rotation device for hoisting boom of bridge crane

An overhead crane and slewing device technology, applied in cranes, transportation and packaging, load hanging components, etc., can solve the problems of short service life of the rotating shaft, vibration in the jogging process, and complicated operation process, so as to prolong the service life and reduce the The effect of failure, smooth transmission

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

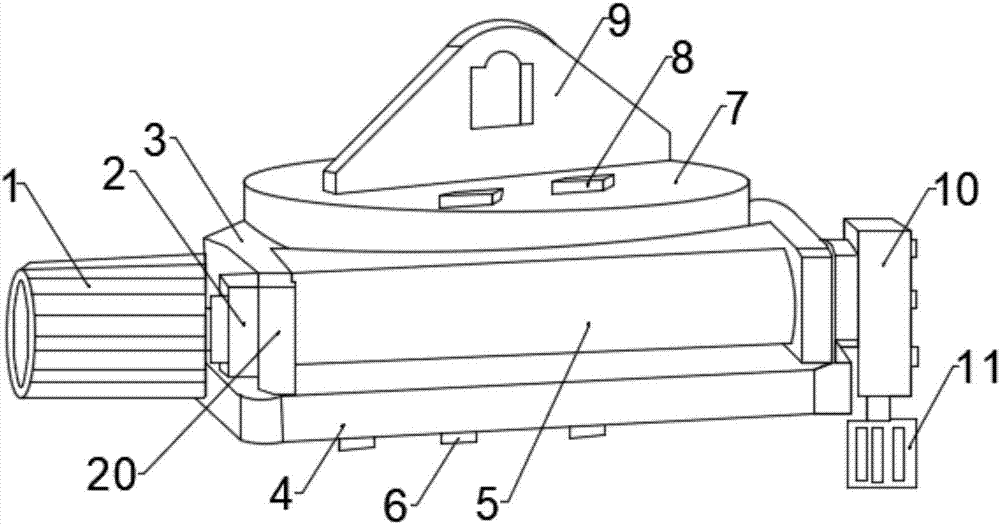

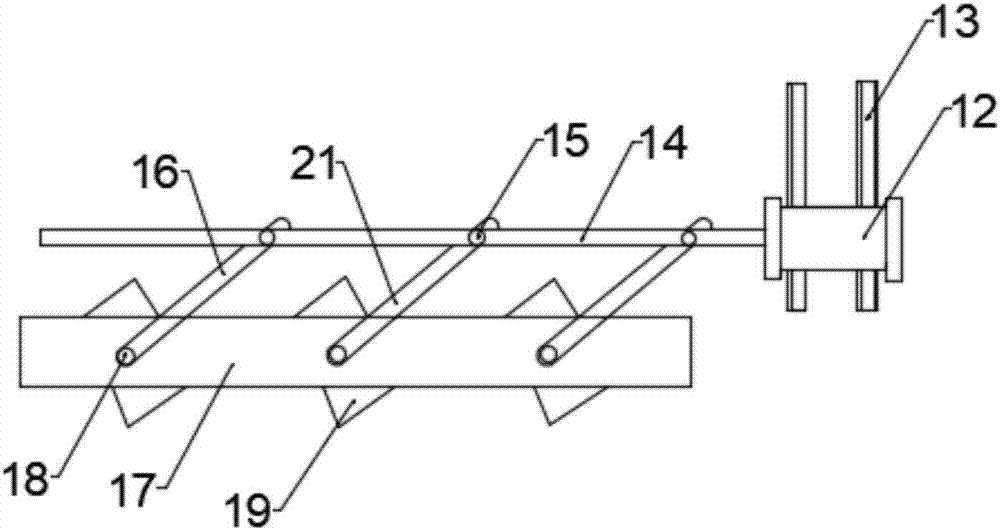

[0023] Such as figure 1 As shown, the present invention provides a limitable slewing device for a boom of a bridge crane, comprising a main motor 1 and a motor slewing adjustment mechanism 5, the output shaft 2 of the main motor 1 passes through the inner wall of the support frame 3 and the motor The rotary adjustment mechanism 5 is axially connected, the main motor 1 is fixedly installed on the left side of the operation platform 4, and a support frame 3 is arranged on the upper surface of the operation platform 4, and the left and right ends of the support frame 3 are all provided with There is an electromagnetic clutch 20, the upper shaft of the inner wall of the support frame 3 is connected to the motor rotation adjustment mechanism 5, and the motor rotation adjustment mechanism 5 is arranged on the upper surface of the operating platform 4, and the upper surface of the support frame 3 is also provided with A fixed plate 7, the upper surface of the fixed plate 7 is also pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com