A shaped heater for an aerosol generating system

A heater and aerosol technology, used in water heaters, fluid heaters, pharmaceutical devices, etc., can solve problems such as inefficient heating of tobacco materials, achieve efficient heating treatment, reduce the possibility of damage, reduce temperature and The effect of electricity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

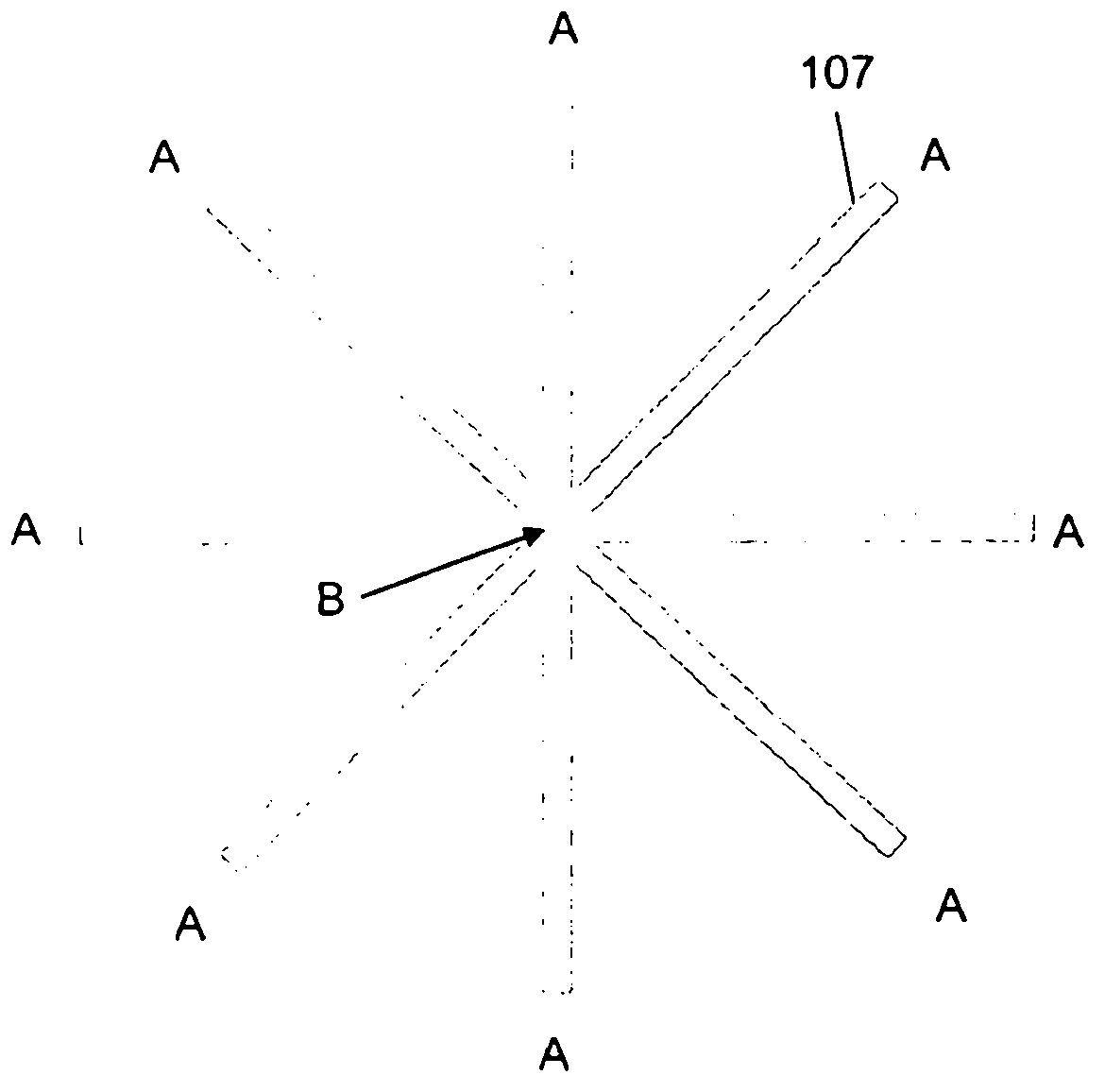

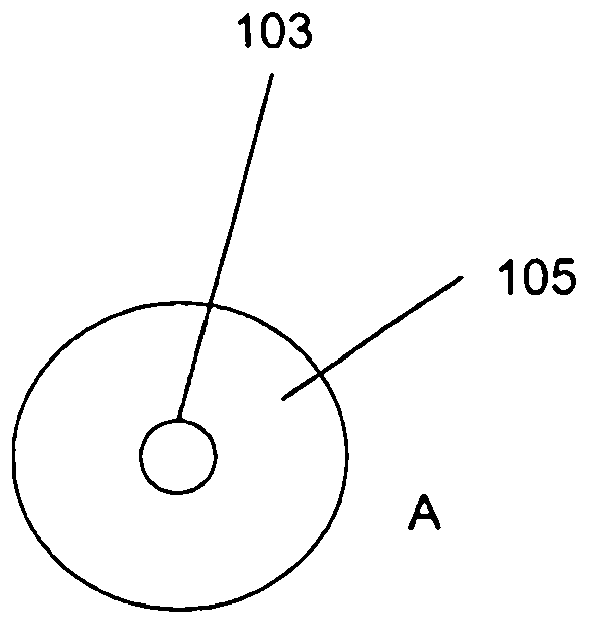

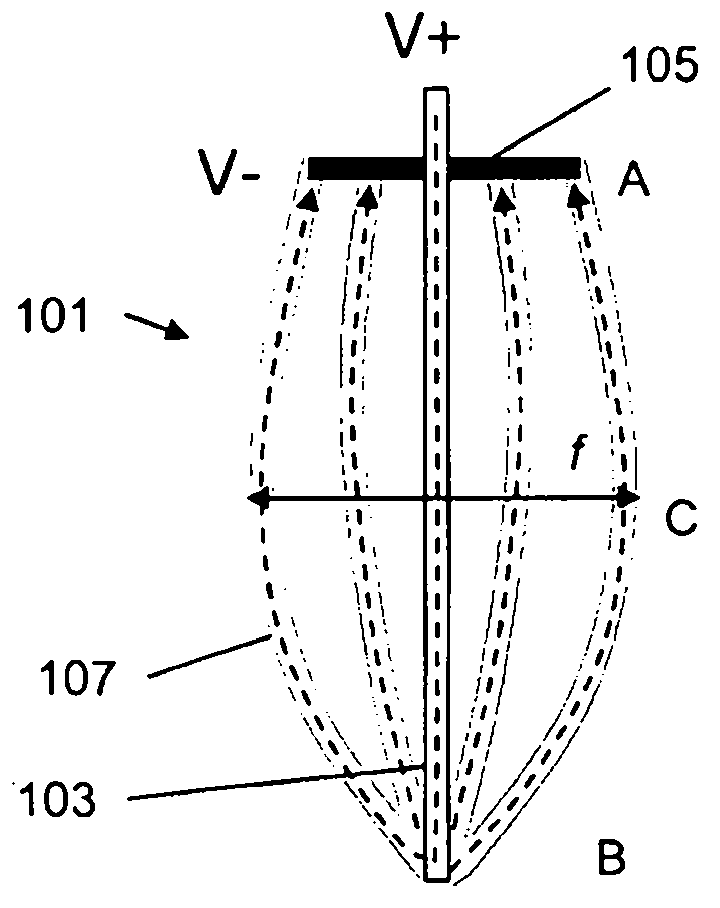

[0064] Figures 1 to 5 , 7 and 8 show a first embodiment of the heater of the present invention. Specific reference figure 1 , 2 and 3, the heater 101 comprises a conductive pin in the form of a common pin 103 , an annular ring 105 and a plurality of heating elements 107 . The assembled heater 101 has a ring end portion A, a heating end portion B and a middle portion C. As shown in FIG. figure 1 The heating element 107 is shown after it has been formed by flat stamping a sheet of suitable material before final assembly. figure 2 The ring portion including annular ring 105 and common pin 103 is shown prior to final assembly. The annular ring 105 may be an electrically insulating material, and the annular ring 105 acts as a support to hold image 3 Location of heating elements of the shape shown. The annular ring 105 can also hold the common pin 103 in a substantially central position on the ring. In the embodiment of centralized control (common control) to the heating e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com