Double-wet type direct gear shift mechanical speed change mechanism for high-speed vehicle

A mechanical variable speed, wet technology, applied in the field of vehicle engineering, can solve the problems of the output speed of the main shaft cannot be too high, the input speed cannot be too high, the transmission efficiency is low, etc., to achieve a good generalization and serialization basis, strong deformation ability, high The effect of power density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

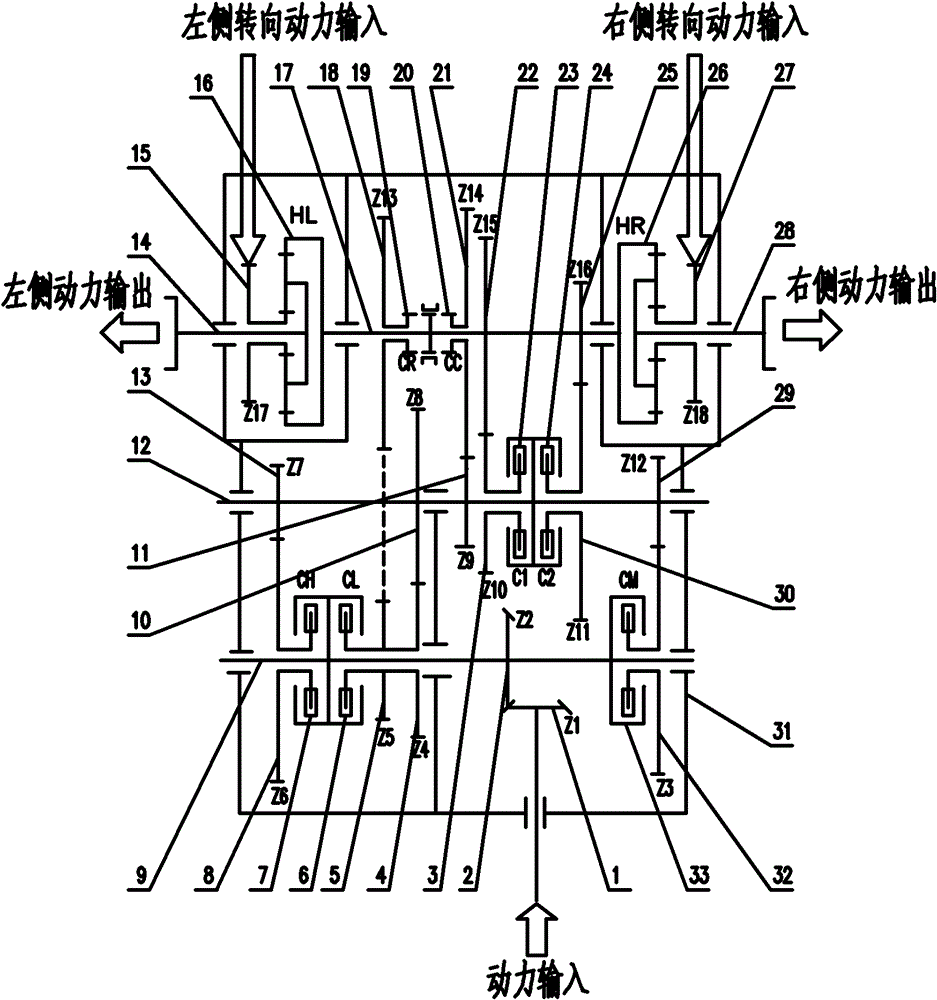

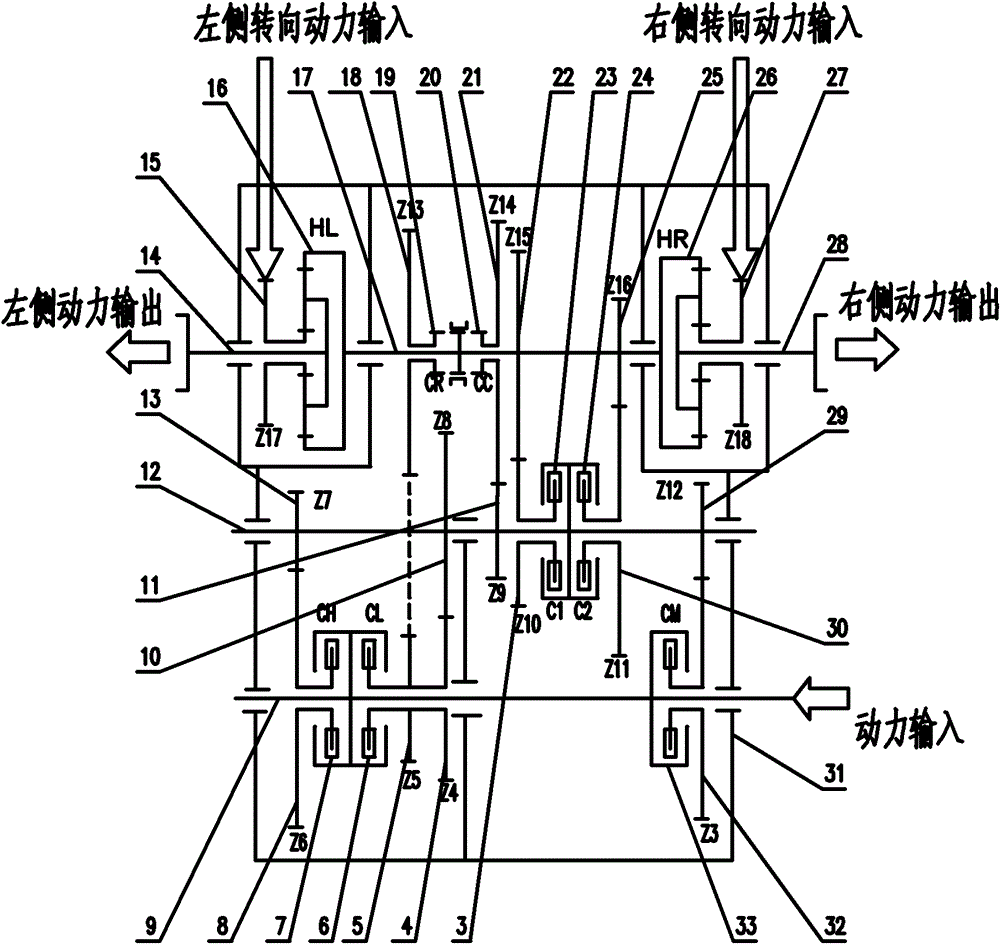

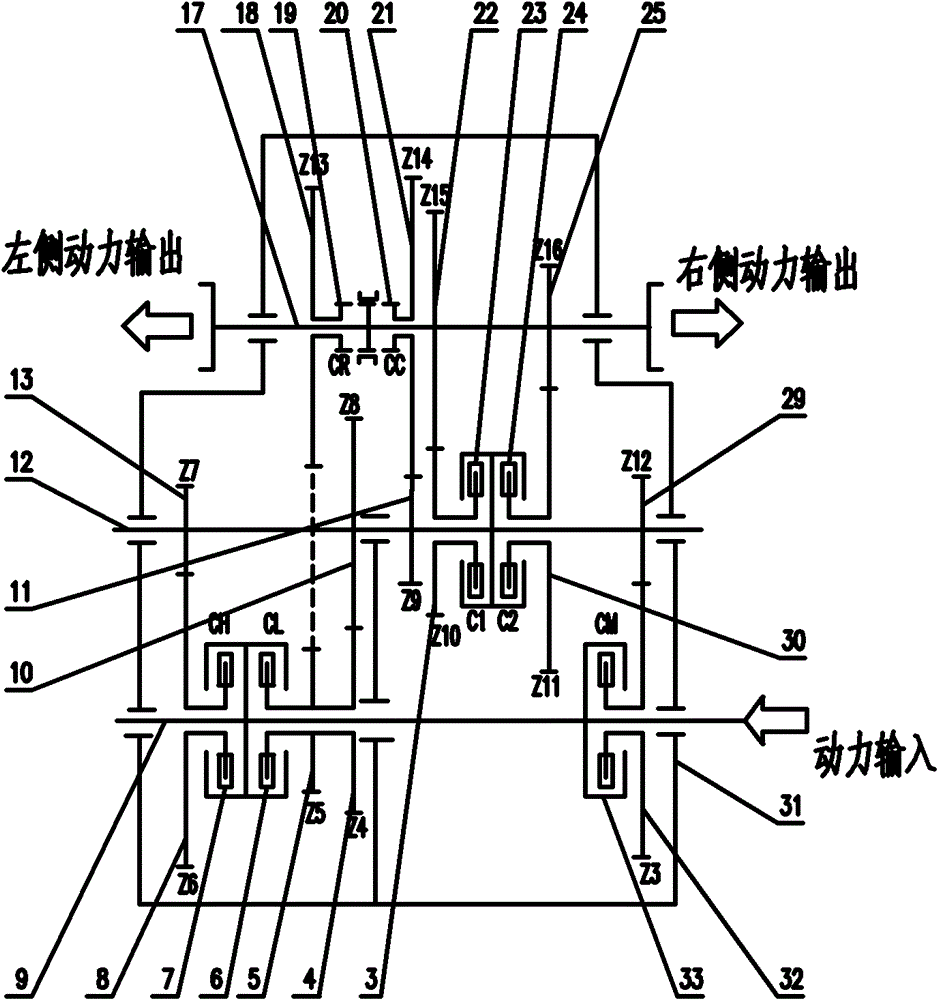

[0015] When the double wet mechanical transmission mechanism is applied to a high-speed crawler vehicle with longitudinally arranged engines, such as figure 1 As shown, the direct drive power input is transmitted from the active bevel gear 1 through the passive bevel gear 2 to the middle of the transmission I shaft 9; figure 2 As shown, the direct drive power input is directly input from the right end of the transmission I shaft 9; when the double wet mechanical transmission mechanism is applied to a high-speed crawler vehicle, as shown in figure 1 with figure 2 As shown, the double wet mechanical transmission mechanism has a left confluence large gear 15, a left confluence planetary row HL16, a right confluence large gear 27 and a right confluence planetary row HR26 connected with the steering power input mechanism; vehicle, such as image 3 As shown, the double wet mechanical transmission mechanism is figure 2 On the basis of removing the left confluence large gear 15,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com