Detachable composite hammer head

A compound and hammer technology, applied in the field of machinery, can solve the problems of complex manufacturing process, low yield rate, high manufacturing cost, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

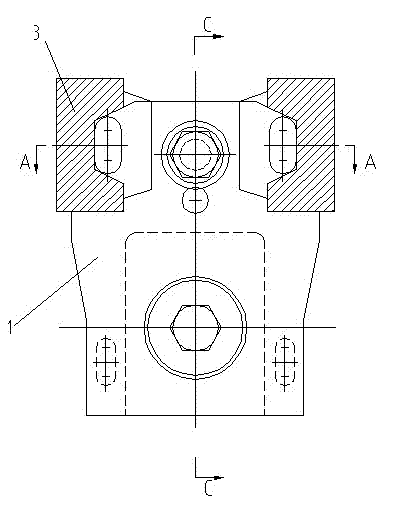

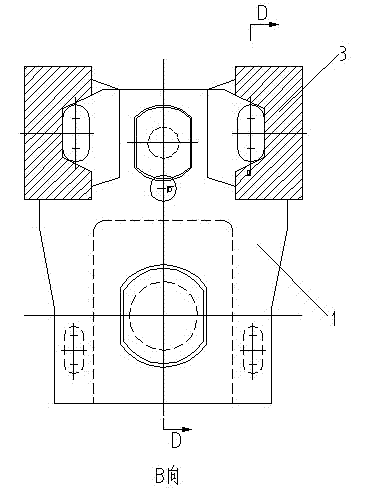

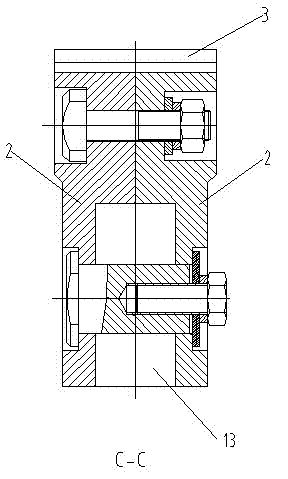

[0049] Removable composite hammer head, including two hammer head connectors 2 connected to form a hammer body 1 and a wear-resistant block 3, the hammer head connectors 2 connected to each other are respectively provided with pins 7 that are connected to each other with pin holes 8.

[0050] The hammer head connecting body clamps and installs the wear-resistant block on the front end of the hammer head body. The contact parts of the hammer head connecting body and the wear-resistant block are respectively provided with bosses 4 or grooves 5, and the bosses and grooves are matched and connected with each other. . The wear-resistant block is two pieces, which are respectively composed of a wear-resistant head 9 and a clamping block 10. The wear-resistant head is in the shape of a cuboid, and the clamping block extends to the middle of the wear-resistant head to form a trapezoidal groove 11. The boss or groove is arranged in the trapezoidal groove , two wear-resistant blocks ar...

Embodiment 2

[0054] Removable composite hammer head, including two hammer head connectors 2 connected to form a hammer body 1 and a wear-resistant block 3, the hammer head connectors 2 connected to each other are respectively provided with pins 7 that are connected to each other with pin holes 8.

[0055] The hammer head connecting body clamps and installs the wear-resistant block on the front end of the hammer head body. The contact parts of the hammer head connecting body and the wear-resistant block are respectively provided with bosses 4 or grooves 5, and the bosses and grooves are matched and connected with each other. . Wear-resistant block is a piece, is made of two wear-resistant heads 9 and a clamping block 10, and two wear-resistant heads are respectively arranged on the two ends of clamping block, and wear-resistant head is rectangular parallelepiped, and clamping block two ends respectively extend to The middle part of the wear-resistant head forms a trapezoidal groove, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com