Patents

Literature

36results about How to "Reduce follow-up work" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

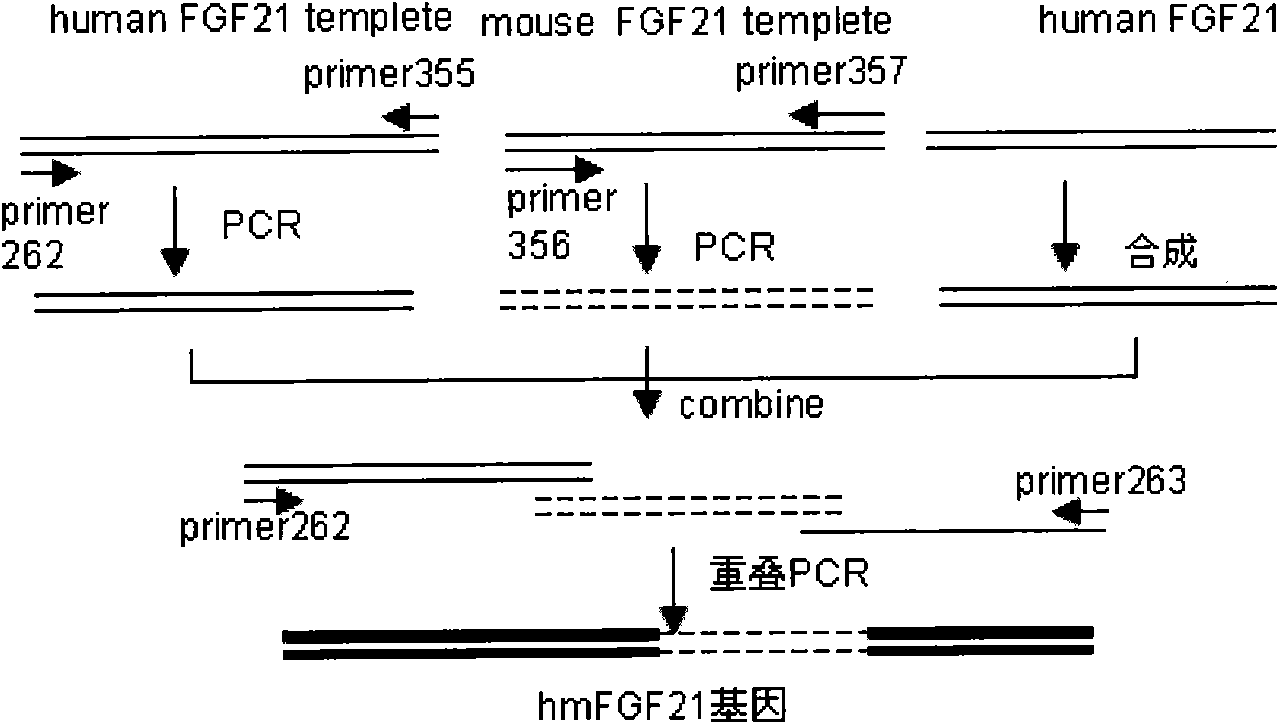

Mutant fibroblast growth factor and use thereof in treating endocrine diseases

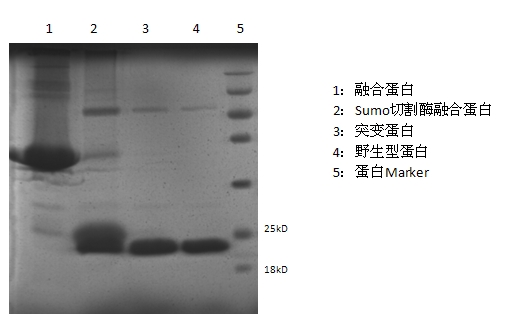

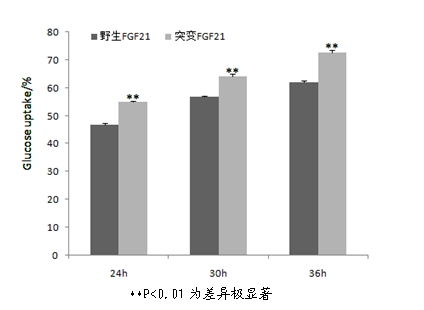

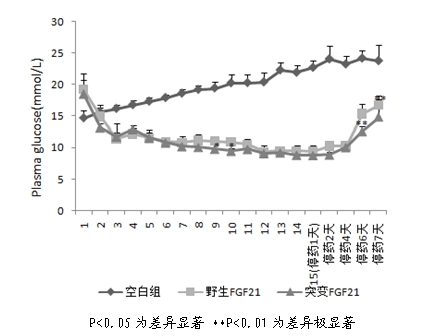

ActiveCN102603886AImprove stabilityQuick effectBacteriaPeptide/protein ingredientsArginineCell membrane

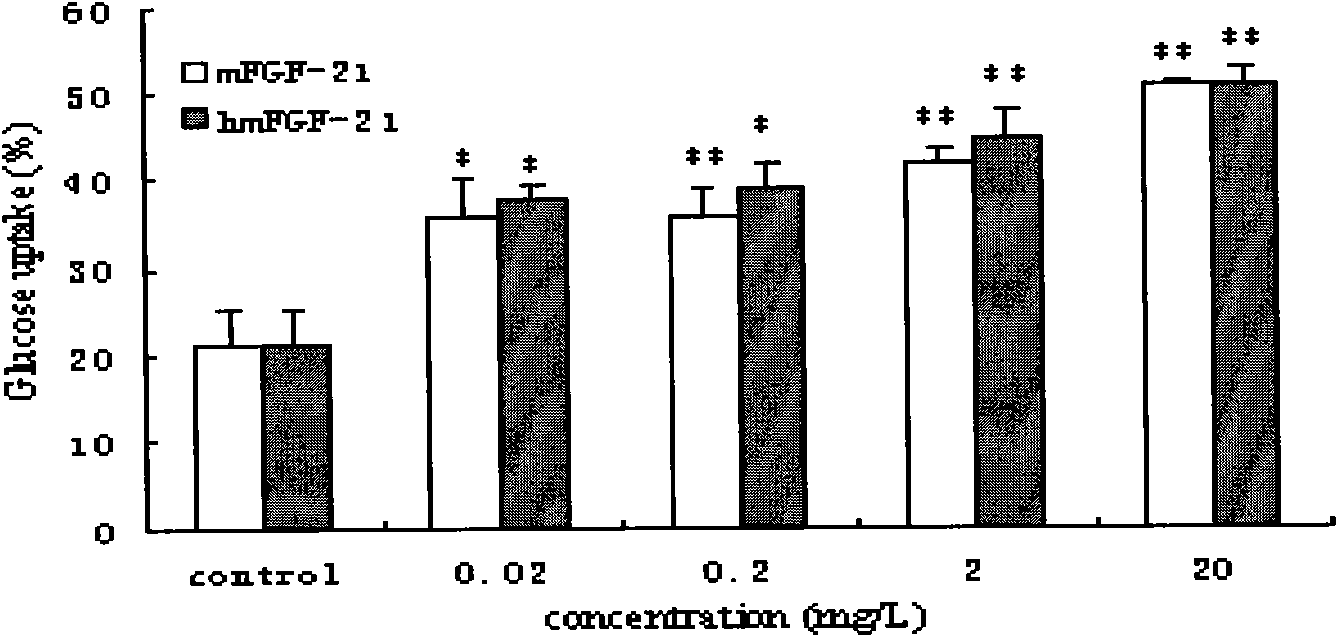

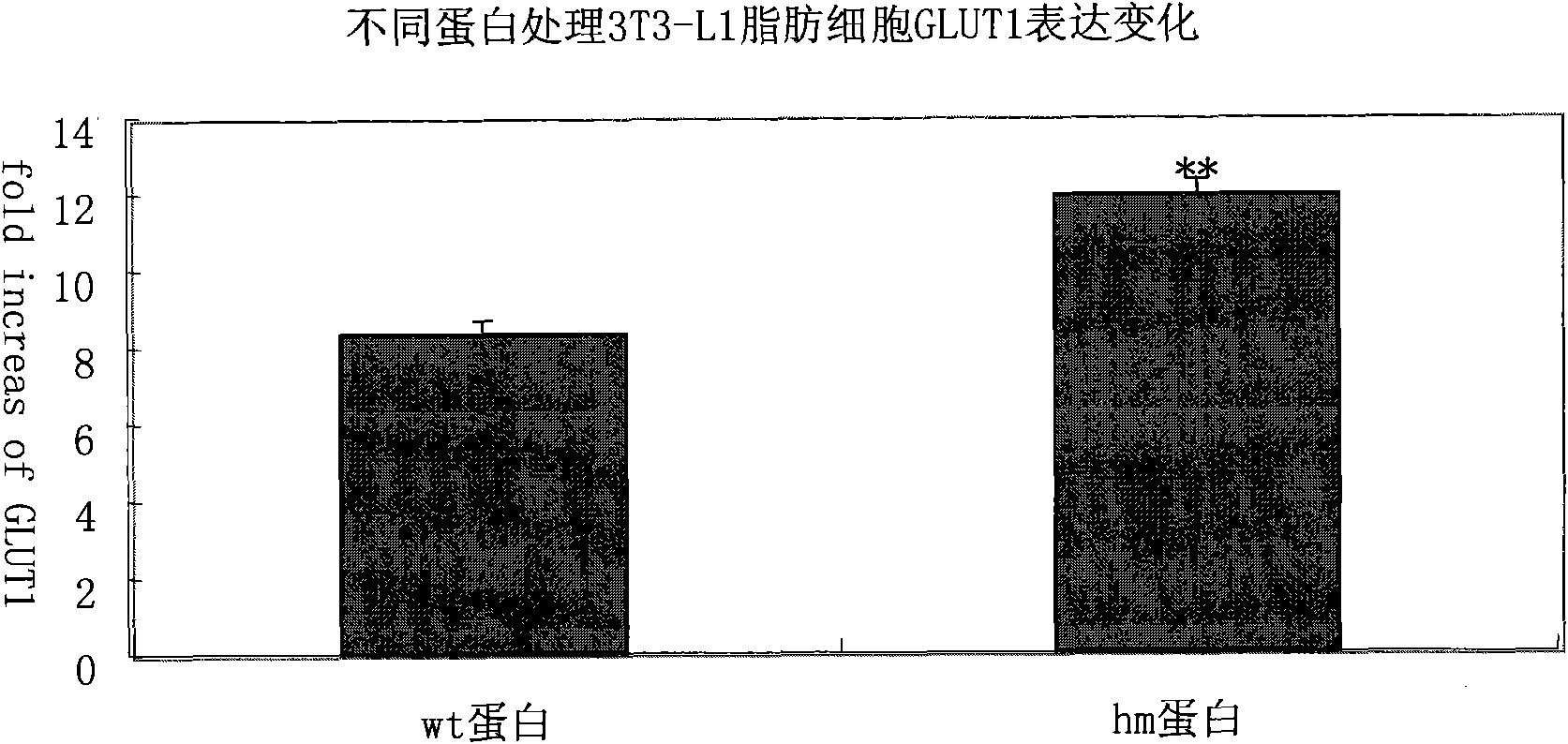

The invention discloses a mutant fibroblast growth factor (FGF-21) and use of the mutant fibroblast growth factor in treating endocrine diseases. The amino acid sequence of the fibroblast growth factor-21 disclosed by the invention is shown as SEQ ID NO: 2, and the sequence of a gene for encoding the mutant fibroblast growth factor is shown as SEQ ID NO: 1. According to the invention, a wild typeFGF-21 is used as a template, two arginine (Arg) residues are introduced through a downstream primer, and a mutant is obtained through polymerase chain reaction (PCR). The strong basicity and positive charges in the physiological condition of Arg are mainly utilized so that the isoelectric point of FGF-21 is up-regulated, and FGF-21 binding to the surfaces of cell membranes is facilitated. The results of an animal experiment show that the mutant FGF-21 disclosed by the invention can more effectively reduce the blood glucose level in an animal, and furthermore, the mutant disclosed by the invention has the advantages of fast onset of drug action, lasting drug effect and the like in reducing the blood glucose level. The mutant GF-21 disclosed by the invention can be used as a medicine to treat endocrine diseases such as diabetes, metabolic syndrome, lipid metabolism disorder and the like.

Owner:TIANJIN TASLY PHARMA CO LTD

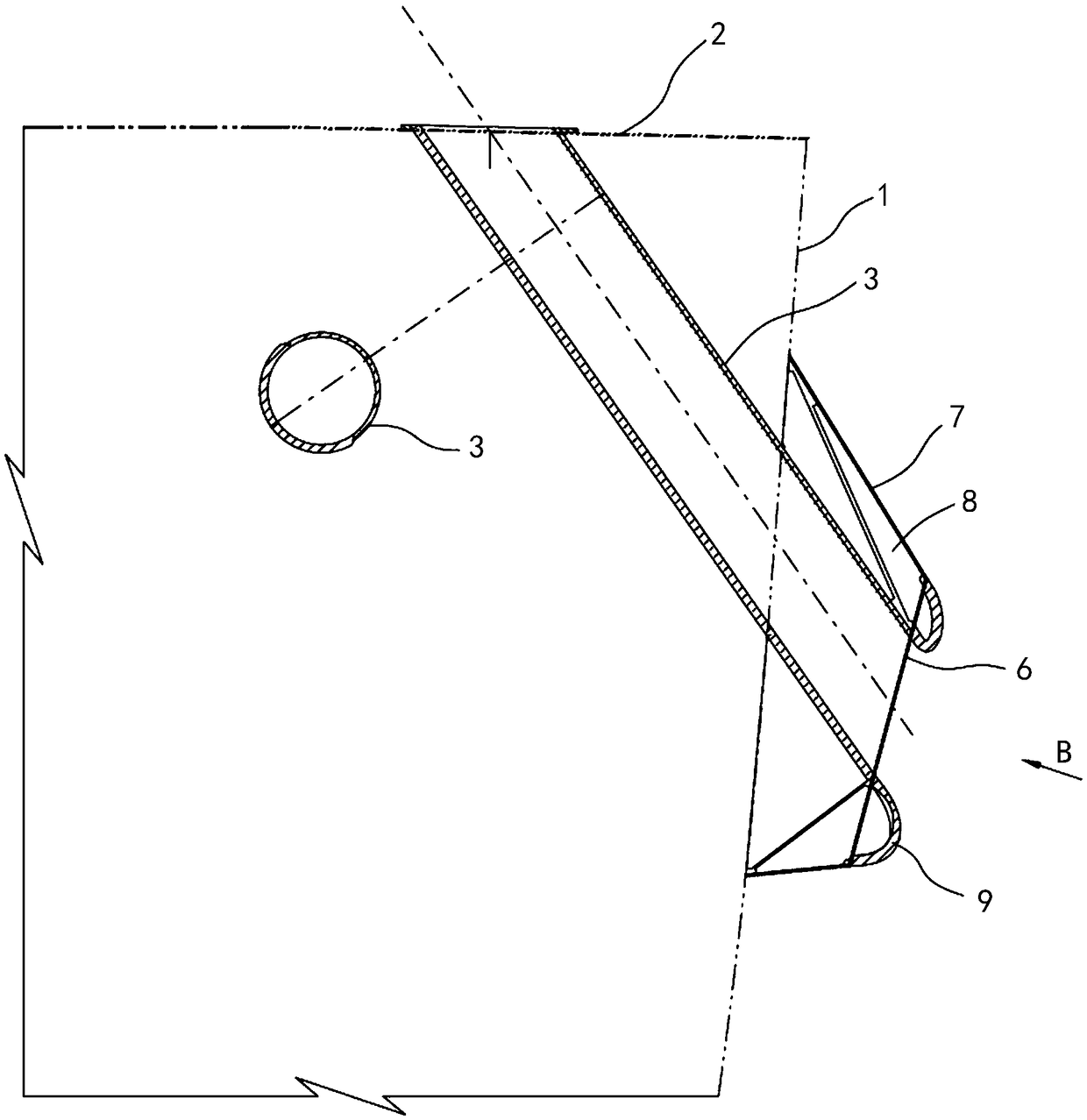

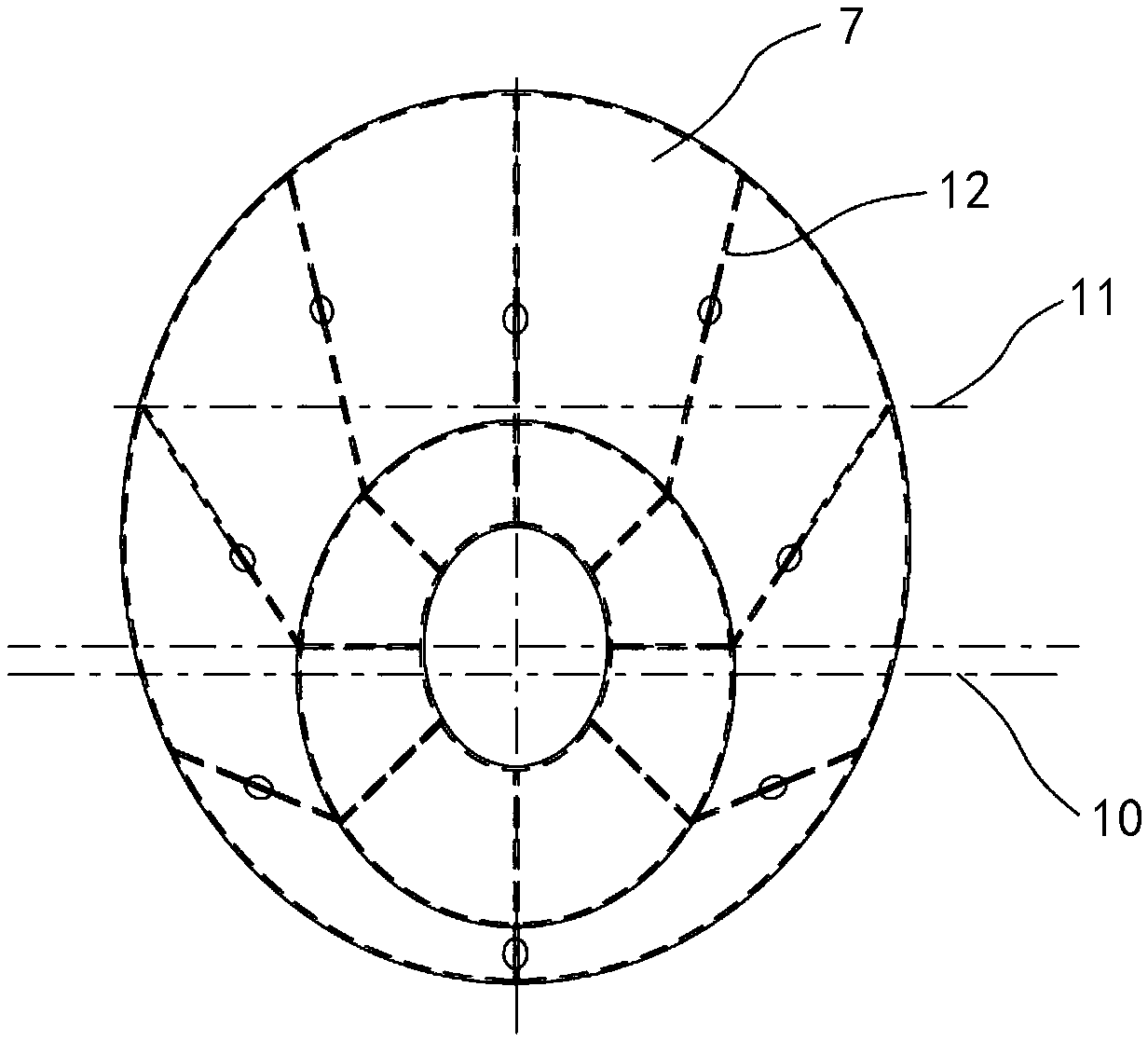

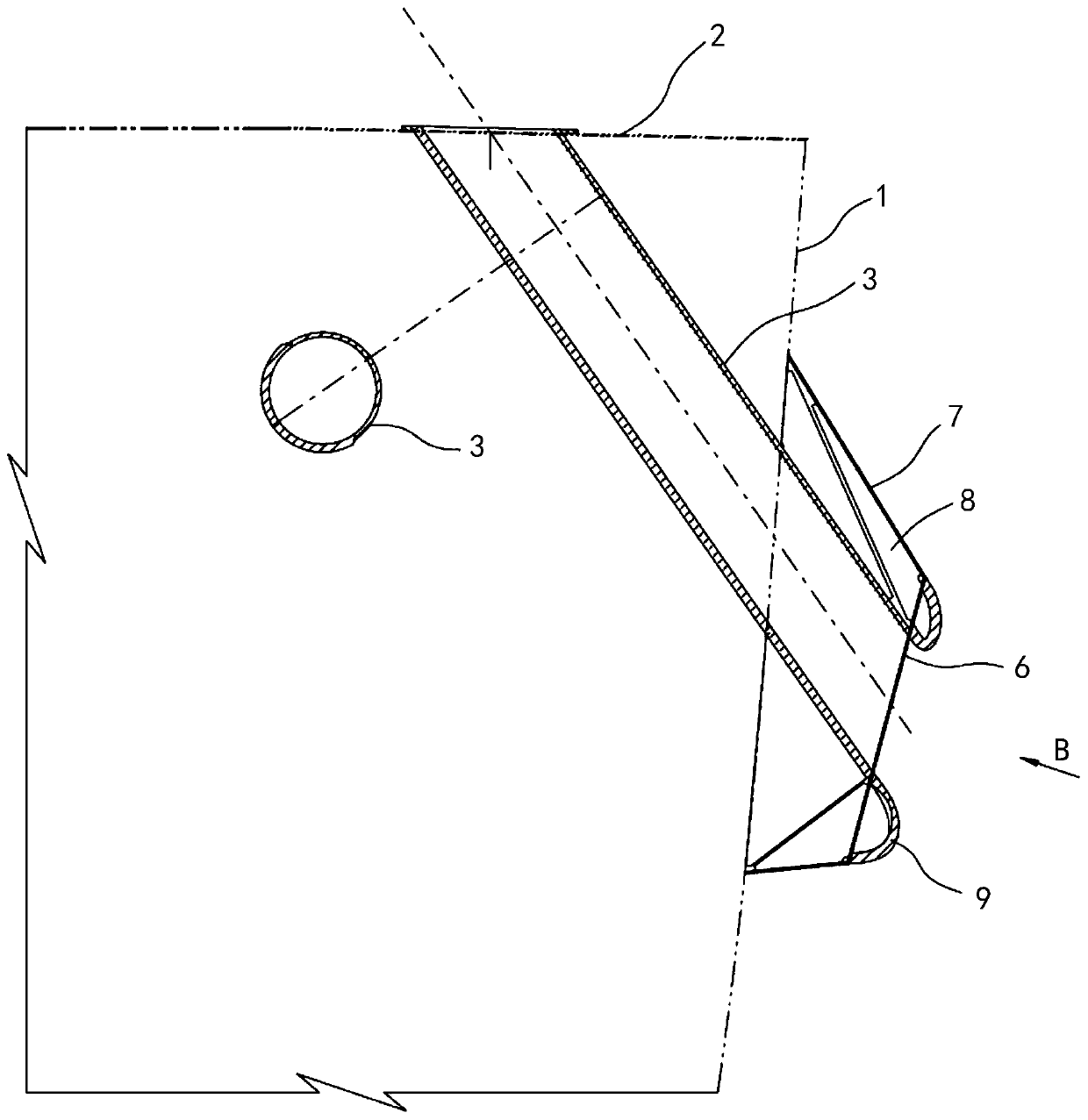

A manufacture and mounting method of anchor chain barrel and anchor platform

ActiveCN109094723AImprove installation accuracyImprove work efficiencyVessel designingMarine engineeringSecond rib

A method for manufacture and installing an anchor chain barrel and an anchor platform by marking an intersection line intersecting the outer plate and a first mounting line of the mounting rib on theanchor chain barrel, A first horizontal line and a first rib line are marked on the anchor platform, Draw the centerline of the hull on deck, A second rib line and a mounting direction, A second horizontal line is drawn on the hull outer panel, The third rib line and the installation direction are used to align the marking lines by using the anchor chain barrel, the anchor platform, the deck and the outer plate in the installation process, thereby finally improving the installation accuracy of the anchor system as a whole and achieving the purpose of controlling the installation accuracy. Theinstallation method can reduce the follow-up work and improve the work efficiency of the ship construction as a whole.

Owner:CSSC HUANGPU WENCHONG SHIPBUILDING COMPANY

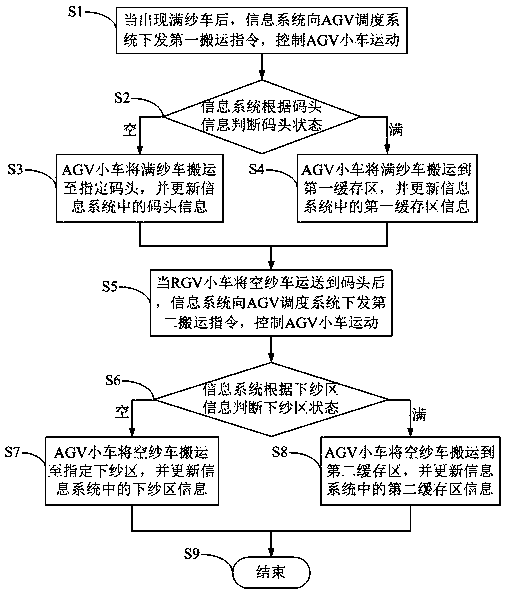

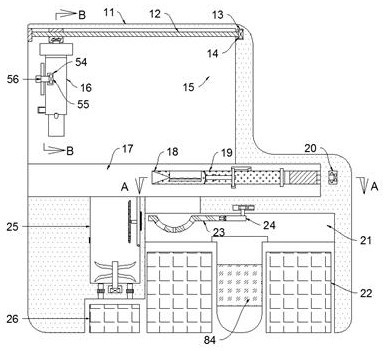

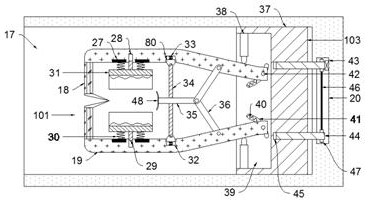

AGV control method

InactiveCN110580028AImprove the level of informatizationReduce follow-up workElectric/hybrid propulsionTotal factory controlYarnInformatization

The invention provides an AGV control method. The method comprises the following steps: when a full yarn vehicle appears, an information system controls an AGV to move through an AGV scheduling system; the information system judges a wharf state according to wharf information, and if the wharf state is vacant, the full-yarn vehicle is carried to a designated wharf and the wharf information in theinformation system is updated; otherwise, the full yarn vehicle is carried to a first cache region, and information of the first cache region in the information system is updated; after an RGV transports an empty yarn vehicle to the wharf, the information system controls the AGV to move through the AGV scheduling system; the information system judges the state of a yarn discharging area accordingto information of the yarn discharging area, if the state of the yarn discharging area is vacant, the empty yarn vehicle is carried to the designated yarn discharging area, and the information of theyarn discharging area in the information system is updated; otherwise, the empty yarn vehicle is carried to a second cache region, and information of the second cache region in the information systemis updated until the carrying of the yarn car is completed. Influence on subsequent work is reduced, labor is reduced, time and labor are saved, the work efficiency is improved, and the informatization level of a factory is improved.

Owner:四川长虹智能制造技术有限公司

Mutated human-source fibroblast growth factor and application in treating endocrine diseases

The invention discloses a mutated human-source fibroblast growth factor and application in treating endocrine diseases. The amino acid sequence of the mutated human-source fibroblast growth factor-21 is shown as SEQ ID NO: 2, and the coding genetic sequence is shown as SEQ ID NO: 1. In the invention, a human blood cell nucleic acid is used as a template, FGF-21 genes in a normal human body can be cloned by means of a natural gene bank in quantity, a natural human FGF-21 sample bank can be established, and the natural mutant of the FGF-21 can be obtained by a high-flux screening method. Zoological experiment results prove that the mutated FGF-21 can more effectively reduce the blood sugar level in an animal body, and the mutant has the advantages of quick response, long efficacy duration and the like in the aspect of reducing the blood sugar level. The mutated FGF-21 can be used as medicament for treating diabetes mellitus, metabolic syndrome or lipid metabolism disorder and other endocrine diseases.

Owner:NORTHEAST AGRICULTURAL UNIVERSITY

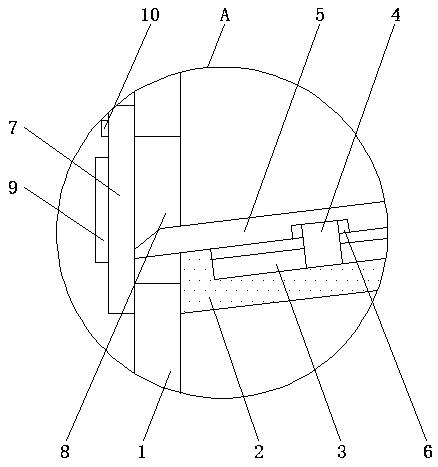

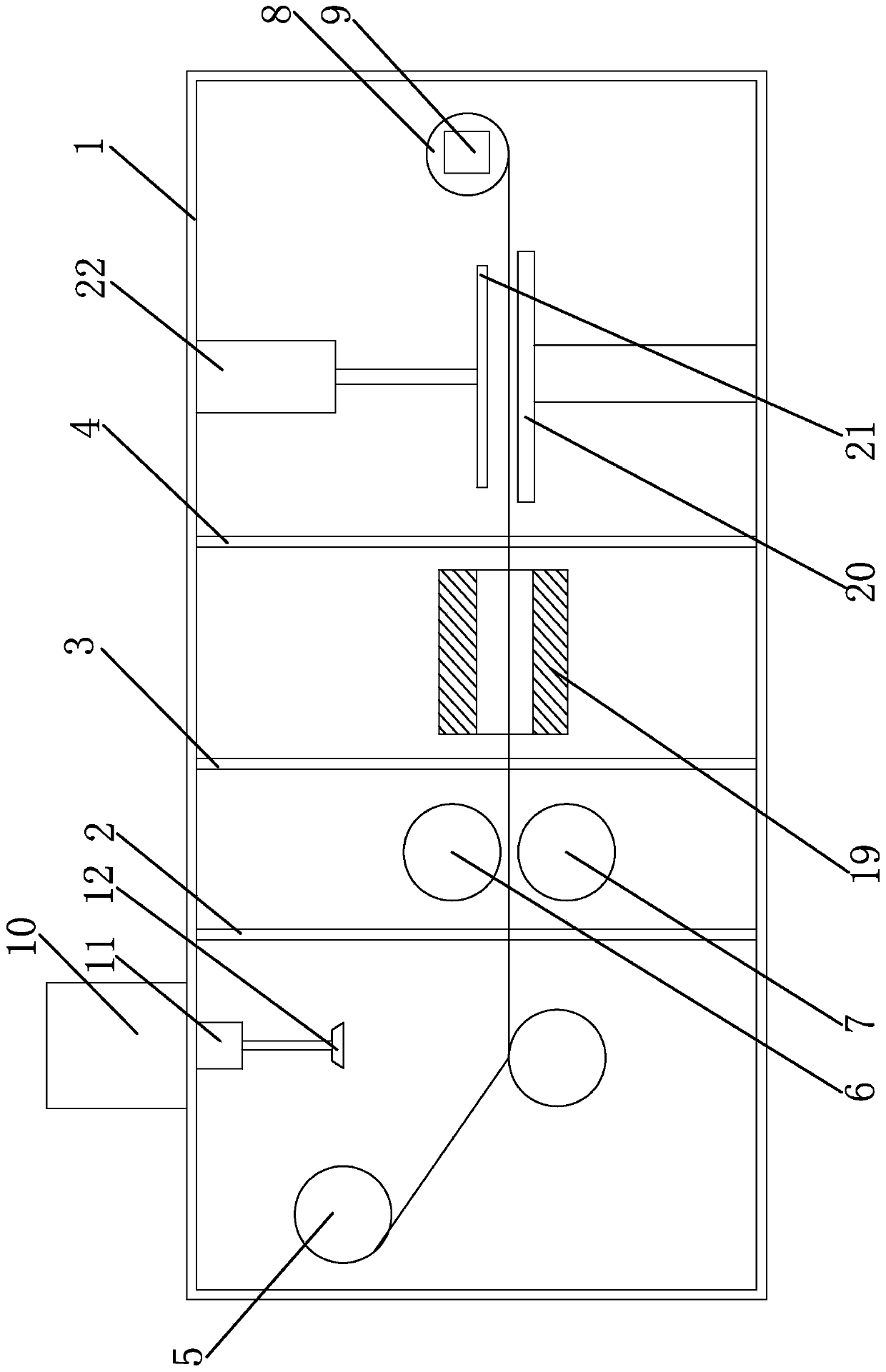

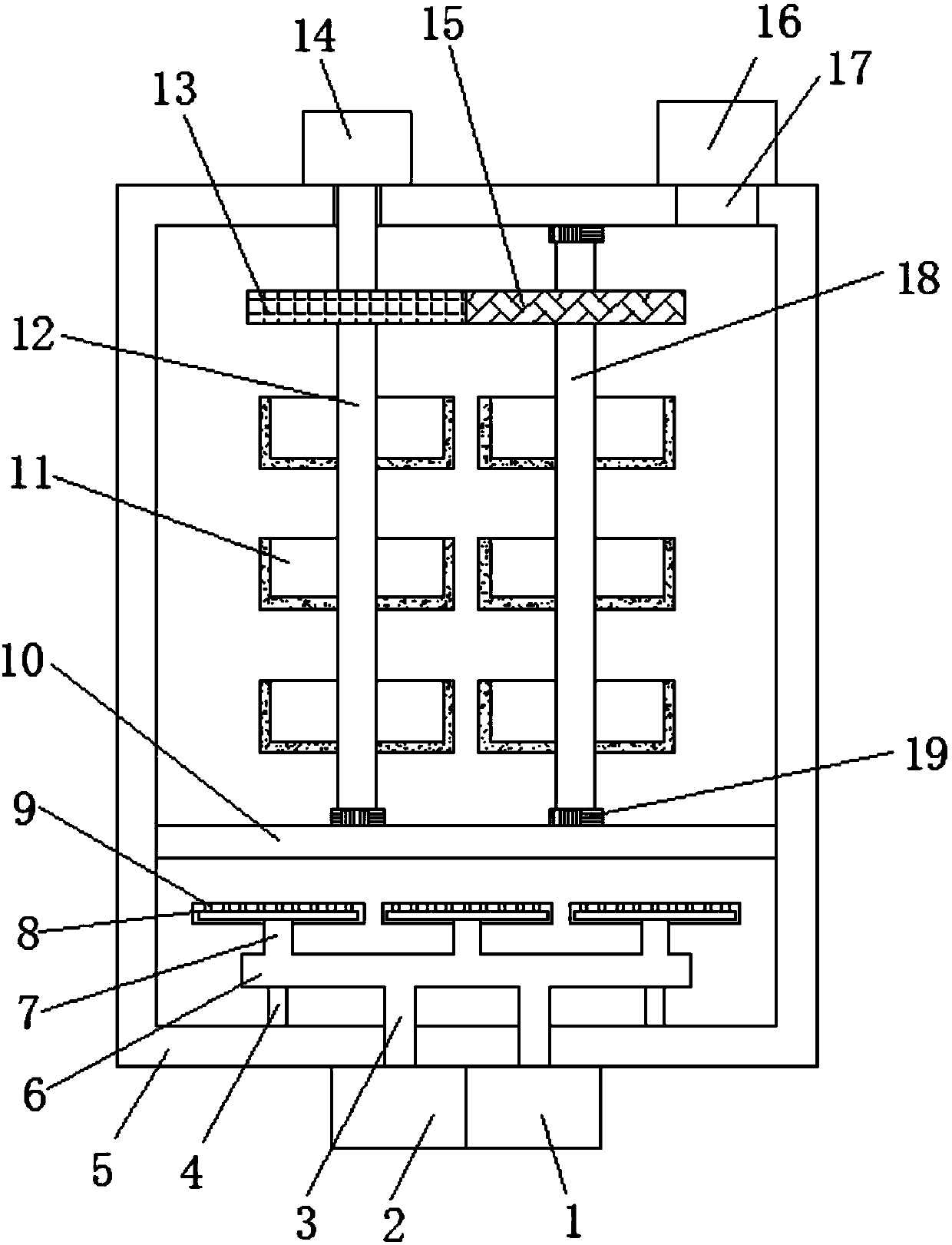

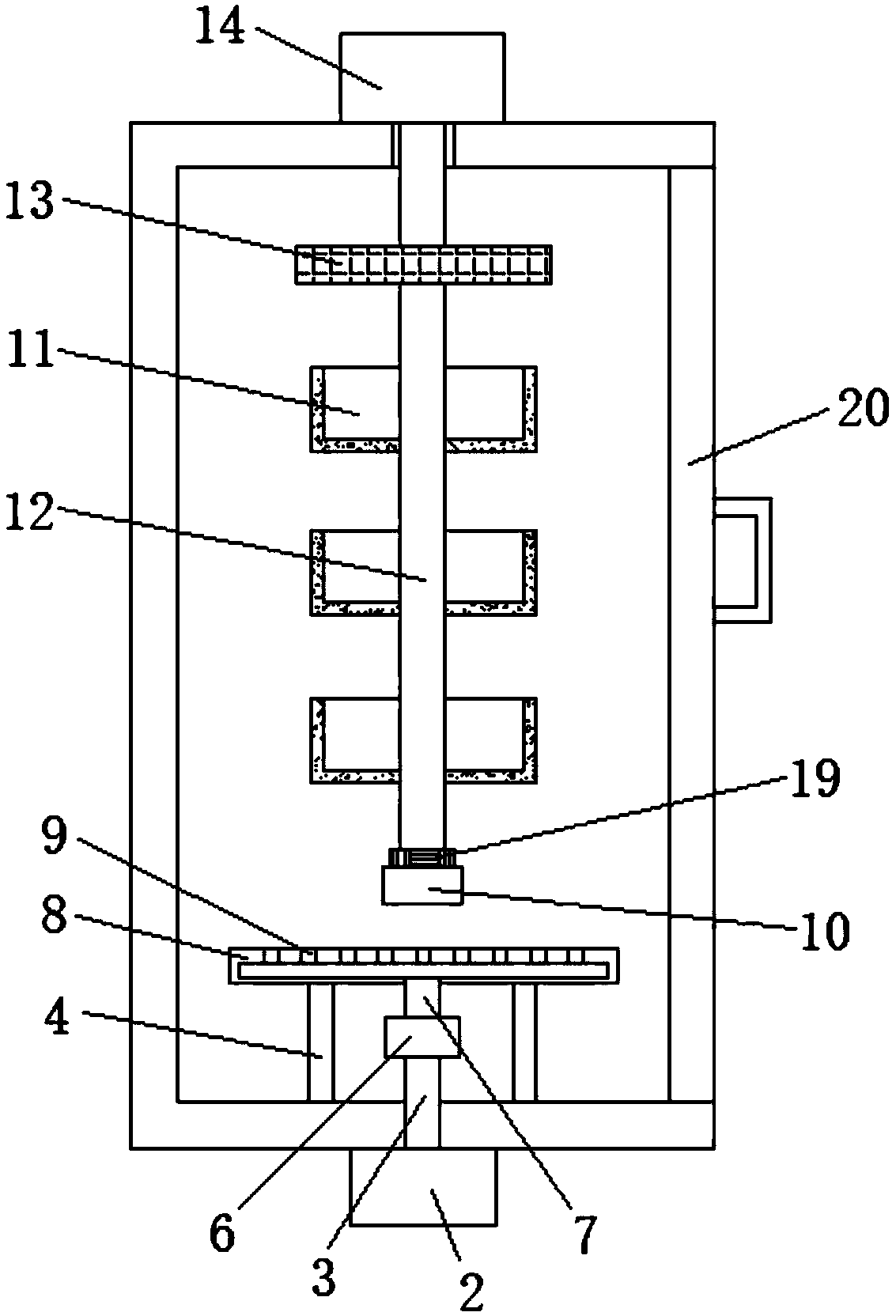

Medical operating room waste solid-liquid separation device

InactiveCN108786262AImprove work efficiencyPlay a shock absorbing roleFiltration circuitsOperating theatresEngineering

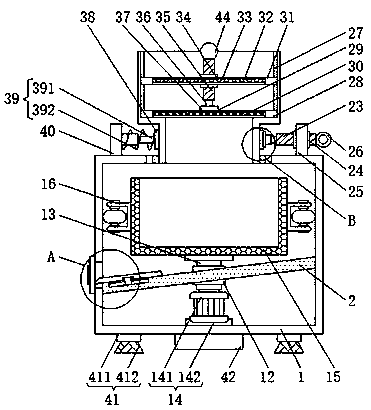

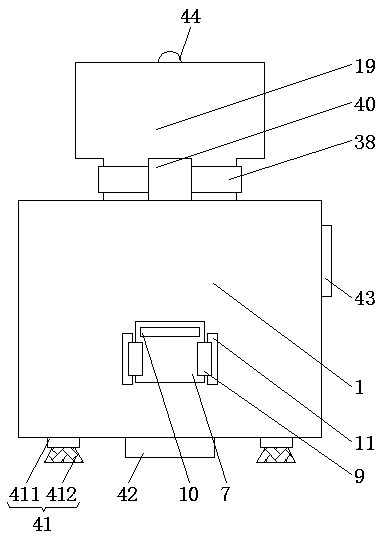

The invention discloses a medical operating room waste solid-liquid separation device, which includes a casing, wherein a first inclined plate is arranged inside the casing; the front side of the first inclined plate is fixedly connected with the front side of the inner wall of the casing; the back side of the first inclined plate is fixedly connected with the back side of the inner wall of the casing; the right side surface of the first inclined plate is fixedly connected with the right side surface of the inner wall of the casing; the left side surface of the first inclined plate is fixedlyconnected with the left side surface of the inner wall of the casing. According to the medical operating room waste solid-liquid separation device, through arranging a first filtering plate and a second filtering plate, waste is sequentially filtered by the second filtering plate and the first filtering plate before entering a net cage and performing centrifugal movement, bigger molecular particles in waste are filtered out by the second filtering plate and the first filtering plate, so that residual waste performs centrifugal movement inside the net cage to reduce deposit volume at the net meshes, thereby not only improving the solid-liquid separation effect, but also improving the working efficiency of staff as waste is avoided from being deposited at the net meshes.

Owner:李彦斌

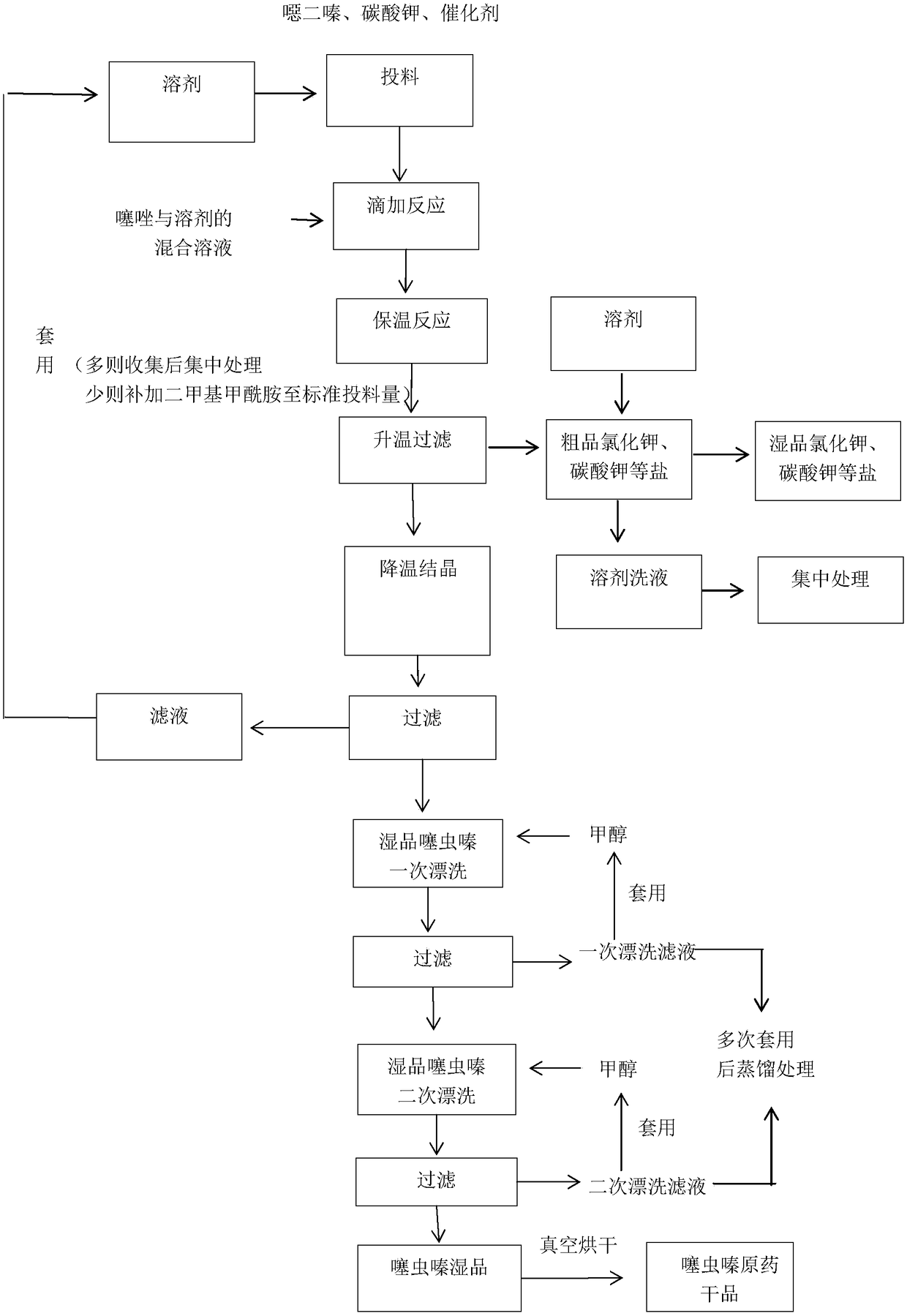

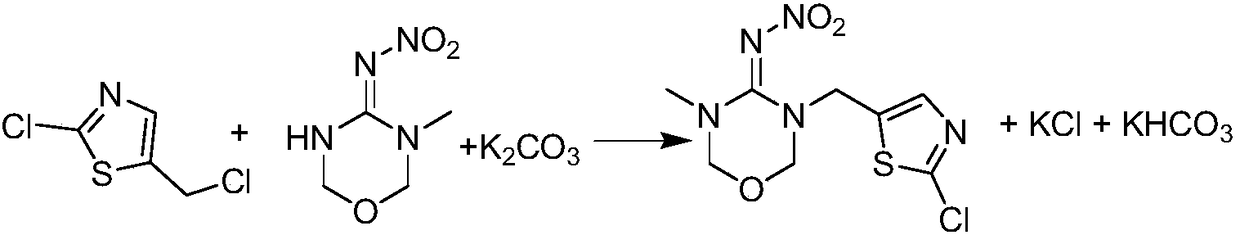

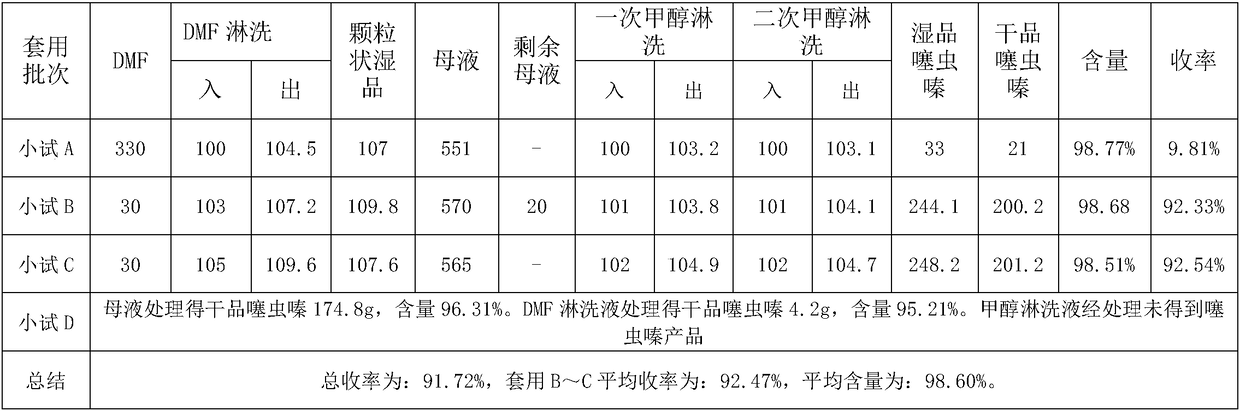

Preparation method of thiamethazide

InactiveCN108822098AHigh reaction yieldSolve the problem of low product yieldOrganic chemistryWastewaterSolvent

The invention discloses a preparation method of thiamethazide. The preparation method comprises the following steps of sequentially adding the measured solvent, 3-methyl-4-nitrocarbamide-1,3,5-oxadiazine, potassium carbonate and catalyst, stirring, uniformly mixing, and heating to 25 to 35 DEG C; dripping a mixture of 2-chloro-5-chloromethylthiazole and solvent into a reaction system at the speedof 40 to 60ml / h, controlling the temperature to be lower than 35 DEG C, stirring to react for 8 to 16h after the mixture of 2-chloro-5-chloromethylthiazole and solvent is dripped, and completely reacting; heating to 65 to 70 DEG C, and filtering coarse salt under the heat condition; cooling to 0 to 5 DEG C, crystallizing, filtering to obtain filtrate and filter cake, treating the filtrate for recycling, spraying the filter cake by methanol twice, and drying under the vacuum condition, so as to obtain the crude drug of the thiamethazide. The preparation method has the advantages that a large amount of subsequent workload is reduced, the highest reaction yield rate of thiamethazide can reach 92% or above, the content is about 98%, and the production of a large amount of wastewater is reduced.

Owner:湖北犇星农化有限责任公司

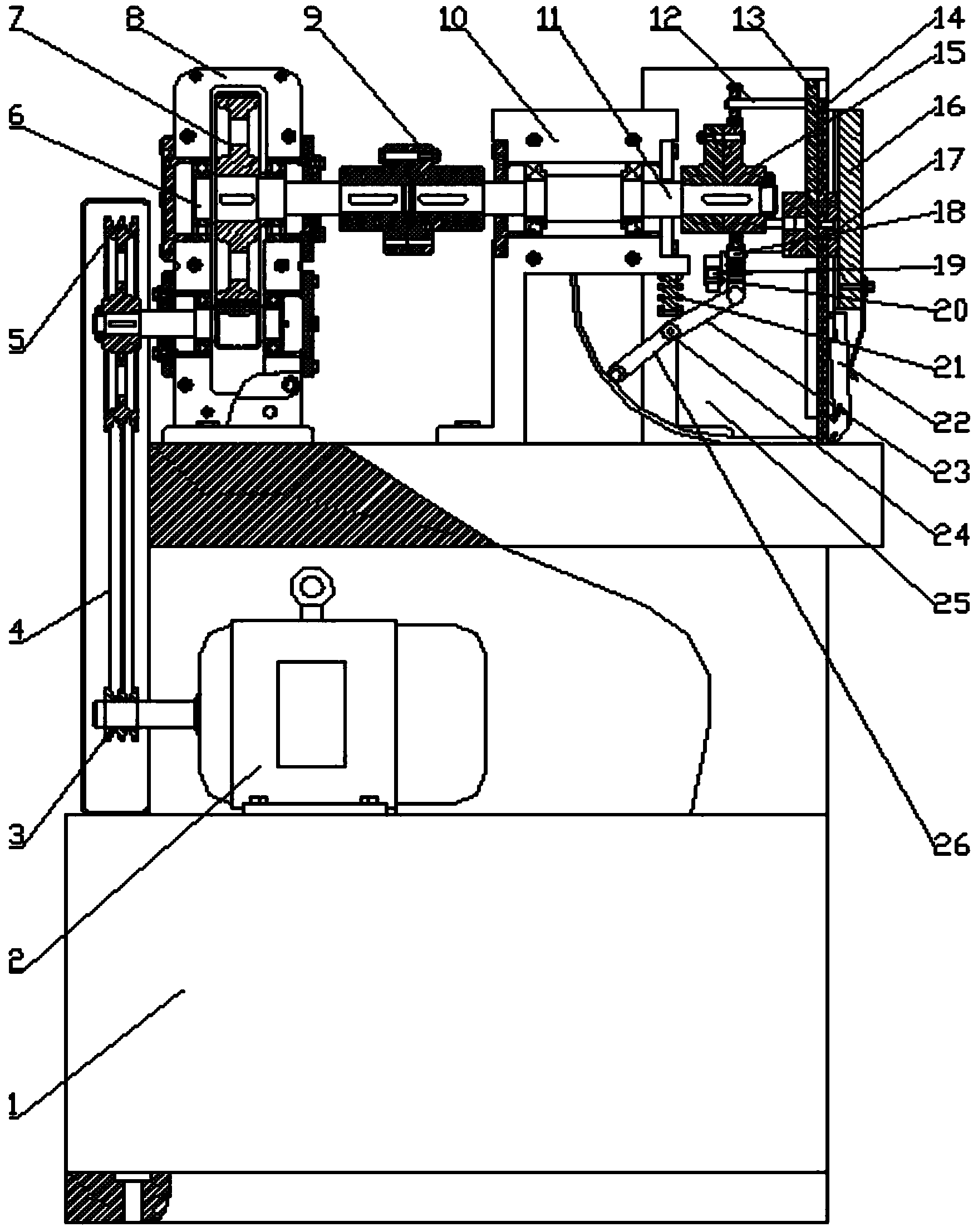

Automatic photoelectric control binding machine for travel book

The invention discloses an automatic photoelectric control binding machine for travel books. The automatic photoelectric control binding machine for the travel books is characterized in that the automatic photoelectric control binding machine comprises a motor, a small pulley, a large pulley, a large gear, a working shaft, a binding slider, a forming slider, a cam, a gland, a slider, a roller shaft, a cutting wheel, a cutting wheel shaft, a connecting rod, a hinge, a box, an oscillating bar, a photoelectric sensor cutter, a wheel, a guide wire hole, a slider, a frame, a connecting rod, an iron wire and a photoelectric wire feeding wheel; the gland is arranged on the outer edge of a machine base; a roller shaft is disposed between the cam and the binding slider; the cutting wheel is mounted on the roller shaft; a tongue-shaped guide block is arranged on the lower portion of the binding slider; a spring is disposed above the connecting rod; the oscillating bar is mounted at the rear end of the connected rod; the iron wire penetrates through a sleeve, the edge of which is provided with a chuck and a spring chuck; the photoelectric sensor cutter is arranged on the upper portion of the rear end edge of the guide wire hole; the photoelectric wire feeding wheel is mounted above the frame.

Owner:成都怡云科技有限公司

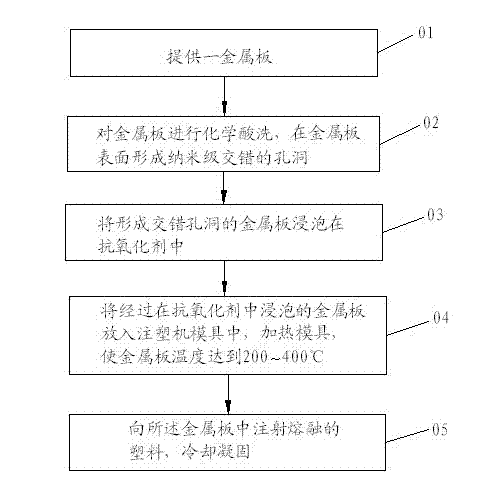

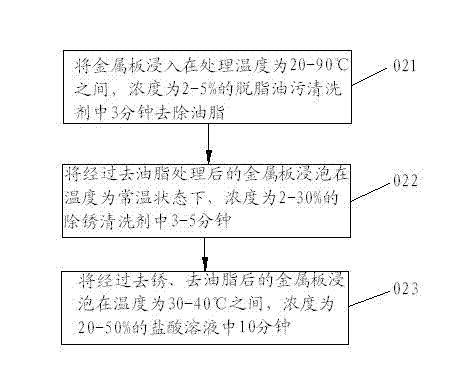

In-mold forming method of outer hardware

The invention discloses an in-mold forming method of outer hardware, which comprises the following steps: providing a metal plate, carrying out chemical acid cleaning on the metal plate to form nano staggered pores on the surface of the metal plate, soaking the metal plate with staggered pores in an antioxidant, putting the metal plate soaked in the antioxidant into a mold of an injection molding machine, heating the mold until the temperature of the metal plate reaches 200-400 DEG C, injecting molten plastic into the metal plate, and cooling to solidify. The invention can integrate the metal and plastic, effectively reduce the thickness of the electronic product, simplify the element design of the product and enhance the binding force, thereby reducing the subsequent operation and lowering the production cost.

Owner:GUANGDONG GREEN PRECISION COMPONENTS CO LTD

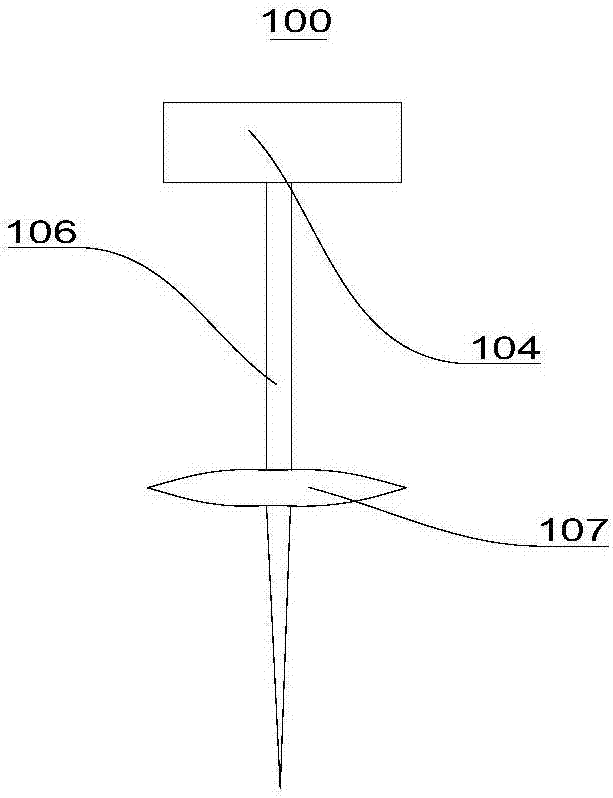

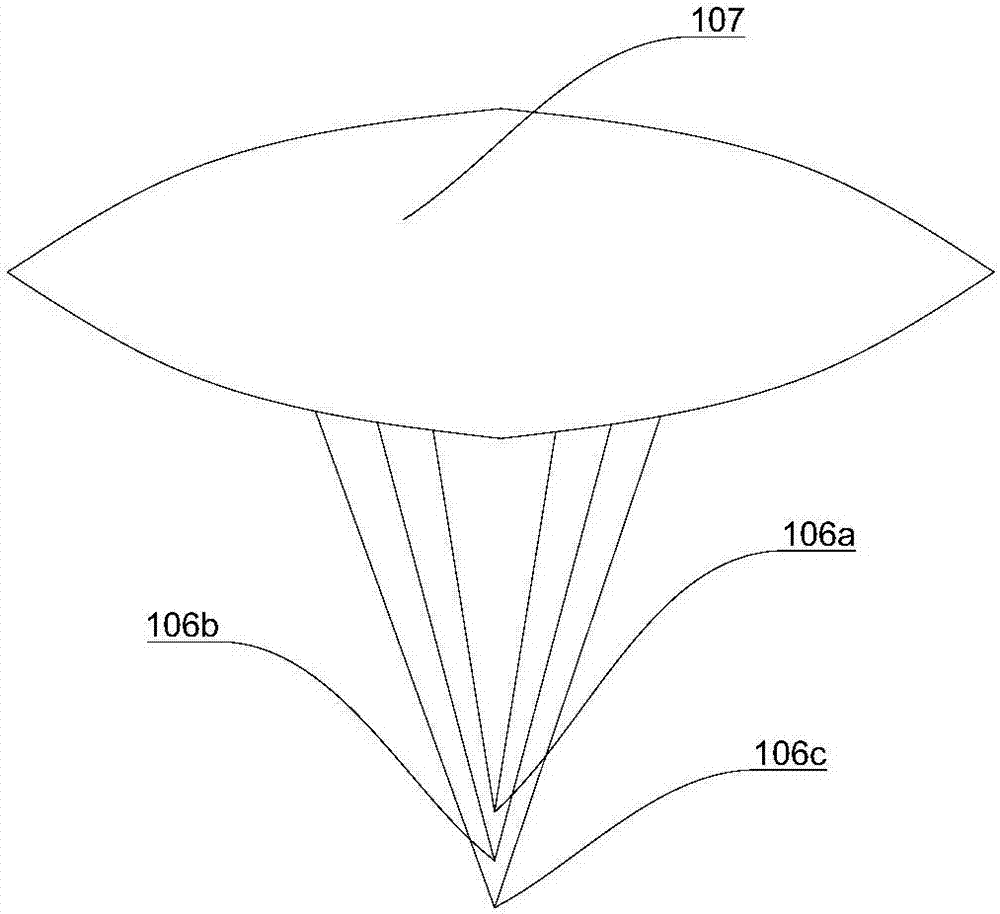

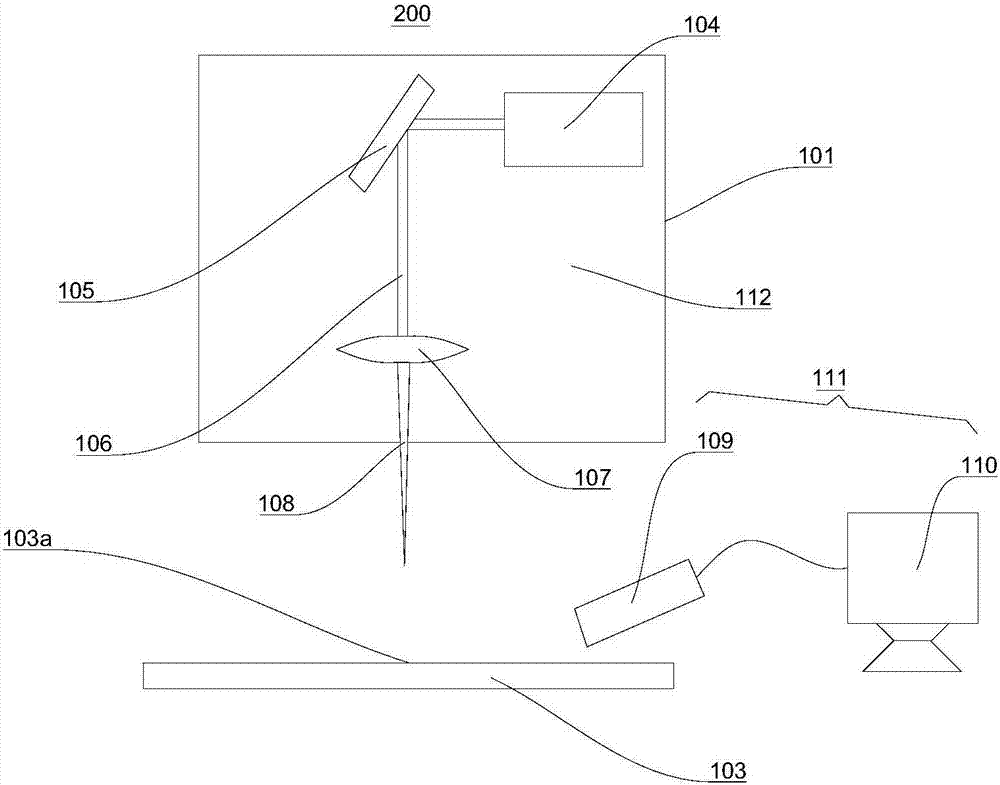

Laser processing device and method for multi-layer material

InactiveCN107511596AFinish quicklyFast preparationLaser beam welding apparatusLaser processingLight spot

The invention provides a laser processing device and method for a multi-layer material and belongs to laser processing materials. The laser processing device for the multi-layer material comprises a light source used for outgoing of laser beams and a multi-focal-point diffraction optical element; and the laser beams are separated through the multi-focal-point diffraction optical element to form a plurality of focusing light spots sequentially arranged in a spaced manner along the spreading path of the laser beams. The laser processing method for the multi-layer material includes the following step that the multi-focal-point diffraction optical element is used for separating the laser beams into the focusing light spots sequentially arranged in the spaced manner along the spreading direction of the laser beams. The focusing light spots are irradiated on the multi-layer material so that the focusing light spots can be located in a plurality of material layers of the multi-layer material. The processing method can fast and efficiently perform laser processing on the multi-layer material, and therefore a high-quality workpiece can be acquired, and the production efficiency is improved.

Owner:南京魔迪多维数码科技有限公司

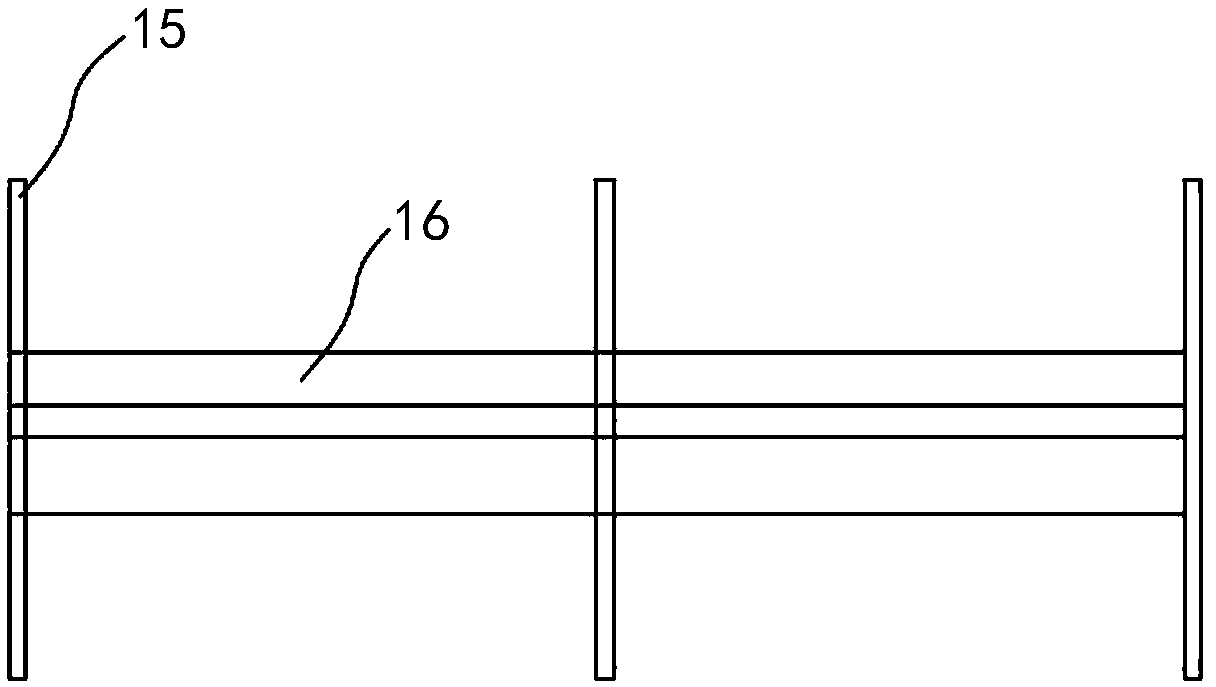

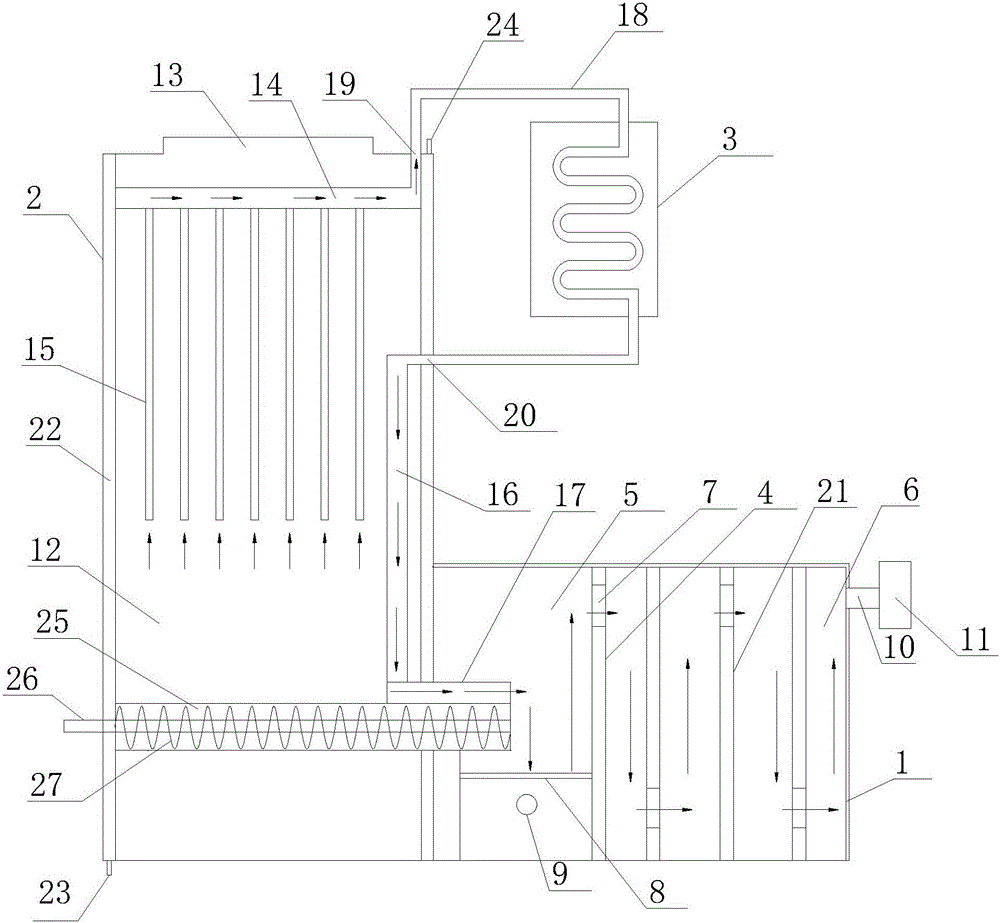

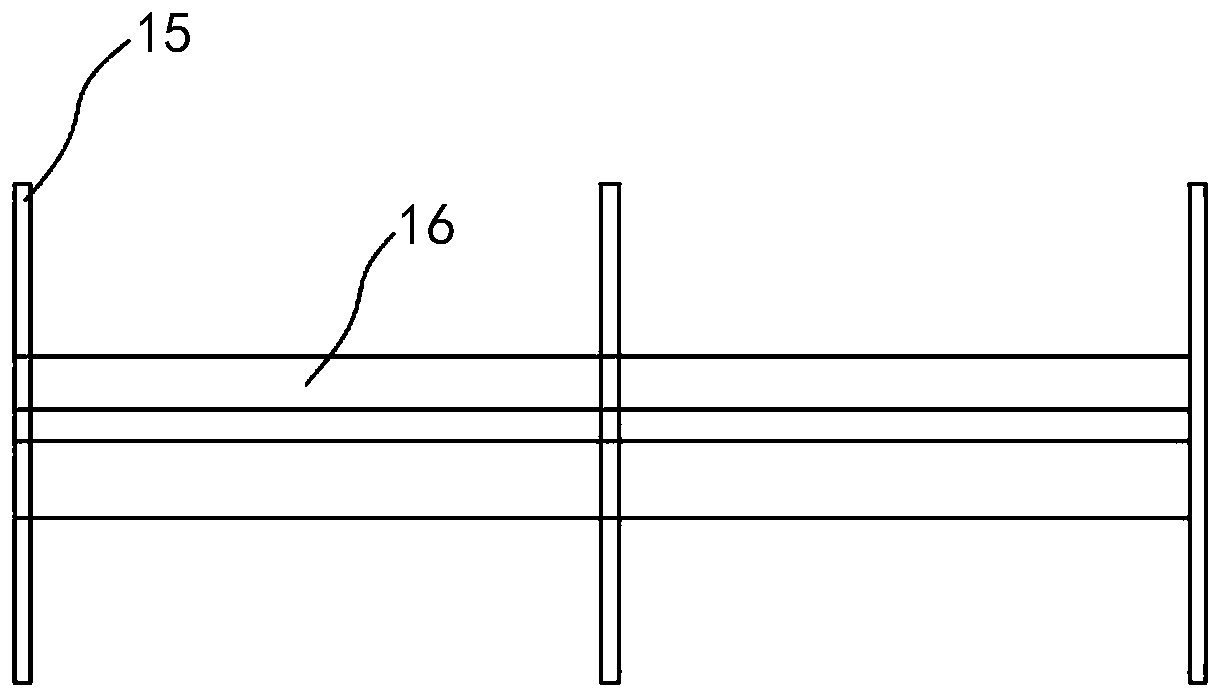

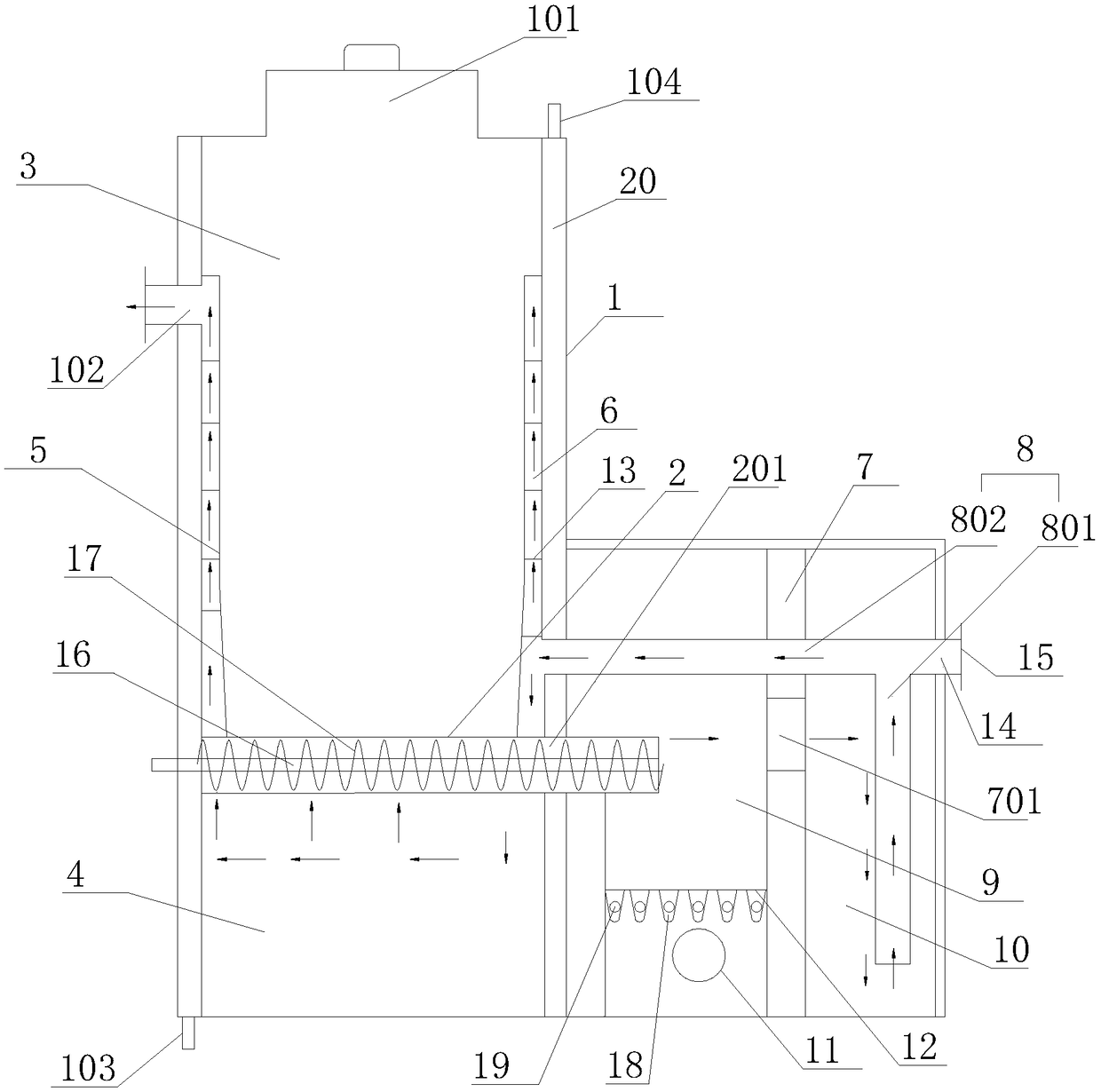

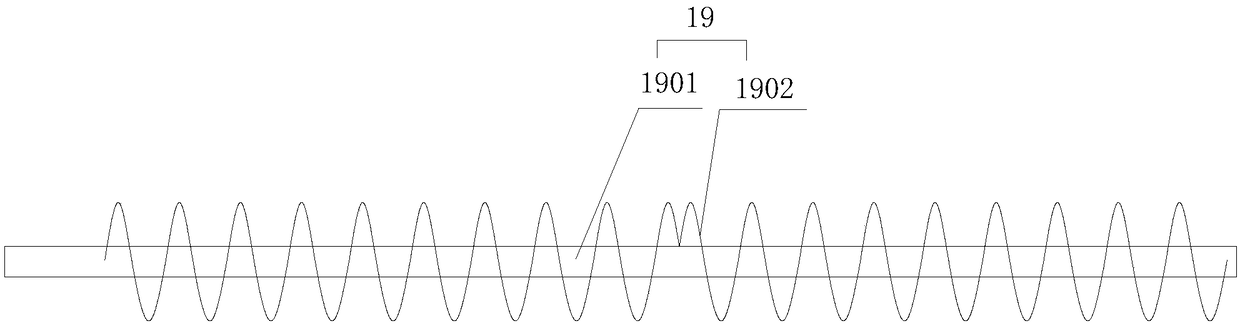

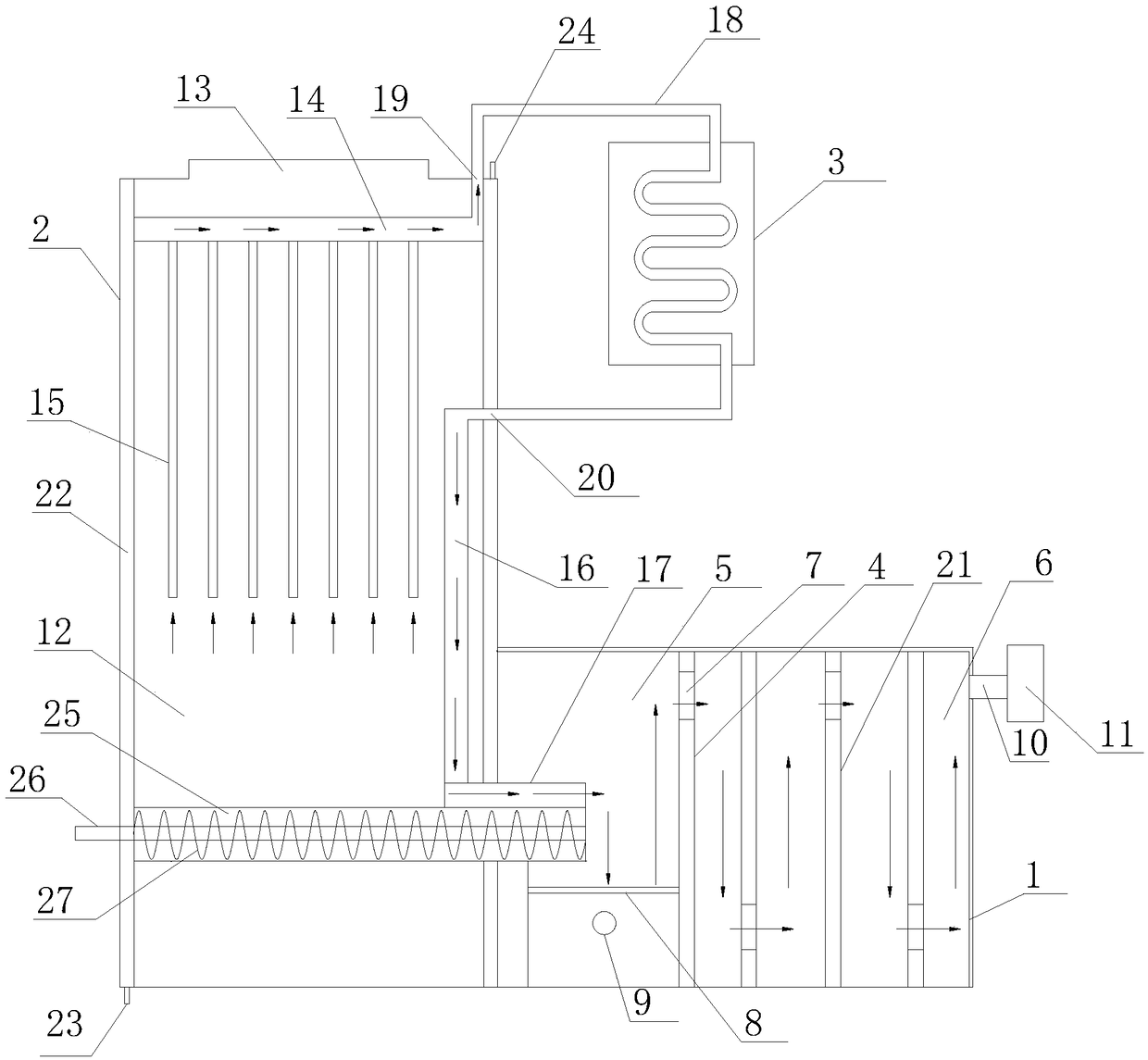

A fabric setting machine

ActiveCN107938233BImprove stylingWrinkles disappearHeating/cooling textile fabricsFabric finishing guides/expandersEngineeringMechanical engineering

Owner:ZHEJIANG TEXWELL TEXTILE

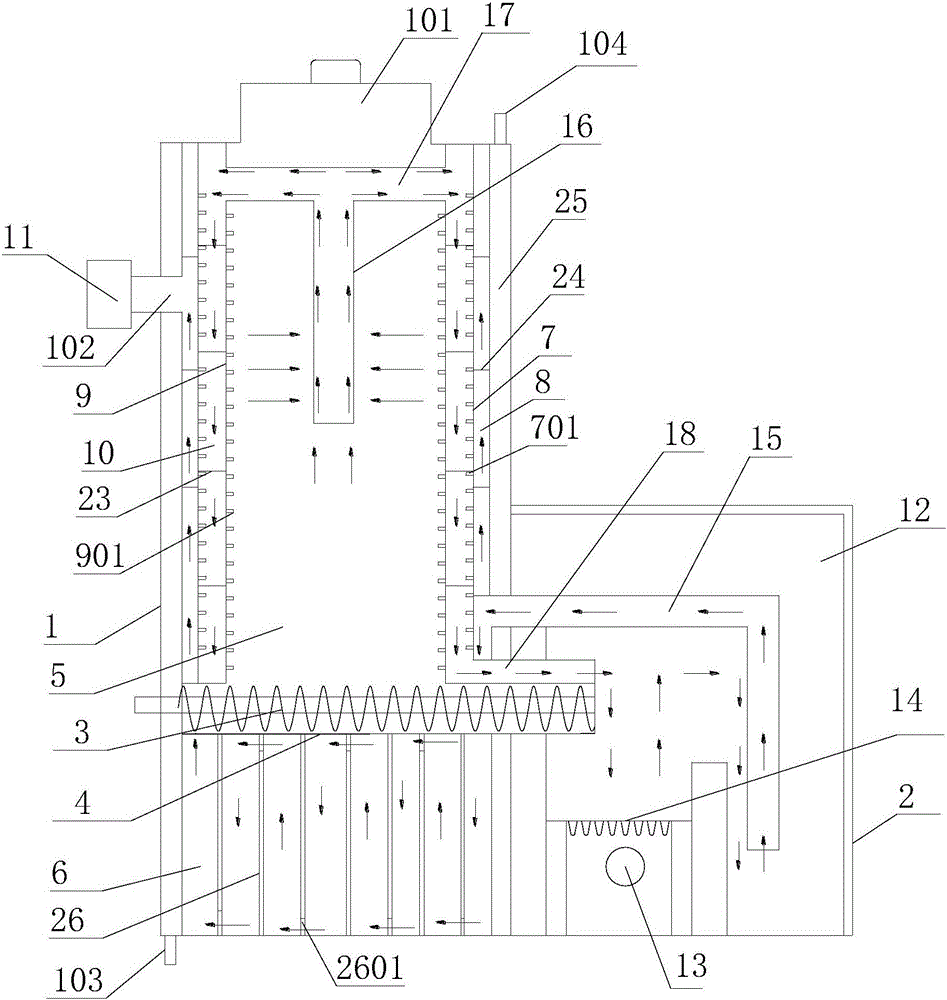

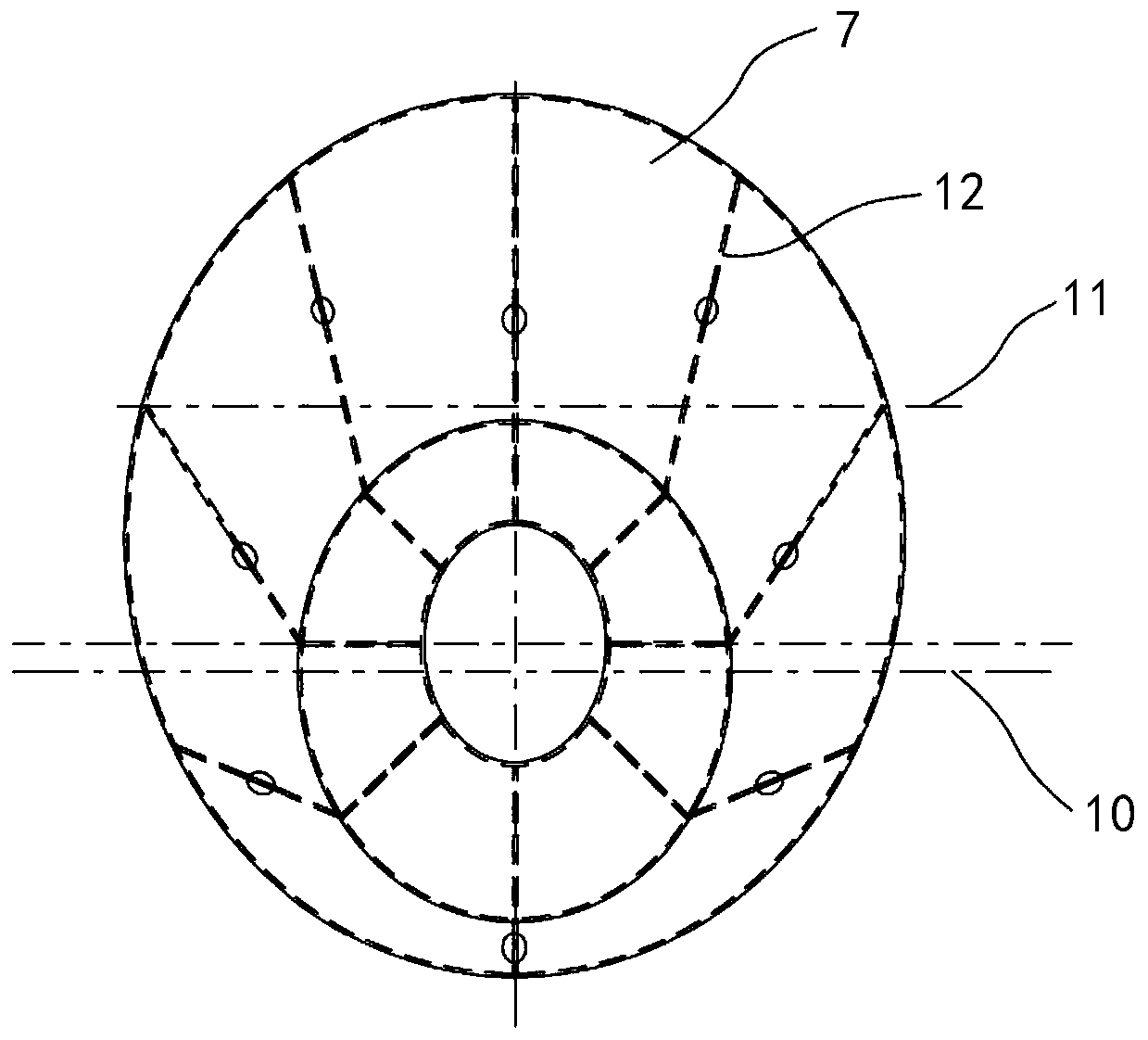

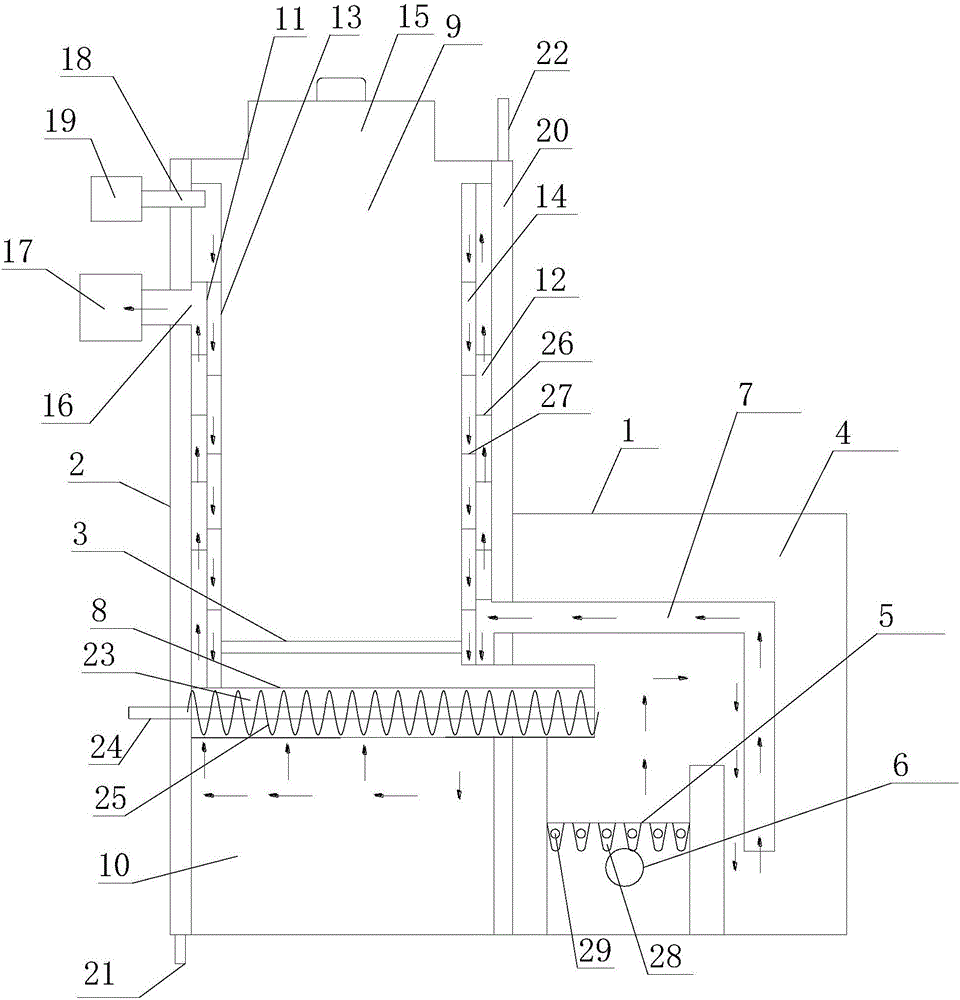

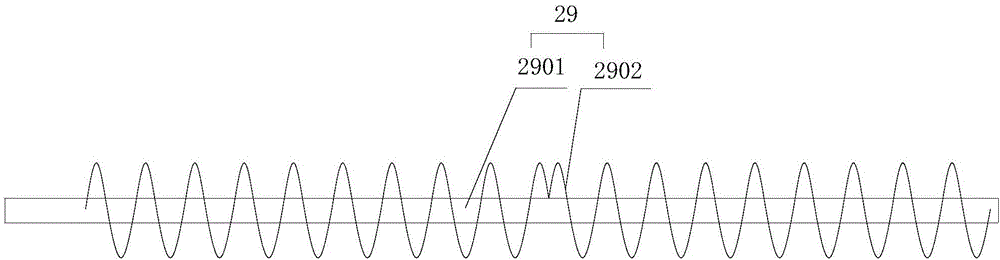

High-temperature incineration refuse treatment device

ActiveCN106765166ABurn fullyImprove combustion efficiencyIncinerator apparatusCombustionProcess engineering

The invention provides a high-temperature incineration refuse treatment device. A combustion cavity and a tail gas buffering cavity are arranged in a first incinerator body. A second incinerator body is provided with a material storage cavity. A heating device is arranged at the bottom of the material storage cavity. A spiral feeding mechanism is used for conveying materials in the material storage cavity into the combustion cavity. An inner circulation mechanism comprises a first gas guide pipe, multiple second gas guide pipes, a third gas guide pipe, a fourth gas guide pipe and an outer gas guide pipe, wherein one end of the first gas guide pipe is sealed, the other end of the first gas guide pipe communicates with a gas outlet, the multiple second gas guide pipes are vertically arranged in the material storage cavity, the gas inlet end of each second gas guide pipe extends into the middle of the material storage cavity, the gas outlet end of each second gas guide pipe communicates with the first gas guide pipe, the gas inlet end of the third gas guide pipe communicates with a gas inlet, the gas outlet end of the third gas guide pipe communicates with the gas inlet end of the fourth gas guide pipe, the gas outlet end of the fourth gas guide pipe extends into the combustion cavity, one end of the outer gas guide pipe communicates with the gas outlet, and the other end of the gas guide pipe penetrates through a cooling water tank to communicate with the gas inlet. The high-temperature incineration refuse treatment device is high in refuse treatment efficiency and in refuse combustion capacity and achieves complete combustion of refuse.

Owner:湖南未名环保科技有限公司

Full combustion treatment equipment for household garbage

InactiveCN106765185AReduce dustAvoid emissionsIncinerator apparatusNon-combustible gases/liquids supplyCombustion chamberEngineering

The invention provides full combustion treatment equipment for household garbage. A cross partition plate in a chamber of a first furnace body divides the chamber into a material storage chamber and a tail smoke chamber; a gap is reserved between a first annular baffle plate and the inner wall of the material storage chamber to form an annular insulating chamber; a gap is reserved between a second annular baffle plate and the first annular baffle plate to form an annular cycle chamber; the second furnace body is provided with a combustion chamber which is internally provided with an oxygen supply device, a furnace bridge and a smoke return pipe, wherein the smoke outlet of the smoke return pipe communicates with the smoke inlet of the tail smoke chamber; a spiral material guiding device is used for conveying a material in the material storage chamber to the combustion chamber; a gas guiding device comprises a first gas guiding pipe, a second gas guiding pipe and a plurality of third gas guiding pipes, wherein the top end of the first gas guiding pipe communicates with the middle portion of the second gas guiding pipe, two ends of the second gas guiding pipe communicate with the annular cycle chamber, and one end of each of the third gas guiding pipes communicates with the annular cycle chamber while the other end extends into the combustion chamber. The equipment provided by the invention can be used for fully treat garbage and is high in utilization ratio of heat generated by garbage combustion.

Owner:SINOBIOWAY DINGHE ENVIRONMENTAL PROTECTION CO LTD

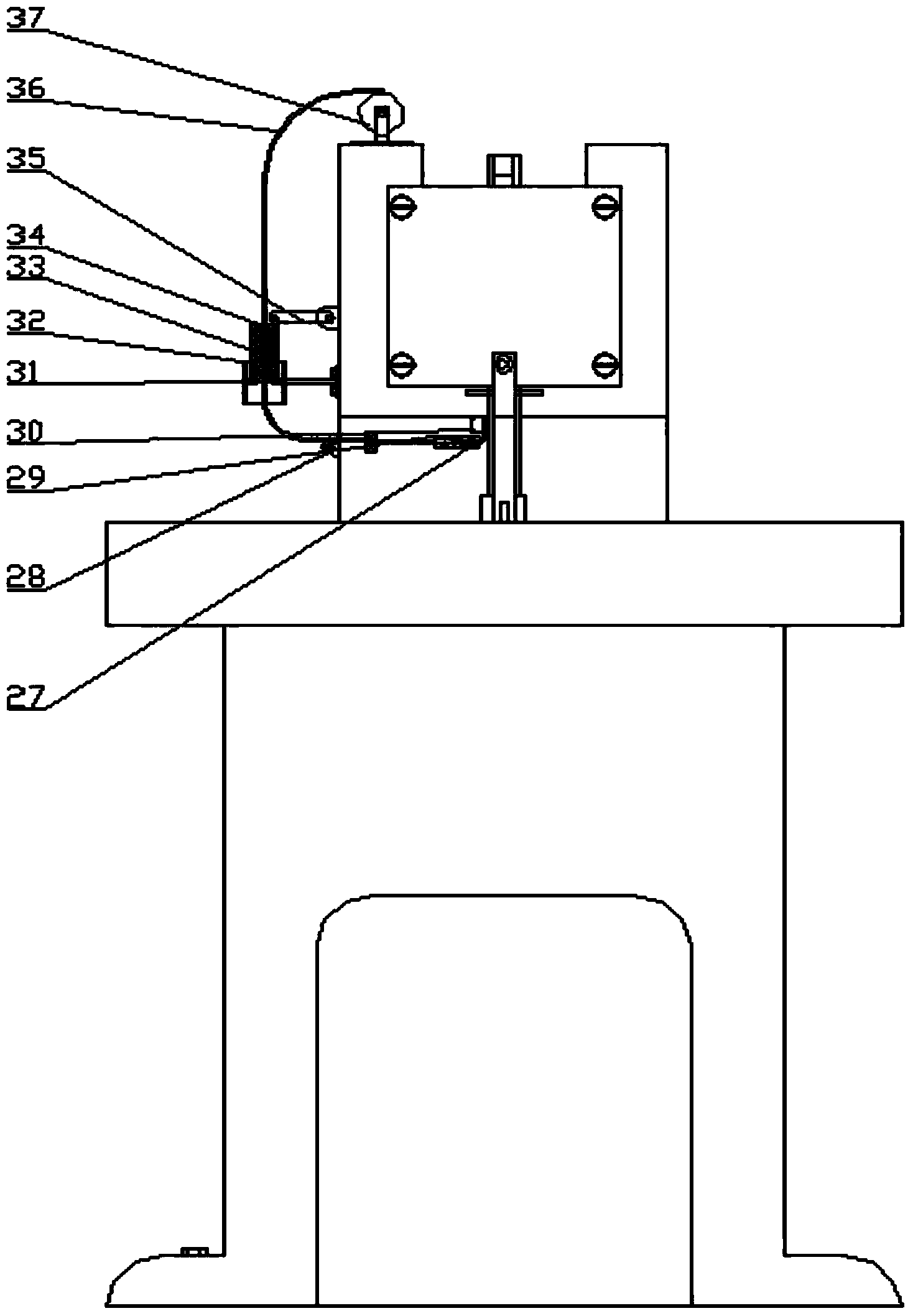

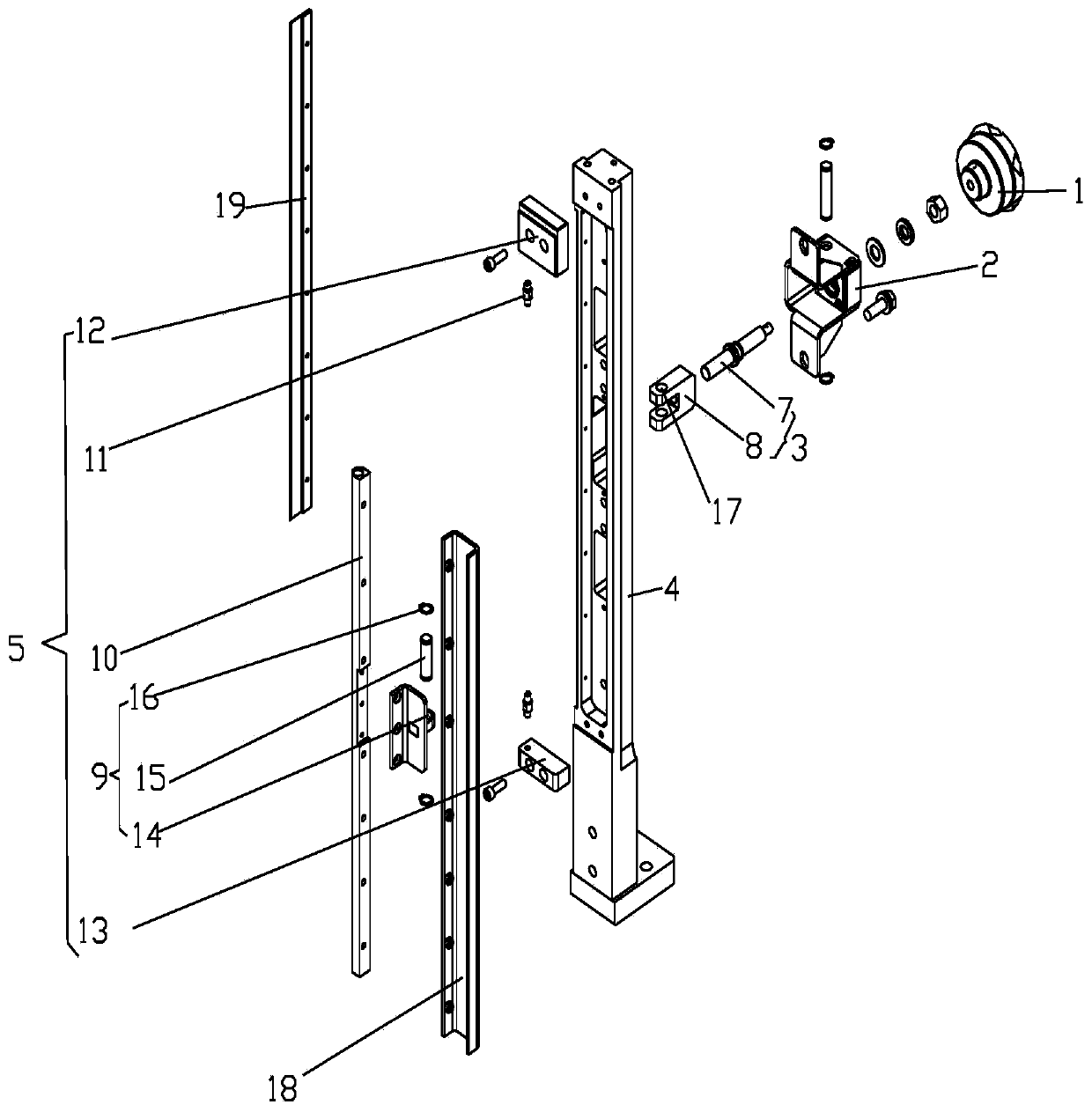

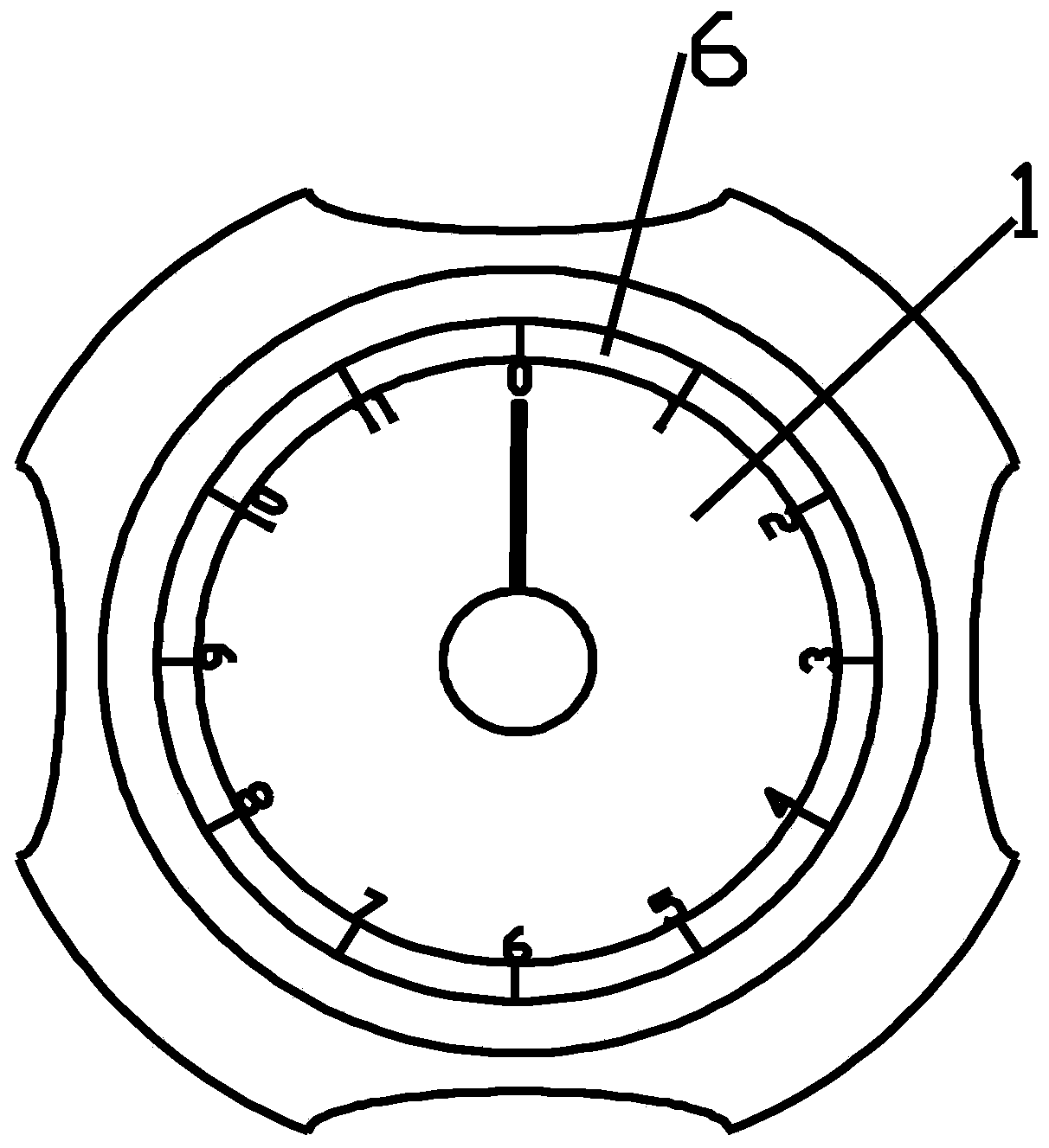

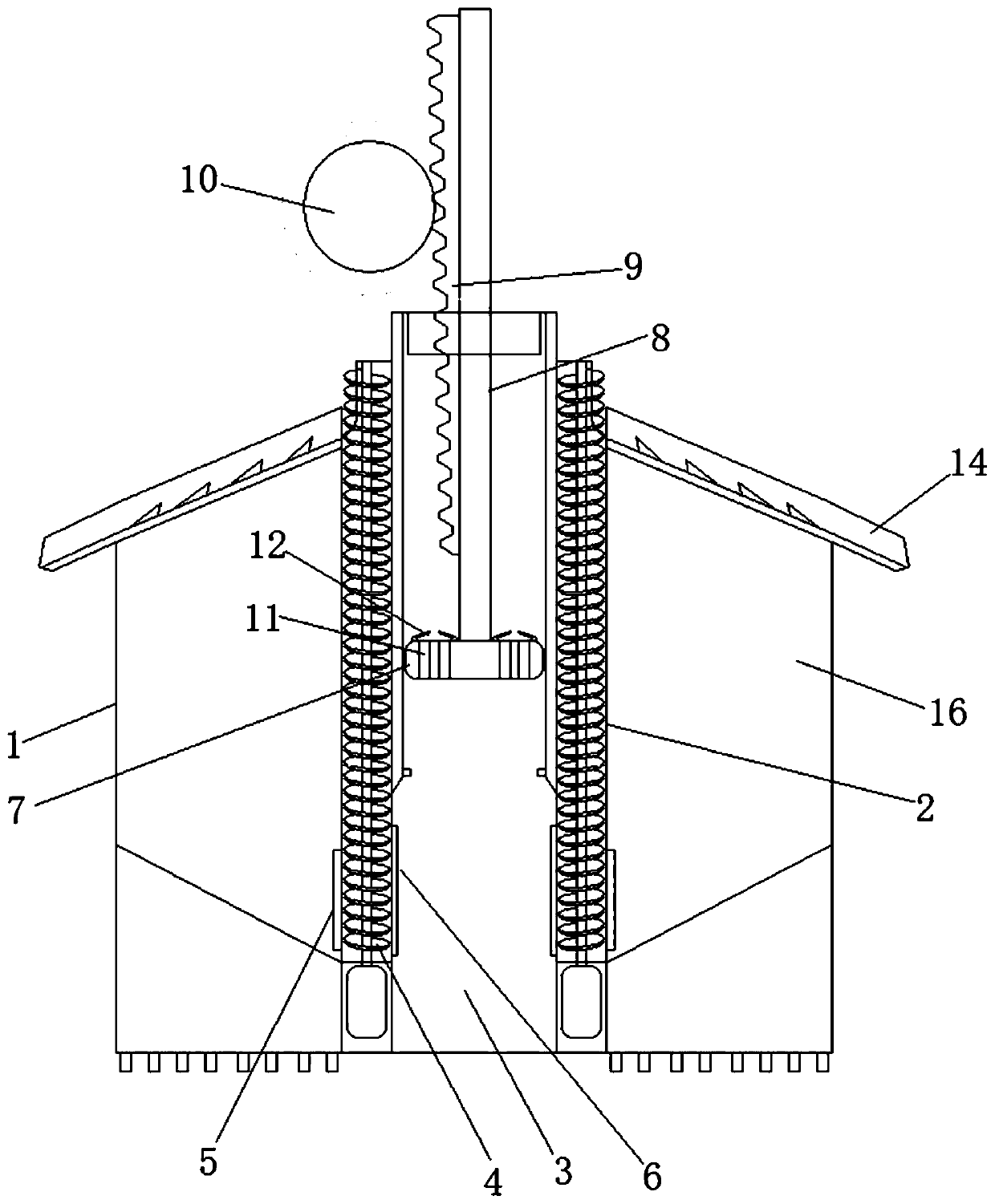

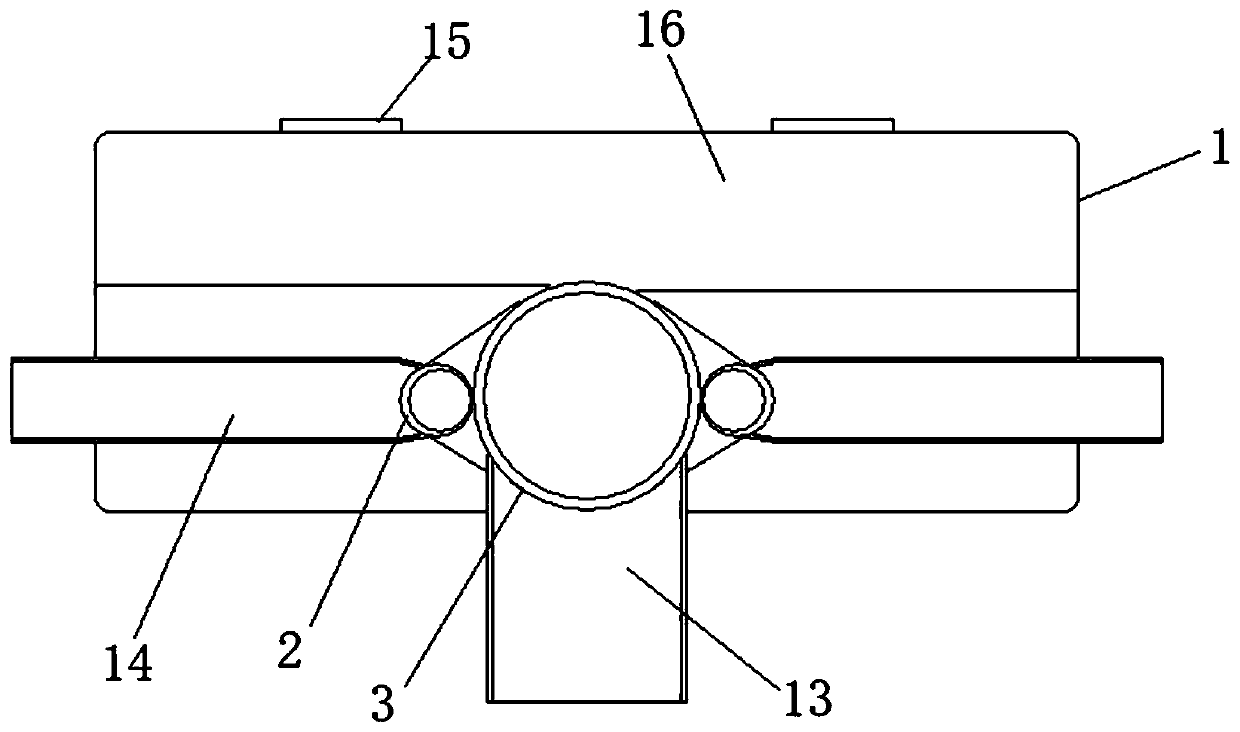

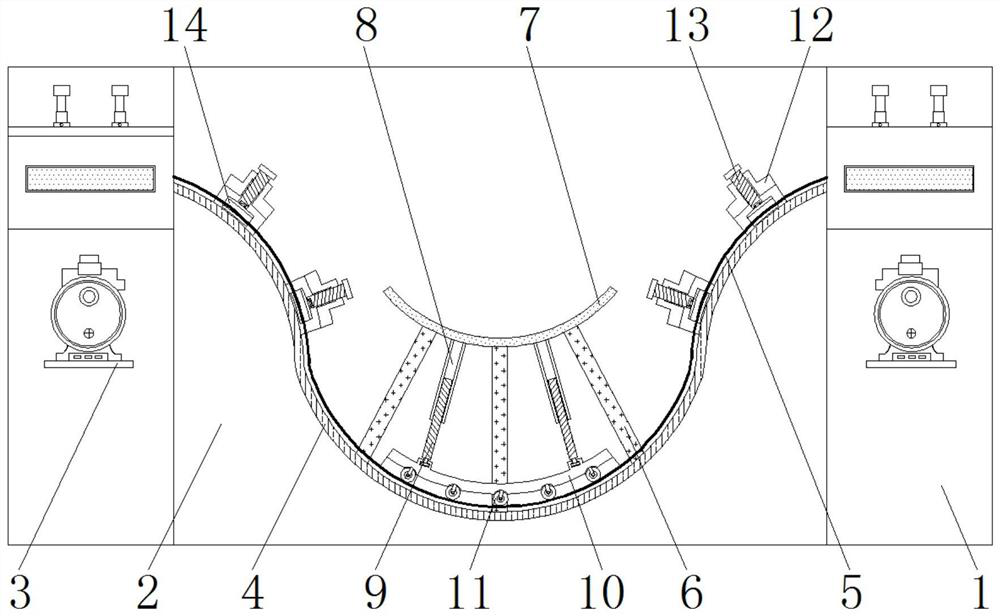

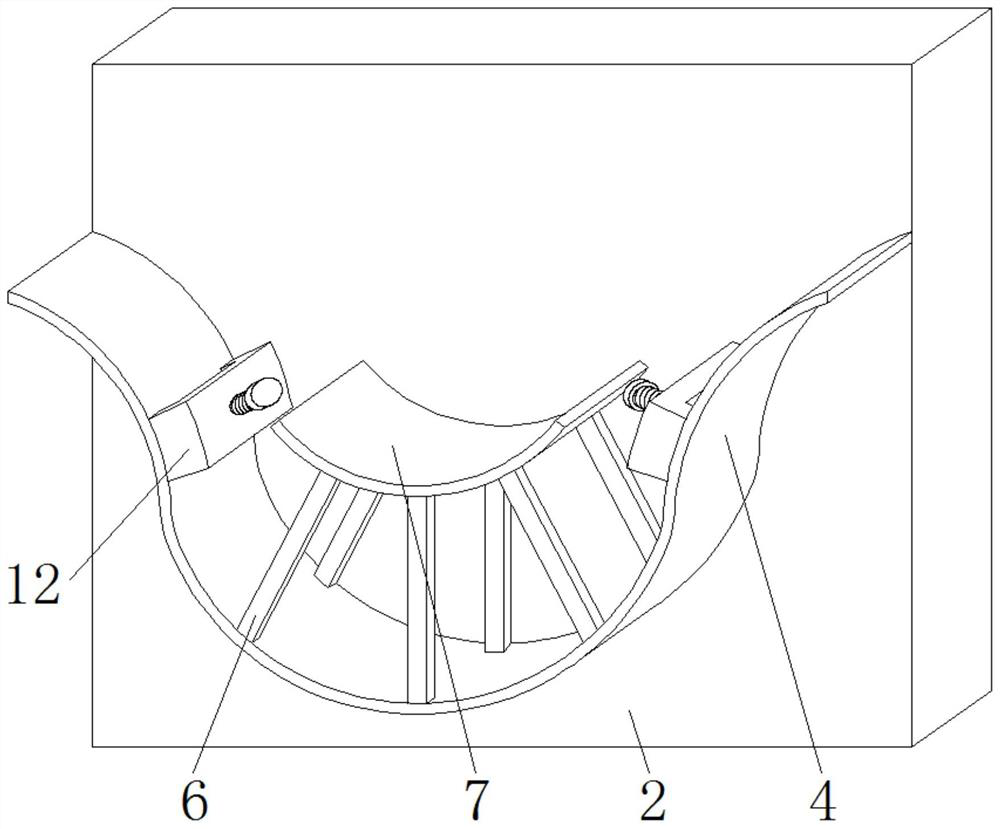

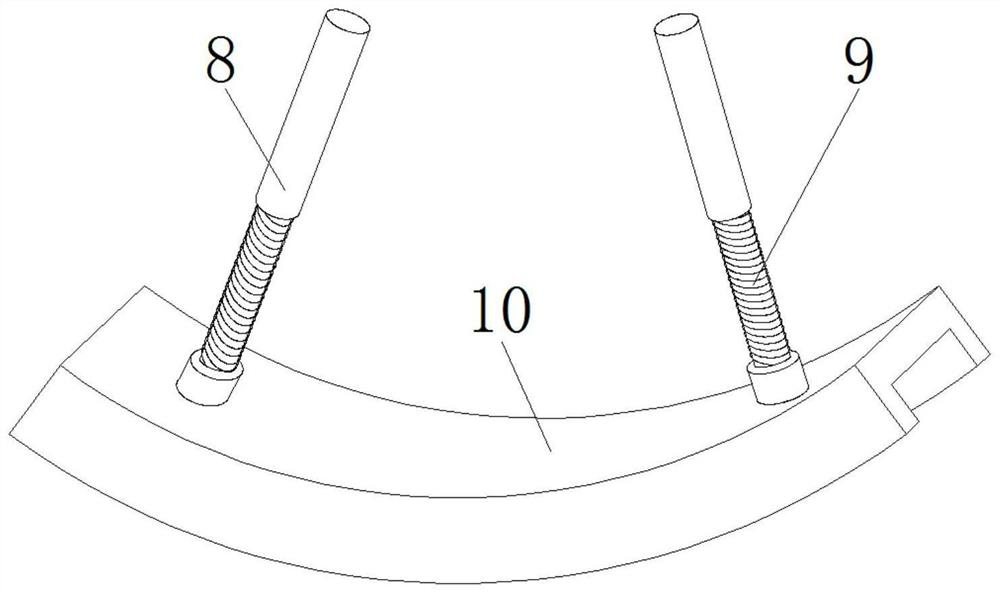

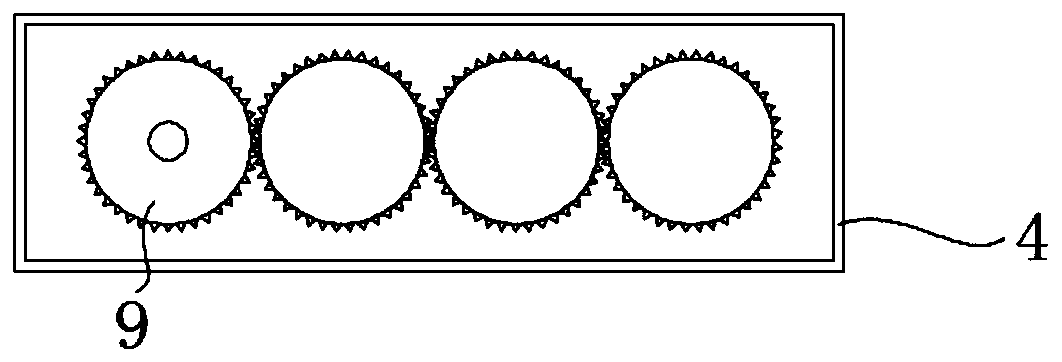

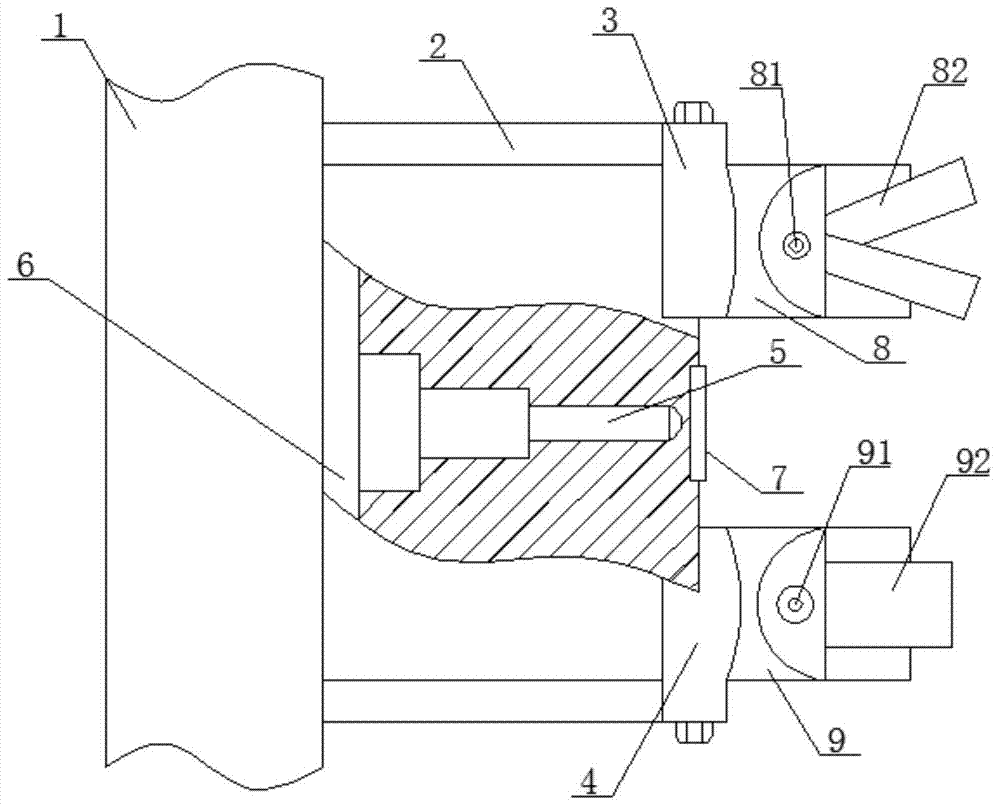

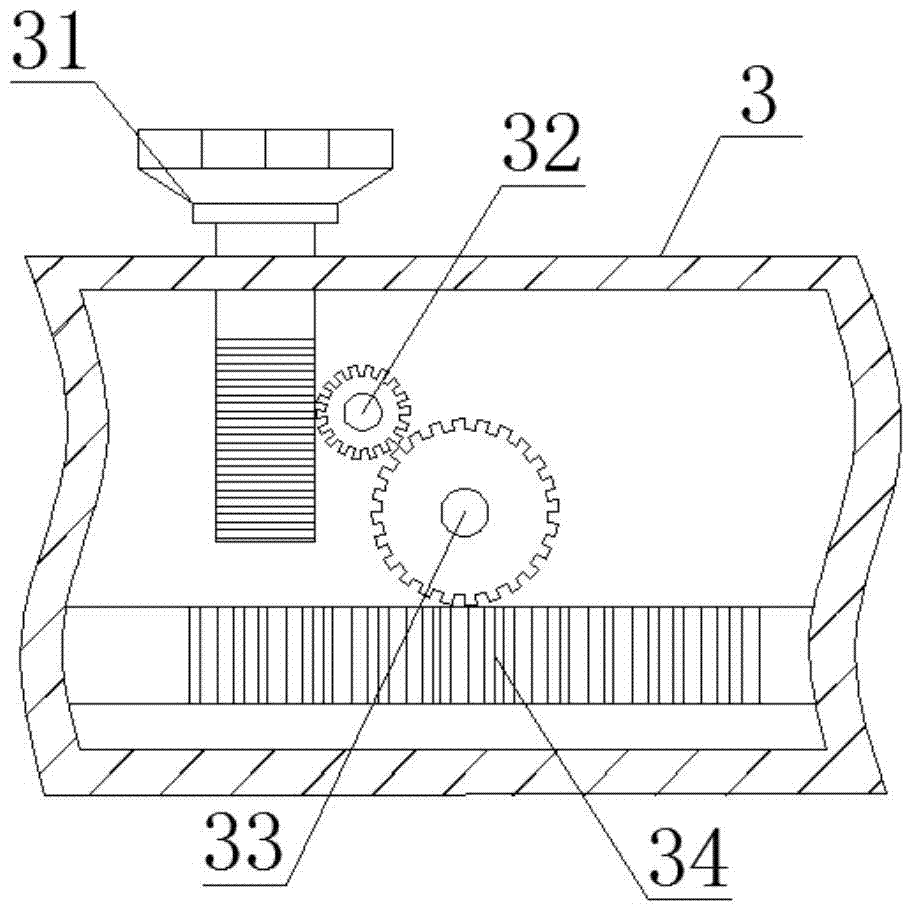

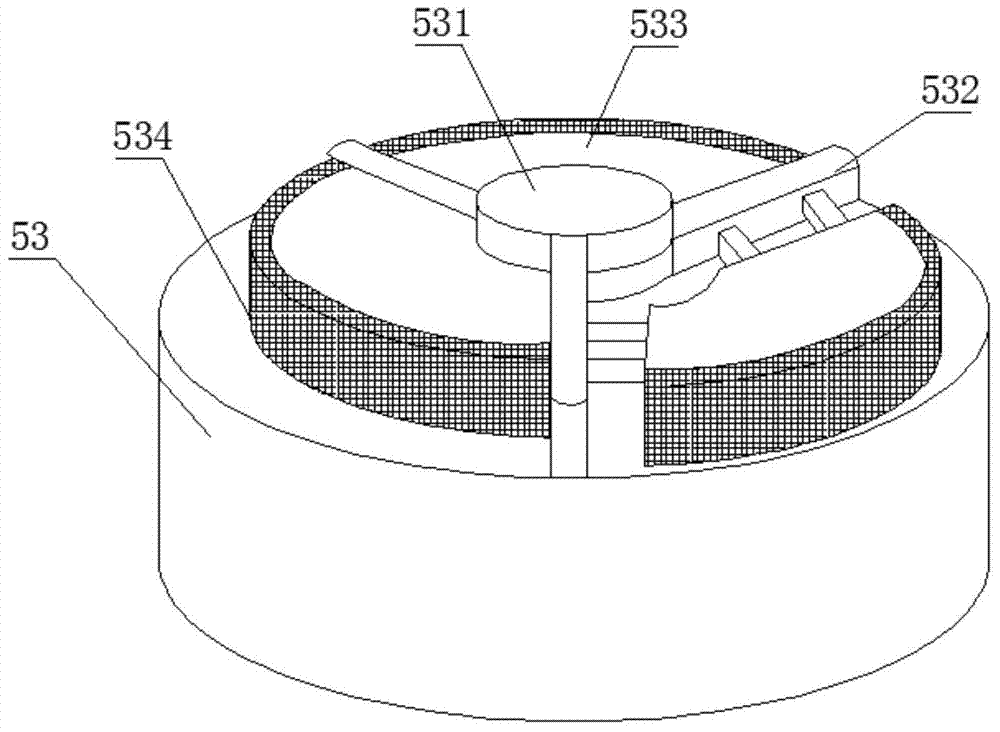

Rotary distance adjusting device

PendingCN110280326AQuick changeStable distanceGrain huskingGrain polishingAgricultural engineeringGrinding wheel

The invention relates to a rotary distance adjusting device. The device comprises an adjusting handle, a handle fixing base, a distance adjusting module, a frame and a rotating module; the adjusting handle penetrates through the handle fixing base to be connected with the distance adjusting module, the distance adjusting module penetrates through the frame to be connected with the rotating module, and the rotating module comprises a connector, a rotating shaft, pins, an upper pressing plate and a lower pressing plate; the connector is connected with the middle of the rotating shaft, the two ends of the rotating shaft are connected with the upper pressing plate and the lower pressing plate through the pins respectively, the upper pressing plate is connected with the upper part of the frame, and the lower pressing plate is connected with the lower part of the frame. The rotary distance adjusting device achieves the purpose of precisely adjusting the distance through the distance adjusting module, ensures the consistency of the vertical spacing between a rice cutter and a grinding wheel, and reduces the rice damage rate of a finished product.

Owner:SATAKE MFG SUZHOU

Small and medium-sized riverway upstream water-soil separation device

The invention discloses a small and medium-sized riverway upstream water-soil separation device comprising a river interception bin; a sludge discharge bin and a filtered water discharge bin are fixedly arranged in a river interception plate, a piston pipeline is arranged on the upper portion of the filtered water discharge bin, and a negative pressure pipeline is arranged on the lower portion ofthe filtered water discharge bin; a spiral blade is arranged in the sludge discharging bin, a water inlet is formed in the bottom of the sludge discharging bin, a filtering opening is formed between the sludge discharging bin and the negative pressure pipeline, and the filtering opening is covered with a sludge filtering layer; a piston is arranged in a piston pipeline of the filtered water discharge bin, a lifting rod is arranged on the upper portion of the piston, a rack is arranged on the lifting rod in the length direction of the lifting rod, an incomplete gear meshed with the rack is arranged above the filtered water discharge bin, a plurality of through holes are formed in the piston, and turnover covers are hinged to the through holes. Sand and sludge in a riverway can be continuously filtered, and water and soil loss and downstream riverbed lifting are avoided.

Owner:ANHUI ACADEMY OF ENVRIONMENTAL SCIENCE RESEARCH

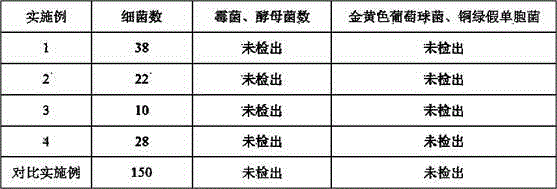

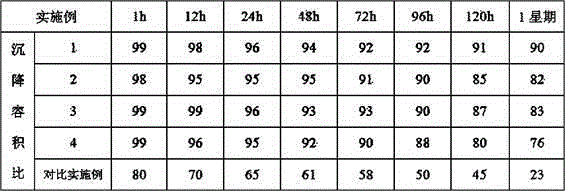

Preparation method of calamine lotion

ActiveCN104940137AImproved powder solubilityImprove bioavailabilityInorganic active ingredientsSolution deliveryMicroorganismEngineering

The invention provides a preparation method of a calamine lotion. The method specifically includes the steps of: mixing and grinding, cleaning, liquid preparation mixing, and filling, thus obtaining a finished product. The product obtained by the method provided by the invention has suspension liquid with good stability and lasting suspension property, the microorganisms are effectively controlled, and no gravel feel is generated during application of the lotion.

Owner:HUNAN ER KANG PHARMA

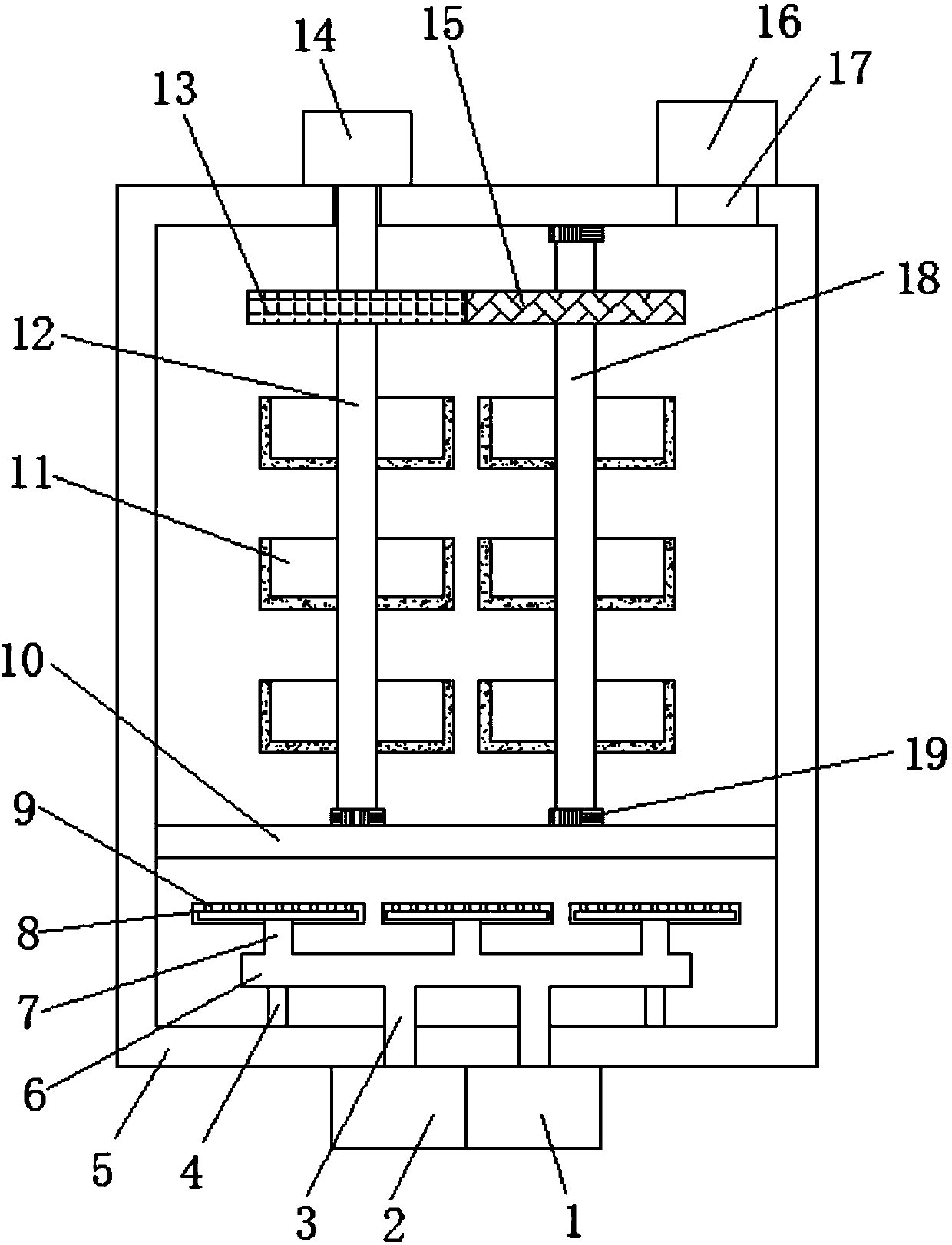

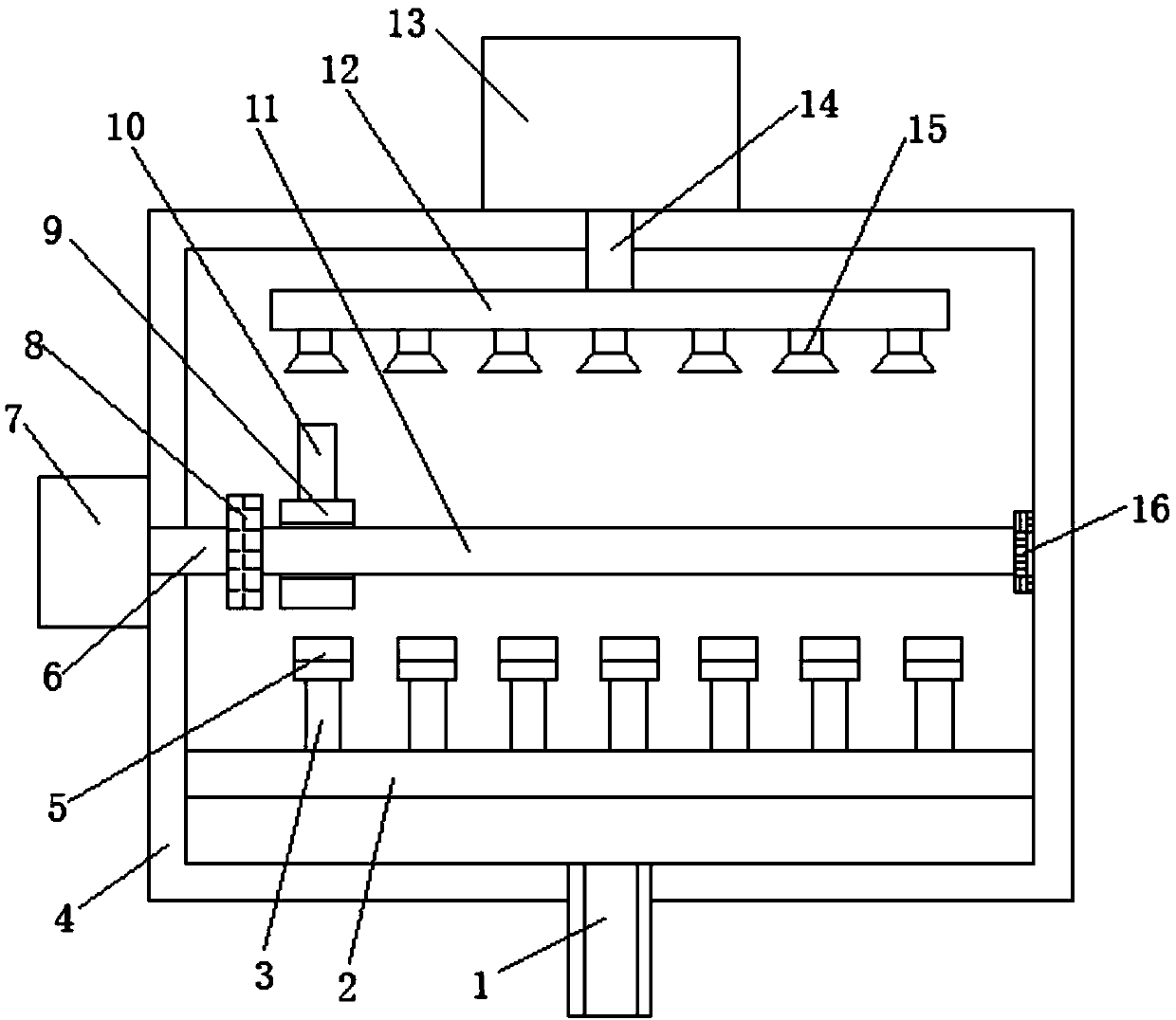

Mechanical accessory drying device for machine tool machining

InactiveCN109990587ADry evenlyTimely useDrying gas arrangementsDrying machines with non-progressive movementsEngineeringDrive motor

The invention discloses a mechanical accessory drying device for machine tool machining. The mechanical accessory drying device comprises a drying box. A hot wind blower and a cold wind blower are fixed to the middle position of the bottom end of the drying box. The cold wind blower is located on one side of the hot wind blower. Wind input pipes arranged vertically are fixed to the middle positions of the top ends of the hot wind blower and the cold wind blower correspondingly. The top ends of the wind input pipes penetrate through the outer wall of the bottom end of the drying box and extendinto the drying box. Transverse pipes arranged horizontally are connected to the top ends of the two wind input pipes. Three connecting pipes arranged vertically are connected to the top ends of the transverse pipes. A wind input disc is connected to the top end of each connecting pipe. A drive motor is fixed to one side of the top end of the drying box. According to the device, mechanical accessories are dried in an all-dimensional manner, drying is uniform, the drying effect is good, when drying temperature of the mechanical accessories rises, the mechanical accessories are cooled, thus themechanical accessories can be used in time, follow-up work of personnel is reduced, flexibility is high, and the working efficiency is high.

Owner:天津永创通达机电科技有限公司

A method for manufacturing and installing anchor chain cylinder and anchor platform

ActiveCN109094723BImprove installation accuracyImprove work efficiencyVessel designingMechanical engineeringHull

The invention discloses a production and installation method of an anchor chain cylinder and an anchor platform. The intersecting line intersecting with the outer plate and the first installation line for installing the rib plate are marked on the anchor chain cylinder, and the anchor platform is marked on the anchor platform. Mark the first horizontal line and the first rib line, draw the center line of the hull, the second rib line and the installation direction on the deck, and draw the second horizontal line, the third rib line and the installation direction on the outer plate of the hull. During the installation process , using the method of aligning each marking line with the anchor chain barrel, anchor platform, deck and outer plate, the overall installation accuracy of the anchor system is finally improved, and the purpose of controlling the installation accuracy is achieved. This installation method can reduce follow-up work, Improve the overall work efficiency of shipbuilding.

Owner:CSSC HUANGPU WENCHONG SHIPBUILDING COMPANY

A domestic waste disposal device

The invention discloses a domestic garbage treatment device which comprises a furnace body and a spiral conveying mechanism; the furnace body is provided with a first cavity and a second cavity; a transverse baffle is arranged in the first cavity and divides the first cavity into a storage cavity and a tail smoke preheating cavity; an annular baffle is arranged in the storage cavity and encloses an annular smoke return cavity with the inner wall of the storage cavity together; a vertical partition plate and a smoke return pipe are arranged in the second cavity; the vertical partition plate divides the second cavity into a combustion cavity and a tail smoke cavity; the combustion cavity is internally provided with an oxygen supply device and a furnace bridge; a smoke inlet of the smoke return pipe extends into the bottom of the tail smoke cavity; a smoke outlet of the smoke return pipe communicates with a smoke inlet of the tail gas preheating cavity; and the spiral conveying mechanism is used for conveying a material in the storage cavity into the combustion cavity. According to the domestic garbage treatment device, auxiliary heating is carried out on garbage in the storage cavity by utilizing a great quantity of heat carried by oxidation tail gas produced by garbage combustion, so that the garbage is guaranteed to reach a combustion point when entering the combustion cavity, and the utilization ratio of the heat generated by garbage combustion is increased.

Owner:SINOBIOWAY DINGHE ENVIRONMENTAL PROTECTION CO LTD

Energy-saving and environment-friendly type garbage disposal device

The invention provides an energy-saving and environment-friendly type garbage disposal device. A first furnace body is provided with a combustion chamber. A second furnace body is provided with a cavity. The cavity is divided into a storage cavity body and an auxiliary heating cavity through a transverse partition plate in the cavity. A gap is reserved between a first annular baffle and the inner wall of the storage cavity body, and an annular heat preservation cavity is formed. A gap is reserved between a second annular baffle and the first annular baffle, and an annular oxygen supply cavity is formed. A feed inlet communicating with the storage cavity body is formed in the top end of the second furnace body. The second furnace body is provided with a smoke exhaust pipe communicating with the annular heat preservation cavity. The air exhaust end of the smoke exhaust pipe is connected with a first draught fan. The second furnace body is provided with an oxygen supply pipe communicating with the annular oxygen supply cavity, and the air inlet end of the oxygen supply pipe is connected with a second draught fan. A spiral feeding mechanism is used for conveying materials in the storage cavity body into the combustion chamber. A plurality of air guide pipes are arranged at the bottom of the storage cavity body side by side, and the two ends of each air guide pipe communicate with the annular oxygen supply cavity. By means of the energy-saving and environment-friendly type garbage disposal device, garbage can be disposed thoroughly and can also combust sufficiently, and the utilization rate of heat generated by combustion of garbage is high.

Owner:SINOBIOWAY DINGHE ENVIRONMENTAL PROTECTION CO LTD

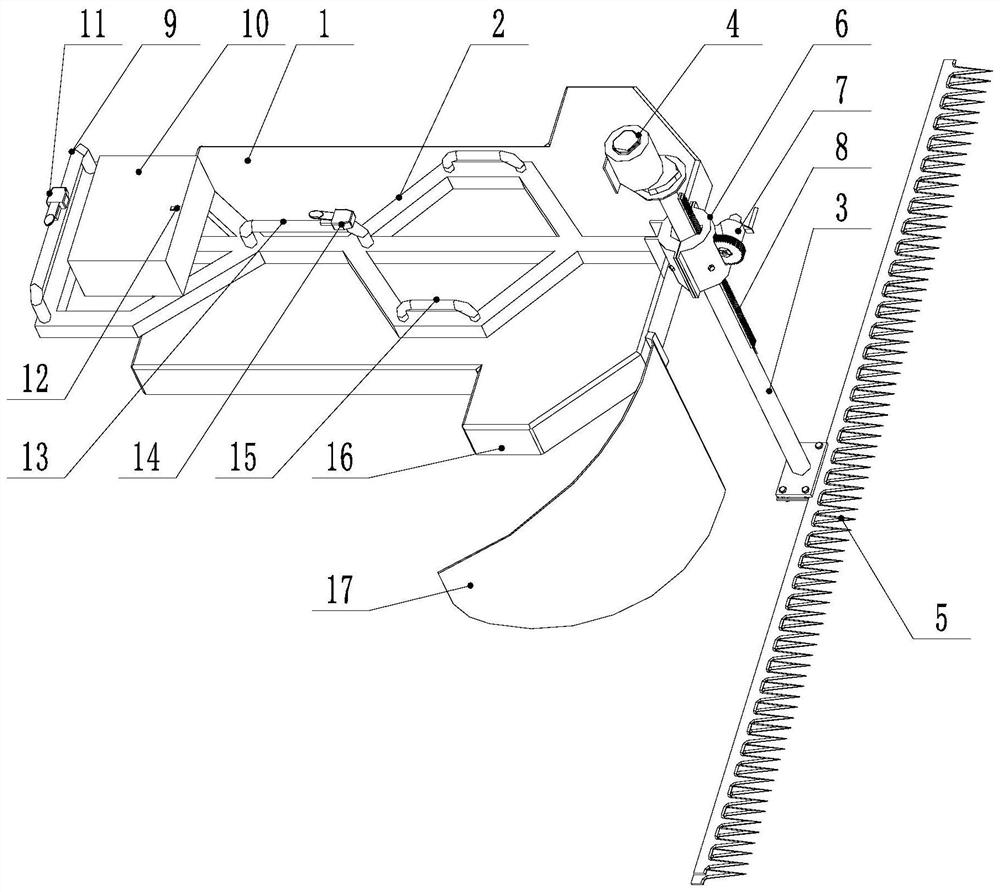

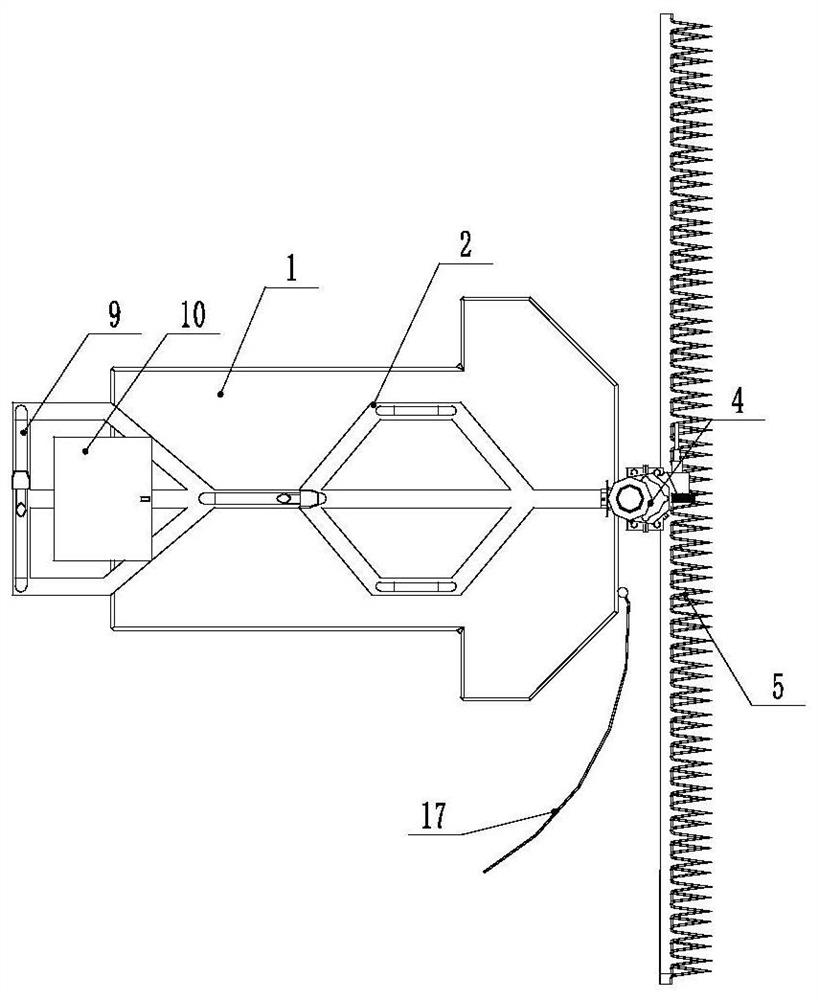

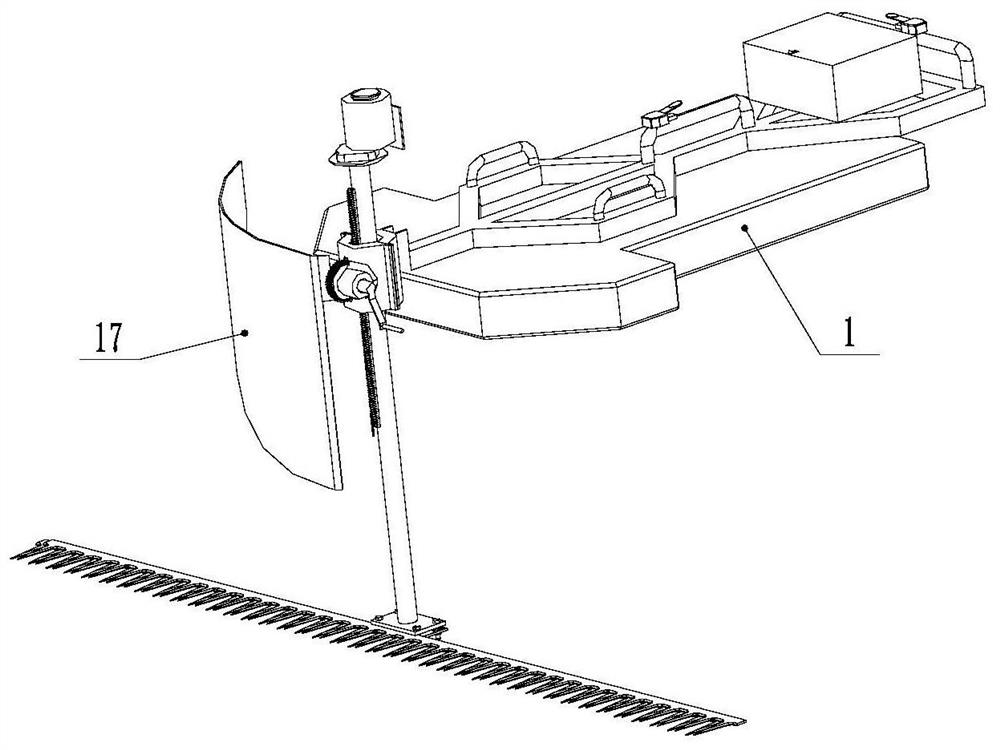

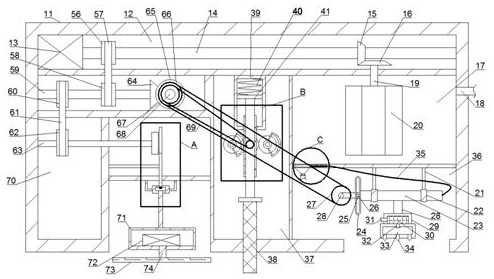

Cress harvester

The invention discloses a cress harvester. The cress harvester comprises a floating plate, a support, an adjusting stand column, a storage battery, a motor and a cutting assembly, wherein the supportis arranged above the floating plate; the front end of the support is connected with the adjusting stand column through a sleeve cylinder; a backward pushing handle is arranged at the tail end of thesupport; the motor is arranged at the top end of the adjusting stand column and connected with the cutting assembly arranged at the bottom end of the adjusting stand column through a transmission mechanism; at least one side of the front end of the floating plate extends outwards to form a side stop block; a side baffle plate is arranged below the side stop block; the storage battery is arranged at a position, close to the backward pushing handle, above the support; a power switch is arranged on the storage battery; a first control switch is arranged on the backward pushing handle; the power switch and the first control switch controls the storage battery to communicate with the motor; and the cutting assembly is driven to conduct cutting operation after the motor is powered on. The cressharvester provided by the invention realizes cress harvesting, and is simple in operation, high in harvesting efficiency and high in practicability.

Owner:NANJING INST OF VEGETABLE SCI +1

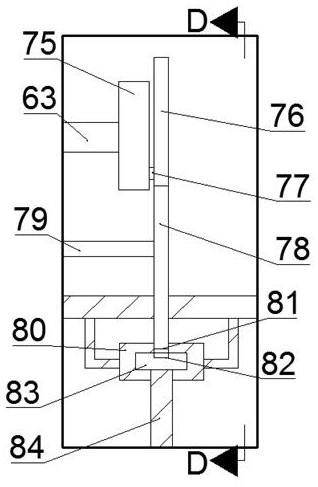

Annealed wafer sliding positioning device capable of reducing friction

PendingCN112620515ALower bootEffective guidanceMetal-working feeding devicesPositioning devicesElectric machineryEngineering

The invention discloses an annealed wafer sliding positioning device capable of reducing friction. The annealed wafer sliding positioning device comprises an annealed wafer feeding device, a fixed lining board, a driving motor and an annealed wafer material, wherein the inner side of the annealed water feeding device is integrally provided with the fixed lining board; the front side of the fixed lining board is provided with a sliding support plate; the annealed water material is tightly attached to the middle of the upper side of the sliding support plate; the lower ends of fixed mounting rods are welded to the outer side of the upper part of the sliding support plate; a mounting top plate is fixed to the upper ends of the fixed mounting rods; and a fixed support cylinder is integrally arranged in the middle of the lower side of the mounting top plate. The annealed wafer sliding positioning device capable of reducing the friction can effectively guide annealed wafers, buffers the impact force generated when the returned wafers move, guarantees the stability during sliding, can be adjusted according to the thicknesses and the moving speeds of the annealed wafers, is high in flexibility, can effectively reduce the friction, can protect the annealed wafer material, and improves the sliding efficiency.

Owner:芜湖品金电器科技有限公司

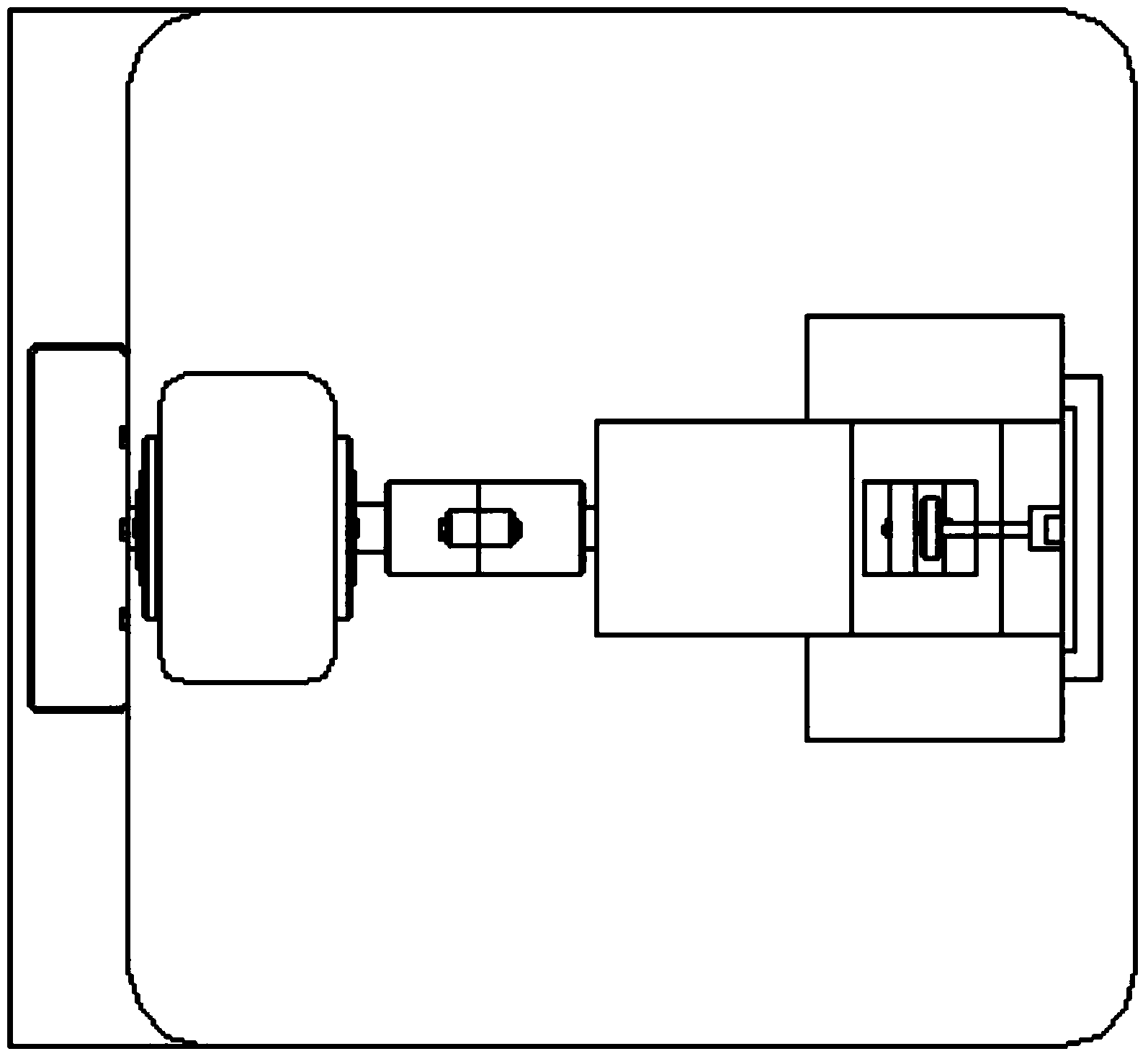

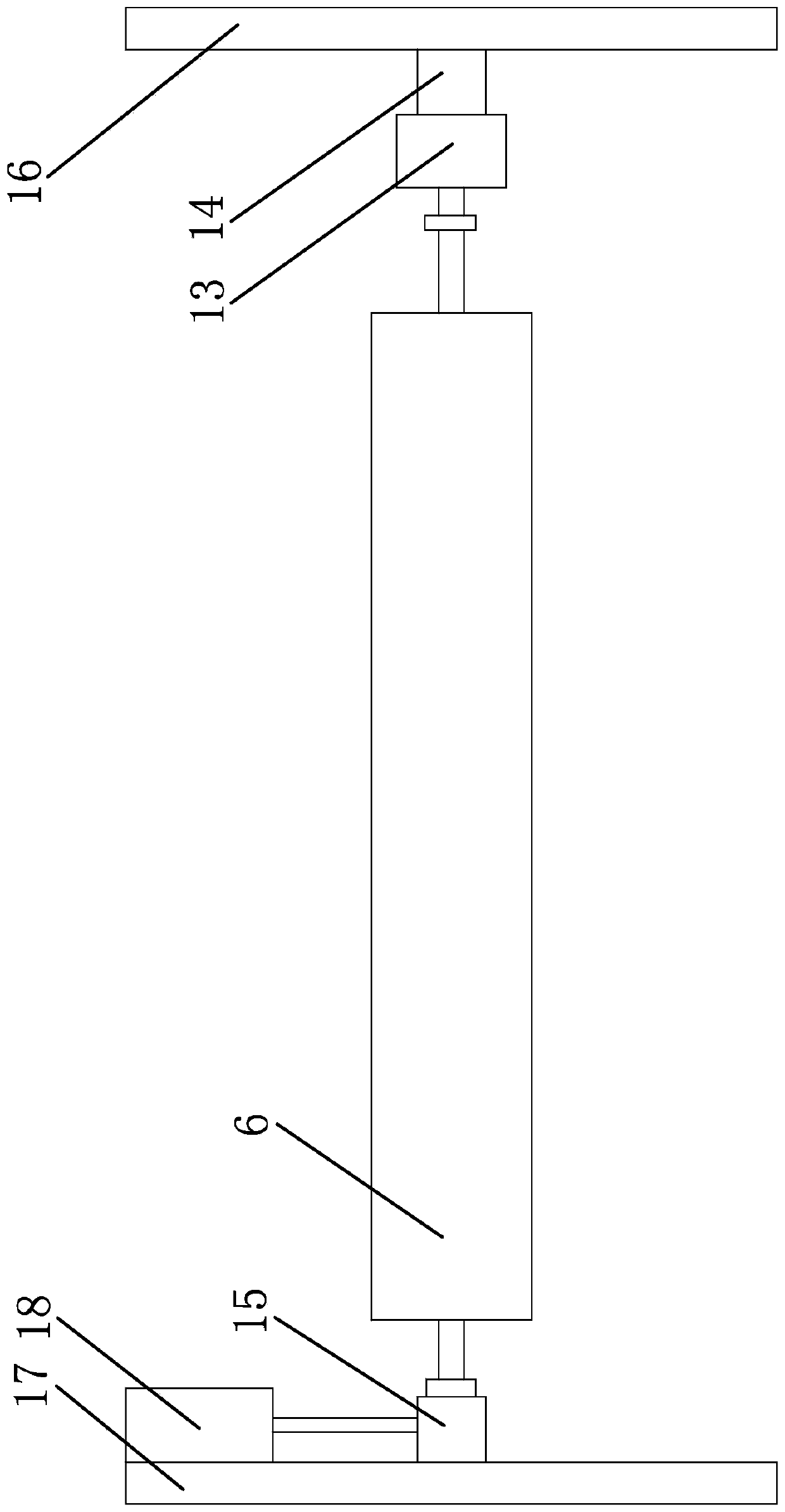

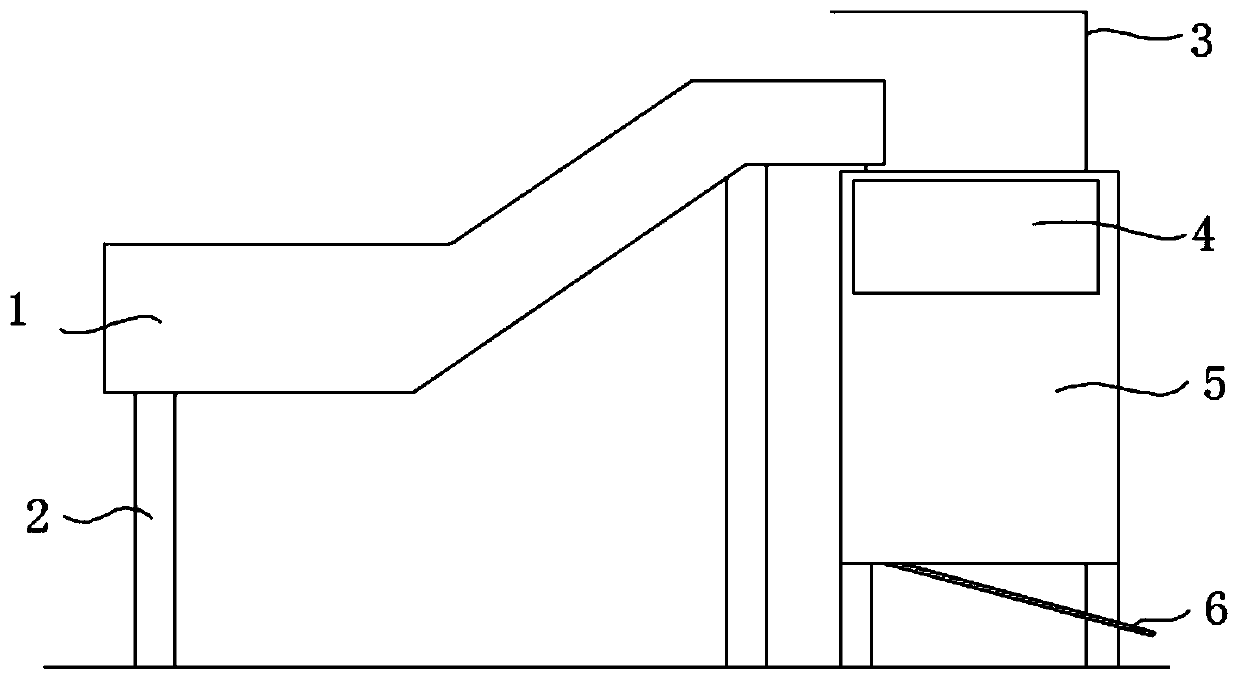

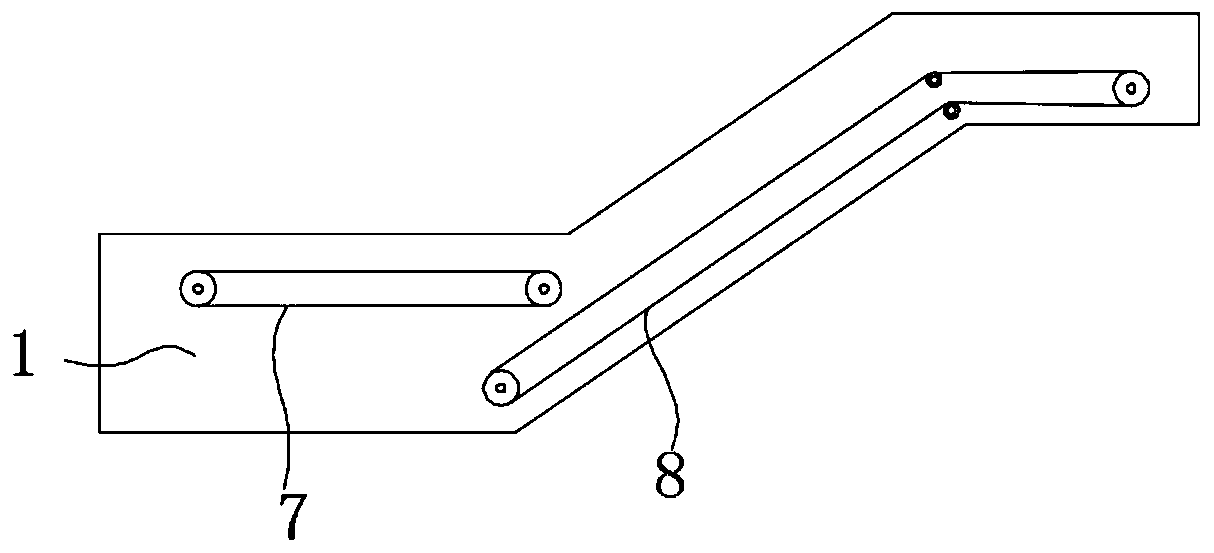

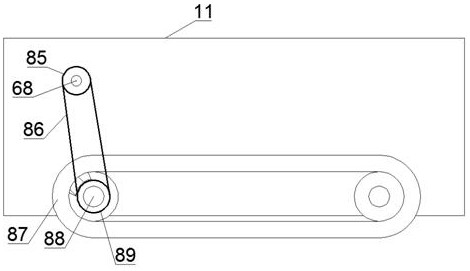

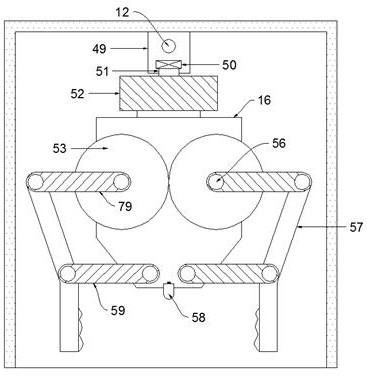

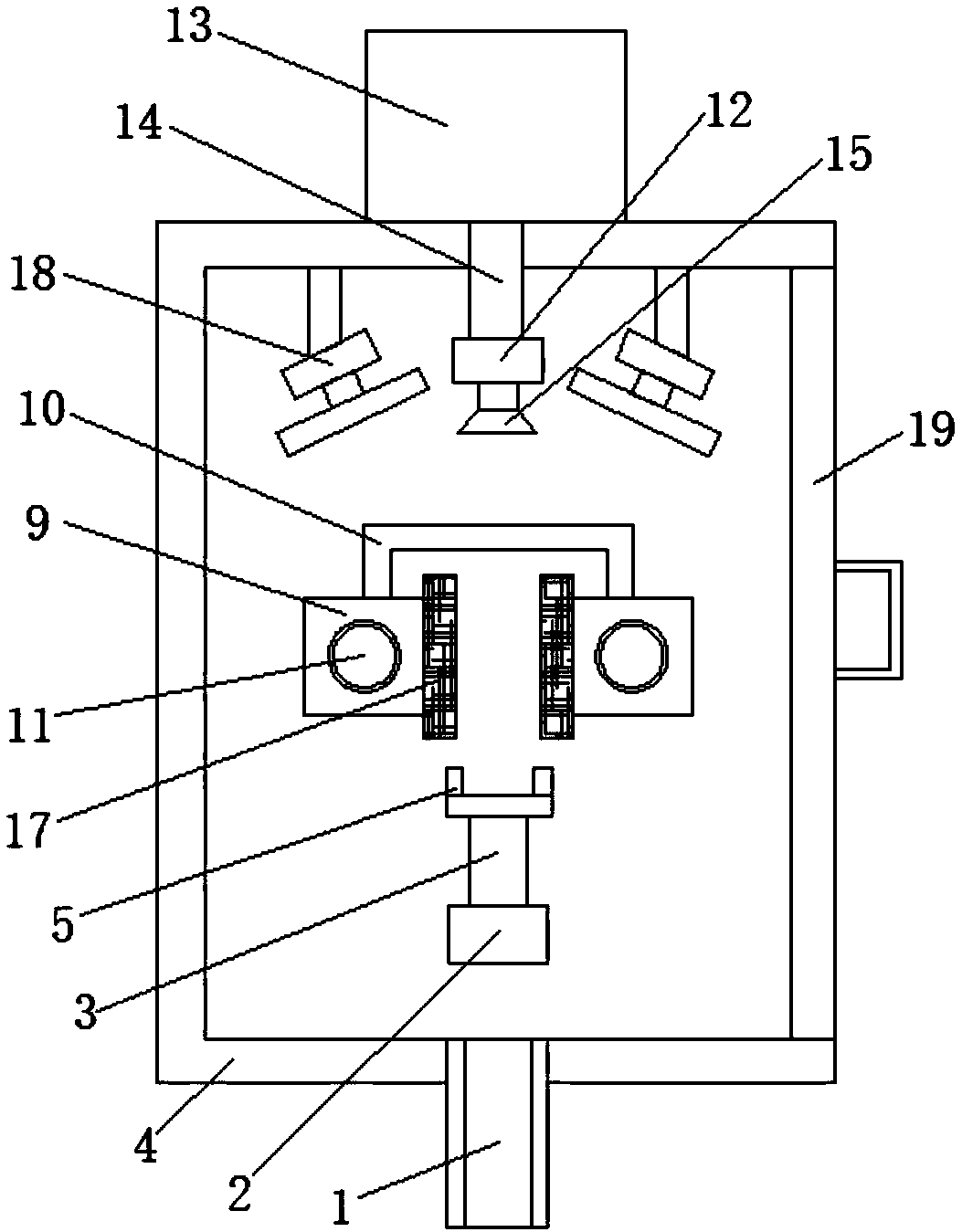

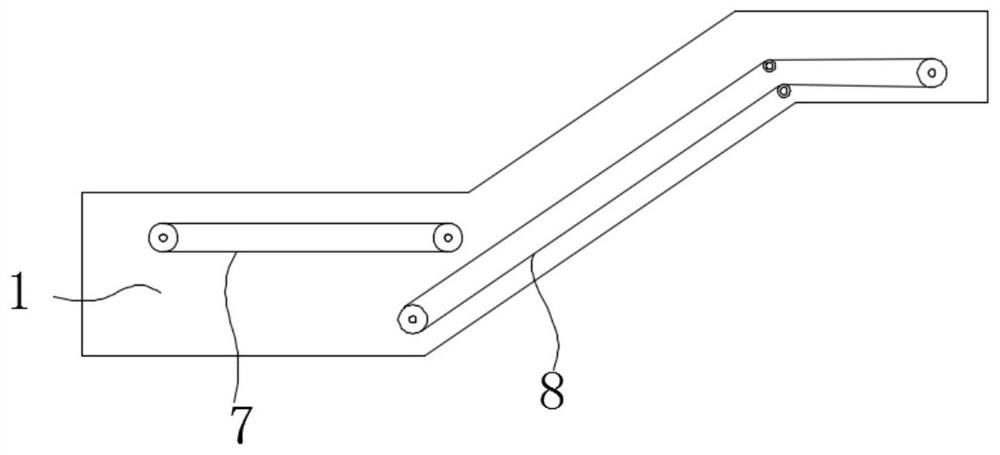

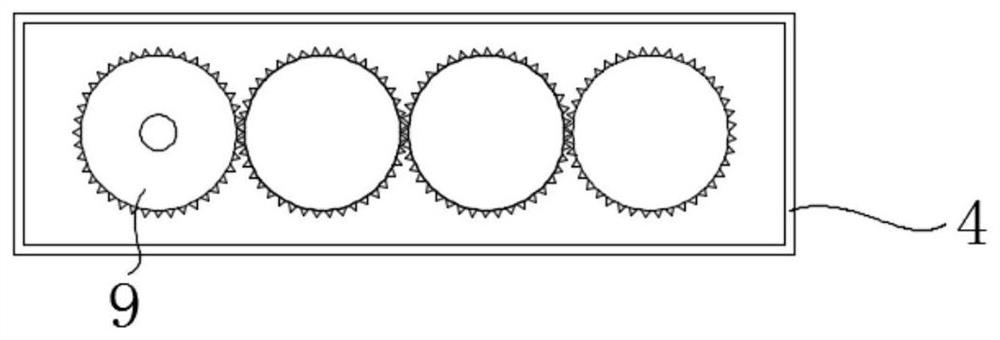

Crushing device for waste foamed plastic

ActiveCN110815650ACompletely brokenReduce follow-up workPlastic recyclingMechanical material recoveryEnvironmental geologyMechanical engineering

The invention discloses a crushing device for waste foamed plastic. The crushing device for waste foamed plastic comprises a transmission device, a crushing cylinder and supporting legs arranged at the bottoms of the transmission device and the crushing cylinder, wherein a cavity is arranged in the crushing cylinder, a material inlet is arranged at the upper end of the crushing cylinder, a material outlet is arranged at the lower end of the crushing cylinder, a discharge plate is arranged at the bottom of the material outlet, a discharge end is arranged at one end of the transmission device, amaterial conveying end is arranged at the other end of the transmission device, and the material conveying end extends to the material inlet of the crushing cylinder. When the device is used, a worker only needs to put materials on the horizontally-arranged discharge end, and the transmission device automatically conveys the materials to the interior of the crushing cylinder for crushing work; according to the device, large pieces of materials can be firstly stirred, are crushed by the crushing device after stirred is completed, the materials are crushed more thoroughly, secondary utilizationcan be carried out without secondary processing, follow-up work is saved, and production efficiency is improved.

Owner:丰县建鑫泡沫制品有限公司

Automatic cement floor laying device

InactiveCN112681694APouring evenlyWell mixedBuilding constructionsElectric machineryStructural engineering

The invention discloses an automatic cement floor laying device. The automatic cement floor laying device comprises a main body, wherein a power cavity is fixedly formed in the main body; a first motor is fixedly arranged in the power cavity; a first motor shaft is rotatably arranged on the first motor; and an auxiliary power cavity is formed in the main body. The motor drives travelling wheels to travel, so that the device moves freely; a left-right swinging sweeping mechanism controlled by the motor can replace manual operation to sweep dust; and a dust collecting device and a spraying device are arranged in the device, the sweeping mechanism swings in the left-right direction to control the two devices to be opened at an interval, and therefore, dust in air is fully wetted and adhered by water and then is collected by the dust collecting device. The device is simple in structure and convenient to maintain in the later period, can perfectly use machinery to replace manual operation, and is high in practicality, the operation efficiency is improved, and the risk of manual operation is reduced.

Owner:漳州盛之昌贸易有限公司

Inner and outer chamfering cutter head of end facing machine

The invention creatively provides an inner and outer chamfering cutter head of an end facing machine. The inner and outer chamfering cutter head comprises a cutter head body, a base, a chamfering cutter device and an end facing cutter device, wherein the chamfering cutter device is connected with a first angle adjusting device which is fixedly connected with the base; the end facing cutter device is connected with a second angle adjusting device which is fixedly connected with the base; a burr removing device is arranged in the inner center of the base; a fixing plate is connected to one inner side of the base through a bolt, and while an opening is formed in the other inner side of the base; the burr removing device comprises a fixing seat, an electric rod and a rotating burr removing device which are sequentially connected, wherein the fixing seat is fixedly connected with the fixing plate; the rotating burr removing device can move in and out of the opening through the electric rod. The inner and outer chamfering cuter head is safe, reliable, and convenient to dismount, and can reduce the burr.

Owner:TIANJIN JIEFENG STEEL PIPE IND & TRADE

Intelligent chip for assisting in protein preparation and labeling and assisting method of intelligent chip

InactiveCN113248560AEasy to put inReduce follow-up workPeptide preparation methodsComputer hardwareElectric machine

The invention discloses an intelligent chip for assisting in protein preparation and labeling and an assisting method of the intelligent chip. The intelligent chip comprises a machine body, wherein a working cavity with a leftward opening is formed in the machine body, a threaded shaft is rotatably mounted on the right wall of the working cavity, and a threaded block slidably mounted on the top wall of the working cavity is in threaded connection to the threaded shaft; and a driving shaft is rotationally mounted in the threaded block, a driving motor embedded in the threaded block is connected to the upper side of the driving shaft, the driving shaft extends downwards into the working cavity and is fixedly provided with an electronic telescopic rod, a moving block is fixedly arranged on the lower side of the electronic telescopic rod, and an electric power groove is formed in the moving block. According to the intelligent chip, after eggs are positioned and placed, the eggs are broken in a pushing mode, then the eggs can be better opened through mutual limitation between springs, and waste is avoided.

Owner:黄聪

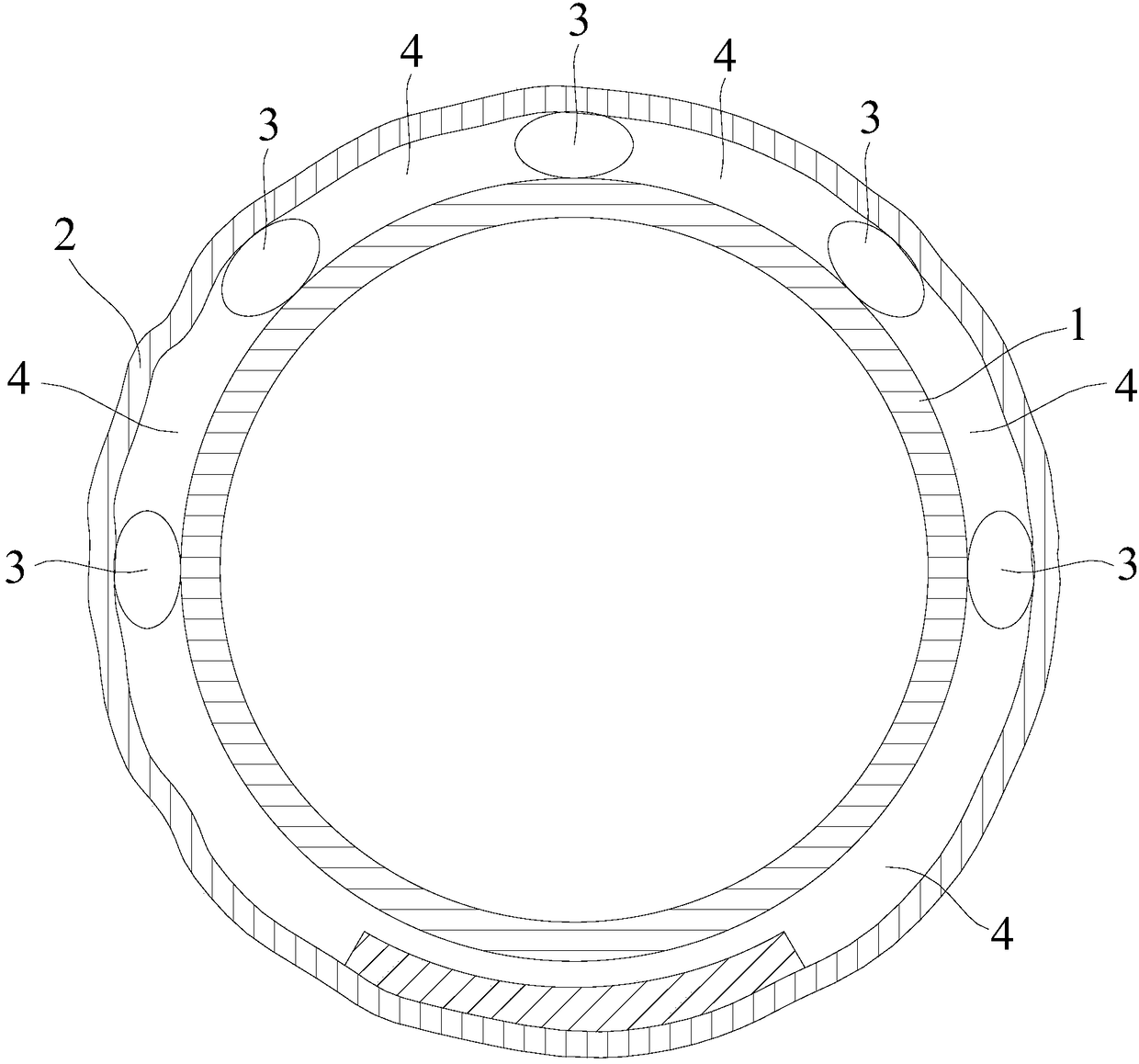

A Limiting Method to Prevent the Displacement of Empty Pushing Segment in Shield

ActiveCN106437756BFunction as limit supportEasy to installUnderground chambersTunnel liningInlet channelOperability

The invention discloses a method for preventing duct piece displacement in the no-load shield tunneling process. The method comprises the following steps that (a) a through hole is formed in a duct piece; (b) a single inlet channel bag-shaped body is plugged into a gap from the through hole; (c) the bag-shaped body is filled with cement slurry by using a grouting machine, and the bag-shaped body expands and is in contact with the duct piece and a preliminary bracing system; (d) after grouting is completed, an inlet channel and the grouting machine are separated; (e) the cement slurry solidifies for forming. By applying the method, the bag-shaped body is plugged into the gap between the duct piece and the preliminary bracing system and is filled with the cement slurry to be supported between the duct piece and the preliminary bracing system and play a duct piece limiting and supporting role. The method is simple in process and good in operability, the consumed working time is short, the cost is low, an implementation effect is good, a hoisting hole or a grouting ole can be closed after implementation, follow-up work is omitted, and popularization is promoted.

Owner:CHINA RAILWAY NO 2 ENG GRP CO LTD

A kind of waste high temperature incineration treatment equipment

ActiveCN106765166BBurn fullyImprove combustion efficiencyIncinerator apparatusCombustionProcess engineering

The invention provides a high-temperature incineration refuse treatment device. A combustion cavity and a tail gas buffering cavity are arranged in a first incinerator body. A second incinerator body is provided with a material storage cavity. A heating device is arranged at the bottom of the material storage cavity. A spiral feeding mechanism is used for conveying materials in the material storage cavity into the combustion cavity. An inner circulation mechanism comprises a first gas guide pipe, multiple second gas guide pipes, a third gas guide pipe, a fourth gas guide pipe and an outer gas guide pipe, wherein one end of the first gas guide pipe is sealed, the other end of the first gas guide pipe communicates with a gas outlet, the multiple second gas guide pipes are vertically arranged in the material storage cavity, the gas inlet end of each second gas guide pipe extends into the middle of the material storage cavity, the gas outlet end of each second gas guide pipe communicates with the first gas guide pipe, the gas inlet end of the third gas guide pipe communicates with a gas inlet, the gas outlet end of the third gas guide pipe communicates with the gas inlet end of the fourth gas guide pipe, the gas outlet end of the fourth gas guide pipe extends into the combustion cavity, one end of the outer gas guide pipe communicates with the gas outlet, and the other end of the gas guide pipe penetrates through a cooling water tank to communicate with the gas inlet. The high-temperature incineration refuse treatment device is high in refuse treatment efficiency and in refuse combustion capacity and achieves complete combustion of refuse.

Owner:湖南未名环保科技有限公司

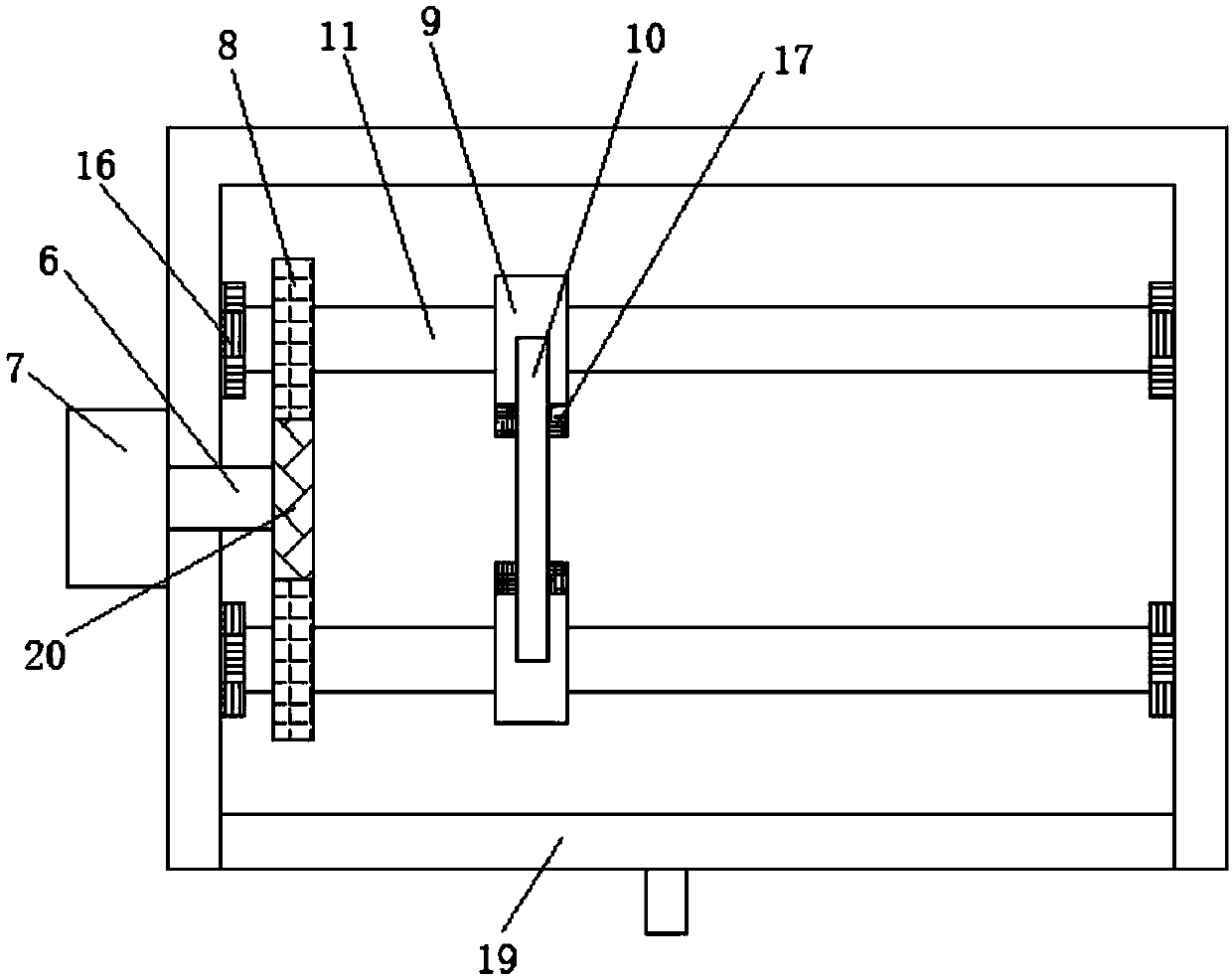

Cleaning device used for machine part machining

InactiveCN109985845AReduce follow-up workStable cooperation with cleaning workDrying gas arrangementsCleaning using toolsMachine partsDrive motor

The invention discloses a cleaning device used for machine part machining. The cleaning device comprises a cleaning tank. A transverse rod which is horizontally arranged is arranged at the bottom endof the interior of the cleaning tank. The two ends of the transverse rod are fixed to the inner walls of the two sides of the cleaning tank. Multiple supporting rods which are evenly arranged are fixed to the top end of the transverse rod. A clamp is arranged at the top end of the supporting rod, and a drive motor is fixed to the middle position of the outer wall of one side of the cleaning tank.An output shaft of the drive motor is connected with a first rotating shaft which is horizontally arranged, and the end, away from the drive motor, of the first rotating shaft penetrates the side wallof the cleaning tank and extends in the cleaning tank. A first gear is fixed to the outer wall of the side, away from the drive motor, of the first rotating shaft, and second rotating shafts which are horizontally arranged are arranged on the two sides of the first rotating shaft. The cleaning device can be used for conducting all-dimensional scrubbing on parts, in addition, dirt which is hard toremove and is hidden in the parts can be thoroughly removed, the cleaning effect is good, air drying can also be conducted on the cleaned parts, the subsequent work of workers is reduced, and the work efficiency is high.

Owner:天津永创通达机电科技有限公司

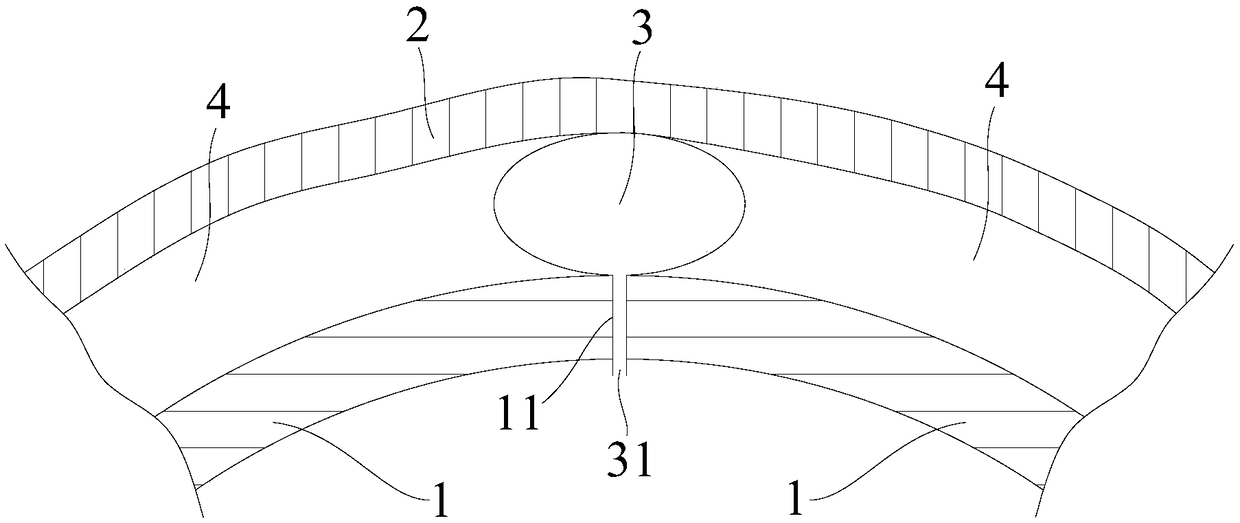

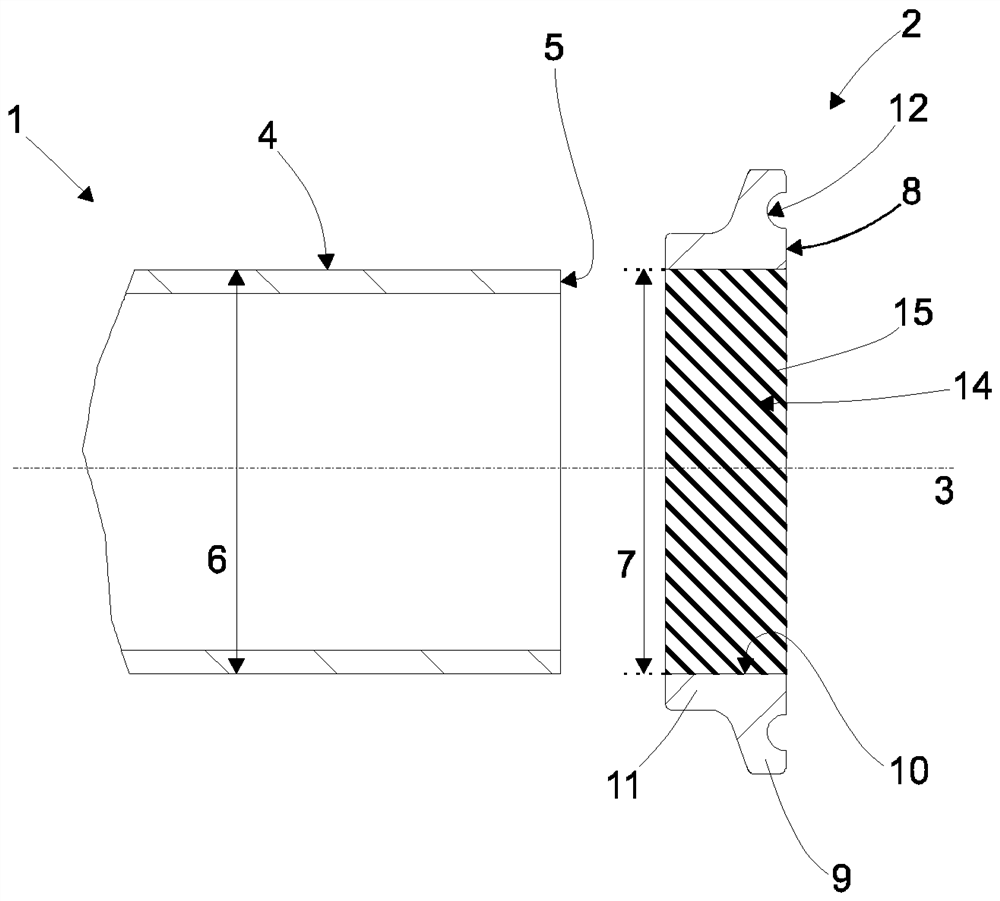

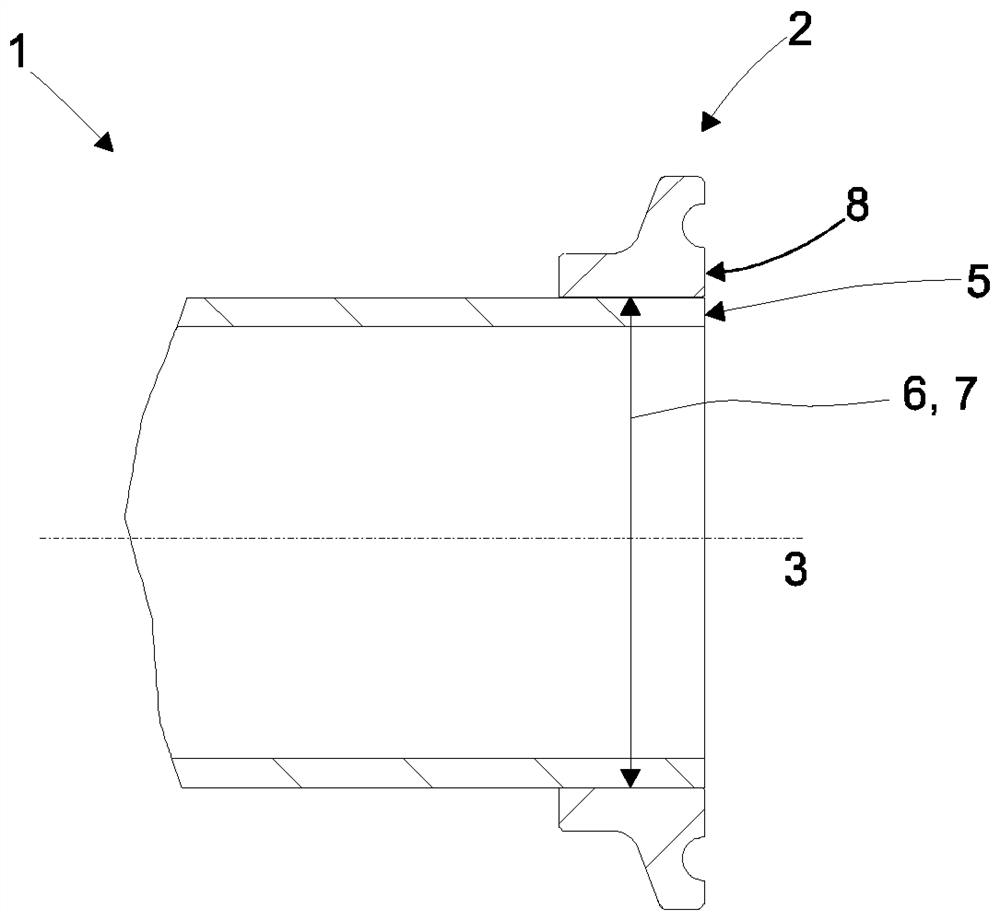

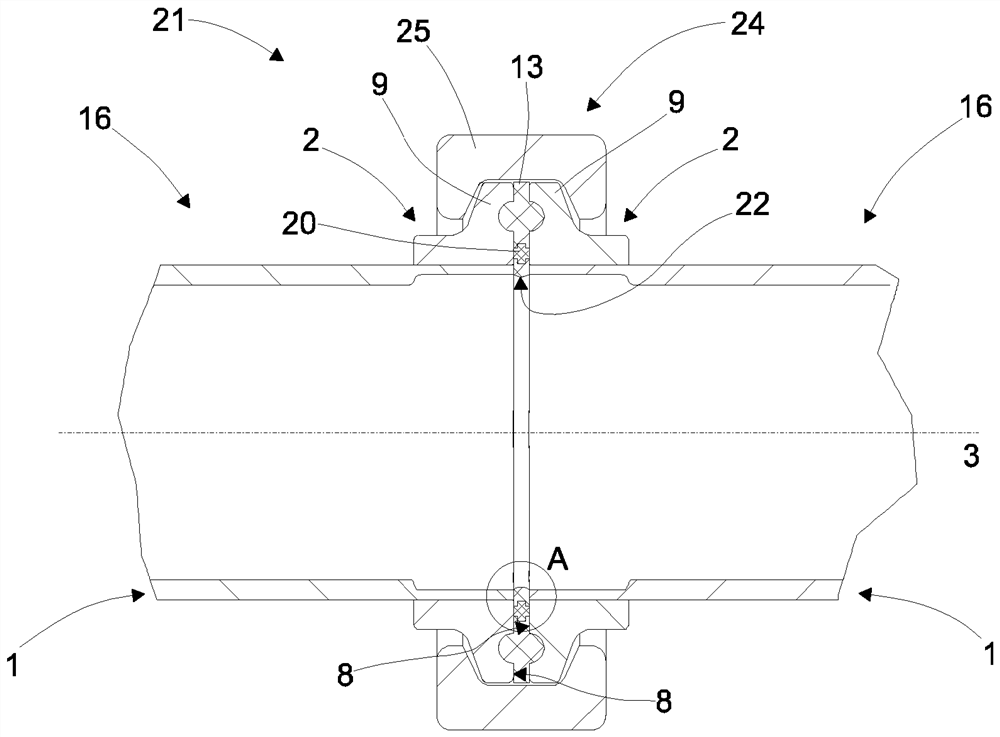

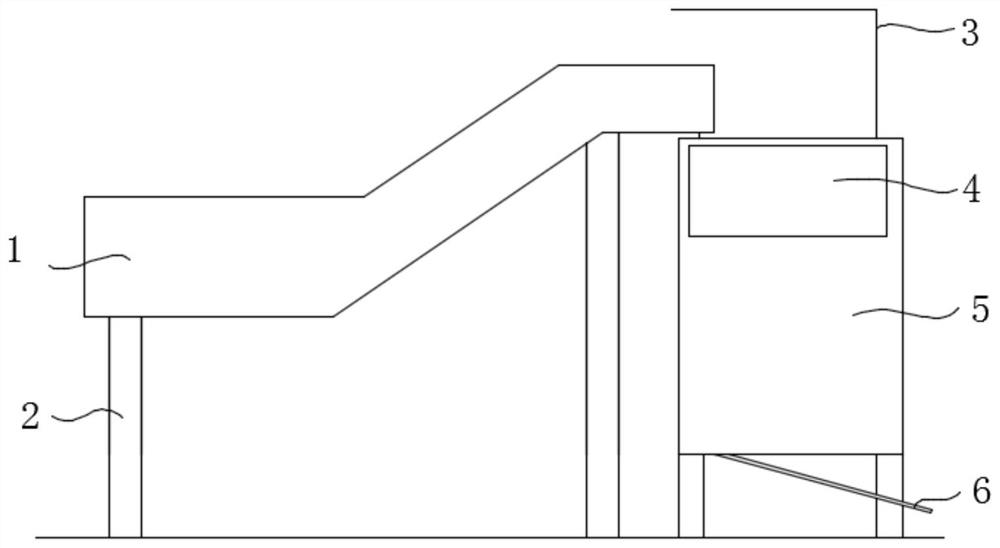

Method for producing pipe assembly and pipe assembly

PendingCN114599908AEliminate dependenciesSimple crimpingEngine sealsFlanged jointsEngineeringStructural engineering

The invention relates to a method for producing a pipe assembly (21) and to a pipe assembly (21) on which the method can be carried out, comprising two pipe units (16) having a pipe central axis (3), the invention relates to a pipe unit (16) comprising a pipe (1) having a pipe outer surface (4), a pipe end face (5) and a pipe outer diameter (6), and a pipe nipple (2) having a pipe nipple inner diameter (7), which has a flange section (9) having a flange section end face (8) and a pipe section (11) having a pipe section inner surface (10), the invention relates to a pipe assembly (1) for a pipeline (1), comprising a seal (13) arranged axially between flange section end faces (8) of a pipe connection sleeve (2) and a tensioning device (24) for axially tensioning flange sections (9) of the pipe connection sleeves (2) of two pipe units (16) against each other, the pipe connection sleeve (2) being inserted onto the pipeline (1) at least until the flange section end faces (8) are flush with the pipeline end faces (5), and the flange sections (9) of the pipe connection sleeves (2) being inserted into the pipeline (1) at least until the flange section end faces (8) are flush with the pipeline end faces (5). According to the invention, the pipe (1) is fixed in the pipe connection sleeve (2) by means of a press-fit (17) resulting from the radial expansion of the pipe (1), and the resulting pipe unit (16) is axially tensioned by tensioning a flange section (9) of the pipe connection sleeve (2) to form a pipe assembly (21).

Owner:GLATT GMBH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com