A kind of spherical hob manufacturing method

A manufacturing method, spherical technology, applied in the field of tool manufacturing, can solve the problems of long time-consuming and high processing costs of spherical hobs, and achieve the effects of saving design and manufacturing costs, improving processing efficiency, and reducing manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

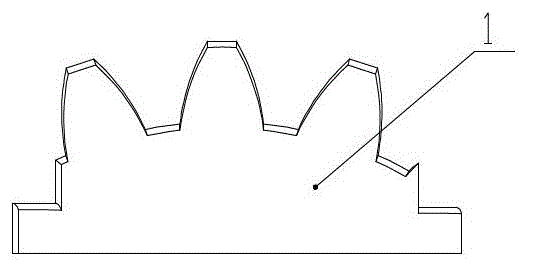

[0022] 1. The processing of the blade: the structure of the blade is as follows: figure 1 as shown,

[0023] (1) Reasonable selection of gear shaper cutter:

[0024] Select the size of the gear shaper cutter according to the required modulus and diameter of the spherical hob, and determine the number of gear shaper cutters required according to the number of blades of the hob and the number of teeth of the gear shaper cutter, so as to save the gear shaper cutter to the greatest extent.

[0025] (2) Grinding:

[0026] On the surface grinder, use the small end face of the gear shaper cutter as a reference to roughly grind the large end face. Grind the rake angle on the blade to 0°.

[0027] (3) Wire EDM:

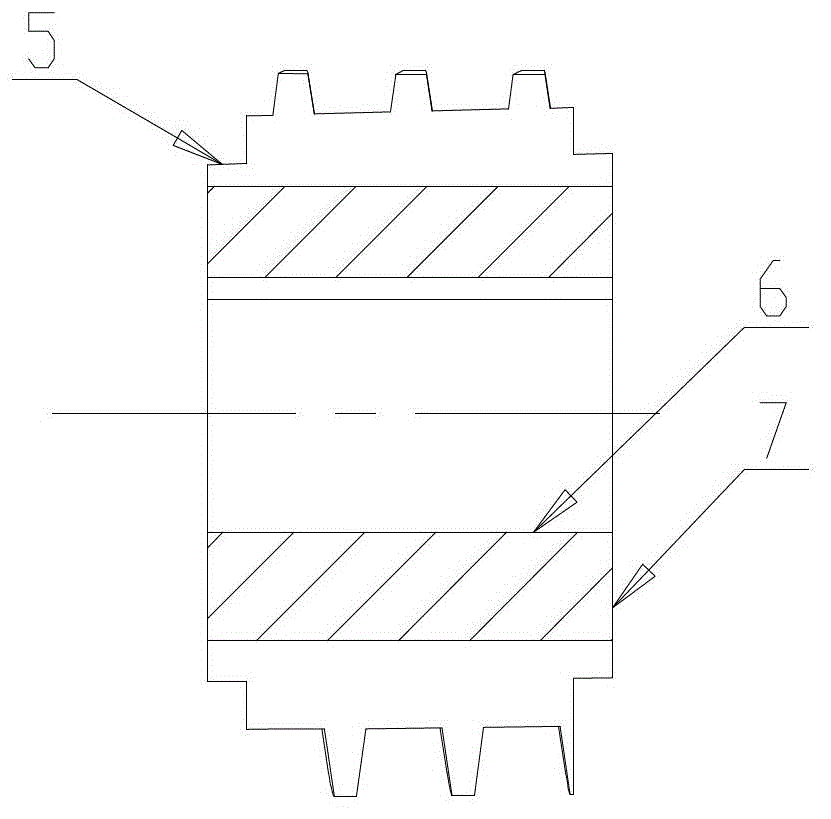

[0028] Based on the large end face, the wire cutting gear shaper is used to process the width of the gear shaper to half of the width of the tooth groove on the cutter body. Based on the small end face of the gear shaper cutter and the outer circle of the cutter teeth, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com