A high-voltage electrostatic precipitator with fog curtain

An electrostatic precipitator, high-voltage electrostatic technology, applied in the direction of external electrostatic separator, electrostatic separation, chemical instruments and methods, etc., can solve the problem of flowing into the next electric field or directly discharging into the chimney from the outlet, corrosion of the electric field pole line of the electrostatic precipitator, Shorten the service life of the electrostatic precipitator and other problems, achieve the effect of improving the volt-ampere characteristics, prolonging the residence time, and improving the dust removal efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

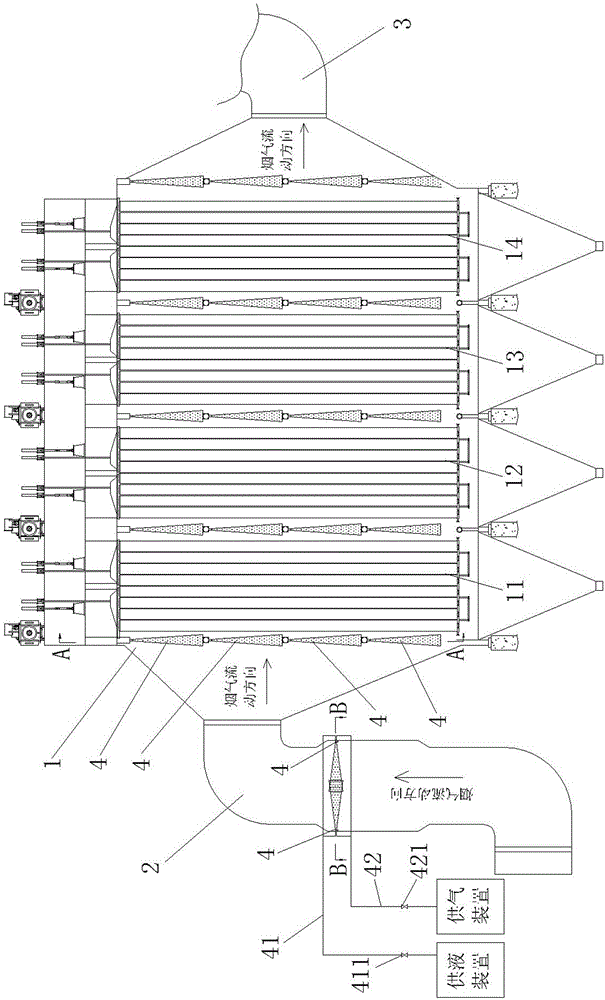

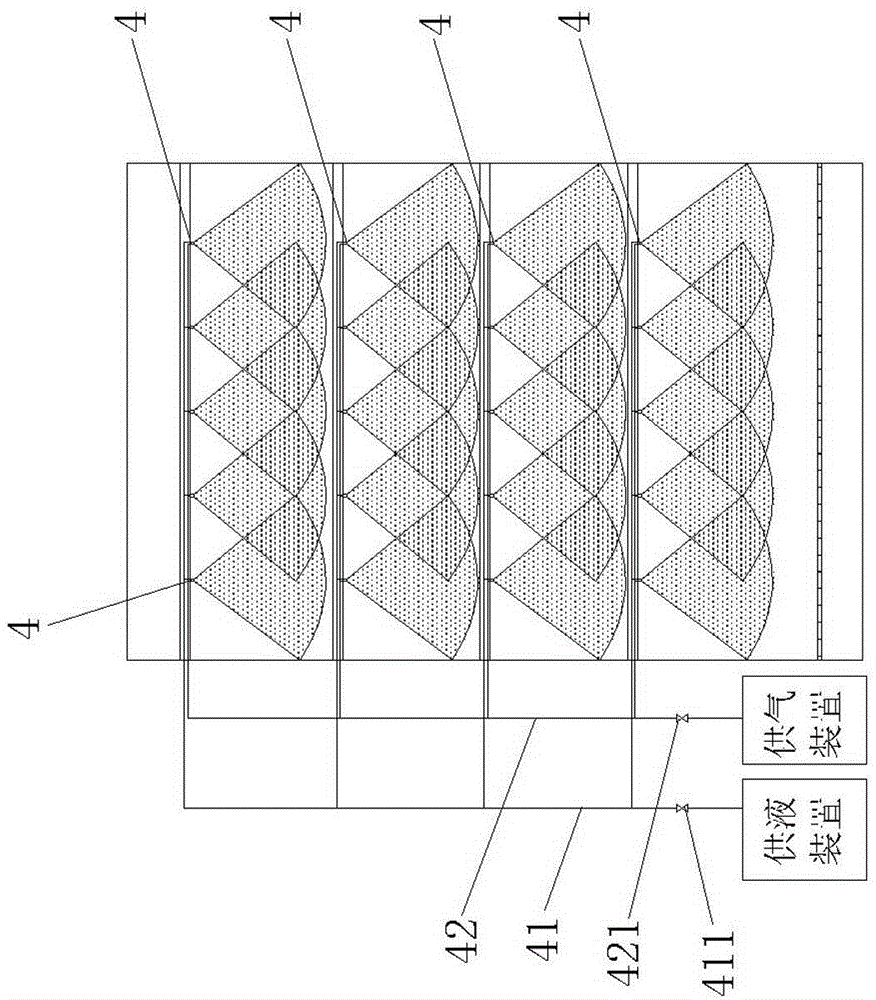

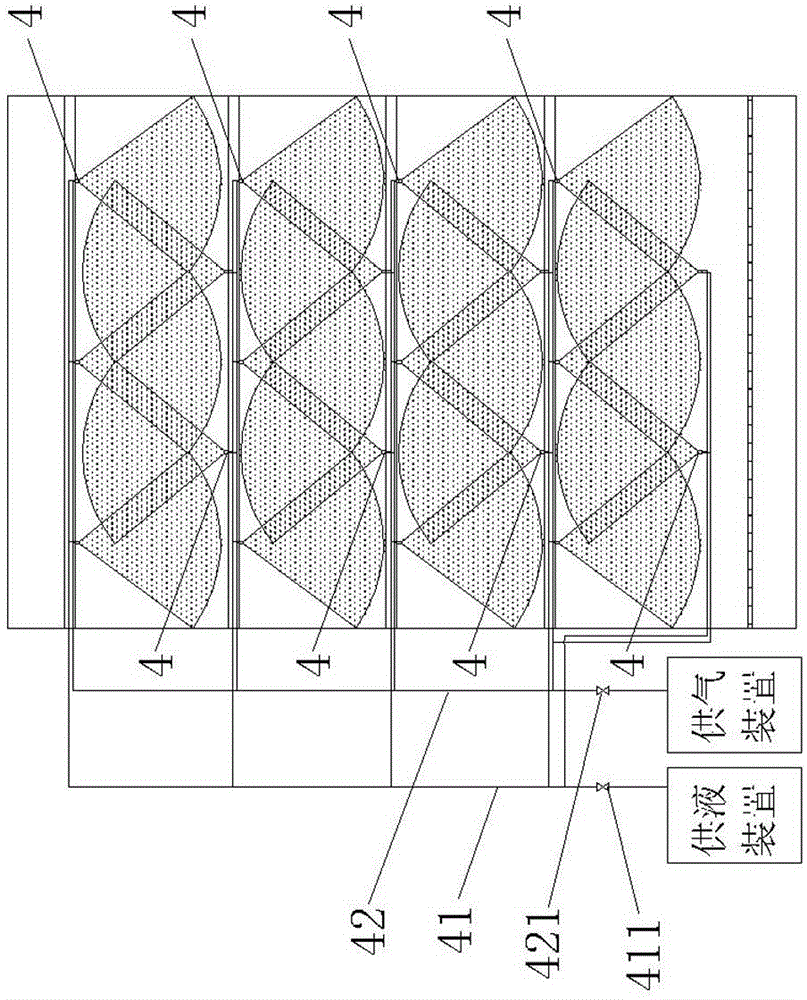

[0028] Embodiment one, Figure 1 to Figure 4 As shown, a high-voltage electrostatic precipitator with a fog curtain includes an electrostatic precipitator body 1, the front end of the electrostatic precipitator body 1 is connected with an air inlet flue 2, and the rear end of the electrostatic precipitator body 1 is connected with an air outlet flue 3 , the electrostatic precipitator body 1 is provided with a first electric field 11, a second electric field 12, a third electric field 13, and a fourth electric field 14. The structures of each electric field are the same. Flue gas between one electric field 11 and the second electric field 12, between the second electric field 12 and the third electric field 13, between the third electric field 13 and the fourth electric field 14, and behind the fourth electric field 14 A plurality of dry fog nozzles 4 are provided on the flow passage, and each dry fog nozzle 4 is connected with the liquid supply pipeline 41 and the air supply p...

Embodiment 2

[0035] Embodiment two, Figure 5 As shown, it is different from Embodiment 1 in that two fog curtains are arranged in front of the first electric field 11, and an ash hopper 5 is added below the two fog curtains. Can further improve the dust removal effect.

Embodiment 3

[0036] Embodiment three, Image 6 As shown, it is different from Embodiment 1 in that the structures of the first electric field 11, the second electric field 12, and the third electric field 13 are the same, and the fourth electric field 14 is the same as that of the first electric field 11, the second electric field 12 1. The structure of the third electric field 13 is different and adopts a rotating plate type electric field. It can better avoid the secondary flying of dust and overcome the back corona of high specific resistance dust.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com