Liquid aluminum transport tank car

A liquid aluminum and transport tank technology, applied in the field of tank trucks, can solve the problems of high temperature, easy cooling and crystallization, and is not suitable for transporting liquid aluminum, and achieves the effect of preventing solidification and temperature reduction, preventing infiltration, and having good thermal insulation effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

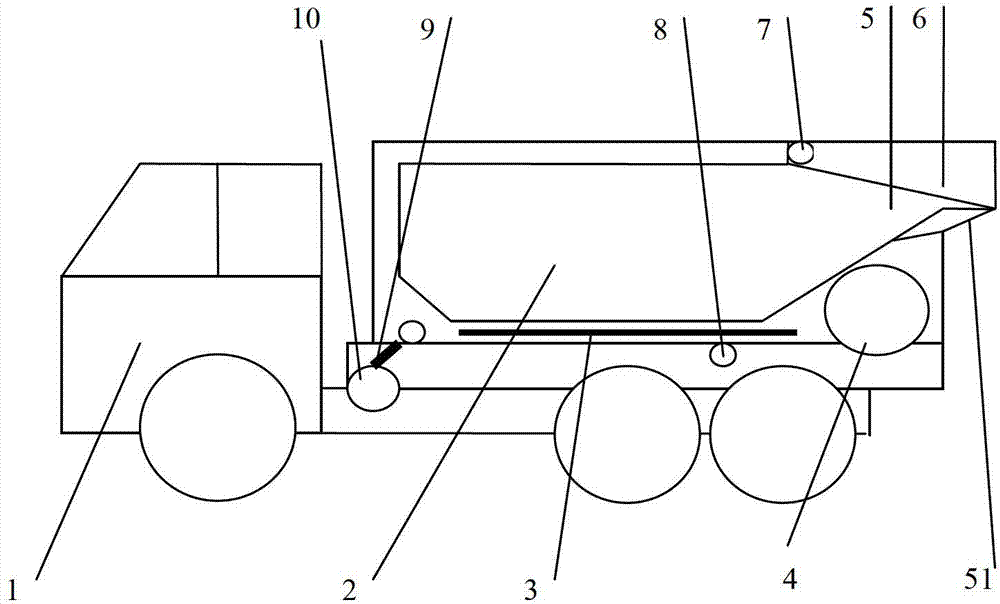

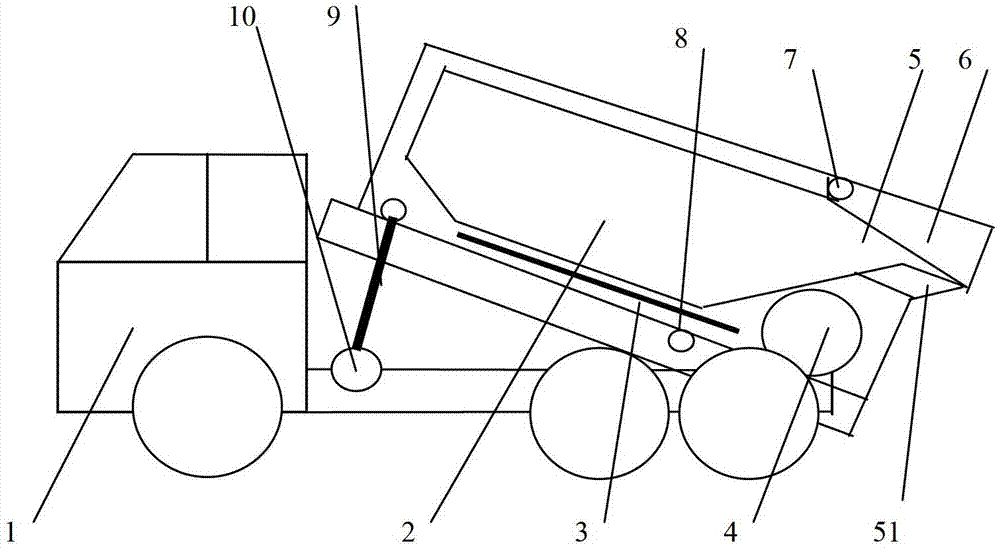

[0020] A kind of liquid aluminum transportation tank truck of the present embodiment is as Figure 1-2 As shown, it includes a car and a heat preservation tank. The heat preservation tank is arranged on the car. The heat preservation tank is a heat preservation tank made of refractory heat preservation bricks. The inlet and outlet are provided with guide grooves for guiding the discharge. The inlet and outlet are provided with a thermal insulation cover, and the thermal insulation cover is connected with the thermal insulation tank through the connection mode of the first rotating pair, and the first rotary pair is connected by a hinge; The jacking device, the jacking device includes a hydraulic motor and a hydraulic cylinder, the hydraulic cylinder is connected to the hydraulic motor drive, the jacking device is arranged at the front end of the thermal insulation tank, and the thermal insulation tank and the car pass through the second The rotating pair is connected, the sec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com