Preparation method for aluminum pot

An aluminum pot and pot body technology, which is applied to cooking utensils, household appliances, applications, etc., can solve the problems of high environmental pollution, large investment in molds, and high cost of pots, so as to avoid environmental pollution, reduce production costs, and reduce costs. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

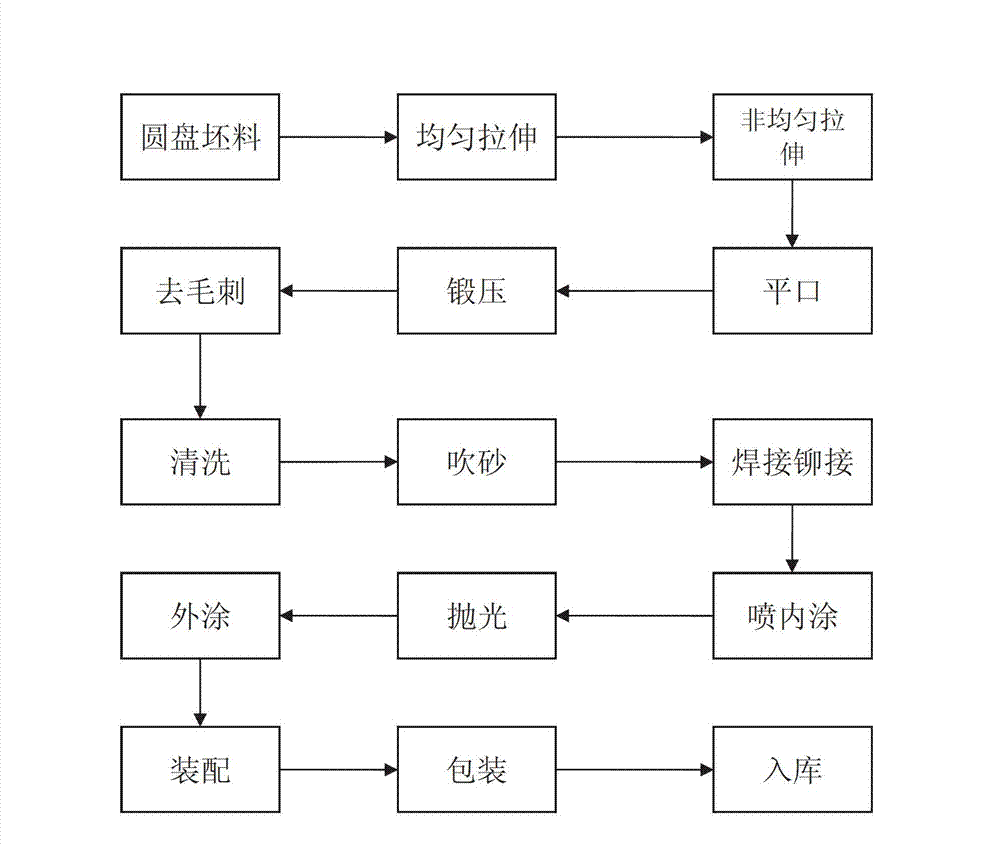

[0017] Example 1, see figure 1 Shown: the preparation method of the aluminum pan, including the following steps in turn:

[0018] A) Material preparation: Cut the aluminum plate into a disc blank, and the thickness of the disc is 8mm.

[0019] B) Uniform stretching: the disc blank is uniformly stretched to form a uniform pot body. The stretching equipment used is a common stretching machine. After stretching, the thickness of the bottom of the pot and the wall of the pot is relatively uniform. That is, the average thickness d of the bottom of the pot and the wall of the pot is both d=3.9mm.

[0020] C) Non-uniform stretching: the pot wall of the uniform pot body is thinned and stretched, and at the same time, the bottom of the uniform pot body is thickened to form a non-uniform pot body. The equipment used is a commonly used thinning and stretching machine. After stretching, the average thickness D of the bottom of the pot is 4.5 mm, and the average thickness of the pot w...

Embodiment 2

[0026] Embodiment 2: the difference with embodiment 1 only lies in:

[0027] The average thickness d of the bottom of the pot and the wall of the pot formed in step B) are both: d=4.0mm;

[0028] The average thickness D of the bottom of the pot body formed in step C) is 4.7 mm, and the average thickness of the pot wall is 2.7 mm.

[0029] The average thickness of the bottom of the pot formed in this embodiment is about 4.7 mm; the average thickness of the pot wall is about 2.7 mm.

Embodiment 3

[0030] Embodiment 3: the difference with embodiment 1 only lies in:

[0031] The average thickness d of the pan bottom and the pan wall of the uniform pan body formed in step B) is: d=4.2mm;

[0032] The average thickness D of the bottom of the pot body formed in step C) is 5 mm, and the average thickness of the pot wall is 2.8 mm.

[0033] The average thickness of the bottom of the pot formed in this embodiment is about 5 mm; the average thickness of the pot wall is about 2.8 mm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com