Axial Rolling Bearings

A rolling bearing and axial technology, applied in the field of axial rolling bearings, can solve problems such as bearing disc wear, axial deep groove ball bearing piston compressor failure, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

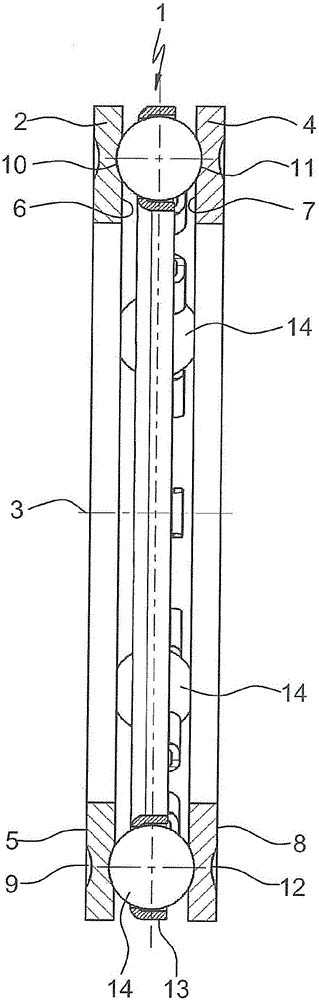

[0012] The drawing clearly shows an axial rolling bearing 1 configured as a single-row axial deep groove ball bearing, which has a first annular bearing disk 2 and is arranged at a distance from this bearing disk in a common The second annular bearing disk 4 on the central axis 3. The bearing disks 2 , 4 are formed here on their inner disk surfaces 6 , 7 with two groove-shaped rolling tracks 10 , 11 pointing toward one another, in which a large number of rollers arranged in rows roll. The rolling elements 14 are held at a uniform distance relative to one another by the bearing cage 13 .

[0013] Furthermore, it is clear from the figures that the two bearing disks 2 , 4 are configured according to the invention on their outer disk surfaces 5 , 8 with further running tracks on their inner disk surfaces 6 , 7 10, 11 Groove-shaped rolling tracks 9, 12 that are identical in terms of positioning, diameter and groove depth, via which the bearing discs 2, 4 can be selected independen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com