Power tool

A technology of power tools and drive shafts, applied in the direction of grinding workpiece supports, etc., can solve the problems of time-consuming, inconvenient, laborious operation, etc., and achieve reliable and firm clamping effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

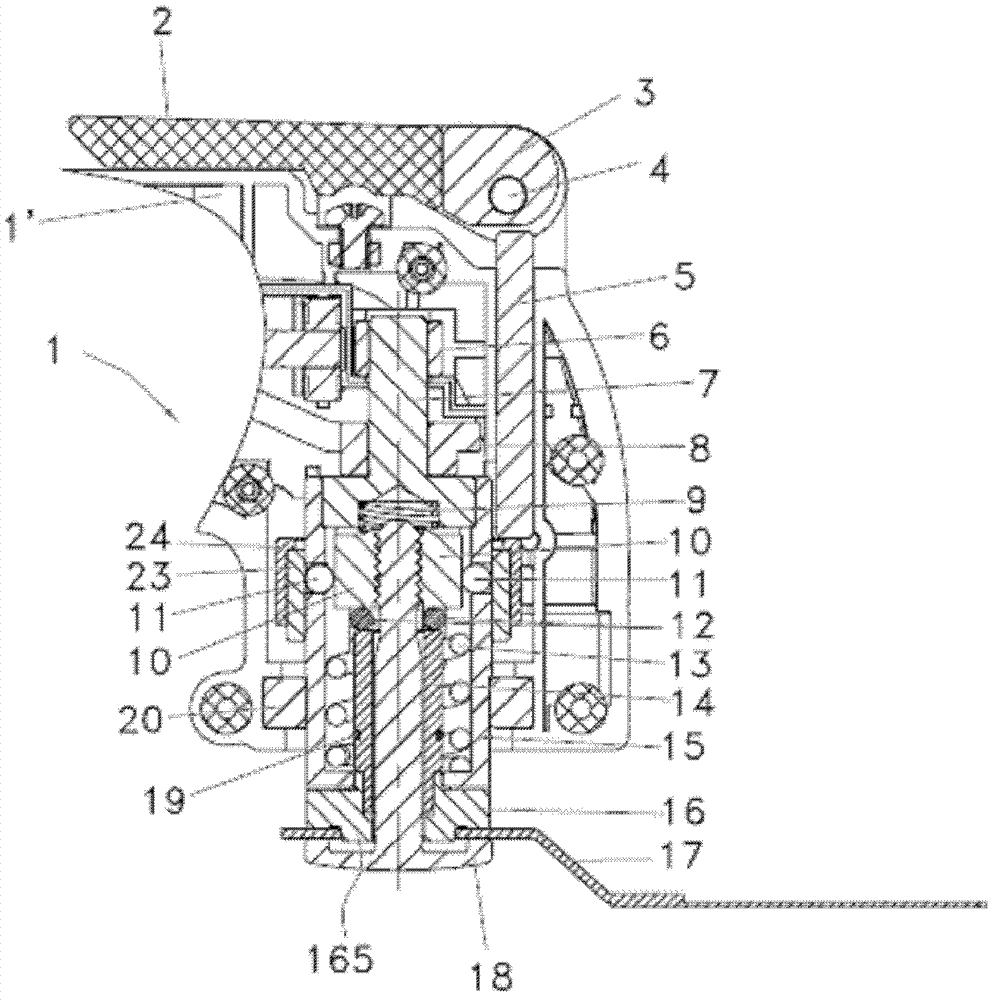

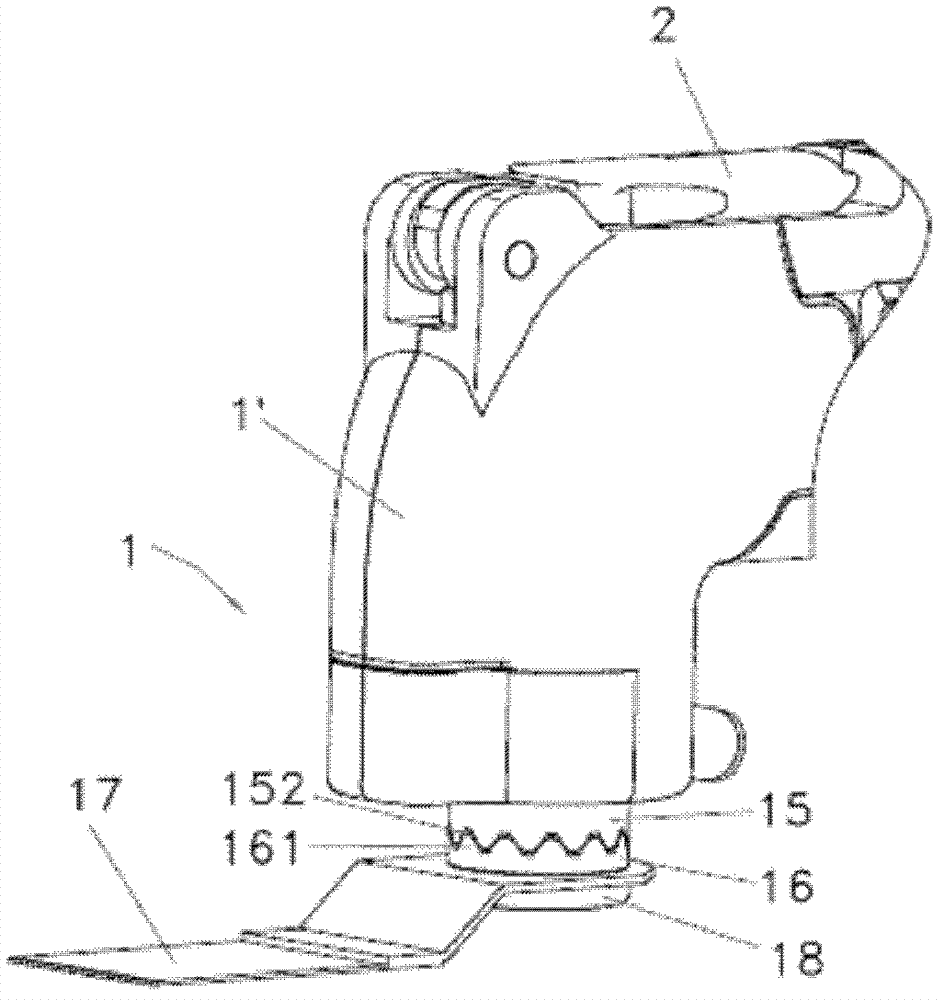

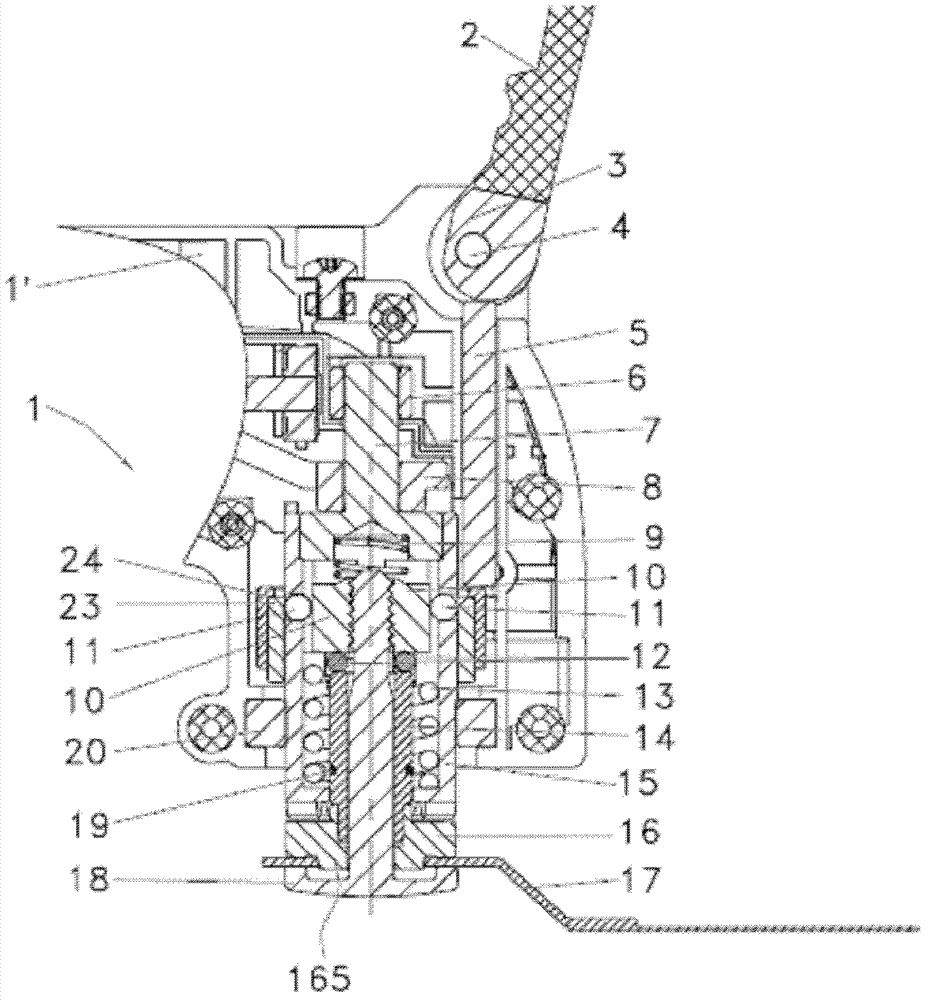

[0035] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings.

[0036] like Figure 1a to Figure 4c and Figure 7 As shown, the present invention is preferably described as a power tool 1 that drives the working element 17 in a vibrating manner. The driving in a vibrating manner can be broadly understood as the multifunctional tool on the existing market drives its working element to go back and forth around its power output shaft. Rotation or reciprocating motion combined with compound motion such as reciprocating movement, the working element can be broadly understood as a saw blade that can be used for sawing, a grinding wheel that can be used for grinding, etc. In this embodiment, the working element 17 is a saw blade. For saw blades used for cutting, the power drive shaft of the power tool 1 is supported by bearings 6 and 20, and under the action of the vibrating support 8, it ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com