Geometric parameter automatic adjusting mechanism and control method thereof

An automatic adjustment and geometric parameter technology, applied in the field of track measurement, can solve the problems of unstable force, easy tilting or flipping of the vertical adjustment mechanism, etc., and achieve the effect of stable screw transmission

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

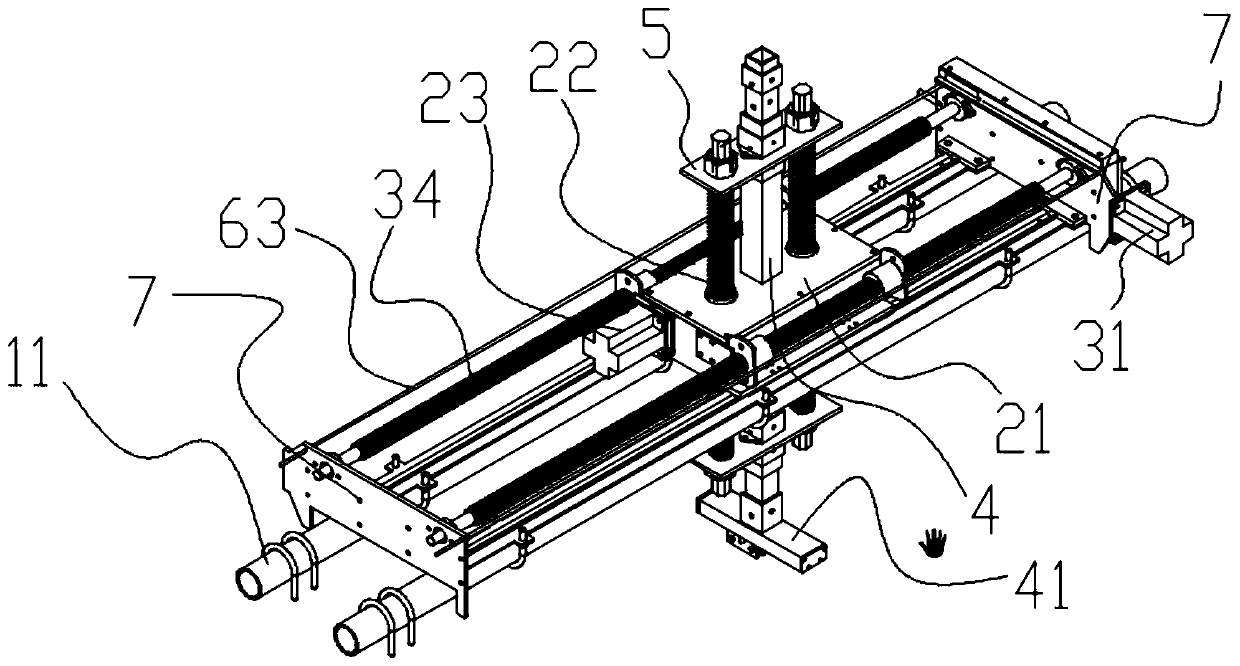

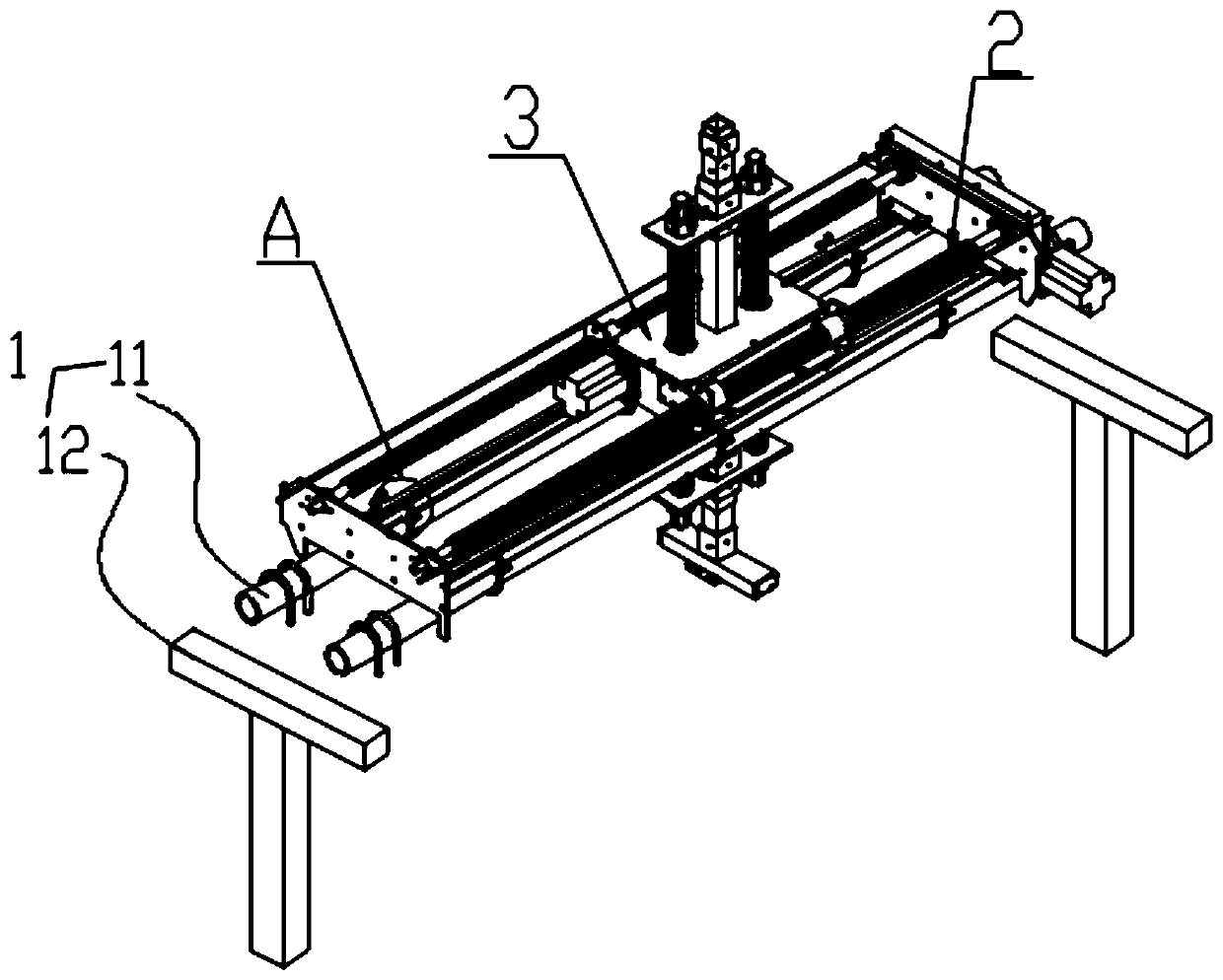

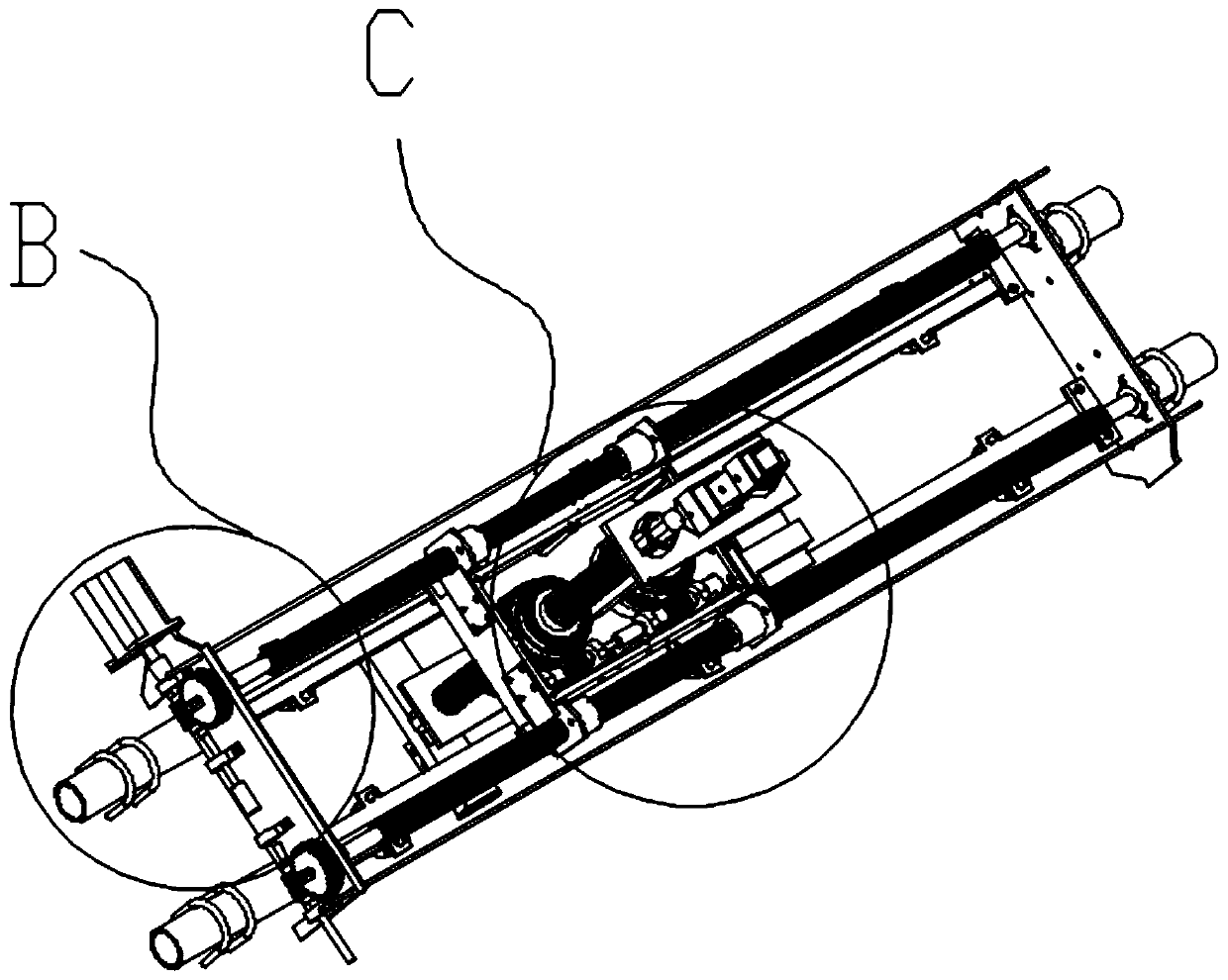

[0043] Such as Figure 1-6As shown, a geometric parameter automatic adjustment mechanism includes a load-bearing platform 1 and a vertical adjustment mechanism 2 and a horizontal adjustment mechanism 3 arranged on the load-bearing platform 1. The load-bearing platform 1 includes an installation steel pipe 11 and is provided with two The two ends of the installation steel pipe 11 are provided with mounting parts 7 for installing the horizontal adjustment mechanism 3; the horizontal adjustment mechanism 3 includes a first motor 31, a first turbine 32, a first worm 33 and multiple A horizontal transmission screw 34, the first turbine 32 and the first worm 33 are arranged on one side of one of the mounting parts 7, the horizontal transmission screw 34 is arranged between the mounting parts 7, and the horizontal transmission screw 34 Connect the first turbine 32, the output shaft of the first motor 31 is connected to the first worm 33; the vertical adjustment mechanism 2 includes a...

Embodiment 2

[0046] Such as Figure 1-6 As shown, in this embodiment, on the basis of Embodiment 1, the automatic adjustment mechanism also includes a connecting steel pipe 4, the two ends of the vertical transmission screw 22 are provided with a fixing frame 5, and the fixing frame 5 is connected to the base 21 is provided with a through hole for the connecting steel pipe 4 to pass through, the axis of the connecting steel pipe 4 is parallel to the axis of the vertical transmission screw 22 , and the bottom of the connecting steel pipe 4 is provided with a wire clamp mechanism 41 .

[0047] The connecting steel pipe 4 is connected with the vertical transmission screw rod 22 by the fixed frame 5, and the through hole for the connecting steel pipe 4 to pass is provided on the base 21 simultaneously. Make whole vertical adjustment mechanism 2 keep steady in the process.

Embodiment 3

[0049] Such as Figure 1-6 As shown, this embodiment is based on Embodiment 1, and both the horizontal conveying screw 34 and the vertical conveying screw 22 are two. The horizontal conveying screw 34 and the vertical conveying screw 22 are arranged in two in order to prevent tilting or overturning during the moving process.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com