A powertrain hydraulic mount with throttle disc

A powertrain, hydraulic mount technology, applied in power plant, jet propulsion, internal combustion propulsion, etc., can solve the problems of insufficiency, limited dynamic hardening frequency, unfavorable vibration isolation, etc., to improve the vibration isolation performance, prolong the Effect of high frequency dynamic hardening frequency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments:

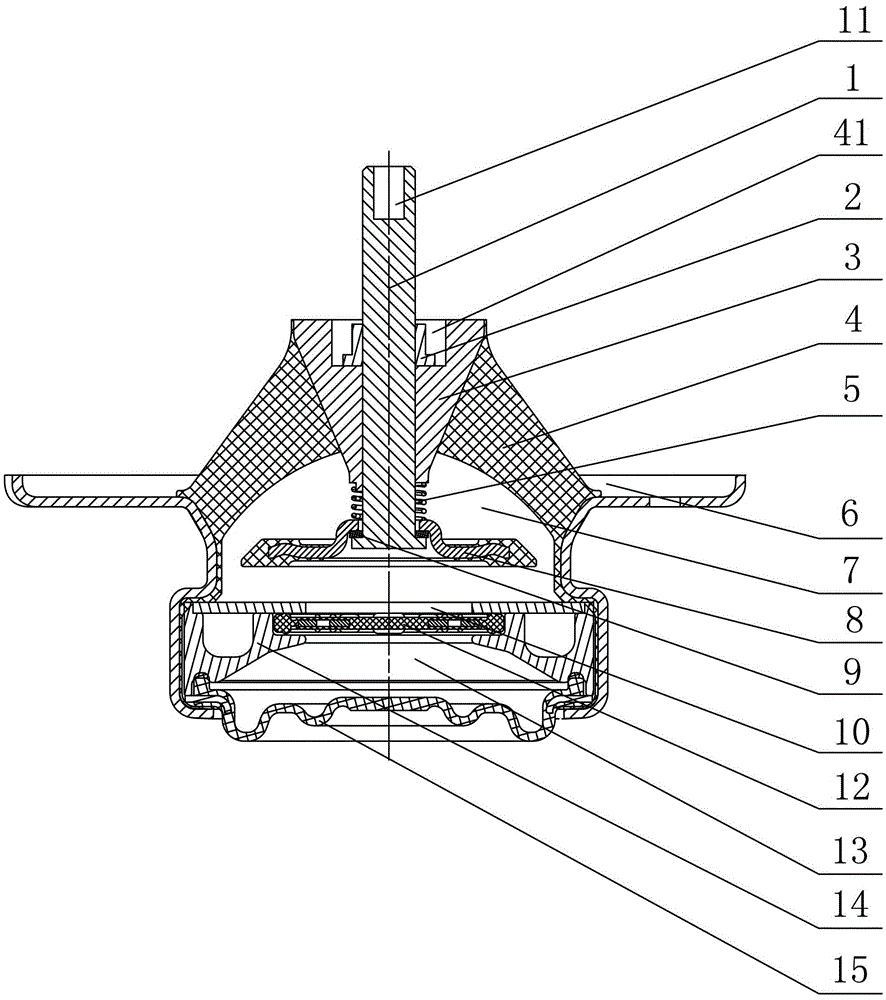

[0020] like figure 1 As shown, a powertrain hydraulic mount with a throttle disc includes a connecting bracket 6 , an elastic main spring 4 arranged on the connecting bracket 6 , an upper liquid chamber 7 and a lower liquid chamber 13 . The elastic main spring 4 is provided with an inner core 3; the upper liquid chamber 7 and the lower liquid chamber 13 are separated by the flow channel assembly, and a throttle disc 8 is arranged in the upper liquid chamber 7; the throttle disc 8 and the inner core 3 Connected by bolts 1 , a spring 5 is arranged between the throttle disc 8 and the inner core 3 .

[0021] The lower end of the bolt 1 is provided with an inner hexagonal screw hole 11 , and the inner core 3 is provided with a threaded hole matched with the bolt 1 .

[0022] The upper end surface of the inner core 3 is provided with a gr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com