Steel plate spring station turnover frame

A technology of leaf springs and revolving racks is applied in the field of revolving racks, which can solve the problems of large space occupation, low safety factor, and irregular arrangement, and achieve the effects of small storage occupation area, reducing labor intensity and improving production efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

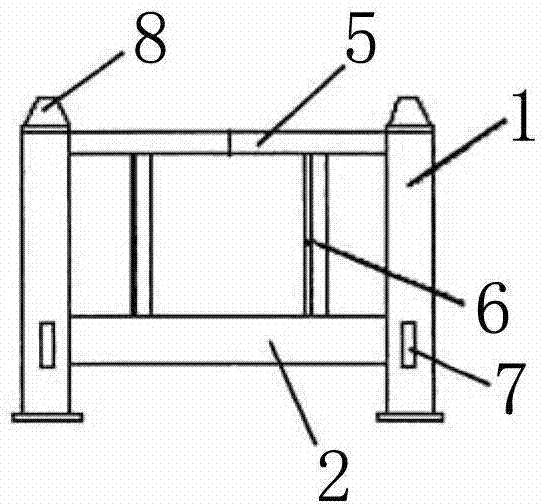

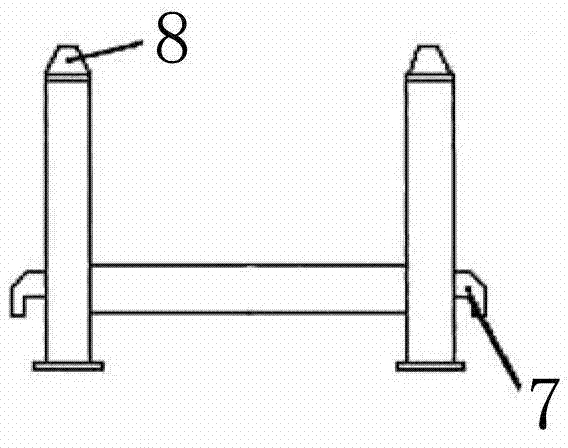

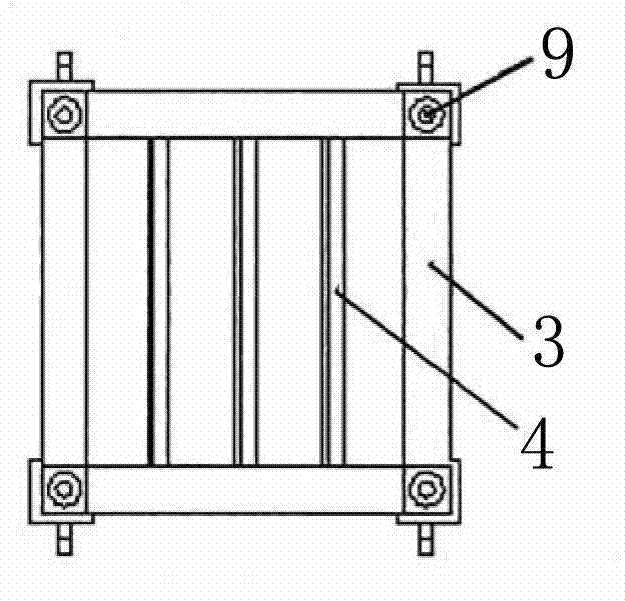

[0013] Such as figure 1 , 2 , 3, the bottom of the four square tubes 1 of the present invention is connected into a square frame 3 by four first cross bars 2, and a support bar 4 is connected between the first cross bars 2 of a pair of sides, wherein A second crossbar 5 is arranged on the upper part of the square pipe 1 on one side, and a vertical rod 6 is longitudinally connected between the second crossbar 5 and the first crossbar 2, and a hoisting hook 7 is provided on the outside of the lower part of the square pipe 1. , the upper end and the lower end of the square tube 1 are respectively provided with a conical head 8 and a conical recess 9. Through the above settings, the present invention is used in each station of leaf spring production, and the leaf springs can be neatly put in, and can be transported by a forklift, or can be hoisted by a crane through the lifting hook 7, and can be stored by two conical cones of the present invention. The head 8 cooperates with th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com