In-site heating regeneration maintenance vehicle for asphalt pavements

A technology of asphalt pavement heating and regeneration, which is applied in the field of integrated asphalt pavement plowing, compacting vehicles, and paving, which can solve the problems of increasing work costs, achieve on-site cost savings, high-efficiency repair operations, and realize reasonable space The effect of using

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

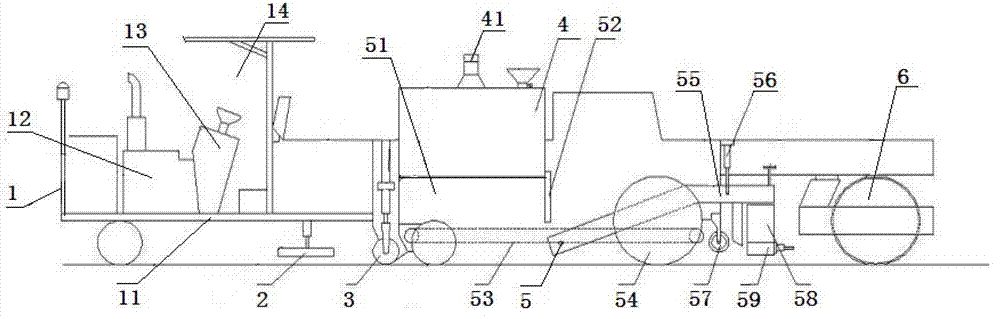

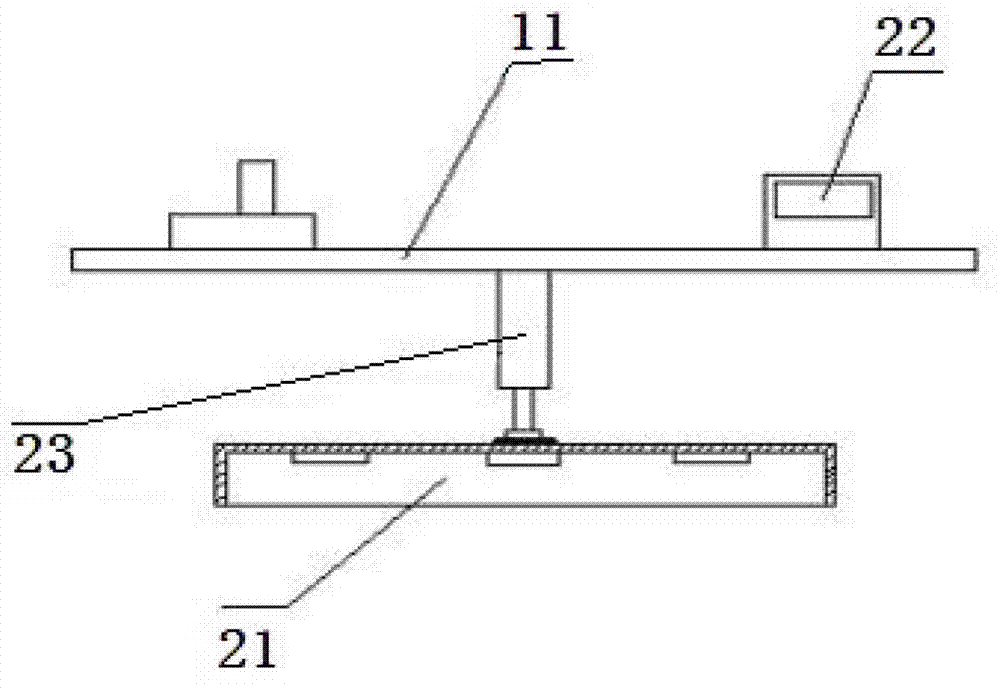

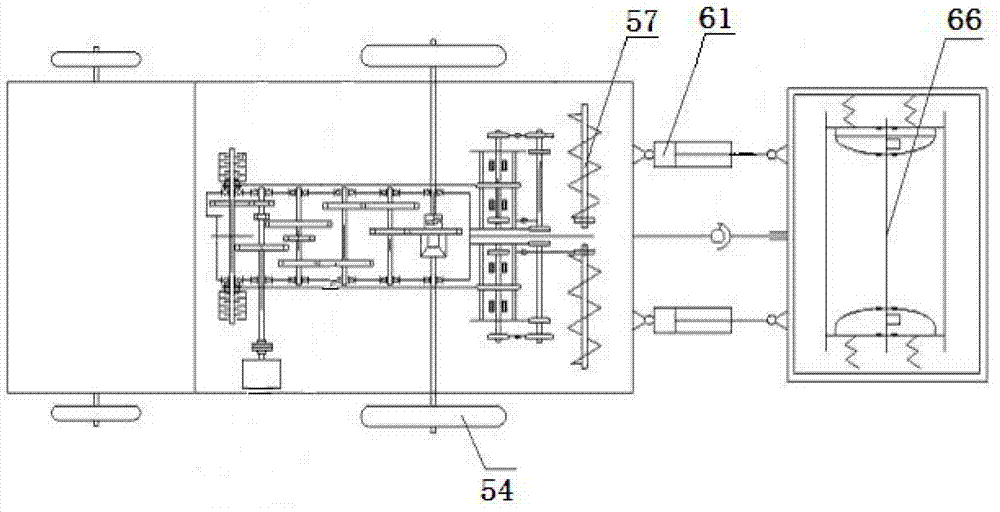

[0024] figure 1 It is a schematic diagram of the overall structure of the in-situ heating regeneration maintenance vehicle for asphalt pavement of the present invention, figure 2 It is a structural schematic diagram of the road surface heating device of the asphalt pavement in-situ heating regeneration maintenance vehicle of the present invention, image 3 It is a structural principle diagram of the asphalt paving device 5 and the road surface compacting device 6 of the asphalt pavement heating regeneration maintenance vehicle in situ of the present invention, Figure 4 It is a schematic diagram of the hydraulic system of the asphalt pavement in-situ heating regeneration maintenance vehicle of the present invention, Figure 5 It is a structural schematic diagram of the compacting device of the in-situ heating regeneration maintenance vehicle for asphalt pavement of the present invention, Figure 6 It is a structural schematic diagram of the planing and milling device of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com