Capacitive pressure sensor

A capacitive, pressure gauge technology used in the measurement of fluid pressure through electromagnetic elements, fluid pressure measurement using inductive changes, and fluid pressure measurement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] Illustrative embodiments are now discussed. Other embodiments may additionally or alternatively be used. Details that may be obvious or not necessary may be omitted to save space or for a more effective presentation. Rather, some embodiments may be practiced without all of the disclosed details.

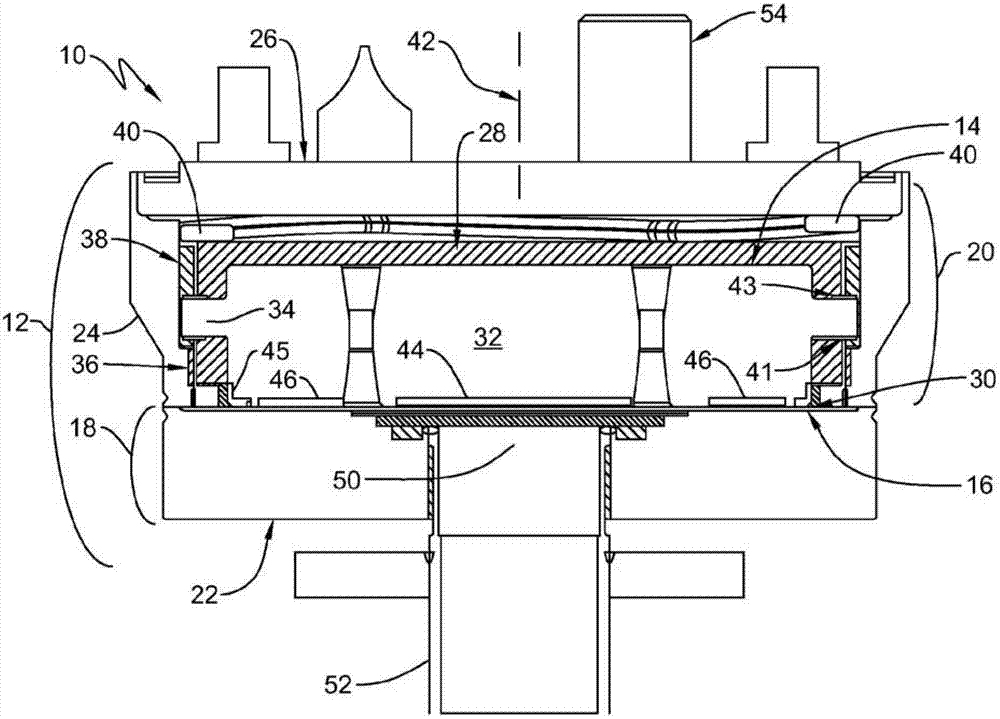

[0039] figure 1The capacitive manometer 10 shown in includes a housing 12 for supporting a fixed electrode structure 14 and a resilient diaphragm 16 . Housing 12 may include a process housing portion 18 and a reference housing portion 20 separated by a resilient membrane 16 . The process housing portion 18 includes a Px cover 22 . Reference housing part 20 includes ring 24 and Pr cap 26 . In the illustrated embodiment, the ring 24 of the reference housing portion 20 includes a hollow cavity 28 for receiving and supporting the fixed electrode structure 14 and resilient diaphragm 16 in a predetermined relationship, thereby maintaining them as defined by a gap 30 of predeter...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com