In-mold forming method of outer hardware

A technology of in-mold molding and hardware, applied in the direction of coating, etc., can solve problems such as low bonding force, inability to weld, insufficient temperature, etc., and achieve the effects of reducing production costs, reducing follow-up operations, and enhancing bonding force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The in-mold forming method of appearance hardware provided by the invention makes metal and plastic integrally formed, which not only has the appearance and texture of metal, but also simplifies the design of product mechanism components, making the product lighter, thinner and smaller, with enhanced bonding force and reduced The follow-up effect is improved and the cost is reduced.

[0027] In order to enable those skilled in the art to fully understand the present invention, the present invention will be further described below in conjunction with the accompanying drawings.

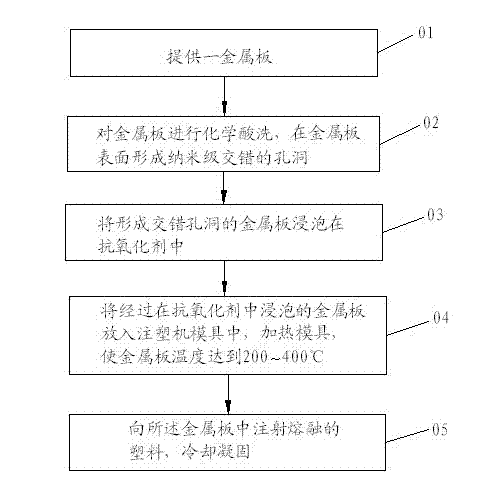

[0028] see figure 1 , is a schematic flow chart of the in-mold forming method for exterior hardware provided by the present invention.

[0029] The in-mold forming method of appearance hardware provided by the present invention comprises the following steps:

[0030] Step 01, providing a metal plate;

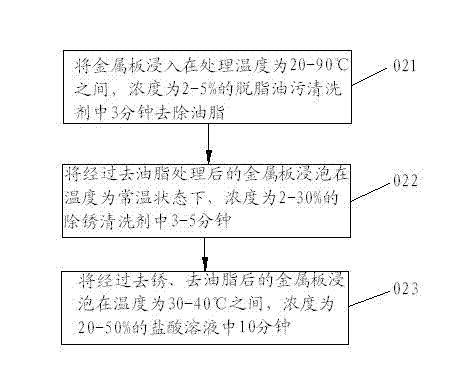

[0031] Step 02, performing chemical pickling on the metal plate to form nanoscale interlaced...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com