Electromagnetic assembly structure of alternating current contactor and alternating current contactor

A technology of AC contactor and assembly structure, which is applied in the direction of electromagnetic relay, detailed information of electromagnetic relay, circuit, etc. It can solve the problems of shortening the service life of the coil, occupying a large space, and complicated wiring, so as to reduce the risk of short circuit, facilitate wiring, The effect of improving assembly efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

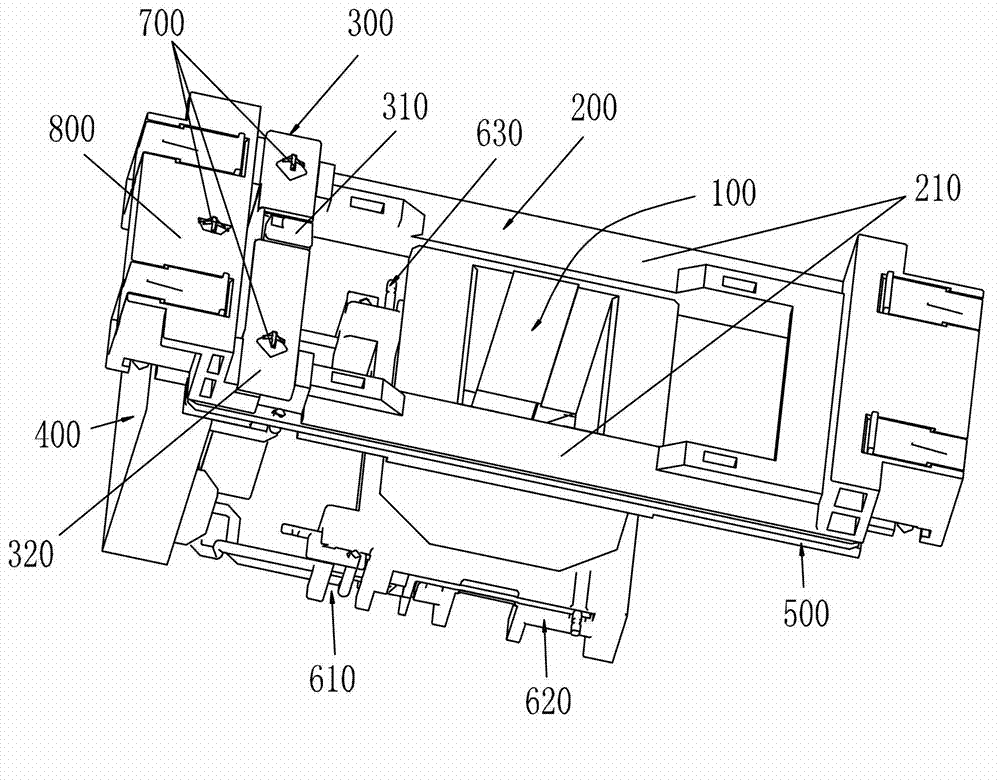

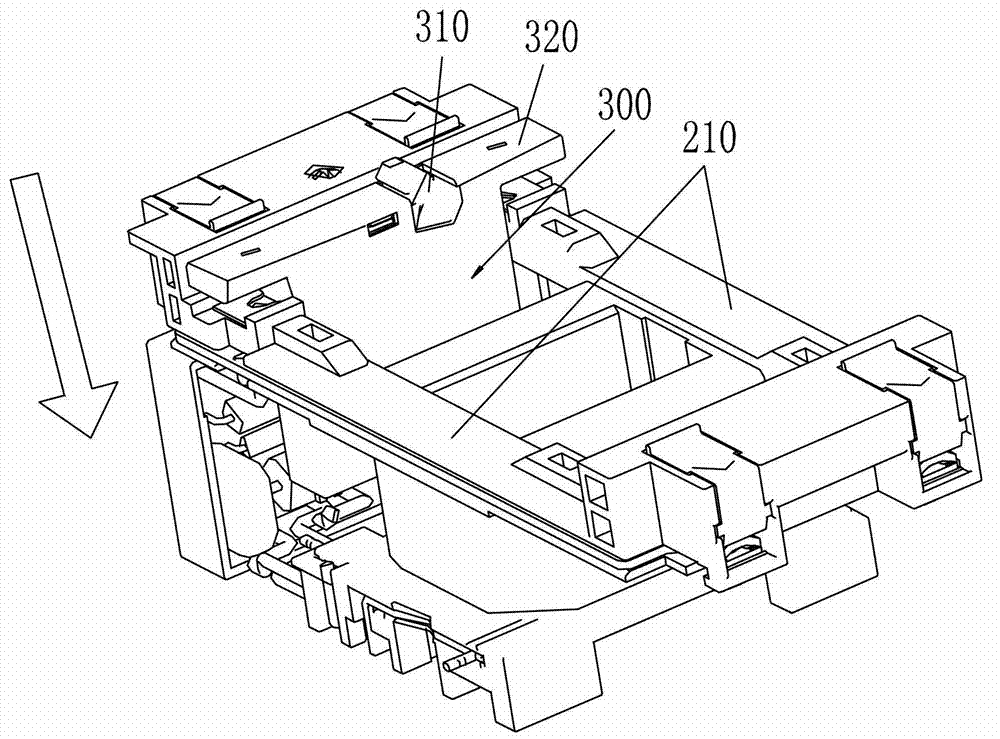

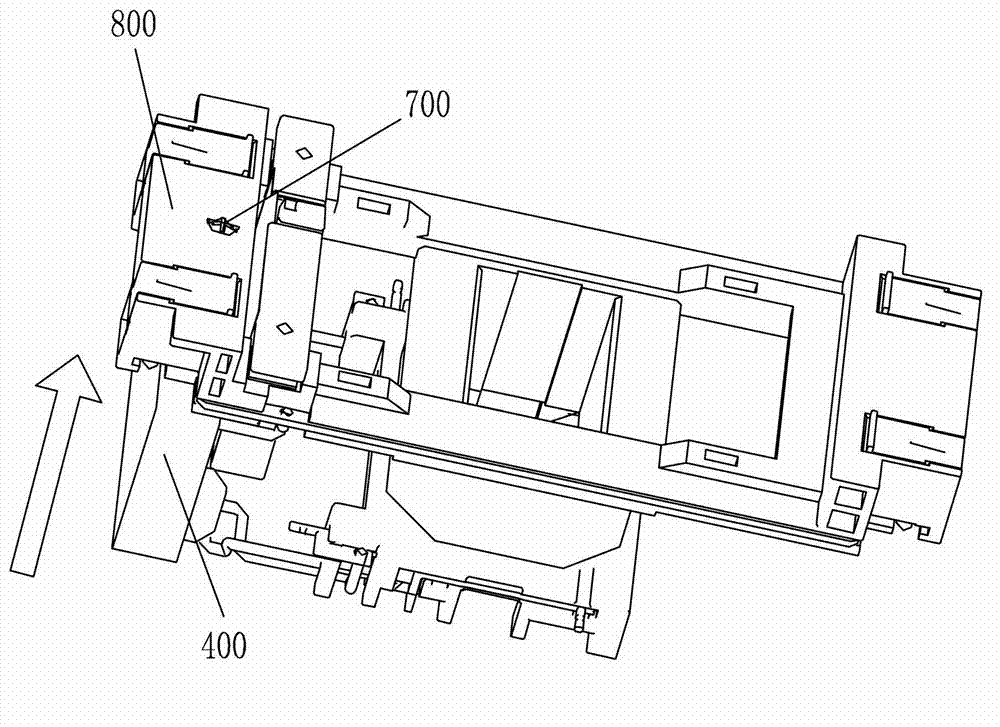

[0024] The invention discloses an AC contactor, which includes an electromagnetic assembly structure of the AC contactor. The electromagnetic assembly structure of the AC contactor includes a control module of the AC contactor, a double coil winding and a coil skeleton for fixing the double coil winding . The double-coil winding includes a starting winding and a holding winding. There is a common end between the starting winding and the holding winding. The lower end of the winding lug is provided with a winding lug; one end of the power lug is coupled to the control module, and the other end is connected to the power input end; one end of the winding lug is coupled to the control module, and the other end is connected to the double coil winding.

[0025] Because the present invention couples the power supply input terminal to the control module through the power supply lug, and couples the double-coil winding through the winding lug, the wiring is convenient and the assembly ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com