Anti-vibration device for loom

An anti-vibration device and loom technology, which is applied to looms, textiles, textiles, and papermaking, can solve the problem of not effectively utilizing the vibration energy of looms, and achieve the effect of preventing impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment approach )

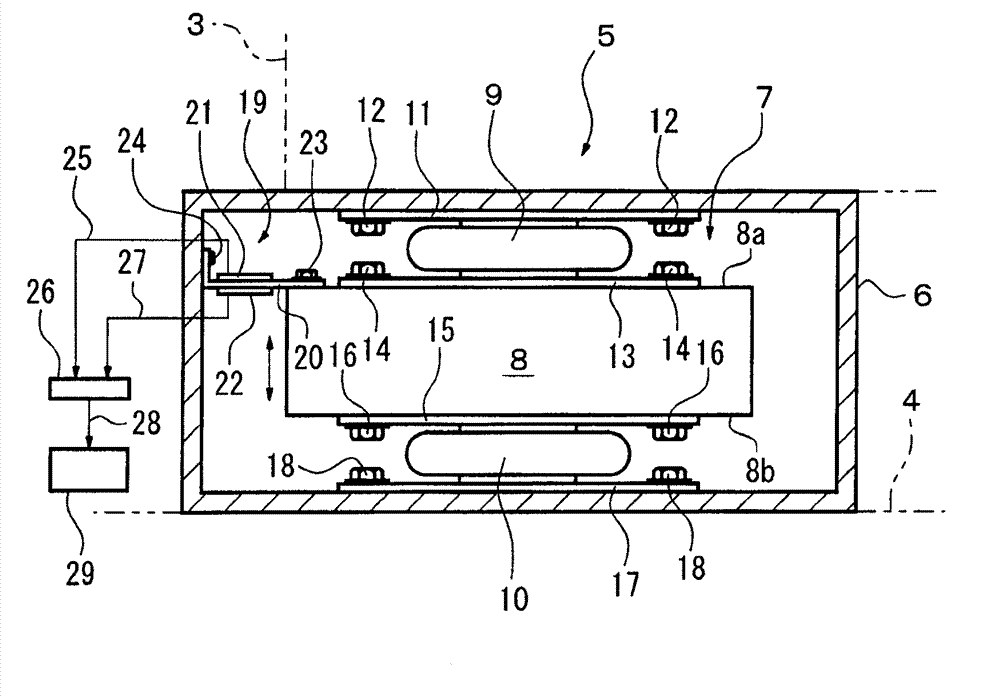

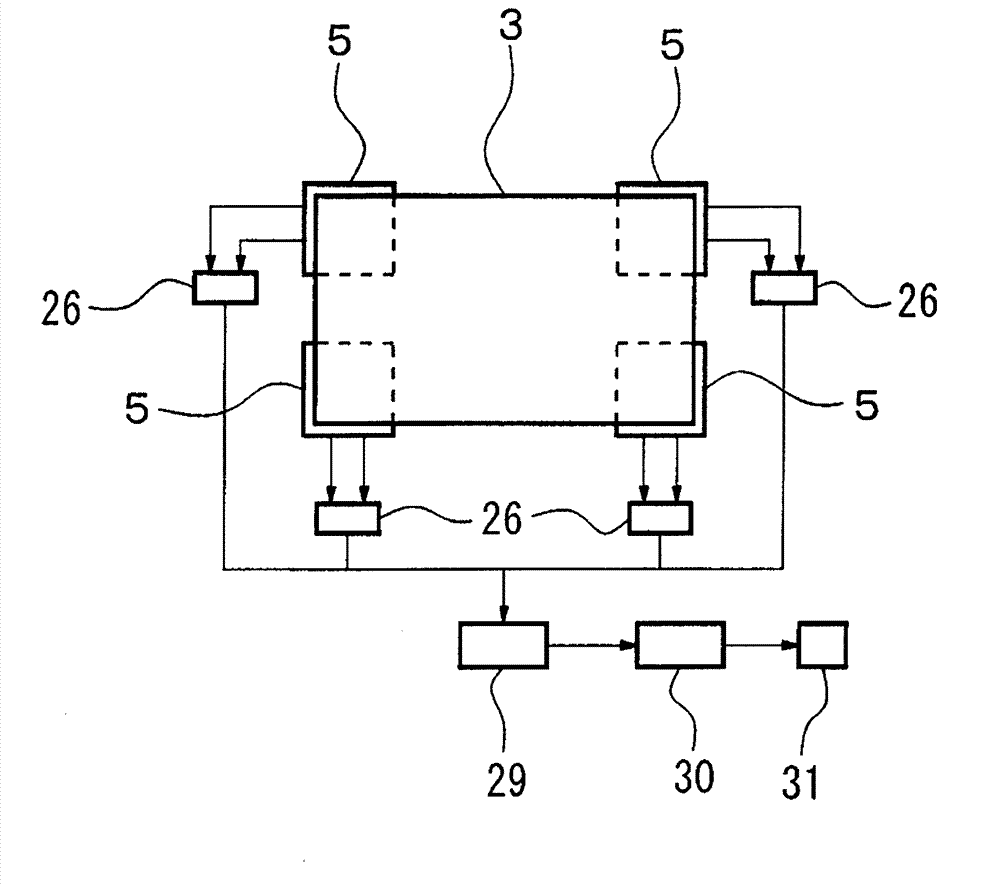

[0018] based on Figure 1 ~ Figure 3 The first embodiment will be described. exist figure 1 Among them, the loom 3 provided with the warp shedding device 1 and the reed 2 as the main source of vibration is placed on the anti-vibration stand 5 as the anti-vibration device installed on the ground 4 . The anti-vibration mounts 5 are arranged at four places, and support the frame of the loom 3 at four corners. In order to stably support the loom 3, it is necessary to arrange the anti-vibration mounts 5 in at least three places, and if necessary, the anti-vibration mounts 5 may be provided in four or more places. In addition, the anti-vibration stand 5 is fixed to the loom 3 with bolts not shown.

[0019] exist figure 2 , the details of the anti-vibration mount 5 will be described. in addition, figure 2 It is a figure showing one of the anti-vibration mounts 5 installed at four locations, and the structure is the same as that of the anti-vibration mounts installed at other ...

no. 2 Embodiment approach )

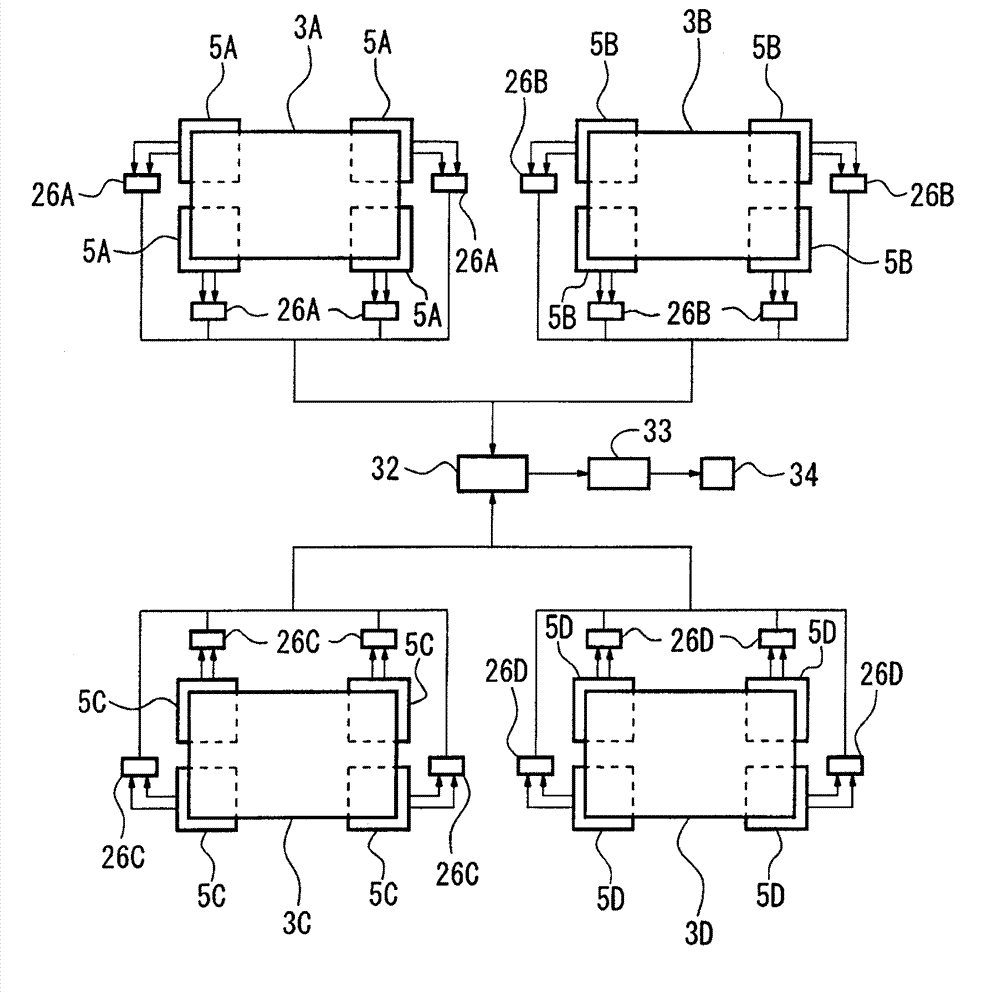

[0032] Figure 4 The second embodiment shows the power utilization form in a weaving factory in which many looms are installed, and the same reference numerals are assigned to the same structures as those in the first embodiment, and detailed description thereof will be omitted.

[0033] Figure 4It shows the power utilization form of four looms 3A, 3B, 3C, and 3D among many looms installed in a weaving factory. Each of the looms 3A to 3D is placed on four anti-vibration stands 5A to 5D installed on the ground, respectively. The anti-vibration mounts 5A to 5D have the same structure as the anti-vibration mount 5 shown in the first embodiment, and each includes figure 2 The vibration absorbing device 7 and the vibration generating mechanism 19 are shown.

[0034] The respective vibration power generating mechanisms 19 arranged on the anti-vibration mounts 5A to 5D are electrically connected to a common storage battery 32 via rectifiers 26A to 26D, respectively. The storage...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com