Dust collector

A vacuum cleaner and dust technology, which is applied in the direction of vacuum cleaners, suction filters, cleaning equipment, etc., can solve the problems of polluting the body and achieve the effect of enhancing comfort, simple structure, and small changes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

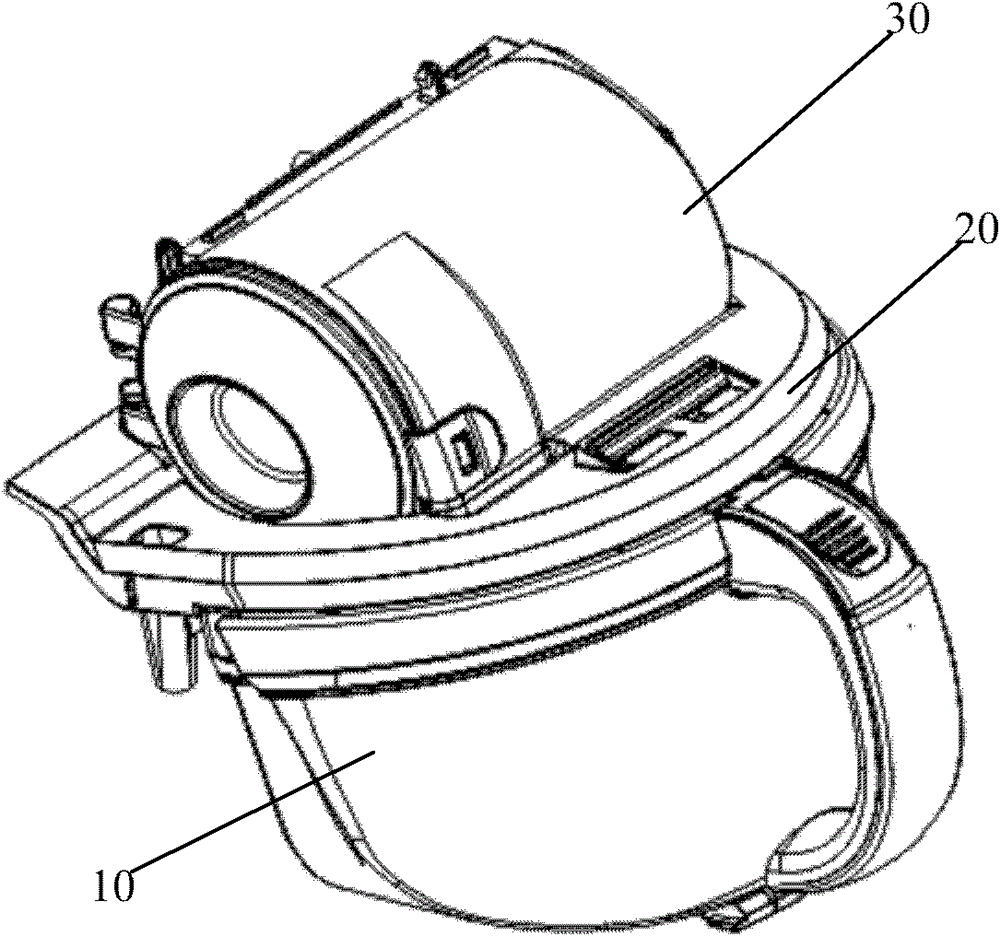

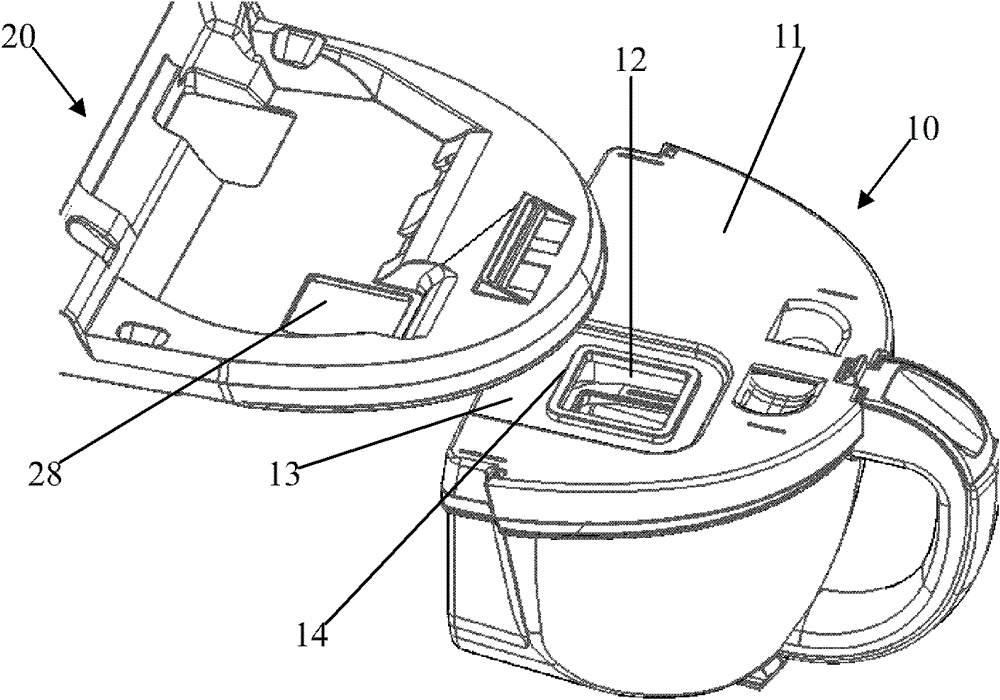

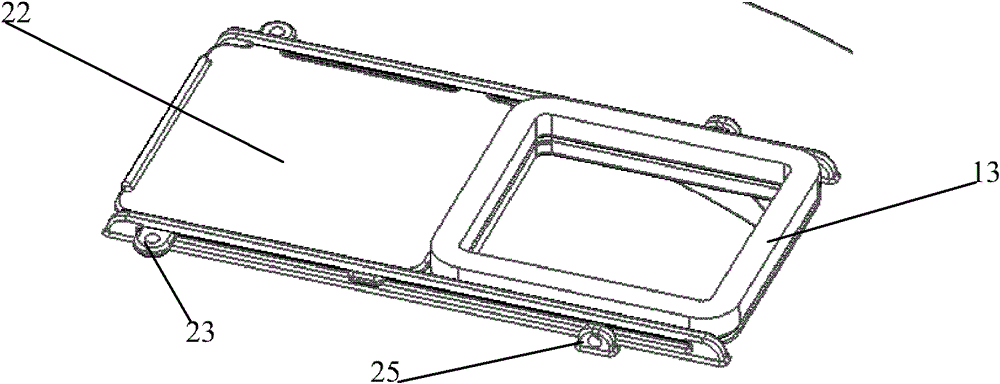

[0019] Such as figure 1 As shown, the horizontal vacuum cleaner of the present invention includes a cylindrical dust collection bucket 10, a dust separator 30 arranged above the dust collection bucket 10, and a dust collection bucket fixed on the body to support the limit and the fixing bracket 20 of the dust separator. The air inlet of the dust separator is connected with the brush head through a pipeline to suck the airflow entrained with dust into it and separate it, and the dust outlet of the dust separator is arranged under one side thereof. The opening end of the dust collecting bucket is provided with a bucket cover, and the bucket cover is provided with dust falling holes. When the dust collecting bucket is installed and set, the dust falling holes on the bucket cover are arranged correspondingly to the dust outlet of the dust separator...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com