Lubricating roller

A technology of rollers and axles, applied in the field of mechanical parts, can solve the problems of easy failure and large friction of casters, and achieve the effect of reducing failure rate, reducing stress and prolonging service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

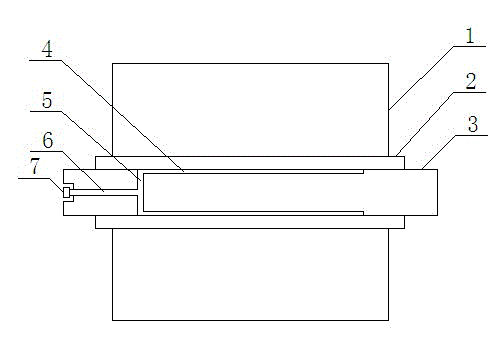

[0012] like figure 1 It is a schematic diagram of the present invention, a lubricating roller, including a wheel body 1, a shaft sleeve 2 and a wheel shaft 3, the wheel body 1 is set on the shaft sleeve 2, the shaft sleeve 2 is set on the wheel shaft 3, and the surface of the wheel shaft 3 is provided with two oil grooves 4. An oil delivery passage 5 is provided inside, and an oil injection passage 6 is provided at the end. The outer end of the oil injection passage 6 exposes the end face of the wheel shaft 3, and the inner end is vertically connected to the middle part of the oil delivery passage 5, and the oil delivery passage 5 is connected to the oil tank 4. The two oil grooves 4 are symmetrical about the axis of the axle 3 . Both ends of the oil delivery channel 5 are vertically connected to two oil grooves 4 respectively. The outer end of the oil injection passage 6 is provided with a filler nozzle 7 .

[0013] An oil groove 4 is added on the wheel shaft 3, and the rot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com