Novel hydraulic gear-shifting pressure regulating valve

A pressure regulation and hydraulic technology, applied to components with teeth, belts/chains/gears, mechanical equipment, etc., can solve the problems of increased shift time, prolonged oil filling process of shift clutches, etc., to shorten shift time Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

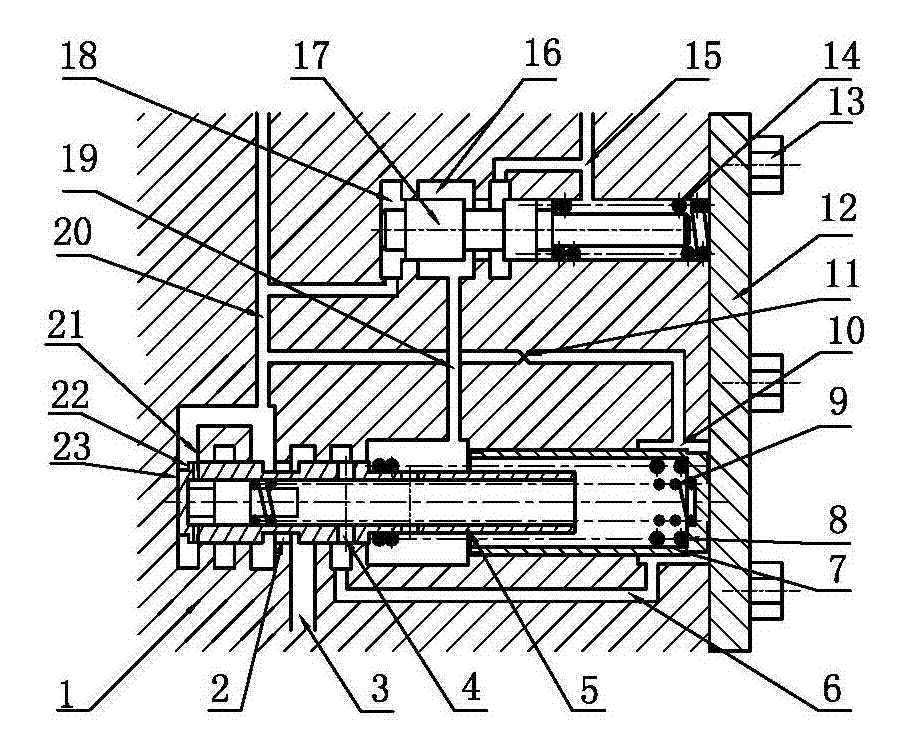

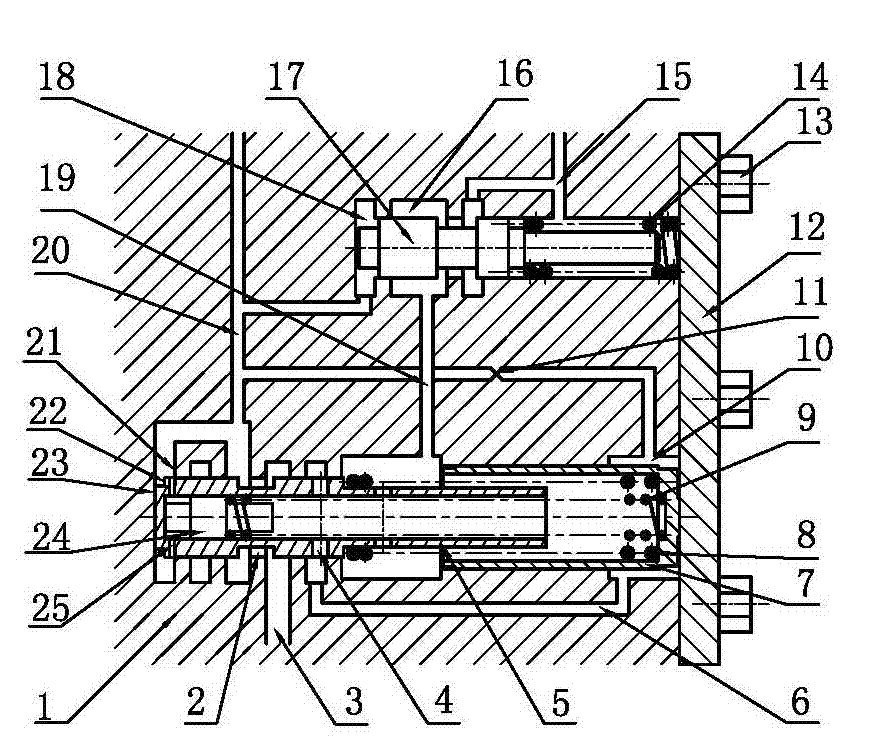

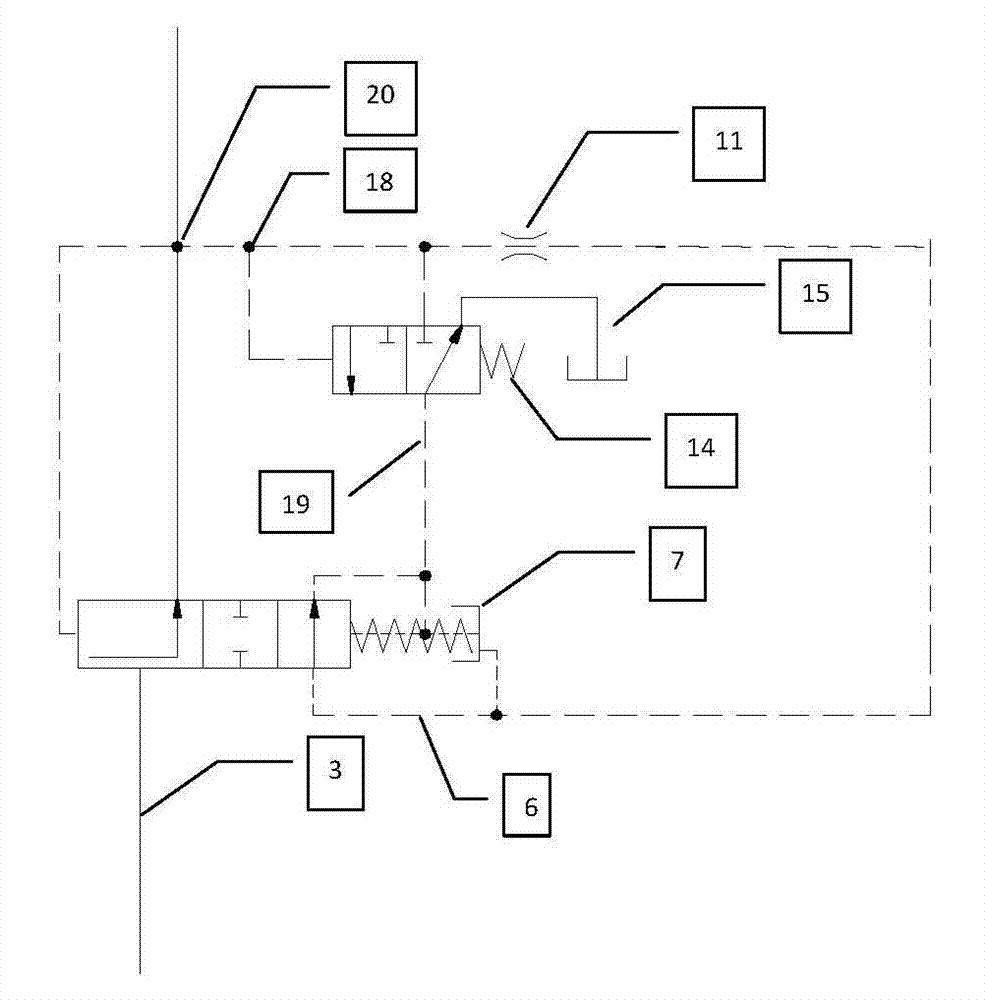

[0021] see image 3 , a new type of hydraulic shift pressure regulating valve, mainly including a body, a pressure control valve spool, an accumulator plunger, an accumulator main spring, an accumulator secondary spring, an orifice, a pressure setting valve spring, a pressure Setting valve spool, quick oil filling spool, quick oil filling small hole. The spool of the pressure control valve is set in the body of the pressure regulating valve for hydraulic shifting. The spool of the pressure control valve is equipped with a quick oil filling spool inside. The left end of the accumulator secondary spring interacts with the right end of the quick oil filling spool to store The right end of the secondary spring of the accumulator interacts with the plunger of the accumulator, the left end of the main spring of the accumulator interacts with the spool of the pressure control valve, the right end of the main spring of the accumulator interacts with the plunger of the accumulator, and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com