Method for preparing antireflection glass with alkaline corrosion method

An anti-reflection glass and alkali corrosion technology, applied in the field of glass surface treatment, to achieve the effect of increasing visual clarity, good anti-reflection performance, and improving photoelectric or photothermal conversion efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0013] Na 2 O-CaO-SiO 2 System glass (soda-lime-silica system glass) substrate surface is cleaned with cleaning agent, and then rinsed with deionized water. Put the glass substrate into the corrosion tank containing NaOH solution with a concentration of 5%, and place it in the tank for 40h, and rinse it with deionized water after taking it out. Put the cleaned glass substrate into a drying oven at 200°C, dry it for 50 minutes, turn off the oven heating switch, and take it out of the oven when the temperature is naturally lowered to 50°C to obtain anti-reflection glass.

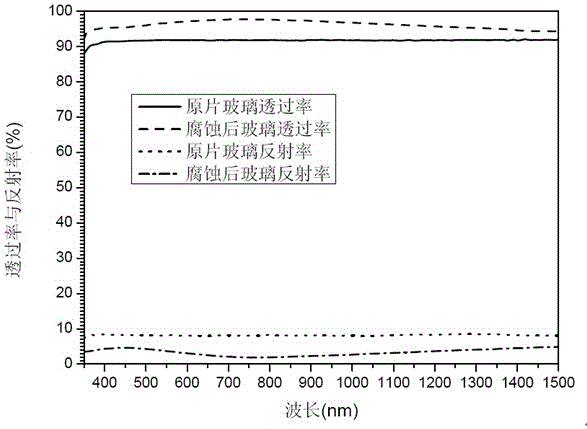

[0014] The measured transmittance and reflectance of anti-reflection glass, see figure 1 . The "original glass" in the picture refers to the Na 2 O-CaO-SiO 2 System glass (soda-lime-silicon system glass) substrate, its transmittance before anti-reflection treatment is about 91%, and its reflectance is about 8%. After the anti-reflection treatment, the visible light transmittance of the glass reaches 97%,...

Embodiment 2

[0016] Na 2 O-CaO-SiO 2 The surface of the glass substrate of the system is cleaned with a cleaning agent, and then rinsed with deionized water. Put the glass substrate into an etching tank containing 1.5% KOH and 0.007% NaOH solution, and place it in the tank for 20 hours, take it out and rinse it with deionized water. Put the cleaned glass substrate into a drying oven at 300°C, dry it for 30 minutes, turn off the heating switch of the oven, and take it out of the oven when the temperature is naturally lowered to 50°C to obtain anti-reflection glass.

Embodiment 3

[0018] Clean the surface of the Na2O-CaO-SiO2 system glass substrate for photovoltaic, photothermal, building, greenhouse and decoration that needs to be anti-reflection treated by calendering or float method with cleaning agent, and then rinse it with deionized water. Put the glass substrate into a solution containing 3% LiOH, 0.001% NaOH, 0.001% KOH and 0.08% Ca(OH) 2 The corrosion tank of the solution, and placed in the tank for 0.5h, after taking it out, rinse it with deionized water. Put the cleaned glass substrate into a drying oven at 500°C, dry it for 10 minutes, turn off the heating switch of the oven, and take it out of the oven when the temperature is naturally lowered to 50°C to obtain anti-reflection glass.

PUM

| Property | Measurement | Unit |

|---|---|---|

| reflectance | aaaaa | aaaaa |

| reflectance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com