Method and equipment for drying filter stick

A drying method and technology of drying equipment, applied in dryers for static materials, drying solid materials, lighting and heating equipment, etc., can solve the problems of poor taste, slow drying speed of filter rods, etc., to avoid too hard or too soft, shortening Drying time, simple effect of equipment structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] First introduce the present invention in the specific embodiment of the test:

[0023] Test equipment: electronic balance, infrared moisture meter, caliper, electric furnace, water bath box, laboratory water ring vacuum pump, beaker.

[0024] Weigh the filter rod before applying glue, that is, the filter element and the outer wrapping paper weigh 4.88g in total, and then apply water-based glue to the filter rod, weighing 5.24g.

[0025] Put the filter rod brushed with water-based glue into the beaker, put the beaker into the water bath, and use a water ring vacuum pump to evacuate the beaker to below 0.011MPa, and control the temperature of the water bath at 45°C. Under this environment, the water bath was 1.5 hours. Afterwards, return the beaker to normal pressure and remove the filter rod. Observe that the shape of the filter rod has no defects such as shrinkage, measure the radial and circumferential dimensions of the filter rod, and there is no obvious change, and...

Embodiment 2

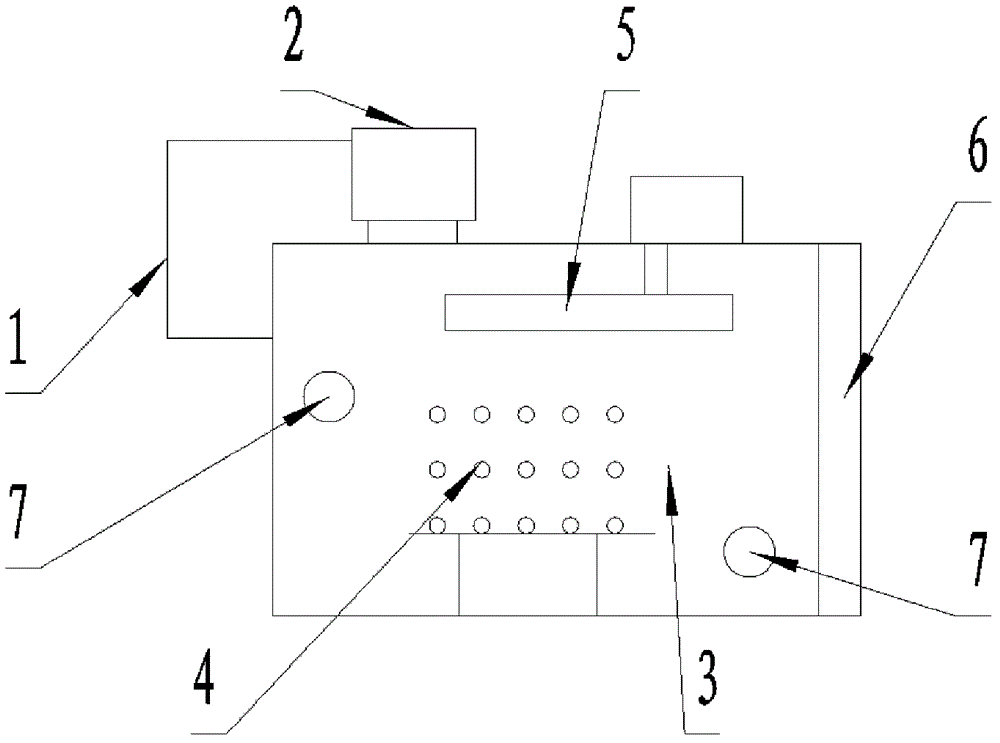

[0027] In order to simulate the actual production situation, in this embodiment, the filter rod is placed in a special drying equipment, such as figure 1 ,. The drying equipment includes: a cabinet 3 for accommodating filter rods, one end of the cabinet 3 is provided with a door 6 for filter rods to enter and exit, a vacuum device 2 is provided outside the cabinet 3, and there is a vacuum device 2 between the cabinet 3 and the vacuum device 2. Line 1 is connected. When the filter rod is put into the cabinet of the drying equipment and the door 6 is closed, the cabinet is in a sealed state, and the vacuum device 2 can be opened to vacuum the cabinet 3 . Inside the cabinet 3 is also provided with a heating device 5, the heating device 5 can raise the temperature in the cabinet, so that the filter rod can be dried at a suitable temperature, which can be dried quickly and the drying efficiency can be improved. A blowing device 7 is also arranged inside the cabinet 3, and of cour...

Embodiment 3

[0030] This embodiment also adopts the drying equipment described in Embodiment 2, except that the heating device adopts an electric heating rod device for heating. After the bonded filter rod is put into the case, start the vacuum device to reduce the pressure inside the case to below 0.011MPa, then energize the electric heating rod to heat the inside of the case at a heating rate of 8°C / min, and put the container The internal temperature is controlled within 50°C, and kept in this environment for 3 hours. Afterwards, the filter rod is taken out to obtain a qualified filter rod product.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com