Large-span integral lifting method for roof frame

An overall lifting and long-span technology, applied in the direction of construction, building structure, and building material processing, can solve problems such as restrictions, large labor force, and long time, so as to solve the constraints of installation conditions, improve safety and efficiency, and ensure safety and quality effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and embodiments.

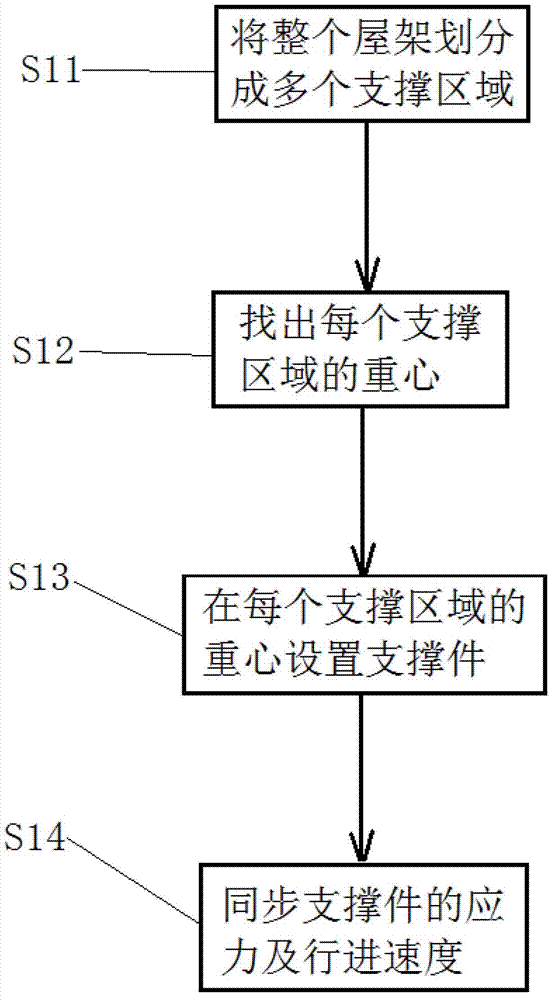

[0017] refer to figure 1 , the overall lifting method of the large-span roof truss of the present invention mainly includes the following four steps:

[0018] S11: dividing the entire roof truss into multiple support areas;

[0019] S12: find out the center of gravity of each support area;

[0020] S13: setting a support member at the center of gravity of each support area;

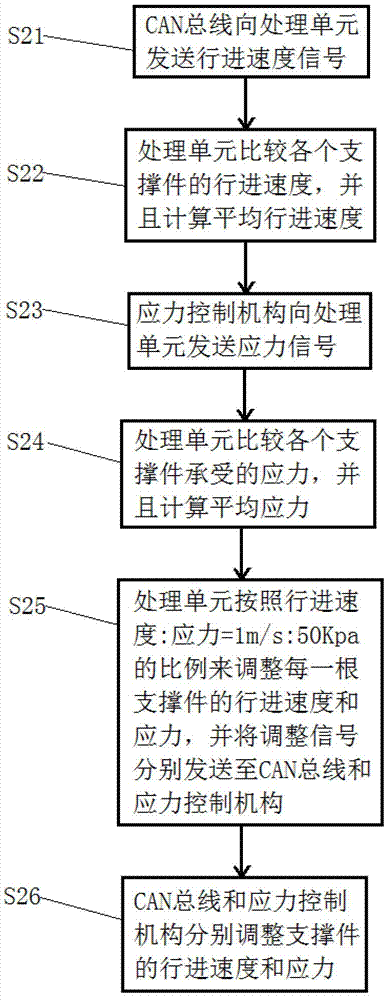

[0021] S14: Stress and travel speed of synchronous supports.

[0022] The specific implementation steps of the present invention will be described below for each step.

[0023] First, divide the entire roof truss into support areas. For example, for the usual large-scale roof trusses, it is generally necessary to divide 6 to 7 support areas per 100 square meters. Of course, for roof trusses with irregular shapes, there may be more detailed divisions....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com